Vertical pumping anti-backflow controlling device and using method

A control device and anti-backflow technology, applied in the direction of control valves, valve devices, cleaning methods and appliances, etc., can solve problems such as blockage in the pipe and affect the pumping effect of the steel pipe column, and achieve the effect of easy unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

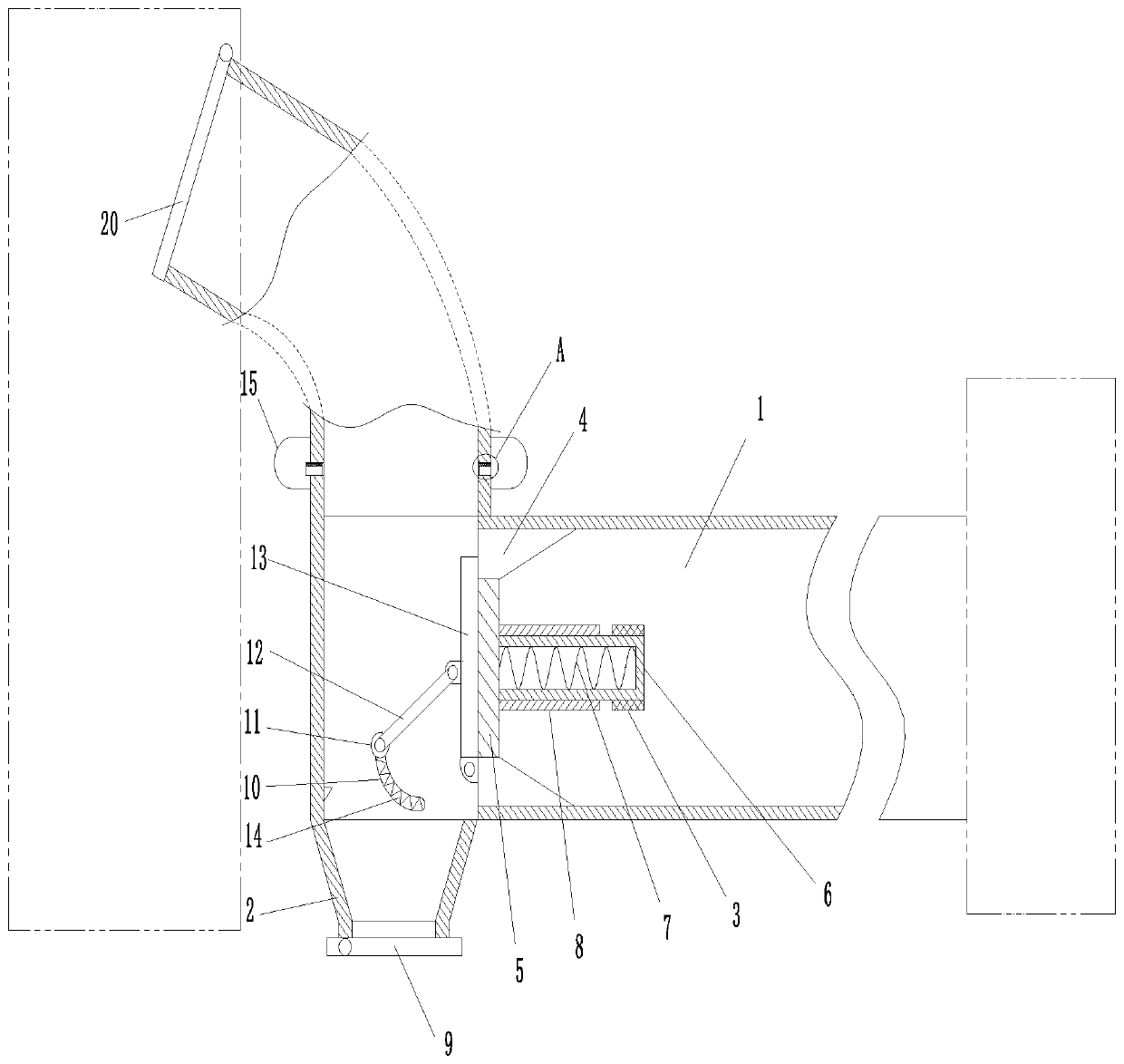

[0030] Such as figure 1 As shown, a vertical pumping anti-backflow control device is connected between the external pumping equipment and the steel pipe column, including the pumping pipe 1 and the transfer pipe 2, and the pumping pipe 1 is provided with an inlet and an outlet The feed port of the pumping pipe 1 is connected to the external pumping equipment. The pumping pipe 1 is provided with an anti-backflow structure, and the anti-backflow structure is used to prevent the concrete in the pipe from backflowing due to negative pressure when the pumping equipment stops. The anti-backflow structure includes a fixed seat 3, a guide seat 4 and a baffle plate 5. The fixed seat 3 is fixedly connected to the middle of the pumping pipe 1. The fixed seat 3 is fixedly connected with a fixed sleeve 6, and the fixed sleeve 6 is provided with a first spring 7. , the guide seat 4 is fixedly connected to the inner wall of the pumping pipe 1 and is located on the side of the fixed seat 3 cl...

Embodiment 2

[0032] Such as figure 1 As shown, the following improvements have been made on the basis of Embodiment 1. The transfer pipe 2 and the pumping pipe 1 are intersected. An isolation structure is provided in the transfer pipe 2. The isolation structure includes a chute 10, a sliding pin 11, a connecting rod 12 and Isolation plate 13, chute 10 is opened on the inner wall of transfer pipe 2, and second spring 14 is arranged in chute 10, and slide pin 11 is positioned at chute 10 and is connected with second spring 14, and one end of connecting rod 12 is connected with slide The pin 11 is rotatably connected, the other end of the connecting rod 12 is rotatably connected with the isolation plate 13, the isolation plate 13 is hingedly connected on the guide seat 4, and the isolation plate 13 is attached to the side wall of the baffle plate 5. When pumping, the baffle plate 5 pushes the isolation plate 13 to rotate so that the isolation plate 13 isolates the bottom of the transfer pipe ...

Embodiment 3

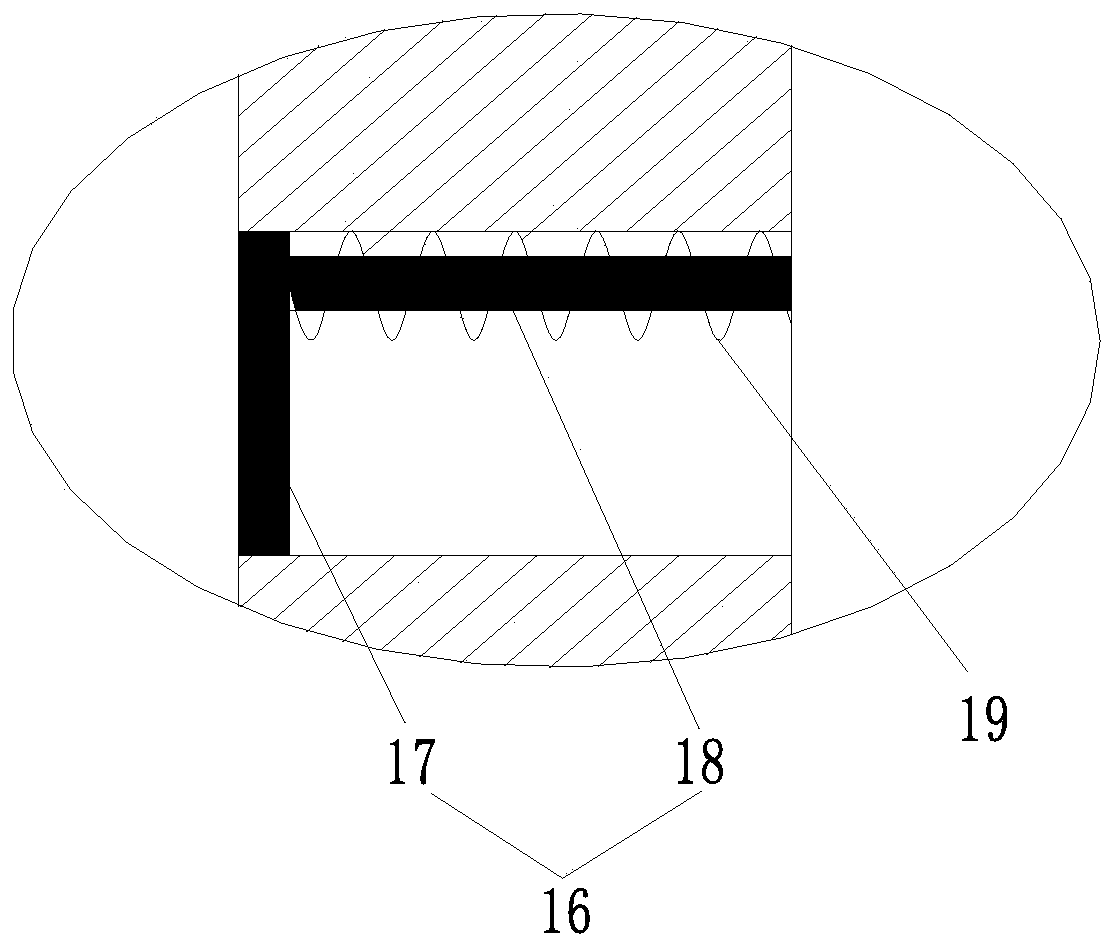

[0035] Such as figure 2As shown, the following improvements have been made on the basis of Embodiment 2. The adapter pipe 2 is provided with a flushing structure, and the flushing structure includes an annular flushing pipe 15. A pipeline is arranged between the annular flushing pipe 15 and the adapter pipe 2. An elastic water stop 16 is provided. The elastic water stopper 16 includes a disc part 17 and a connecting part 18, the disc part 17 is matched with the pipeline, the connecting part 18 is integrally connected with the disc part 17, the outside of the connecting part 18 is connected with a third spring 19, and the third spring 19 One end far away from the connecting portion 18 is connected with a pipe. By supplying water into the annular flushing pipe 15, the water pressure in the pipe is used to push the elastic water stop member 16 to move, and then the water in the pipe flows into the transfer pipe 2 to flush the inner wall of the transfer pipe 2 to prevent cloggin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com