Loading and unloading structure of refrigeration carriage

A car box and box body technology, which is applied in the field of refrigerated transportation, can solve the problems of expanding the horizontal space occupation of the car box, poor heat preservation effect, and increasing transportation costs, etc., to achieve the effect of ensuring safety and reliability, good positioning effect, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

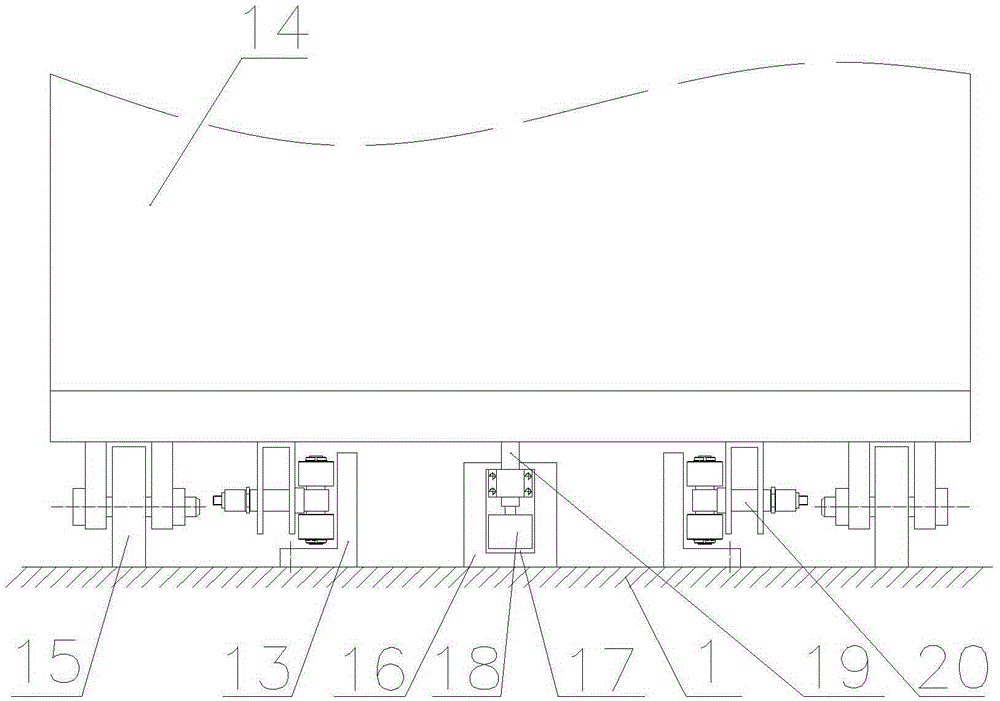

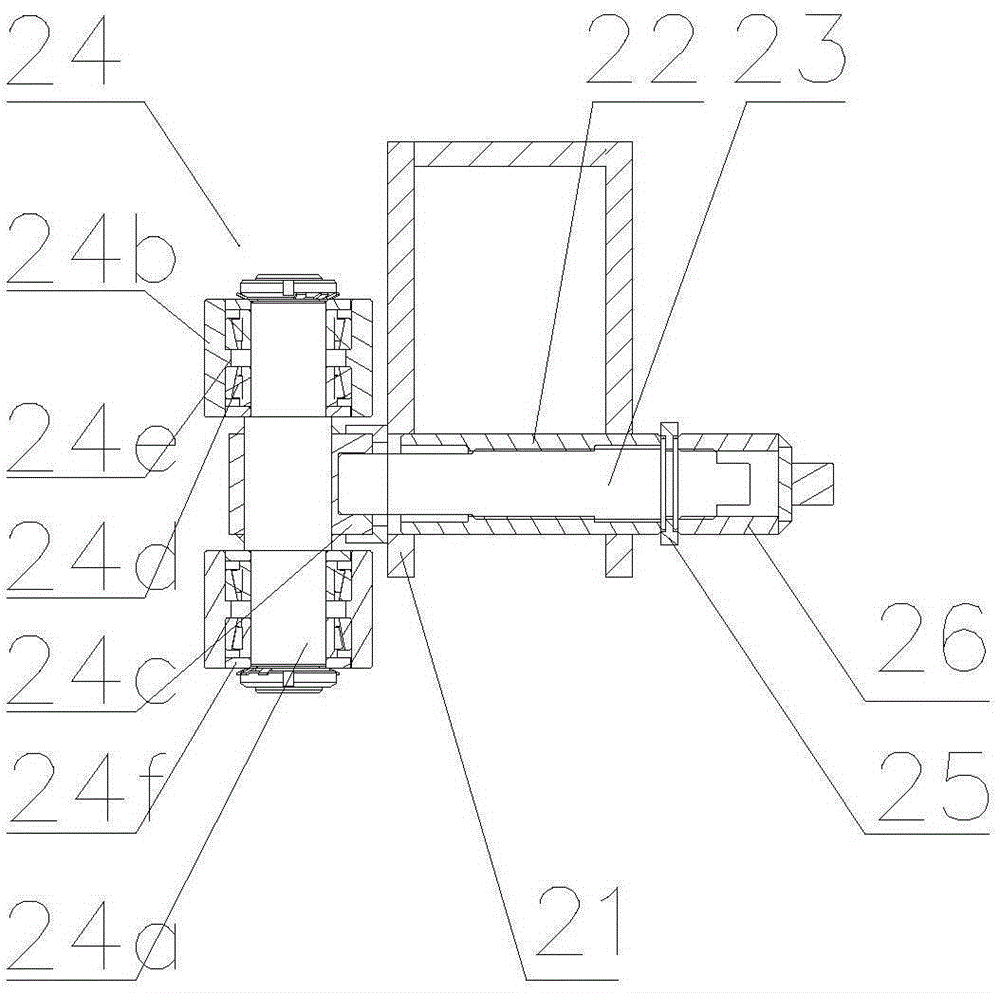

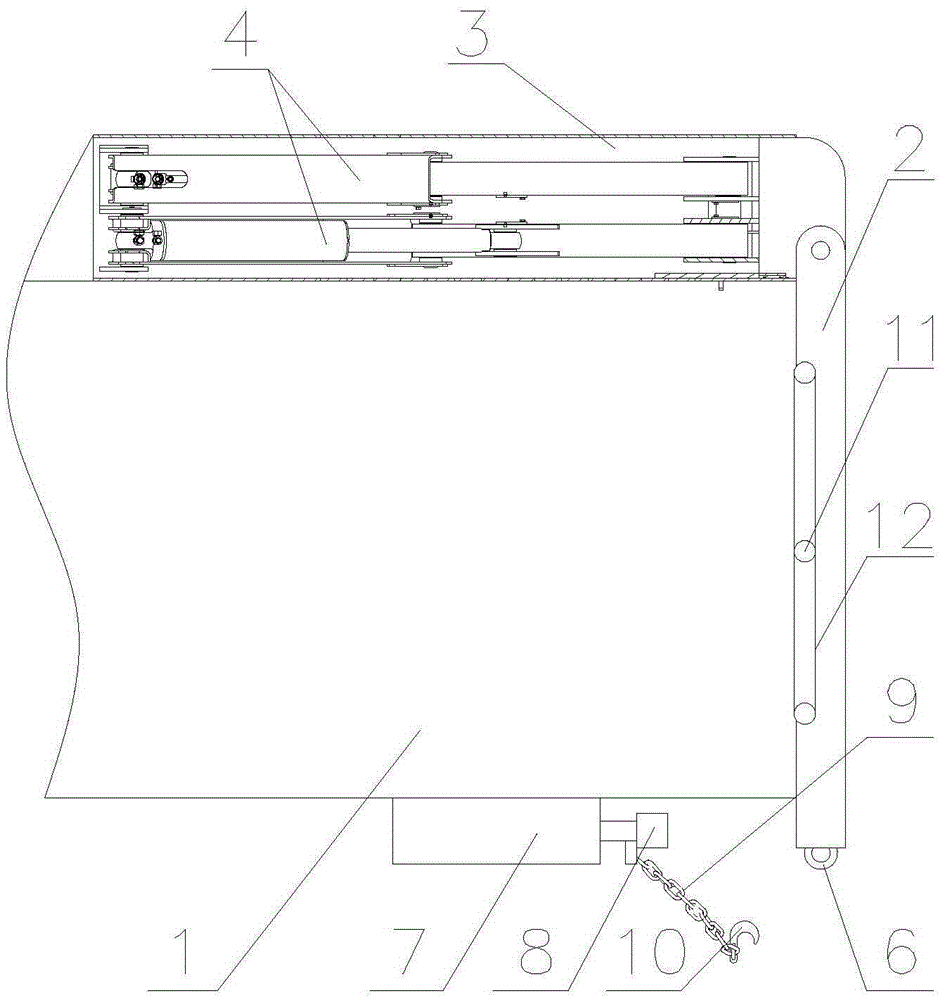

[0039] see figure 1 , figure 2 , is a preferred embodiment of the loading and unloading structure of the refrigerated truck box, including a box body 1, and one end of the box body 1 along the longitudinal direction is provided with a cargo inlet and outlet, and the box body 1 is provided with x pairs of boxes The track 13 extending longitudinally of the body 1, x≥2, the cross section of the track 13 is L-shaped, the vertical plates of each pair of track 13 are arranged oppositely, the flat plate of the track 13 is fixed on the bottom plate of the box body 1 by bolts, and also includes y 1 container 14, y≥x, y container 14 is divided into x groups, corresponding to x pairs of rails 13, two rows of supporting rollers 15 are arranged below the container 14, and the two rows of supporting rollers 15 are located on the corresponding two rails 13 The outer sides of each cargo box 14 are supported on the bottom plate of the box body 1 by supporting rollers 15, so that the cargo bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com