Precision casting blade tenon tooth machining front reference conversion clamp and using method thereof

A datum conversion and blade technology, which is applied in manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of high scrap rate of blade tenon teeth processing, unstable processing process, vibration of grinding tenon teeth, etc. Compact, convenient unloading, stable and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

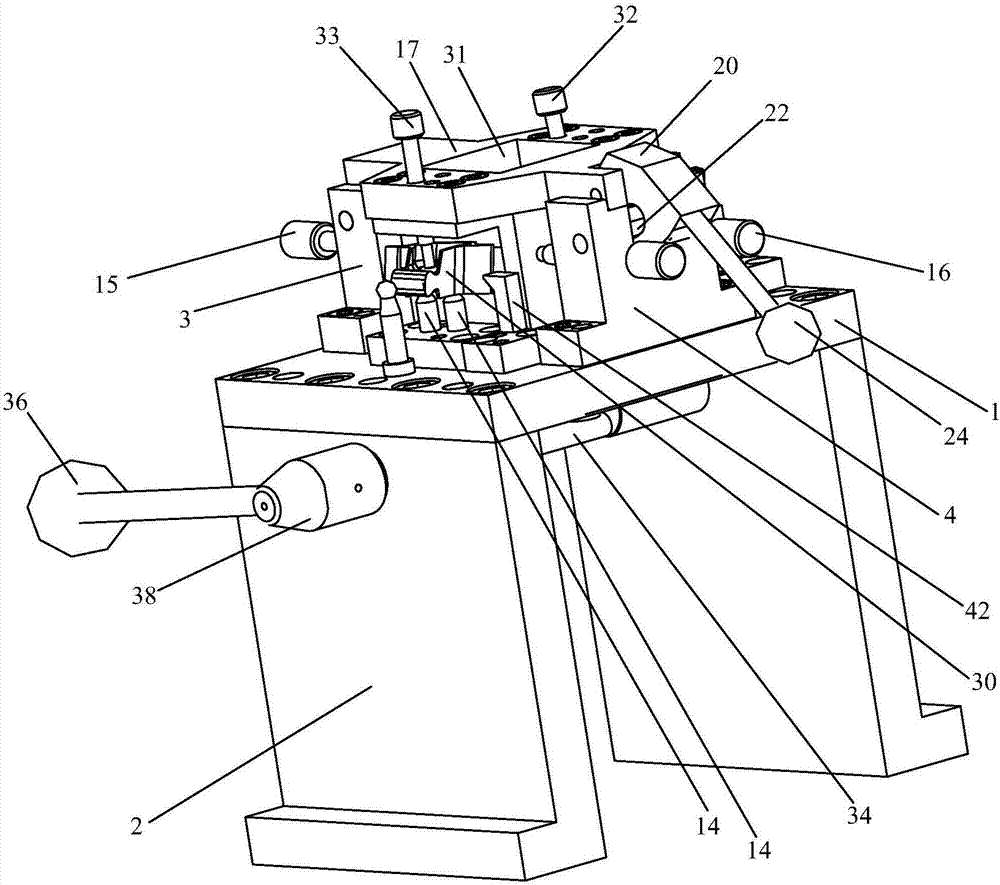

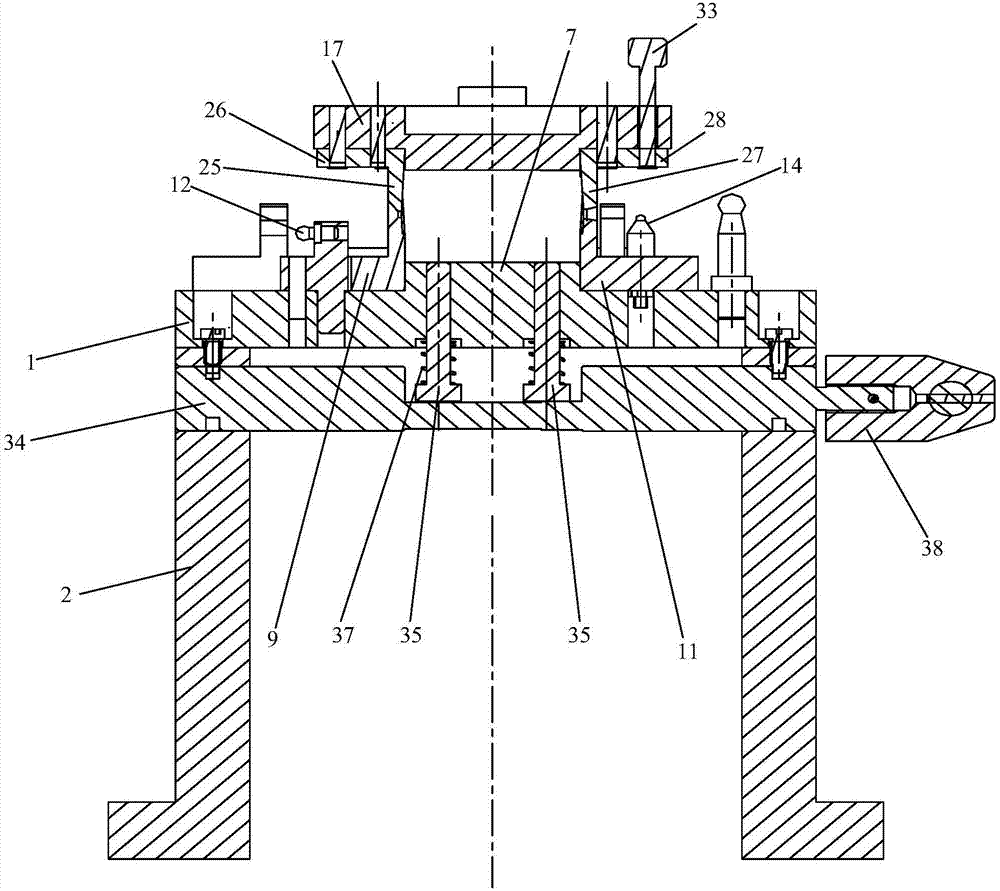

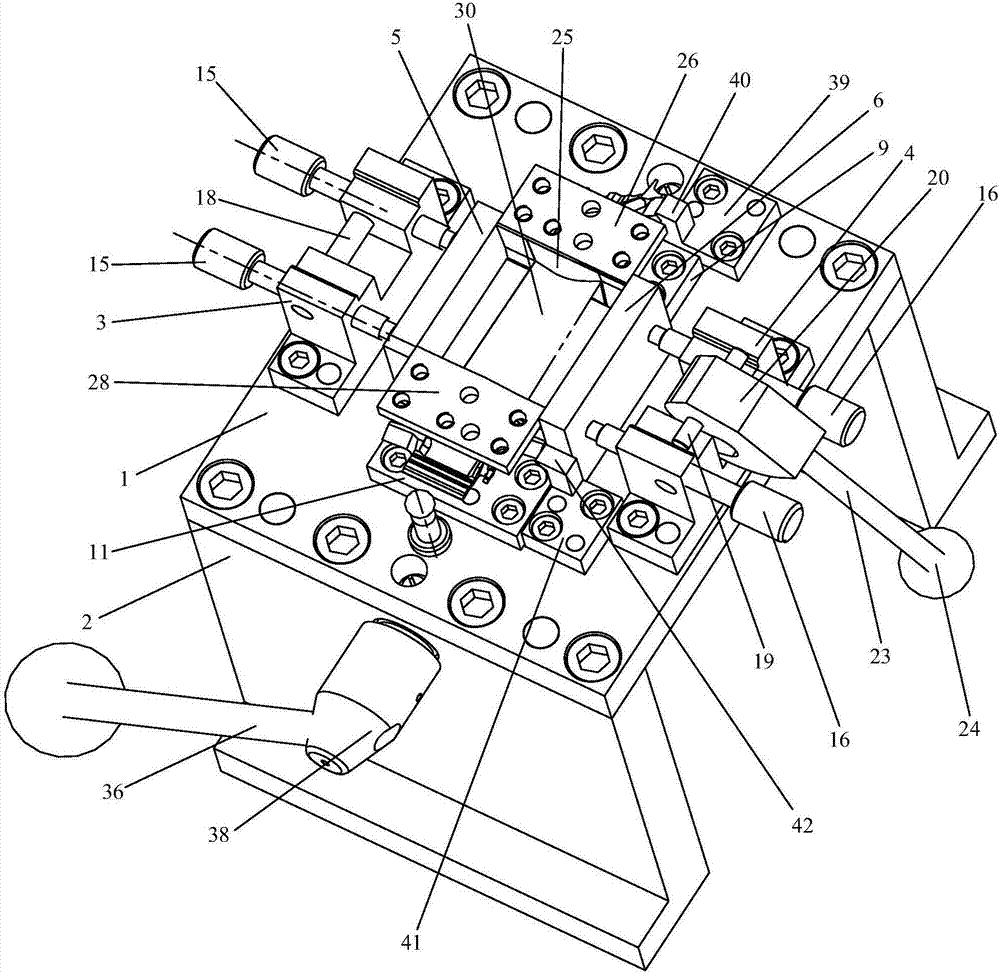

[0027] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 7 As shown, the present invention provides a reference conversion fixture before tenon tooth processing of precision casting blades, which includes a support plate 1, a support foot 2, a first hinge support 3, a second hinge support Seat 4, first side baffle 5, second side baffle 6, turning cavity and unloading mechanism;

[0028] A leg 2 is provided under the support plate 1, and a square protrusion 7 is arranged at the center of the support plate 1; a first lower baffle plate 8 and a second lower baffle plate 10 are installed on the support plate 1, and a second lower baffle plate 8 is arranged on the outside of the first lower baffle plate 8. One positioning block 9, second positioning block 11 is arranged on the outside of the second lower baffle plate 10, the first lower baffle plate 8 is close to the first side of the square protrusion 7, the second lower baffle plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com