Rotary combined lifting sling for metallurgy

A combination of spreader and rotating motor technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inability to adjust the rotation, scalding workers, spilling of molten steel, etc., to prevent the hook from swinging, improve safety, The effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

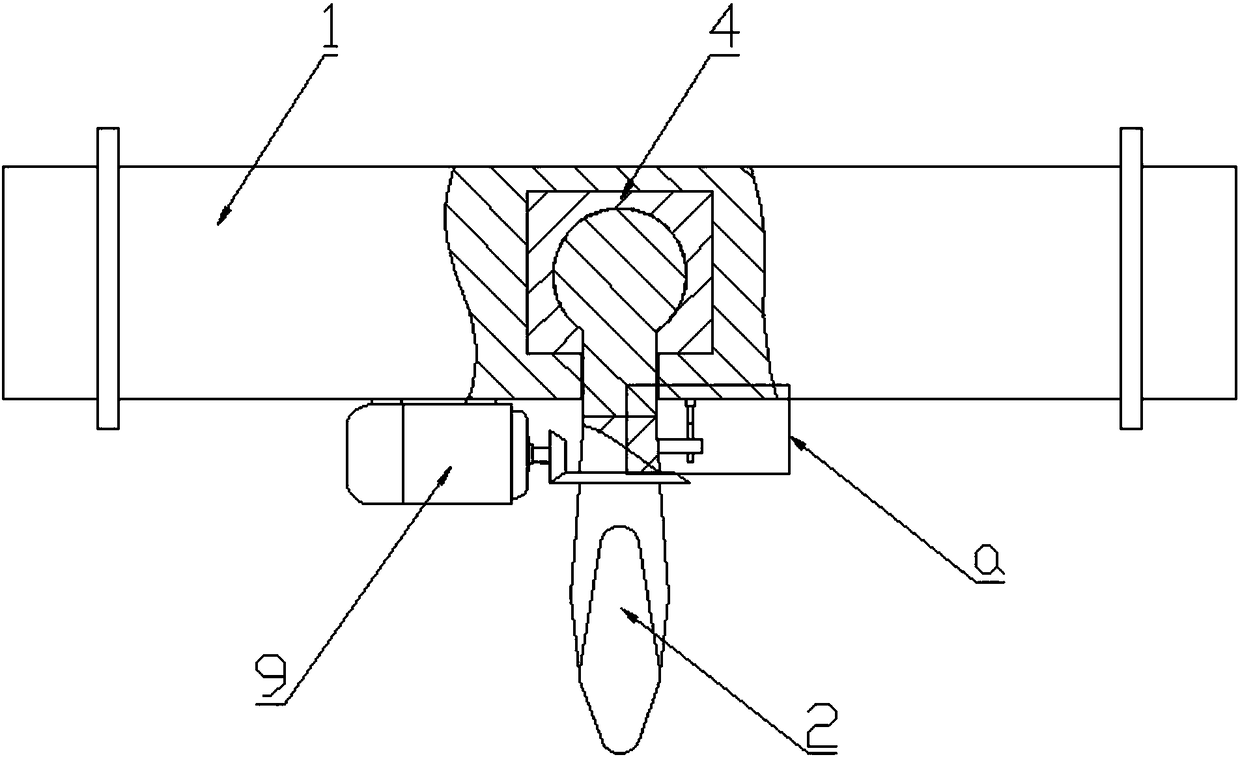

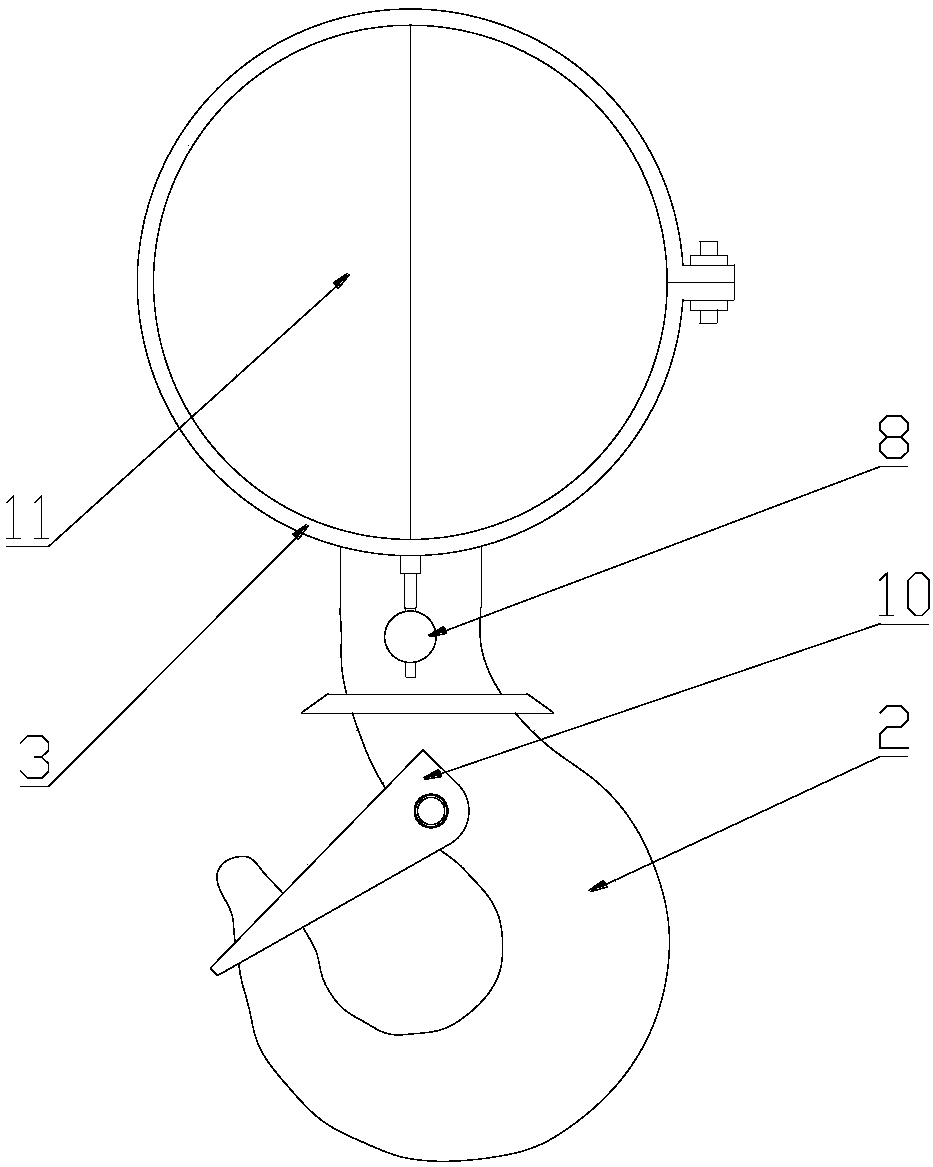

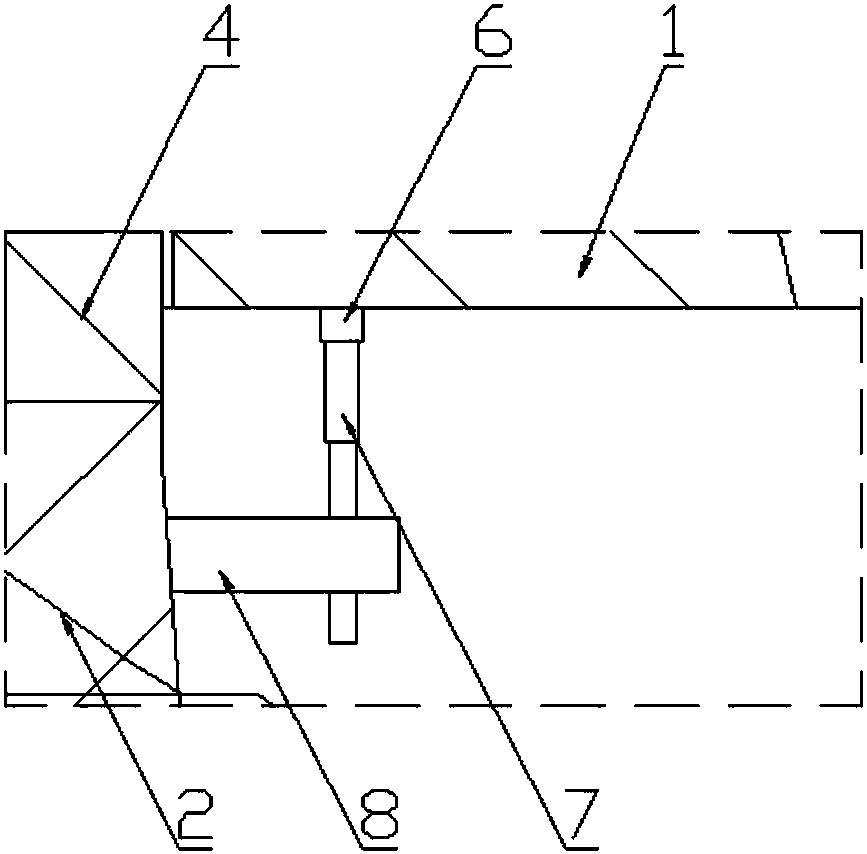

[0016] Such as Figure 1-4 As shown, a metallurgical rotatable combination hanger includes a balance beam 1, a ball joint 4 is arranged inside the balance beam 1, and the ball pin of the ball joint 4 protrudes from the balance beam 1 and is fixedly connected There is a suspension hook 2, and the suspension hook 2 is provided with an anti-tripping ring 10, the upper end of the anti-tripping ring 10 is hinged with the hook handle of the suspension hook 2, and the lower end is locked on the hook head of the suspension hook 2 Above, the balance beam 1 is provided with a hook rotating motor 9, the output end of the hook rotating motor 9 is connected with the handle of the hook 2 through a bevel gear pair, and the hook 2 and the A rotation locking mechanism is provided between the balance beams 1, and the rotation locking mechanism includes a positioning tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com