Link bolt with unloading overflow valve

A technology of hinged bolts and relief valves, applied in the directions of screws, safety valves, balance valves, etc., can solve the problems of adding parts, inconvenient use of devices, troublesome processes, etc., to stabilize the liquid pressure, realize unloading, and achieve obvious effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

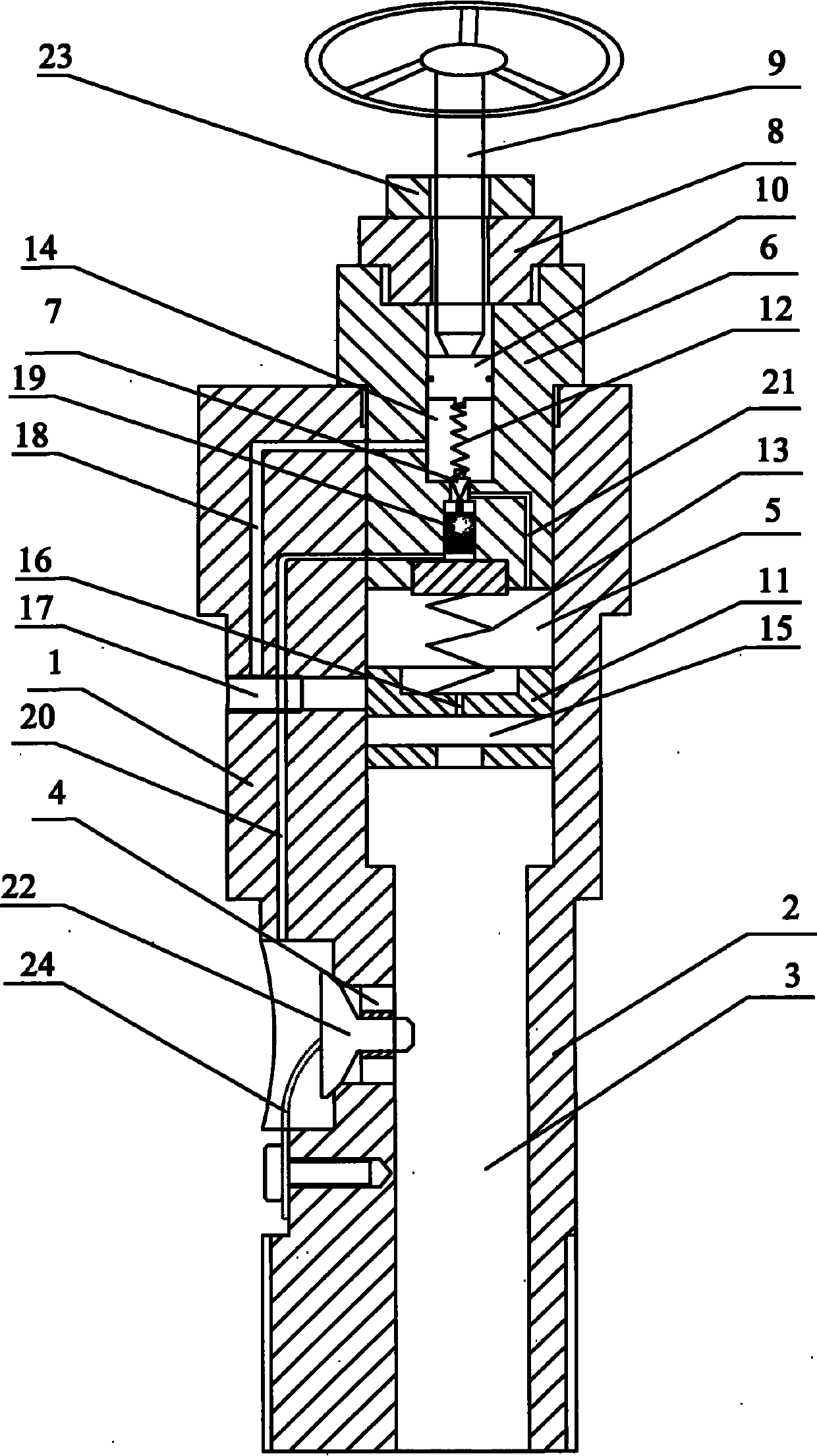

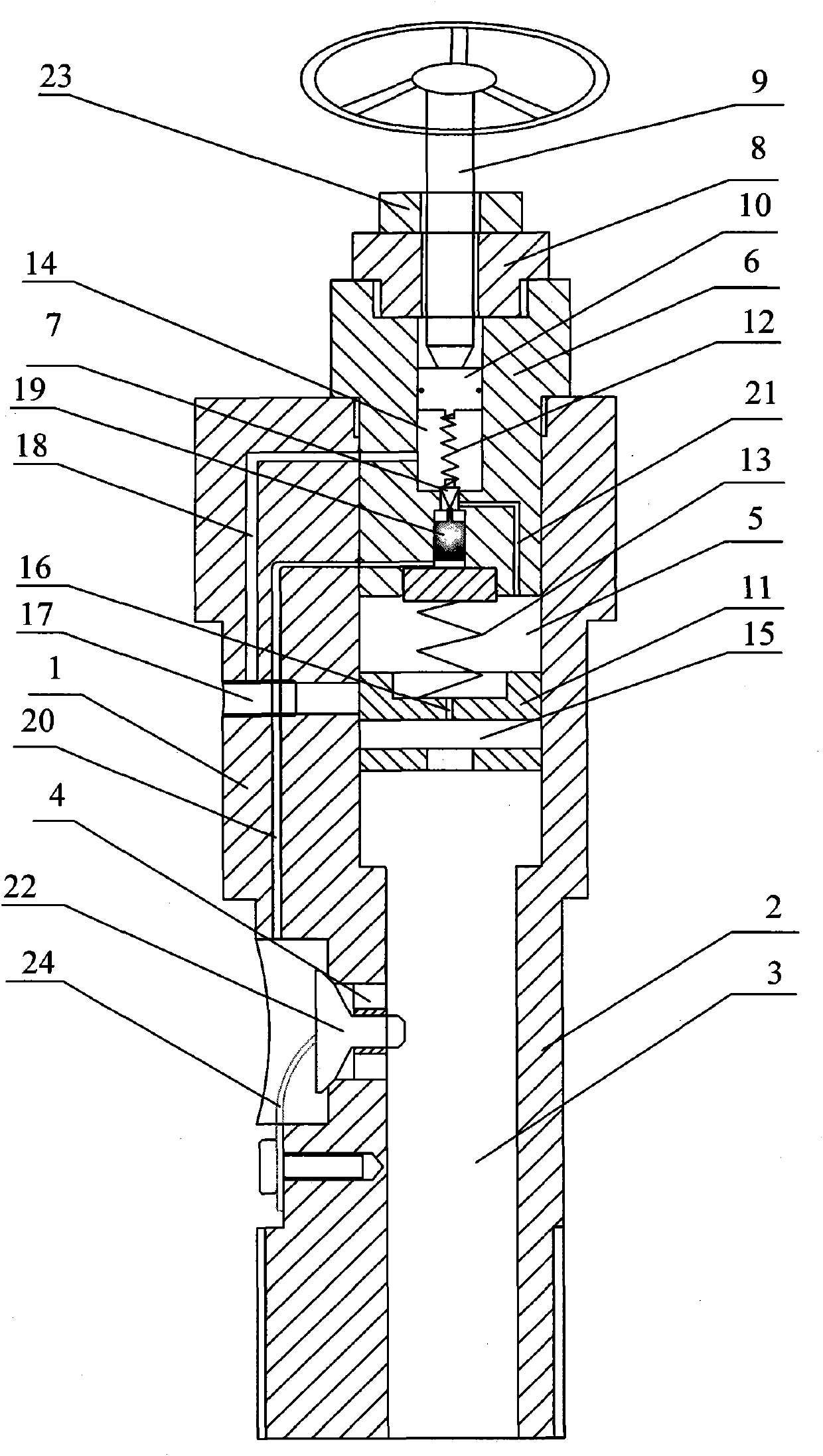

[0014] The hinged bolt with an unloading overflow valve of the present invention includes a bolt head 1 and a screw rod 2. A central channel 3 is provided inside the screw rod, and a transverse channel 4 communicates with the central channel 3 on the wall of the screw rod.

[0015] The hinged bolt also includes an unloading overflow valve, the bolt head 1 is provided with an installation channel 5 communicating with the central channel 3, and the described unloading overflow valve includes a gland 6, a cone valve 7, an adjusting Nut 8, adjusting rod 9, piston type spring seat 10, pressure regulating piston 11, spring I 12, spring II 13, internal thread is provided in the described bolt head 1, gland 6 is connected on the bolt head 1 by thread, Described gland 6 is provided with a cavity 14, and described piston type spring seat 10, cone valve 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com