Strip expanding drum device

A reel expansion and contraction technology, which is applied in the field of expansion and contraction reel devices, can solve problems such as screw thread wear, troublesome unloading work, and difficulty in rotating the central screw, achieving simple production, simple and practical structure, and shortened unloading operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

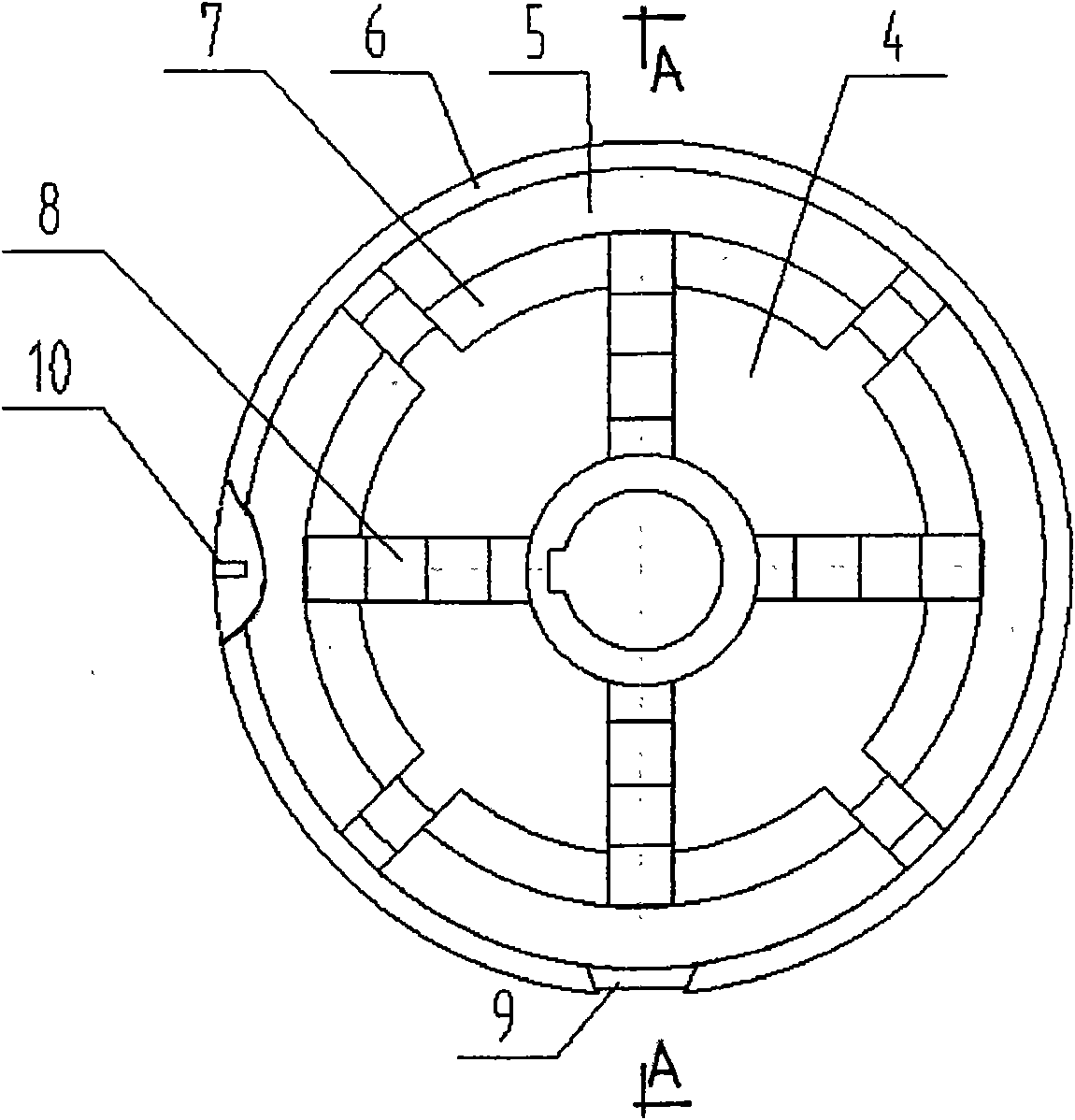

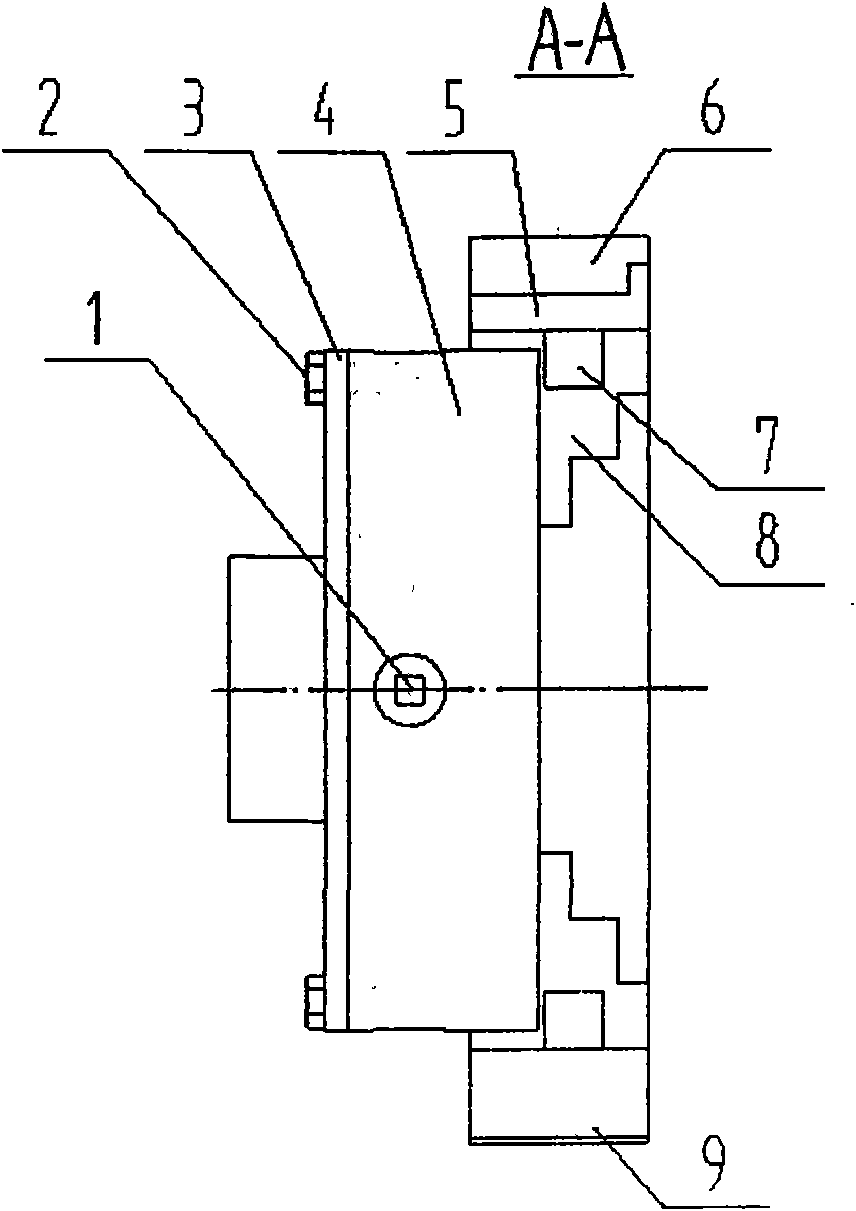

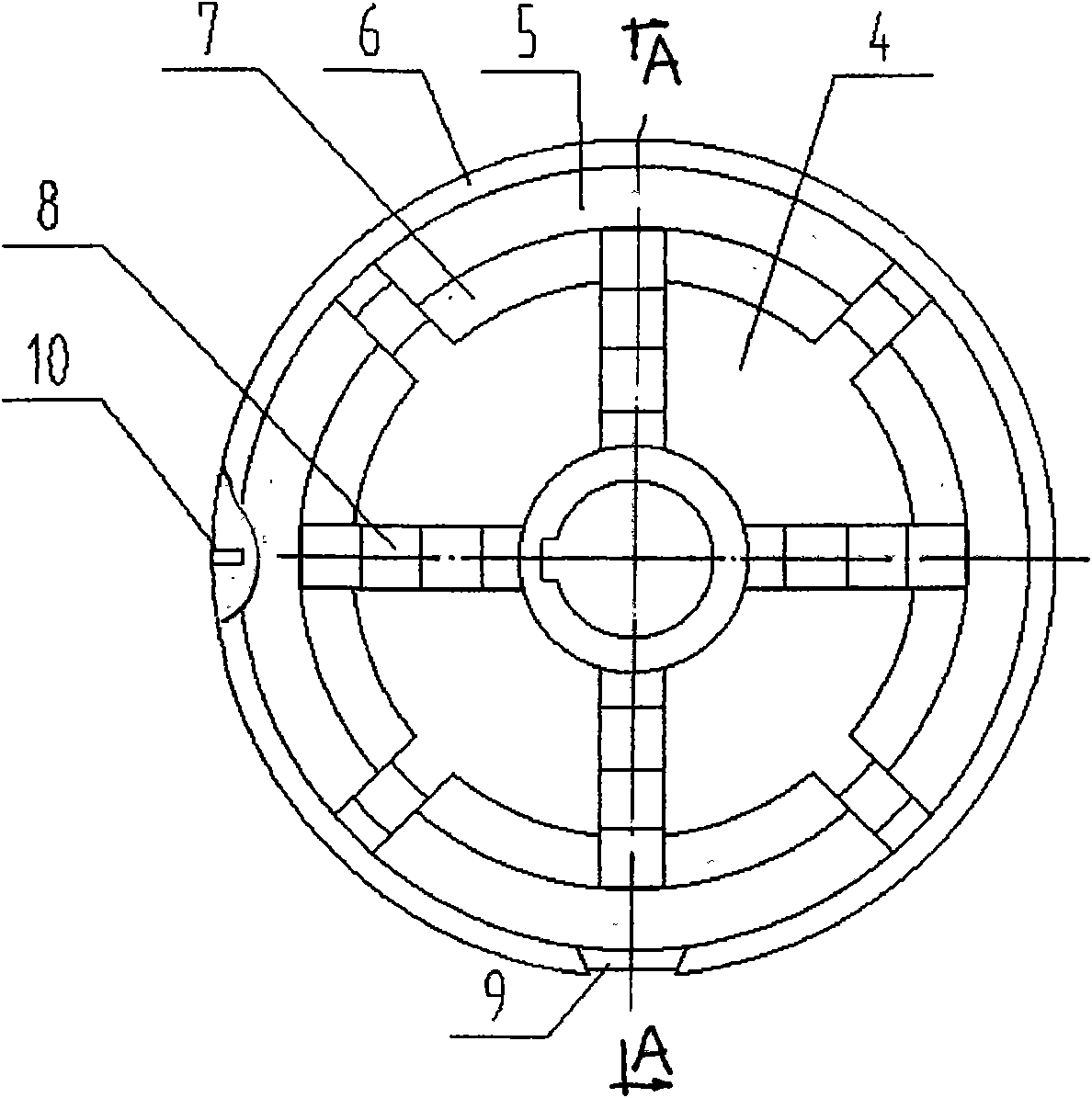

[0012] The following are the embodiments made according to the technical solution of the present invention in conjunction with the accompanying drawings to further illustrate the present invention.

[0013] like Figure 1~2 As shown, the reel device is composed of a lathe four-claw self-centering chuck 4, a lathe chuck anti-jaw 8, a bow block 5, a bow block reinforcement rib 7, a connecting flange 3, an elastic ring 6, and a wedge 9, etc. . The working principle of the lathe four-jaw self-centering chuck is: insert it into the square hole 1 on the small bevel gear and rotate, the small bevel gear will drive the big bevel gear to rotate, the plane thread on the back of the big bevel gear and the back of the four chuck anti-jaws 8 thread meshes. When the plane screw thread rotates, it drives the four claws to move synchronously in the radial direction, and each of the four chuck anti-jaws 8 fixes a bow-shaped block 5, and one of the wedge block 9 and the bow-shaped block 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com