Self-unloading type material shifting and transporting hopper

A self-unloading and hopper technology, applied in the field of self-unloading material moving hoppers, can solve the problems of leakage, increase the working time, occupy the space of the barrel, and achieve good material sealing, reduce labor intensity and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

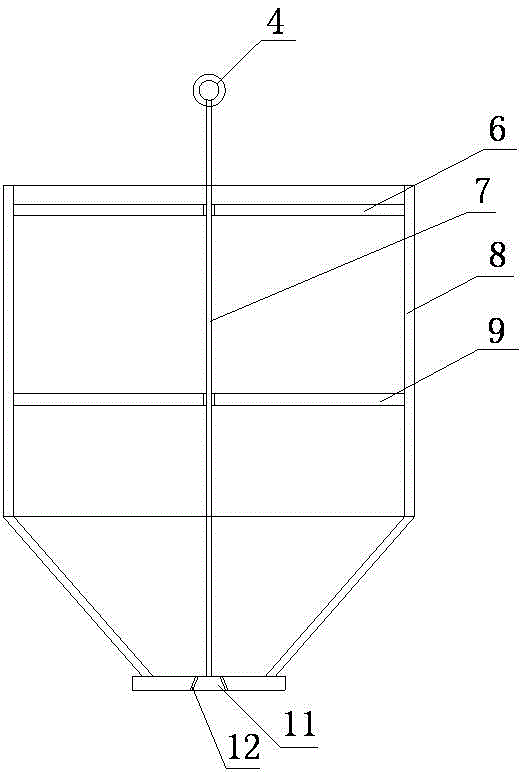

[0022] refer to Figure 1~Figure 2 , a self-unloading material transfer hopper of the present invention, comprising a hopper 8 with a tapered lower part, a guide bracket is arranged inside the hopper 8, a boom 7 is movable through the center of the guide bracket, and a suspension ring is arranged at the top of the boom 7 4. A plug 11 is provided at the lower end, and a frustum-shaped through hole 12 is provided on the bottom plate of the hopper 8 , and the plug 11 cooperates with the frustum-shaped through hole 12 to realize the sealing of the hopper 8 .

[0023] In this embodiment, the lower part of the hopper 8 is a conical structure, the upper part is a cylindrical structure, and the upper part has an opening for charging.

[0024] There are 2 groups of guide brackets, which are respectively the first guide bracket 6 and the second guide bracket 9, which are respectively arranged at the opening and the middle part of the hopper 8, and have the functions of wearing and suppo...

Embodiment 2

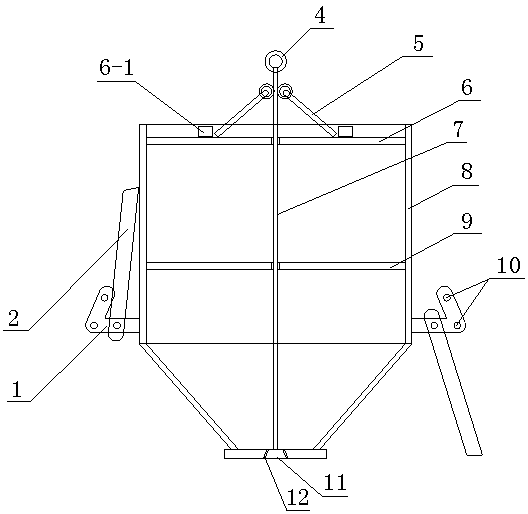

[0029] refer to Figure 3~Figure 4 , a self-unloading material transfer hopper of the present invention, comprising a hopper 8 with a tapered lower part, a guide bracket is arranged inside the hopper 8, a boom 7 is movable through the center of the guide bracket, and a suspension ring is arranged at the top of the boom 7 4. A plug 11 is provided at the lower end, and a frustum-shaped through hole 12 is provided on the bottom plate of the hopper 8 , and the plug 11 cooperates with the frustum-shaped through hole 12 to realize the sealing of the hopper 8 .

[0030] The self-unloading material transfer hopper 8 described in this embodiment is different from Embodiment 1 in that:

[0031] There are 3~4 sets of support assemblies on the side of the hopper 8. The support assemblies are composed of a support 1 and a leg 2 hingedly connected to it. The support 1 is provided with upper and lower limit pins 10; the guide bracket is provided with a stopper 6-1 , the top of the suspender...

Embodiment 3

[0035] See 5~ Figure 6 , a self-unloading material transfer hopper of the present invention, comprising a hopper 8 with a tapered lower part, a guide bracket is arranged inside the hopper 8, a boom 7 is movable through the center of the guide bracket, and a suspension ring is arranged at the top of the boom 7 4. A plug 11 is provided at the lower end, and a frustum-shaped through hole 12 is provided on the bottom plate of the hopper 8 , and the plug 11 cooperates with the frustum-shaped through hole 12 to realize the sealing of the hopper 8 .

[0036] The self-unloading material transfer hopper 8 described in this embodiment is different from Embodiment 2 in that:

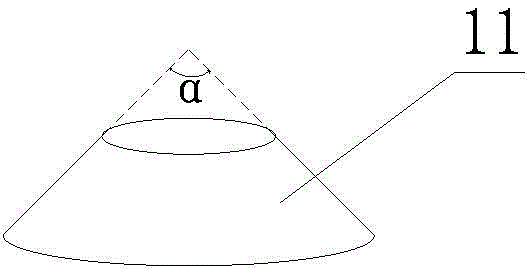

[0037] The upper part of the hopper 8 is provided with auxiliary hooks 3, and the number of auxiliary hooks 3 is 2 to 4, which are evenly arranged on the outer side of the upper part of the hopper 8. The plug 11 is conical, and the degree of the cone angle of the plug 11 is greater than or equal to 150o and Less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree | aaaaa | aaaaa |

| Degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com