Tea leaf dewatering and air-drying device

A tea and water filter tank technology, applied in the directions of tea drying, drying gas arrangement, drying, etc., can solve the problems of incapable of automatic unloading, unfavorable dehydration, easy accumulation of tea leaves, etc. The effect of speed and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

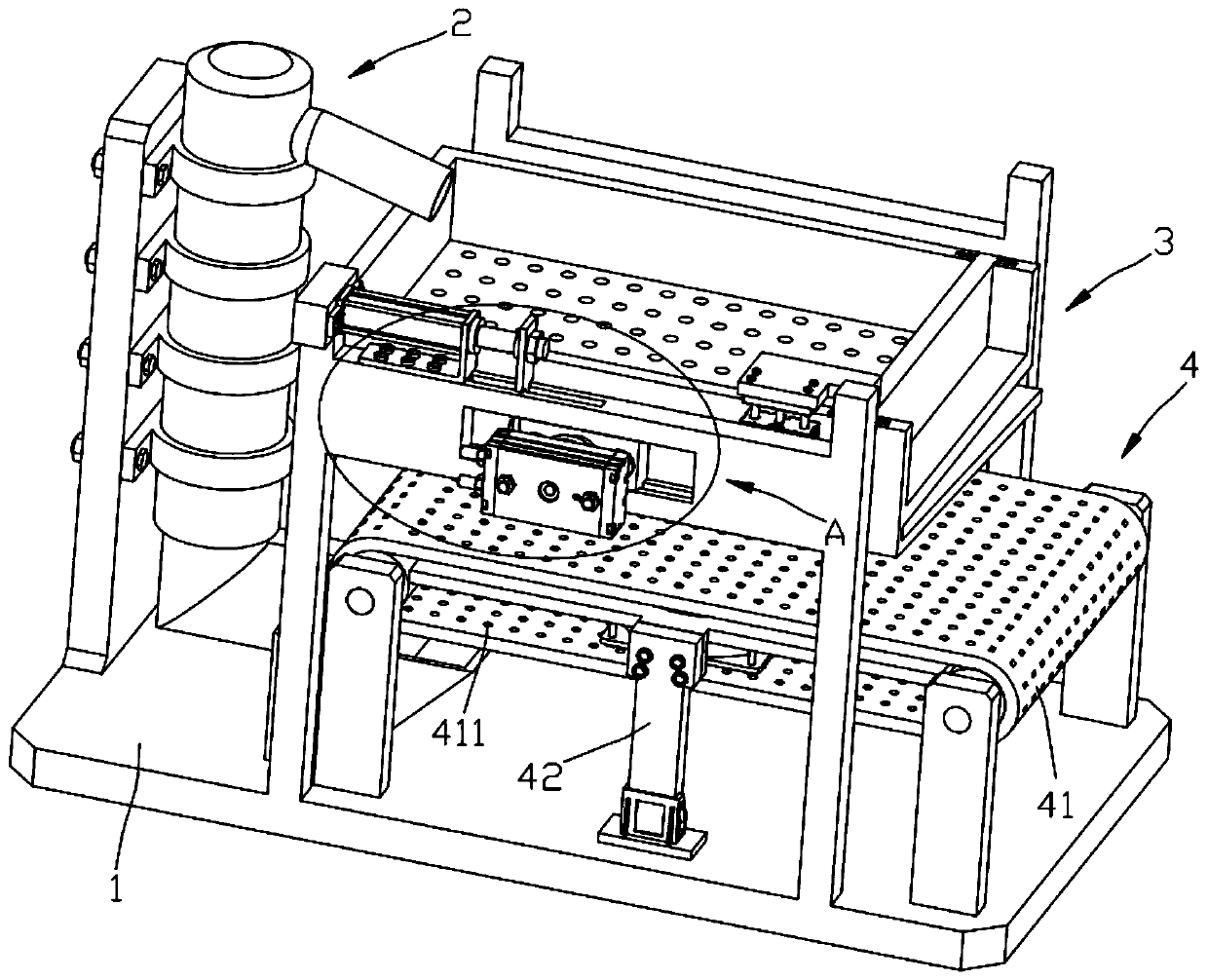

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0025] A device for dehydrating and drying tea leaves, comprising a support frame 1, a lifting conveyor 2, a primary drying mechanism 3 and a secondary drying mechanism 4, wherein:

[0026] The lifting conveyor 2 is fixedly installed on the support frame 1 through several installation collars and bolts, wherein the feeding port of the lifting conveyor 2 is located below the conveyor belt 41, and the discharging port of the lifting conveyor 2 is located above the filter water tank 31. Furthermore, the circular transfer of materials can be realized by lifting the conveyor 2;

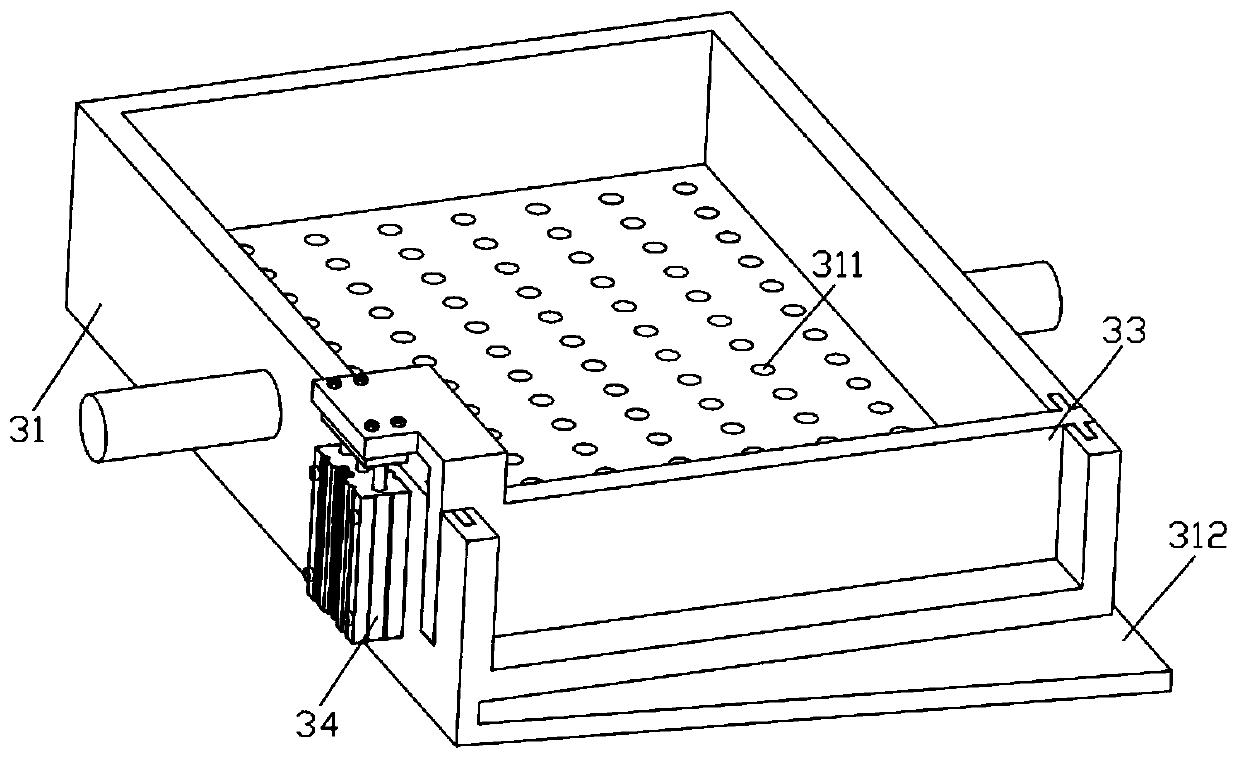

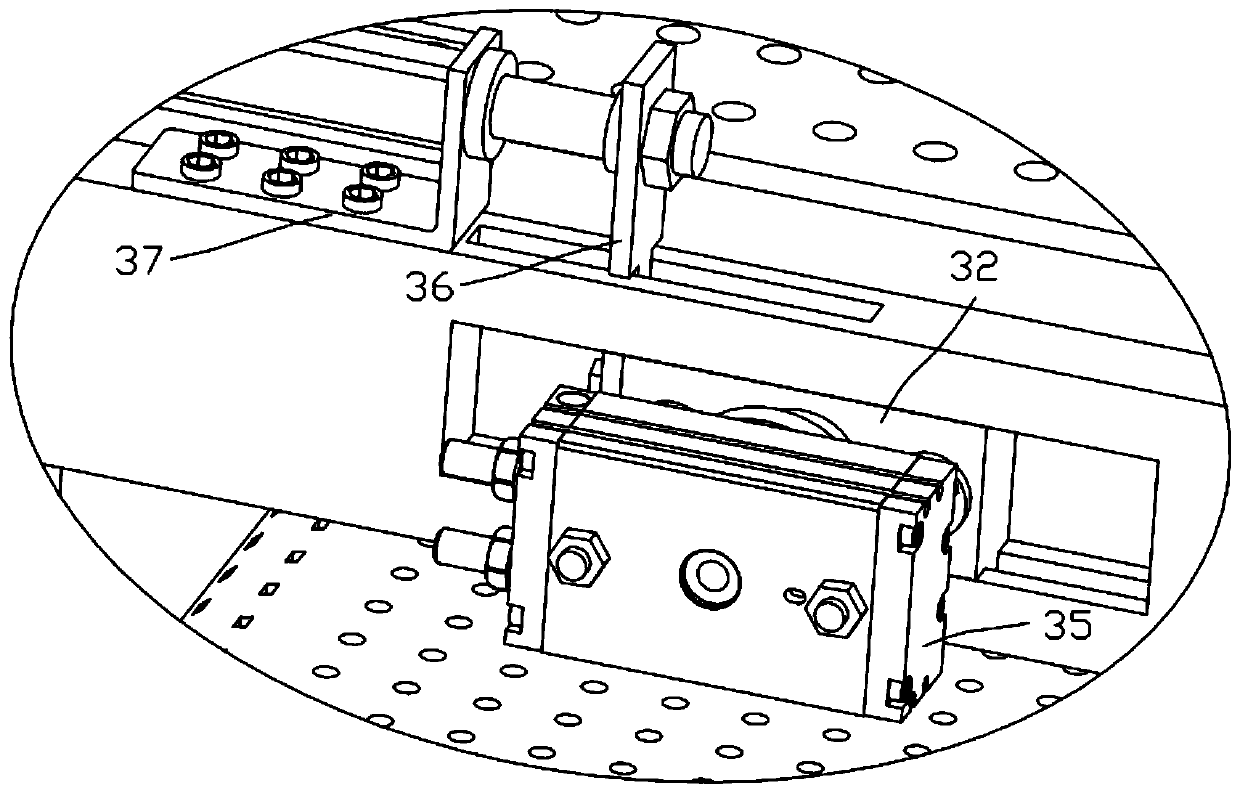

[0027] The first-level drying mechanism 3 comprises a filter tank 31, a slide block 32, a baffle plate 33, a biaxial cylinder 34, a rotary cylinder 35, a connecting plate 36 and a single-axis cylinder 37, and the filter tank 31 is provided with some filter holes 311 and bottom. A drainage plate 312 is provided obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com