Desulfuration water filtering tower

A water tower and desulfurization chamber technology, applied in the field of sulfur-containing gas desulfurization, dehydration and purification equipment, can solve the problems of desulfurization failure, low utilization rate of desulfurizer, inconvenient replacement of desulfurizer, etc. The control of materials and the effect of facilitating automatic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

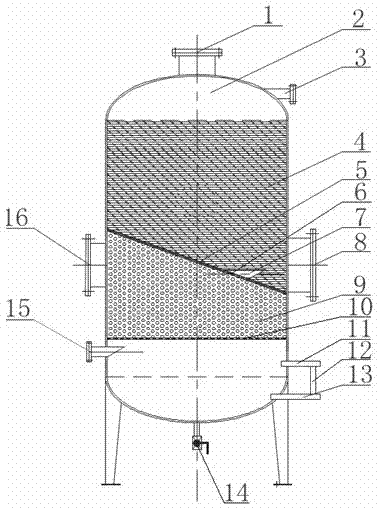

[0028] Embodiment 1: see figure 1 The air passage 7 on the partition 5 is a through hole corresponding to the height of the discharge port 8 and horizontally penetrating through the partition 5. A straight pipe is fixedly connected to one end of the desulfurization chamber 4 of the through hole. The straight pipe It can also be arranged on the through hole and facing above the desulfurization chamber 4, but it is preferably arranged horizontally with the other end of the straight pipe facing the side of the discharge port 8. The through hole is provided with a filter screen, and the other end of the straight pipe is made into a slope facing downward, and a filter screen is arranged on the slope, or the filter screen can also be arranged on the slope of the straight pipe. The effect of filter screen is mainly to stop desulfurization agent from falling in the water filter chamber 9 and prevent dehydration material from entering the desulfurization chamber 4.

[0029] In order t...

Embodiment 2

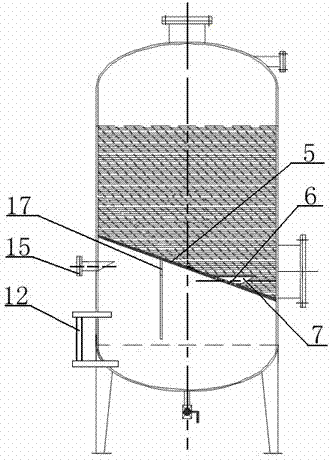

[0036] Example 2: see figure 2 , the high end of the partition 5 is correspondingly arranged on the side of the air inlet 15 of the water filter chamber 9, and a baffle 17 is vertically arranged on the longitudinal section of the water filter chamber 9 between the air inlet 15 and the air passage 7 , the plane of the baffle plate 17 is perpendicular to the axis of the air inlet 15, the upper edge of the baffle plate 17 is connected with the partition plate 5, and the lower edge of the baffle plate 17 is higher than the highest water level height in the water filter chamber 9, namely A passage for gas flow should be left between the bottom of the baffle plate 17 and the water surface in the water filtering chamber. The dehydrated gas can enter the space on the other side of the baffle plate 17 and flow from the gas passage 7 to the desulfurization chamber 4 . That is, the water filtering device is a baffle 17, and the baffle 17 is vertically fixed on the bottom of the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com