Cargo distribution device for logistics

A cargo and logistics technology, applied in the field of logistics, can solve problems such as unloading difficulties and reduce unloading efficiency, so as to achieve the effects of convenient unloading, improving unloading efficiency, and increasing operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

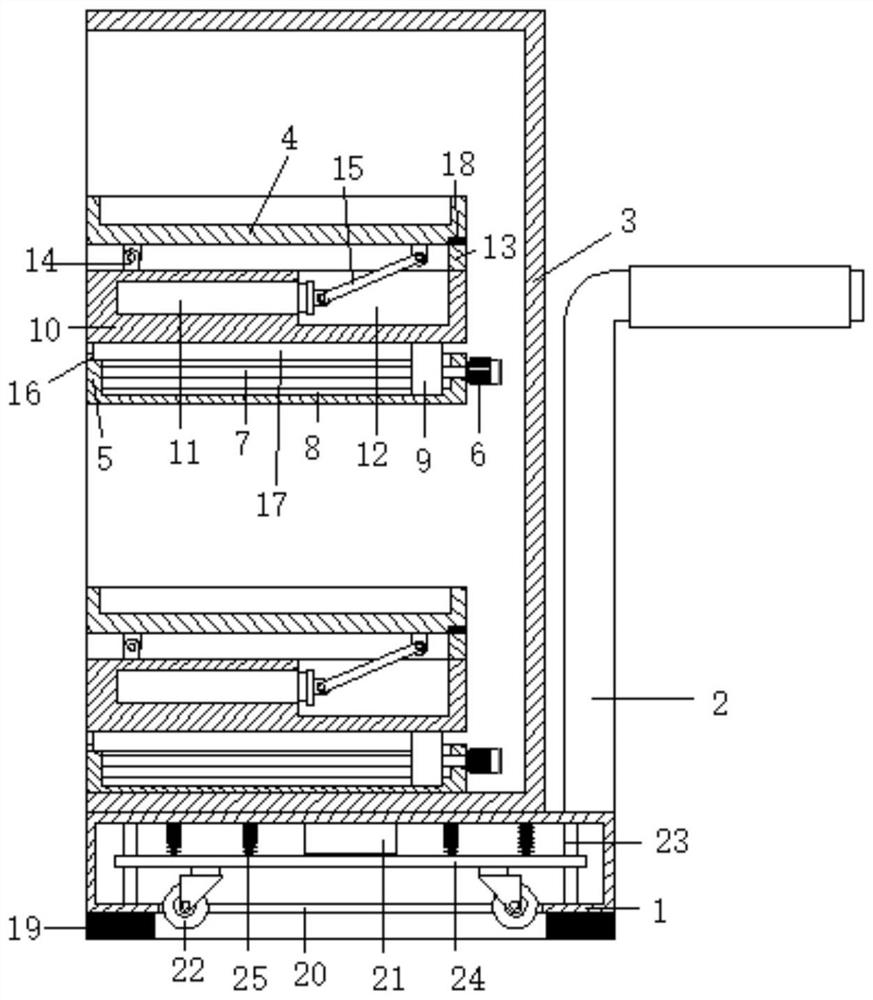

[0023] see figure 1 , a cargo distribution device for logistics, comprising a hollow-out distribution base 1, a push handle 2 fixedly installed on the distribution base 1, and a moving assembly arranged inside the distribution base 1; the distribution base 1 is provided with a single-side opening The cargo storage frame 3 provided at the entrance, the cargo storage frame 3 is provided with a plurality of sets of placement components arranged up and down, and the placement components include a U-shaped placement plate 4, a power component that drives the U-shaped placement plate 4 to tilt, and a U-shaped placement plate that drives the U-shaped Placement plate 4 extends out of the lateral movement assembly of cargo storage frame 3;

[0024] The lateral movement assembly includes a lateral installation frame 5 fixedly installed on the inner wall of the cargo storage frame 3 and a lateral drive motor 6 fixedly installed on the lateral installation frame 5, the output end of the l...

Embodiment 2

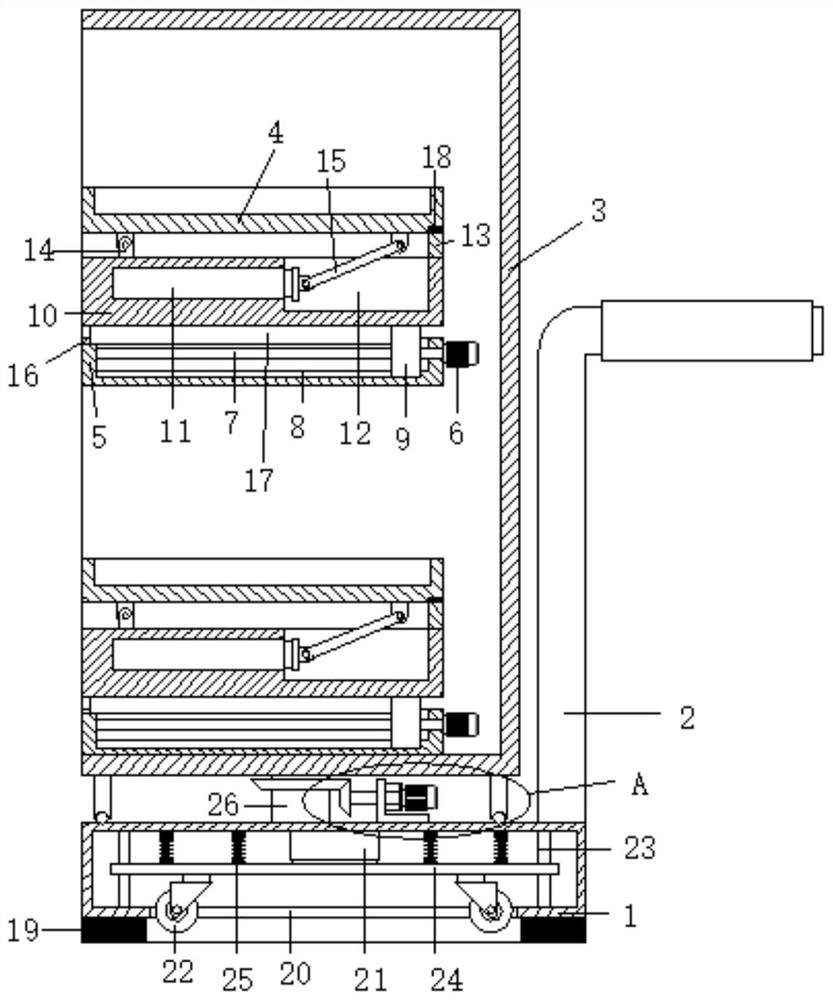

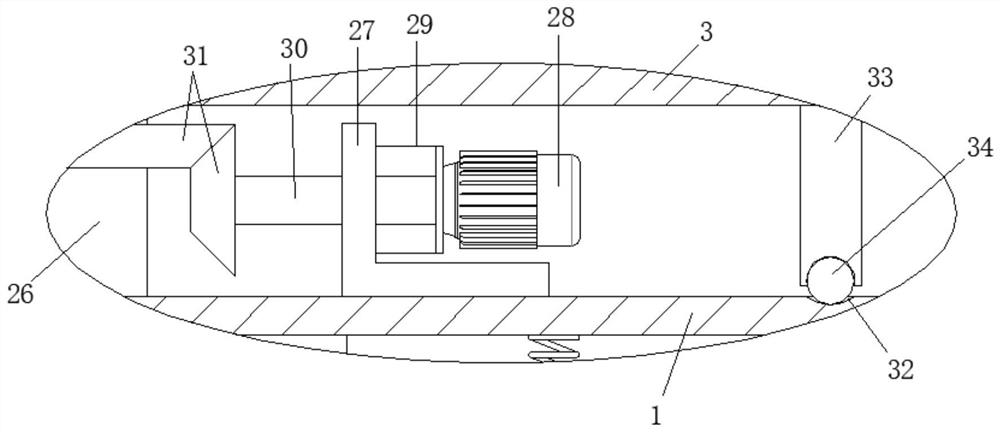

[0034] see Figure 2-3, this embodiment is further improved on the basis of the embodiment, and the improvement is that: a rotating assembly that drives the rotating of the cargo receiving frame 3 is provided between the cargo receiving frame 3 and the distribution base 1, and the rotating assembly includes a rotating motor 28 , the motor bracket 29 that is used to fixedly install the rotating motor 28, the rotation column 26 that is installed on the distribution base 1 and the L-shaped mounting bracket 27 that is fixedly installed on the distribution base 1, and the motor bracket 29 is fixedly installed on the L-shaped installation On the bracket 27, the output end of the rotating motor 28 is fixedly installed with a transmission shaft 30, and the transmission shaft 30 is rotatably mounted on the L-shaped mounting bracket 27, and the transmission shaft 30 and the rotating column 26 are transmitted through a bevel gear pair 31. connected, the cargo storage frame 3 is fixedly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com