Device for realizing reciprocating extrusion process on one-way hydraulic press

A technology of reciprocating extrusion and hydraulic press, which is applied to metal extrusion dies and other directions, can solve the problems of inability to continue the reciprocating extrusion process and macro folding, and achieve the effect of reducing equipment requirements, improving production efficiency and facilitating unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

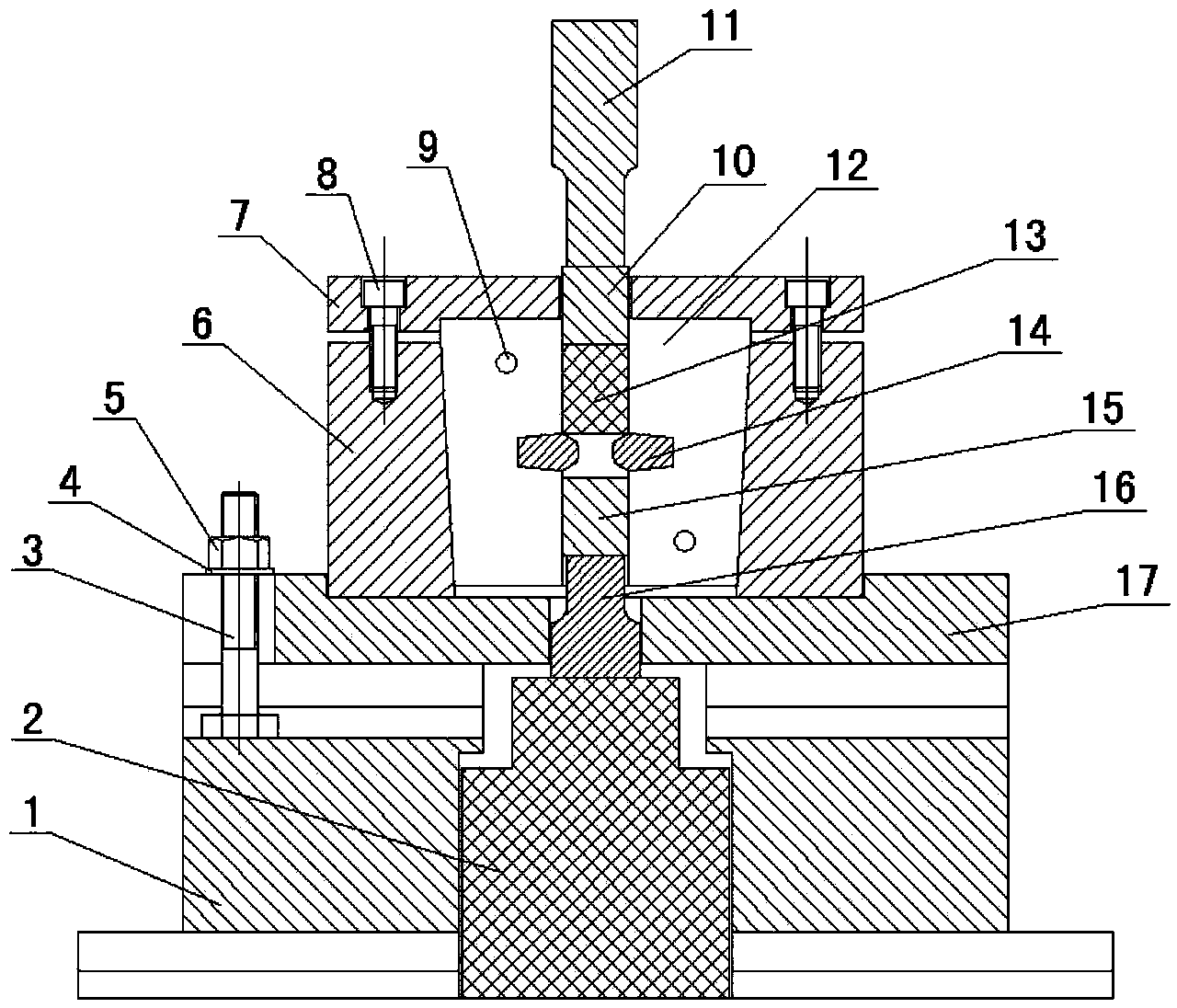

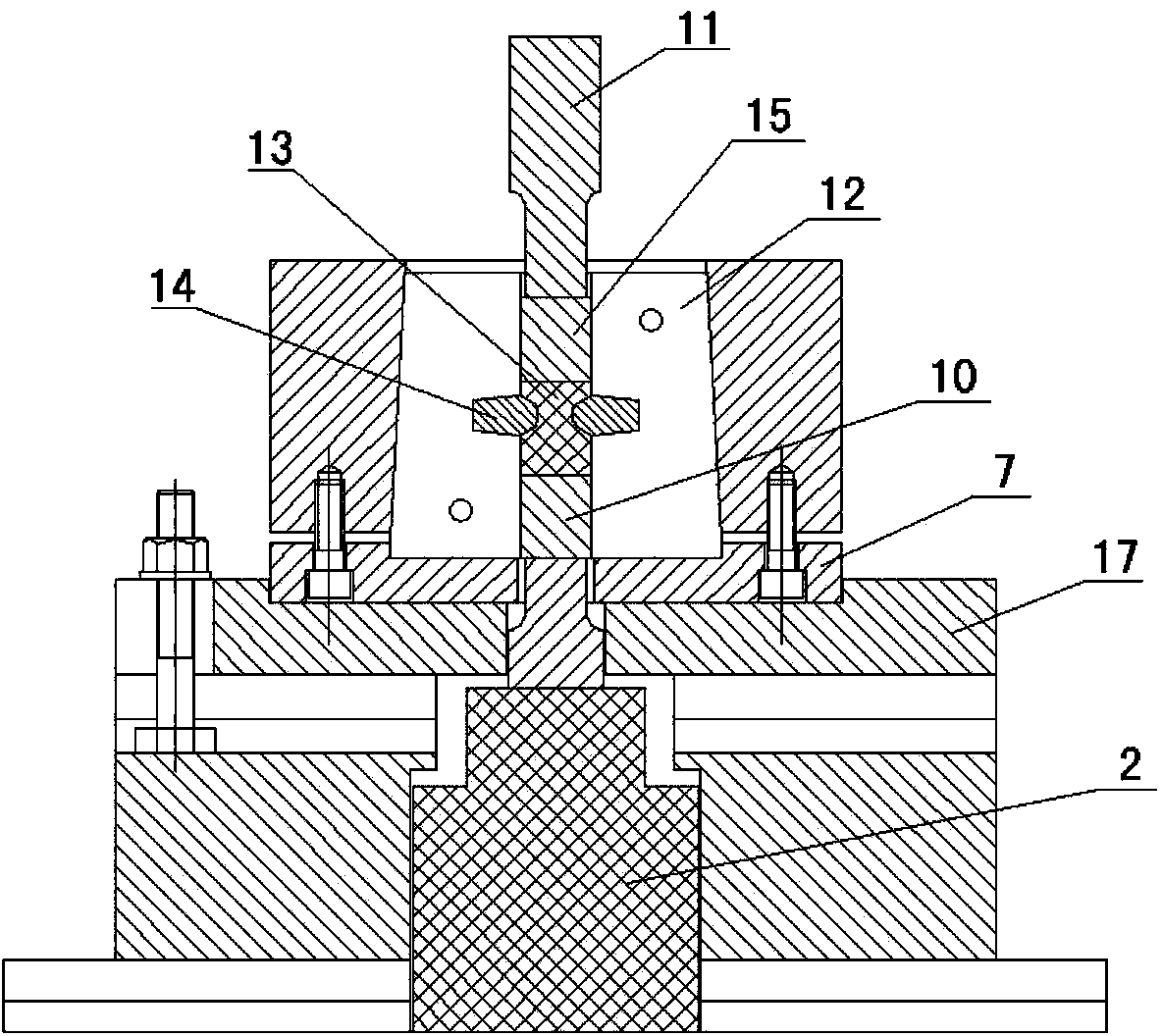

[0031] The structural form of the device used to realize the reciprocating extrusion process on the unidirectional hydraulic press in this embodiment is:

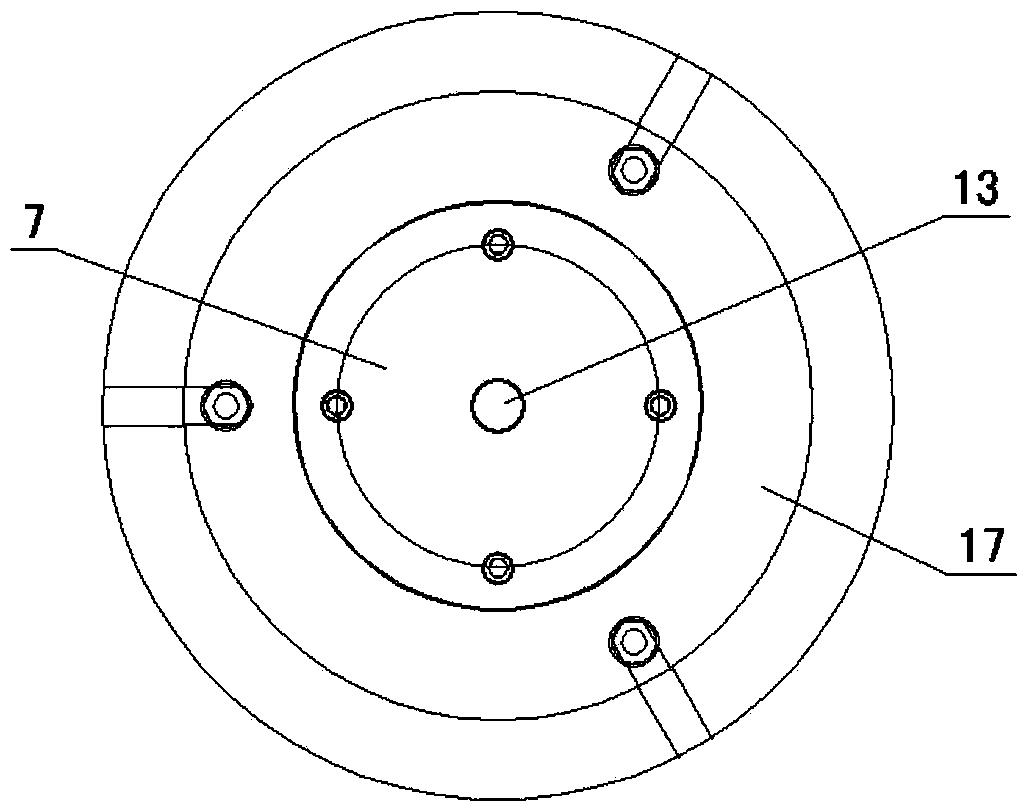

[0032] Such as figure 1 As shown, a pair of semi-annular cylinders are relatively fixed to form an annular extrusion cylinder 12, and the annular extrusion cylinder 12 has a hollow cylindrical cavity axially penetrated; Sliding upper punch and lower punch, the upper punch is composed of an upper punch 11 and an upper pad 10 laminated on the bottom of the upper punch 11, and the lower punch is composed of a lower punch 16 and a lower punch 16 The lower cushion block 15 on the top of the cylinder is formed, and the cylindrical blank 13 is placed in the hollow cylindrical cavity of the annular extrusion cylinder 12 .

[0033] figure 1 As shown in the figure, the core inserts 14 with two opposite lobes are snapped into the groove 18 of the inner cylinder wall of the annular extrusion cylinder 12 and protrude from the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com