Engine transient air-intake control system and control method

A technology of control system and control method, which is applied in the direction of engine control, combustion engine, machine/engine, etc. It can solve the problems that the engine power output cannot achieve good results, the air-fuel ratio cannot be effectively controlled, and the air-fuel ratio is out of balance. , to achieve the effect of improving the precise control of air-fuel ratio, meeting the transient intake demand, and improving the combustion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

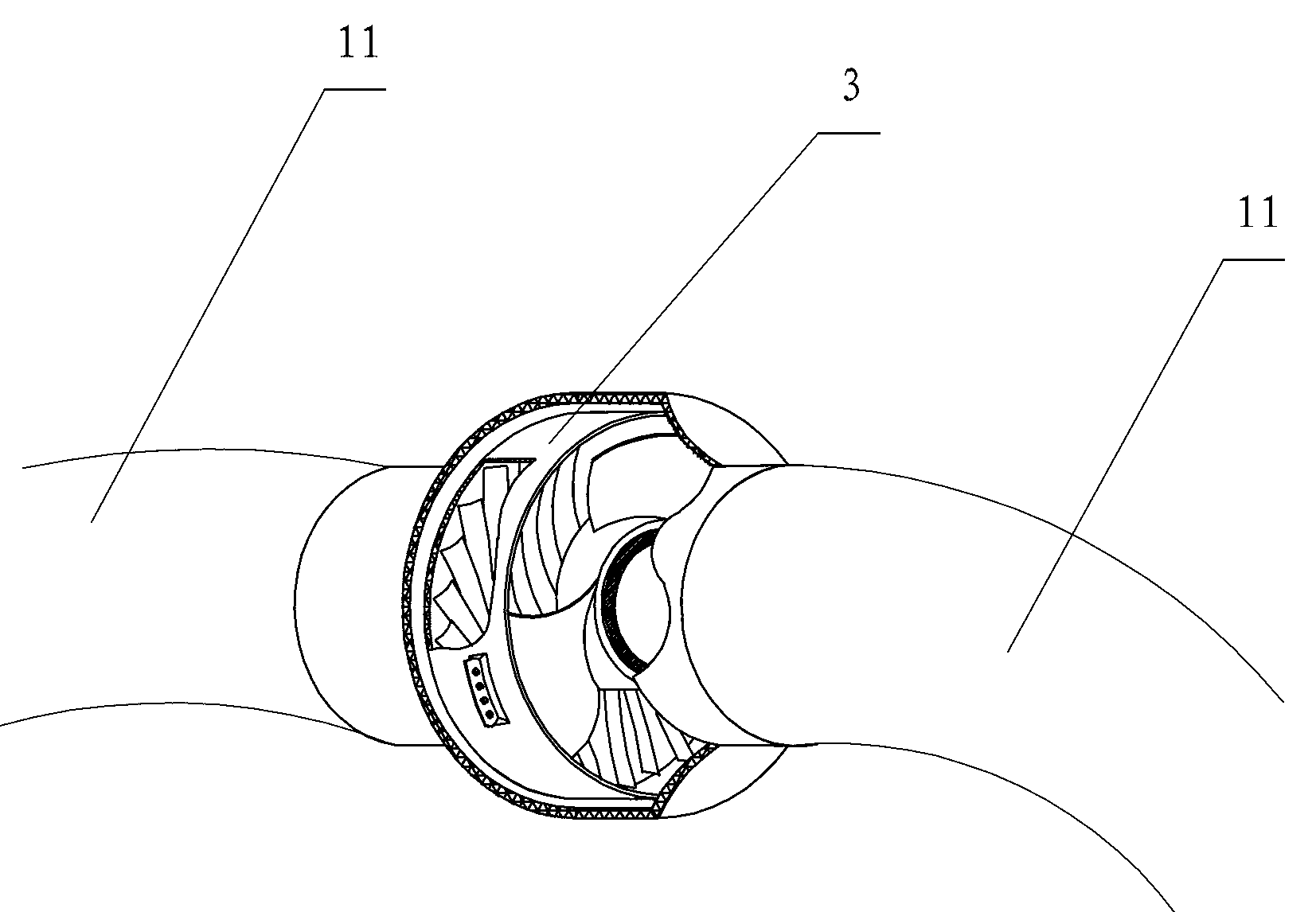

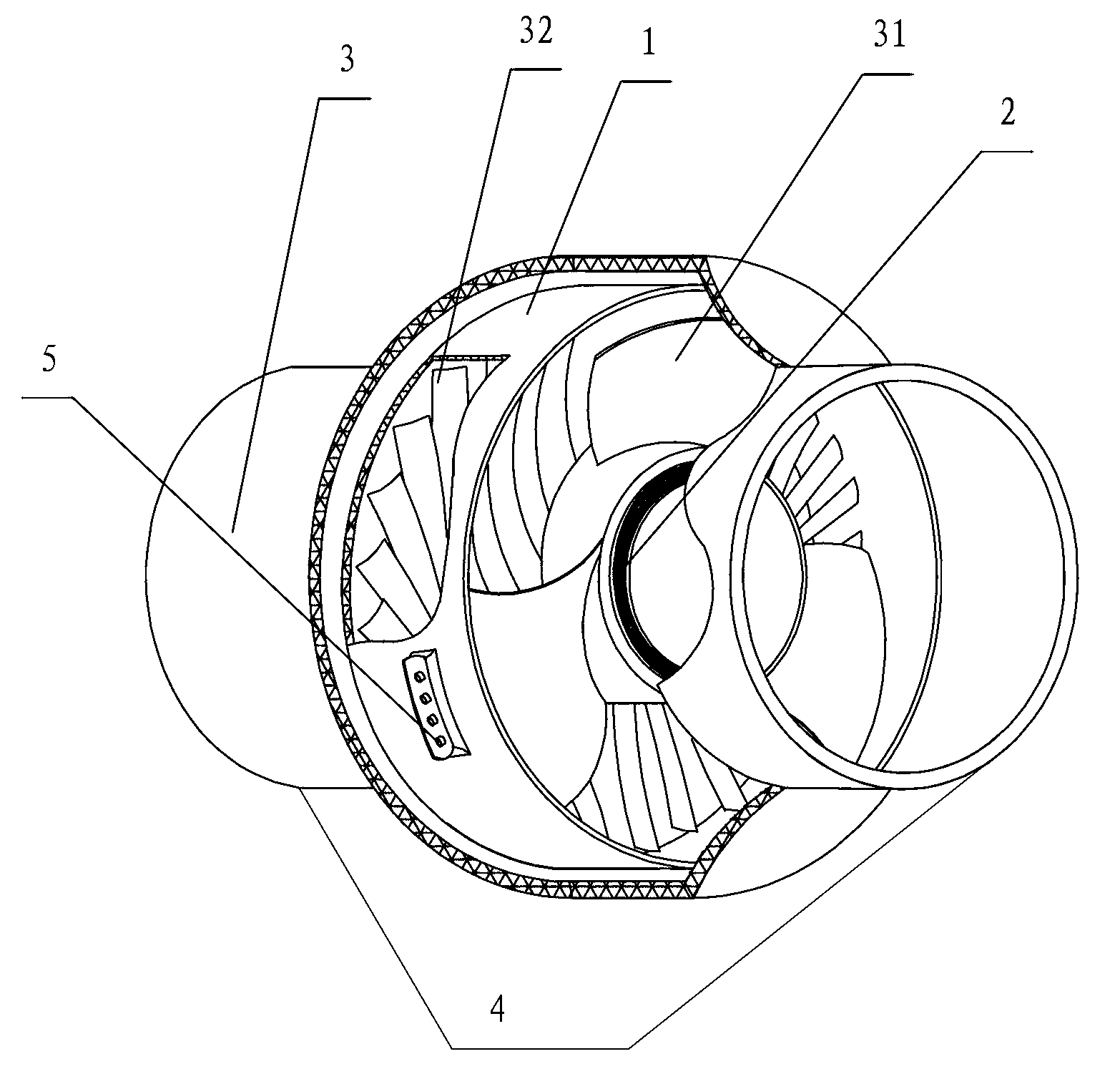

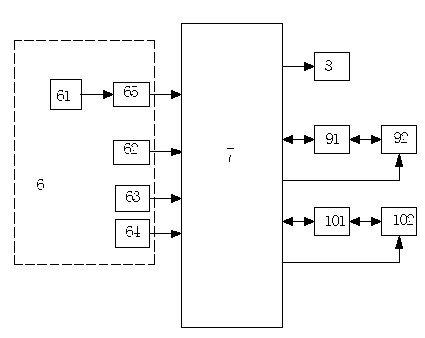

[0038] The engine transient air intake control system involved in the present invention consists of figure 1 As shown, it includes a blower 3 arranged on the intake pipe 11 between the engine intake and the intake manifold to change the air flow direction, and a control system for receiving vehicle status information and controlling the operation of the fan according to the vehicle status information. The fan 3 can be a fan of NMB (Minebéa) company, the model is 3630FTD4WB66E51. In order to describe its structure more clearly, a schematic structural diagram of the fan 3 is provided in this embodiment. Its main structure is as follows figure 2 As shown, a fan housing 1 is included, and a fan motor 2 is arranged in the fan housing 1. The terminal 5 of the fan motor 2 is arranged on the fan housing 1, and the front end of the fan motor 2 is provided with a fan blade that rotates after being powered on. 31, the rear end of the fan motor 2 is provided with a static fan blade 32; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com