Compressive sealing device

A sealing device and sealing gas technology, which is applied to the sealing device of the engine, engine components, machines/engines, etc., can solve the problems of large contact area between the piston and the cylinder, high manufacturing cost, and large frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

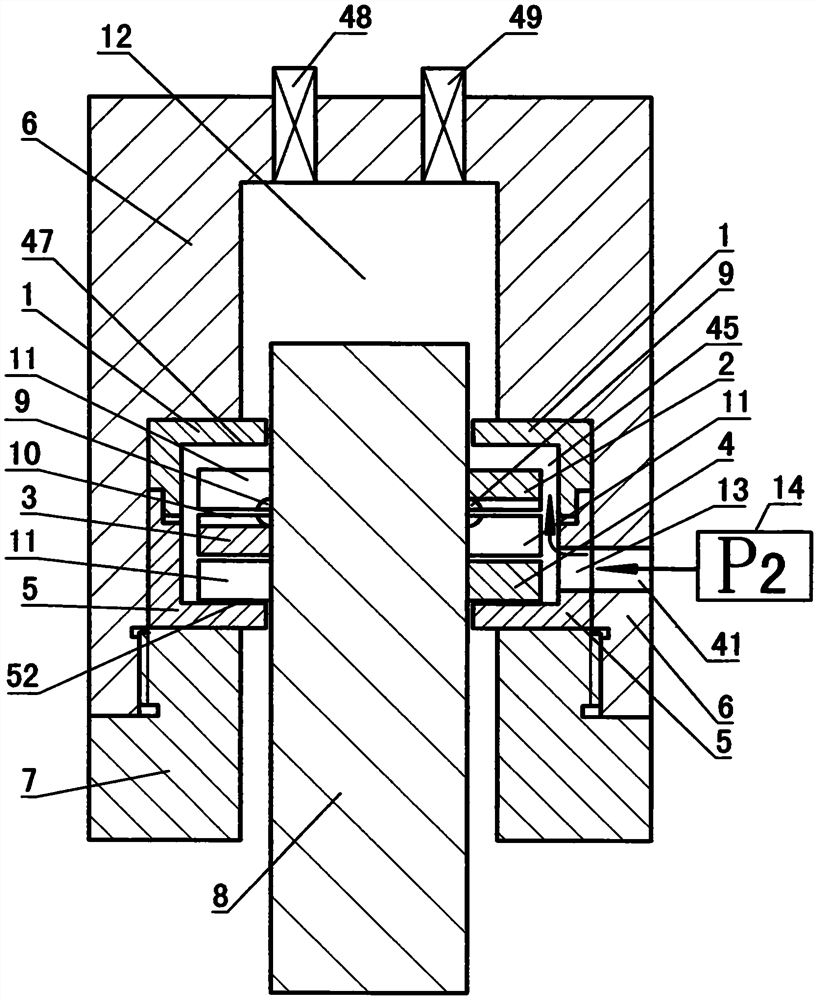

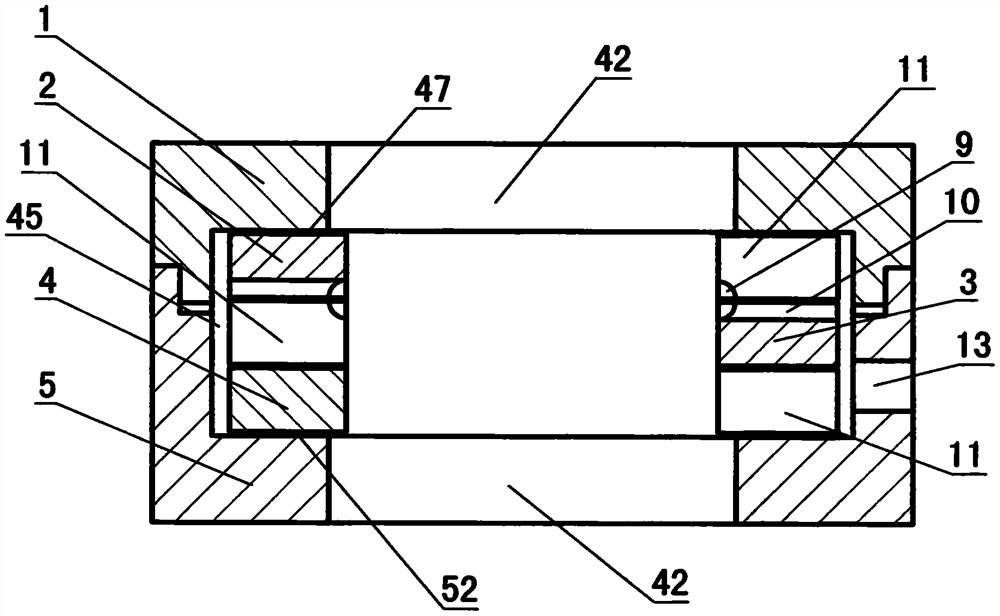

[0048] It is applied to the embodiment of the double-cavity intake and exhaust device.

[0049] The combined use of the two sealing inserts can realize the independent completion of air intake by setting the air intake device on the piston, and complete the exhaust from the cylinder head alone, which speeds up the air intake and exhaust speed and makes the direction of the air flow consistent, making the air flow more efficient. smooth.

[0050] Such as Figure 8 , Figure 9 , Figure 12 Shown: the double-chamber intake and exhaust device consists of cylinder head 15, cylinder block A16, cylinder block B17, cylinder block C18, piston 22 with air passage, upper seal insert 30, lower seal insert 31, intake valve 21, Valve pull rod 24, valve spring 25, valve strut 26 and other components are combined,

[0051] The intake stroke and the exhaust stroke of the dual-chamber intake and exhaust device are independently completed by the piston 22 with air passage and the cylinder he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com