Annealing furnace air-fuel ratio self-optimizing method and device

An air-fuel ratio and self-optimization technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as poor air-fuel ratio control, heat loss, and system combustion instability, and achieve small temperature fluctuations in the furnace and optimal combustion Situation, effect of small gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

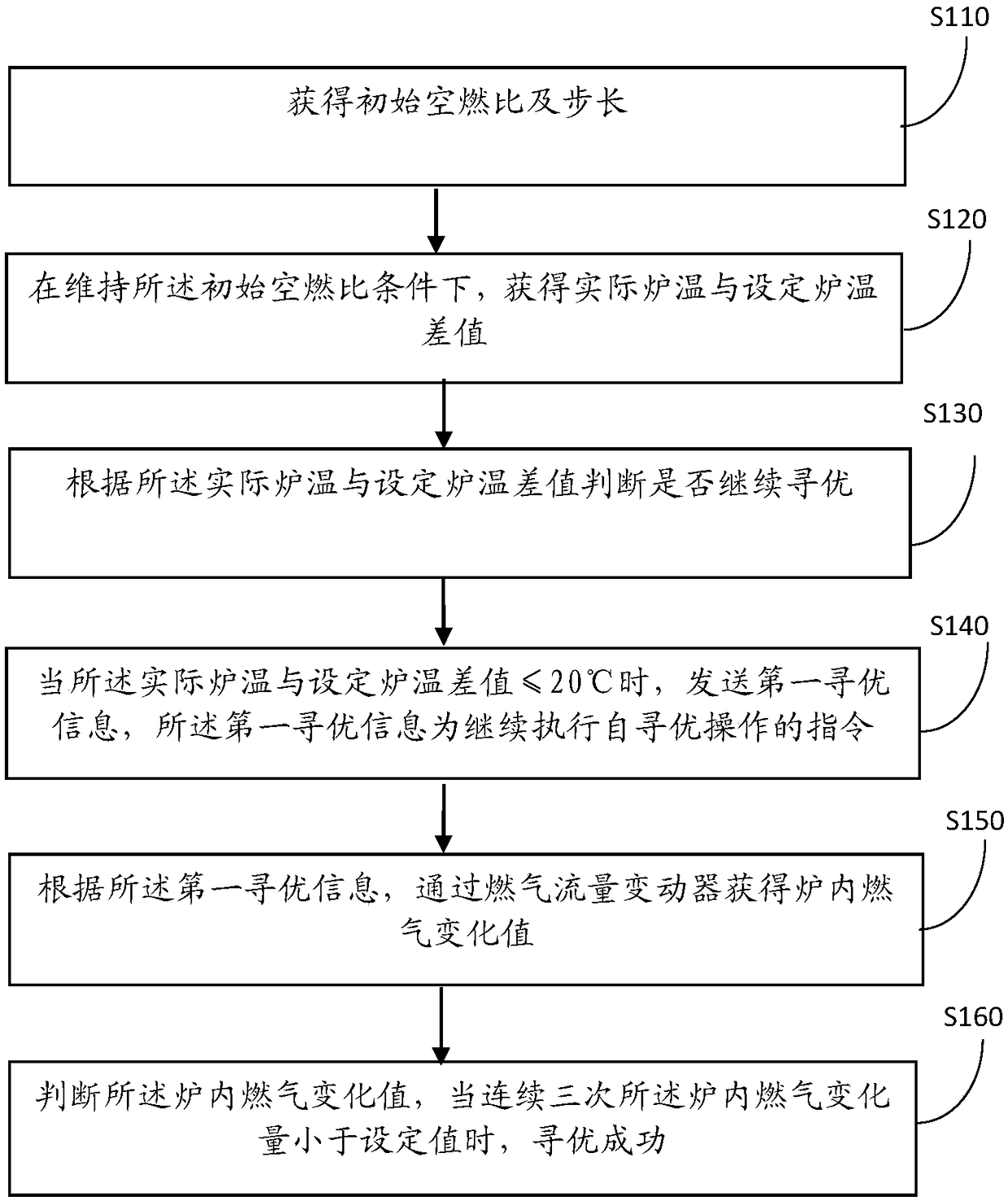

[0045] figure 1 It is a schematic flowchart of a method for self-optimizing the air-fuel ratio of an annealing furnace in an embodiment of the present invention. like figure 1 As shown, the embodiment of the present invention provides a method for self-optimizing the air-fuel ratio of an annealing furnace, the method comprising:

[0046] Step 110: Obtain the initial air-fuel ratio and step size;

[0047] Further, the step size is set to 0-1.

[0048] Specifically, the main task of the combustion control system of the annealing furnace is to adapt the heat provided by the combustion in the annealing furnace to the load of the production line, at the same time ensure that the gas in the furnace can be burned out, realize economical combustion and safe operation, and find the best air-fuel ratio , first set the initial air-fuel ratio and step size in the PID controller of the combustion control system of the annealing furnace, the initial air-fuel ratio is the corresponding ai...

Embodiment 2

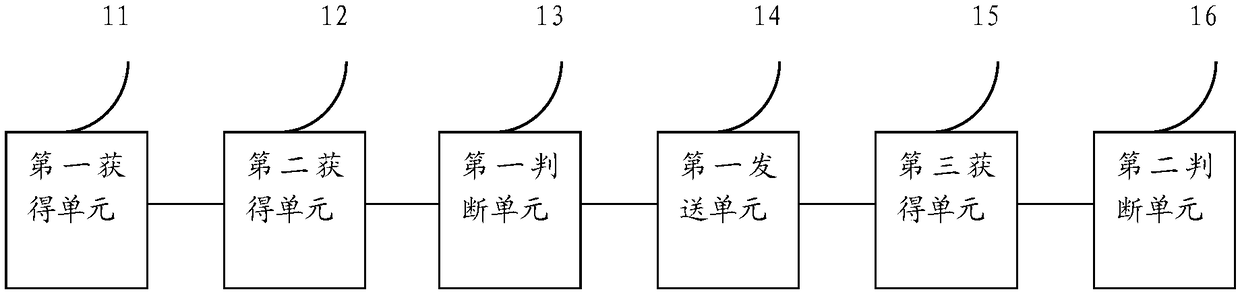

[0063] Based on the same inventive concept as the method for self-optimizing the air-fuel ratio of the annealing furnace in the foregoing embodiments, the present invention also provides a device for self-optimizing the air-fuel ratio of the annealing furnace, such as figure 2 As shown, the device includes:

[0064] A first obtaining unit 11, the first obtaining unit 11 is used to obtain an initial air-fuel ratio and a step size;

[0065] A second obtaining unit 12, the second obtaining unit 12 is used to obtain the difference between the actual furnace temperature and the set furnace temperature under the condition of maintaining the initial air-fuel ratio;

[0066] The first judging unit 13, the first judging unit 13 is used to judge whether to continue to optimize according to the difference between the actual furnace temperature and the set furnace temperature;

[0067] The first sending unit 14, the first sending unit 14 is used to send the first optimization informatio...

Embodiment 3

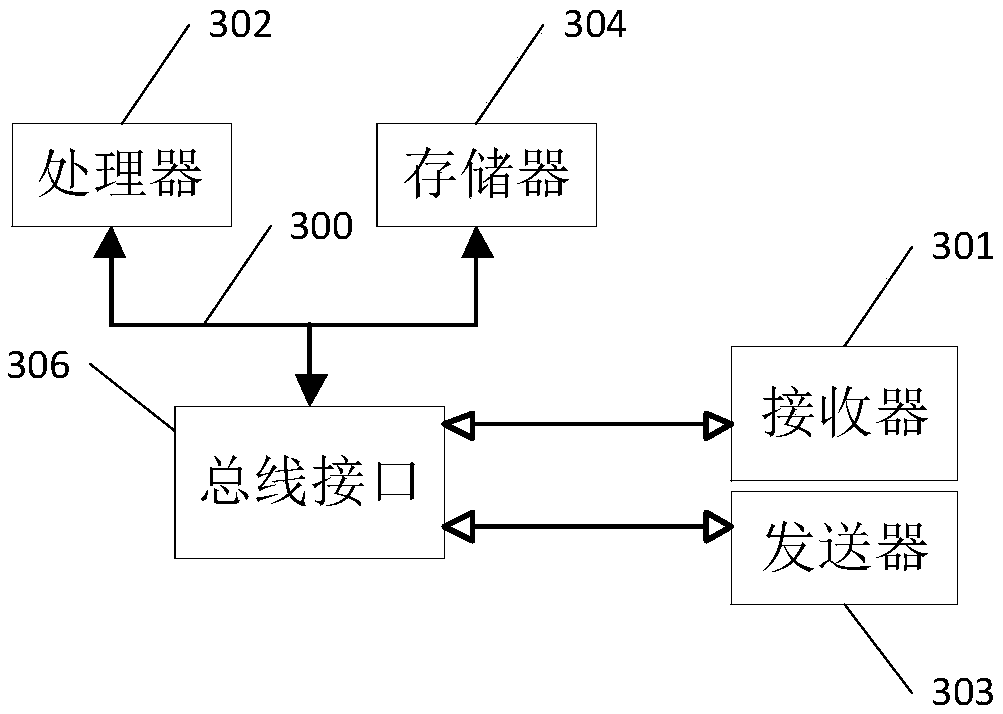

[0083] Based on the same inventive concept as the method for self-optimizing the air-fuel ratio of the annealing furnace in the foregoing embodiments, the present invention also provides a device for self-optimizing the air-fuel ratio of the annealing furnace, on which a computer program is stored, and the program is executed by the processor During execution, the steps of any one of the network authority authentication methods described above are realized.

[0084] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. The bus in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com