Excess air coefficient management system for kiln

A technology of excess air coefficient and management system, applied in the field of kilns, can solve the problems of incomplete combustion, small excess air coefficient, waste of energy, etc., and achieve the effect of improving firing efficiency, stabilizing furnace temperature and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

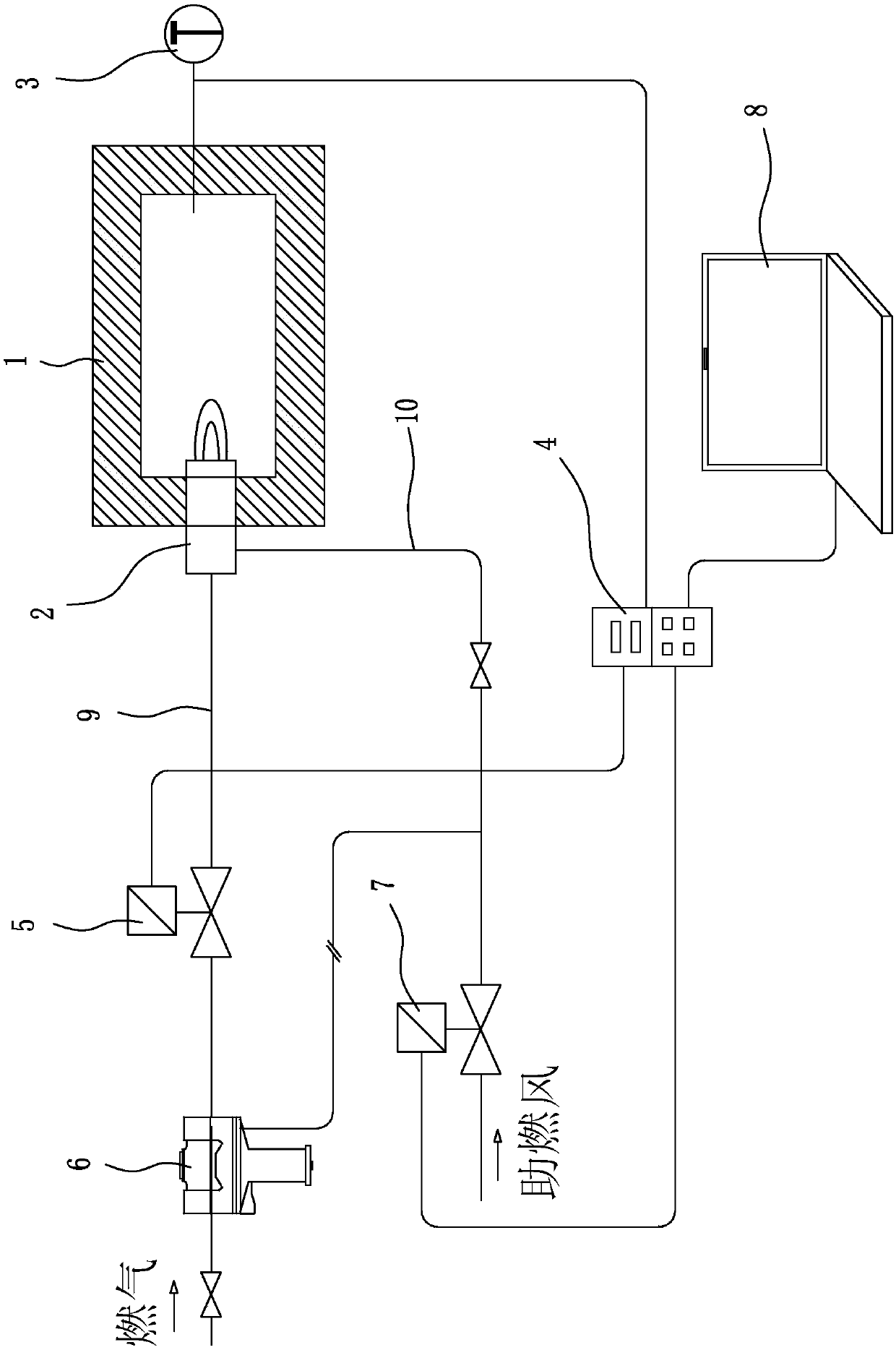

[0008] Such as figure 1 As shown, a kiln air excess coefficient management system includes a burner 2, a thermocouple 3, a temperature control instrument 4, a gas actuator 5, a gas proportional valve 6, and an air actuator 7 installed in a kiln 1. , and an industrial computer 8, in the present invention, the gas actuator 5 and the gas proportional valve 6 are successively connected in series on the gas pipeline 9 of the burner 2, and the air actuator 7 is connected in series on the air pipeline 10 of the burner 2, and the gas The air pressure detection of the proportional valve 6 is connected with the air pipe 10 of the burner 2 , and the thermocouple 3 , industrial computer 8 , gas actuator 5 and air actuator 7 are all connected with the temperature control instrument 4 .

[0009] The working principle of the excess air coefficient management system (taking a single control group as an example): When the thermocouple 3 detects that there is a difference between the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com