Combined protection smelting furnace and smelting method

A combined and smelting furnace technology, applied in the direction of furnaces, furnace components, furnace types, etc., to achieve the effect of improving smelting environmental pollution and promoting metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

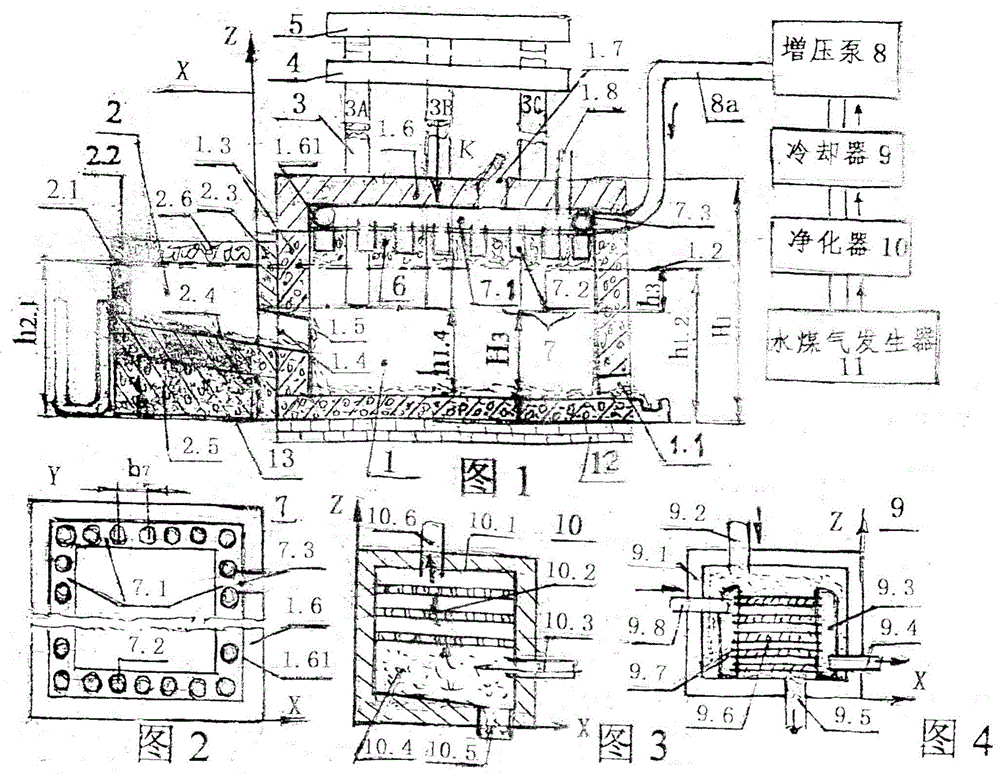

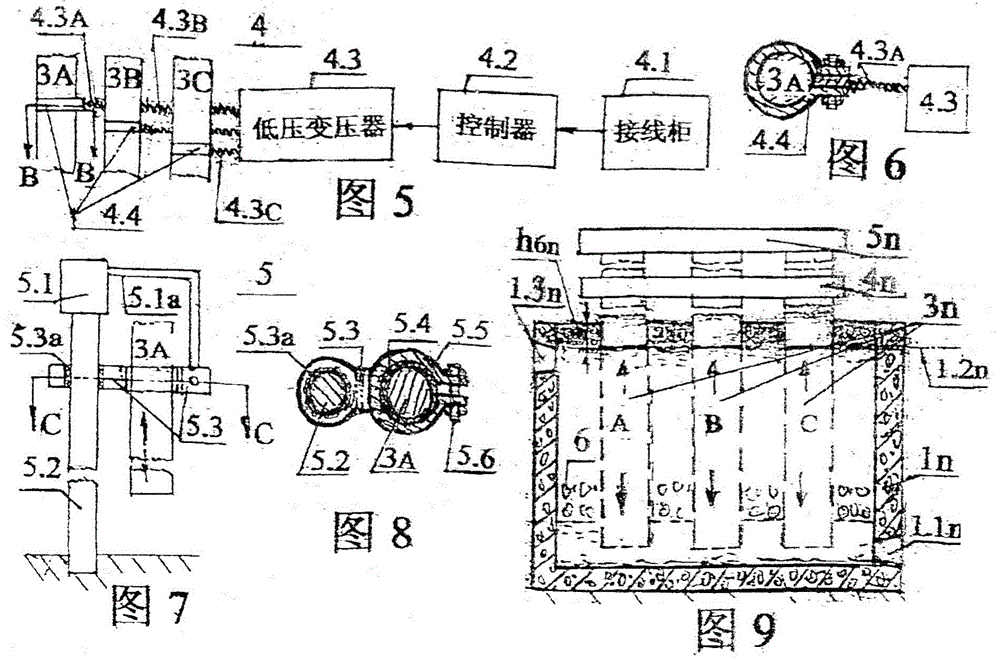

[0022] See figure 1 , The combined protective smelting furnace is composed of a large furnace body 1 heated by AC electrodes and injected with pressure water gas, a small furnace body 2 connected to the large furnace body, and a water gas system 8-11.

[0023] See figure 1 , The inner wall of the large furnace body 1 is a furnace lining made of refractory materials; the bottom of the rear side wall is provided with an outer trumpet-shaped metal outlet 1.1. During operation, solid raw material ore 6 is installed in the large furnace body; three-phase AC electrodes 3 (3A, 3B, 3C) are inserted into the ore, and generally three AC carbon electrodes are used. An AC power distribution device 4 and an AC lifting device 5 are also provided. The insulating insulation layer 12 that useful refractory brick is made is buried on the ground below the body of furnace bottom.

[0024] See figure 1 ,See figure 2 , a furnace cover 1.6 is arranged above the large furnace body 1, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com