Patents

Literature

33results about How to "Realize segmental heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

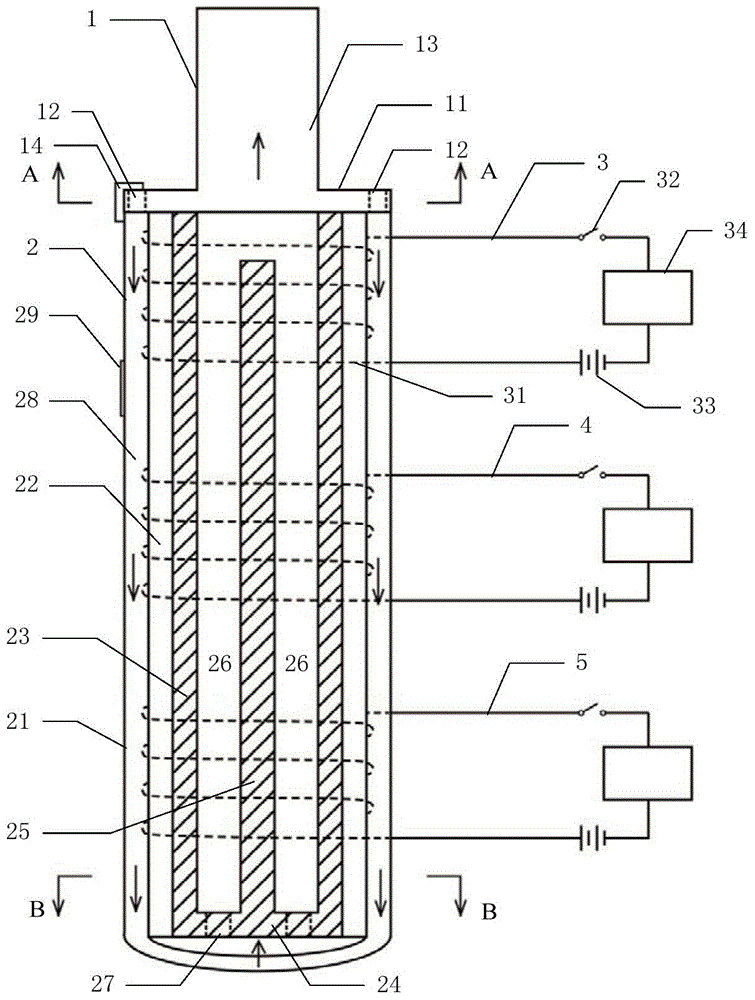

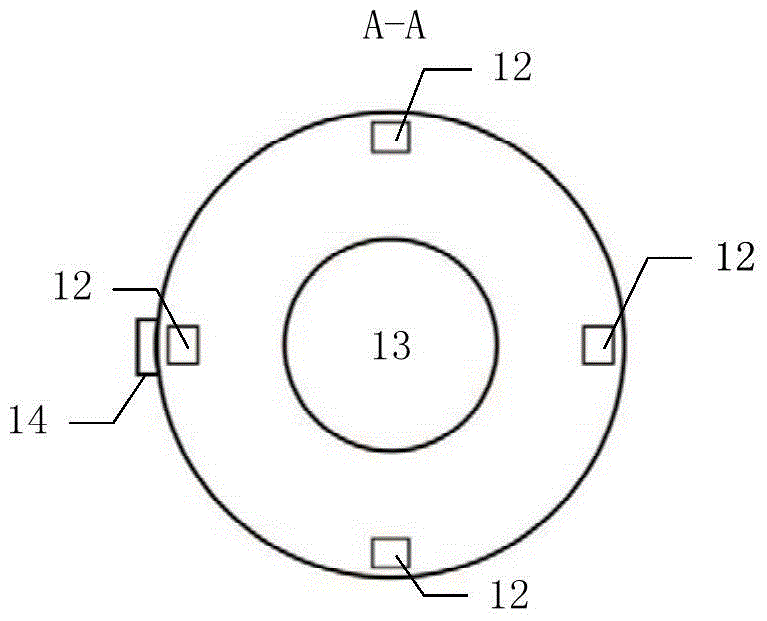

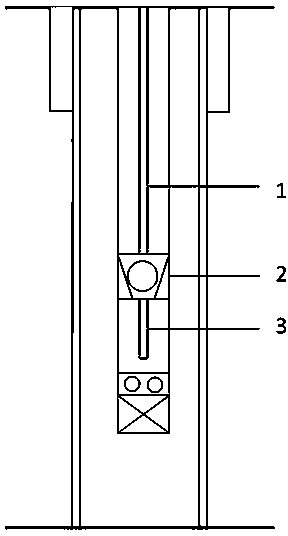

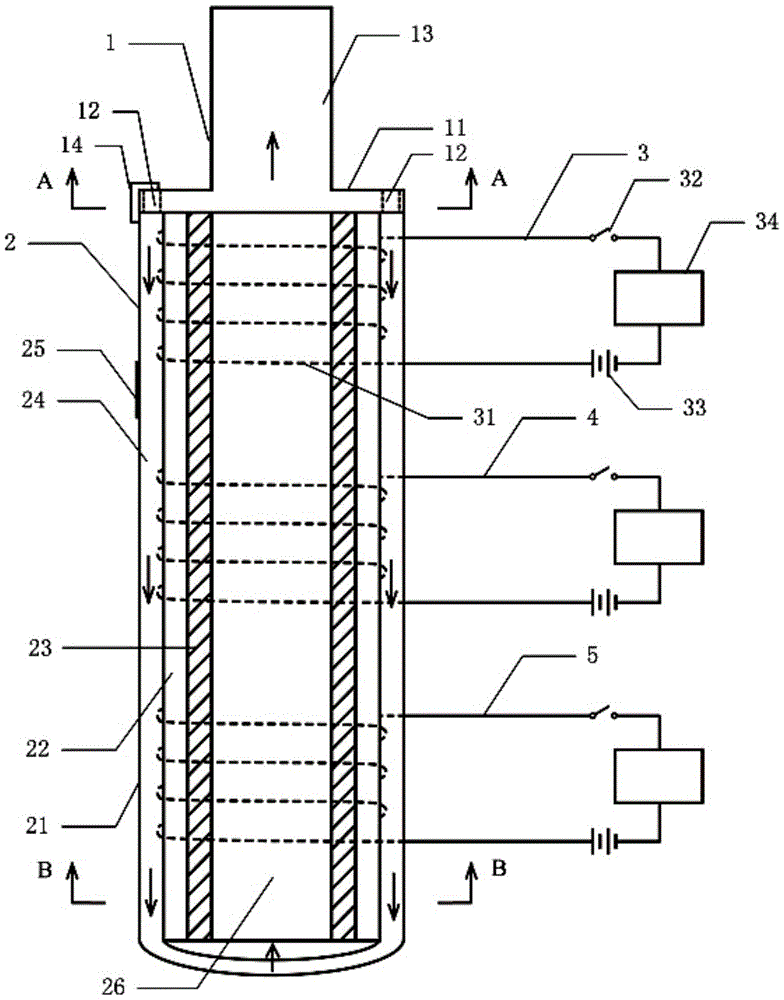

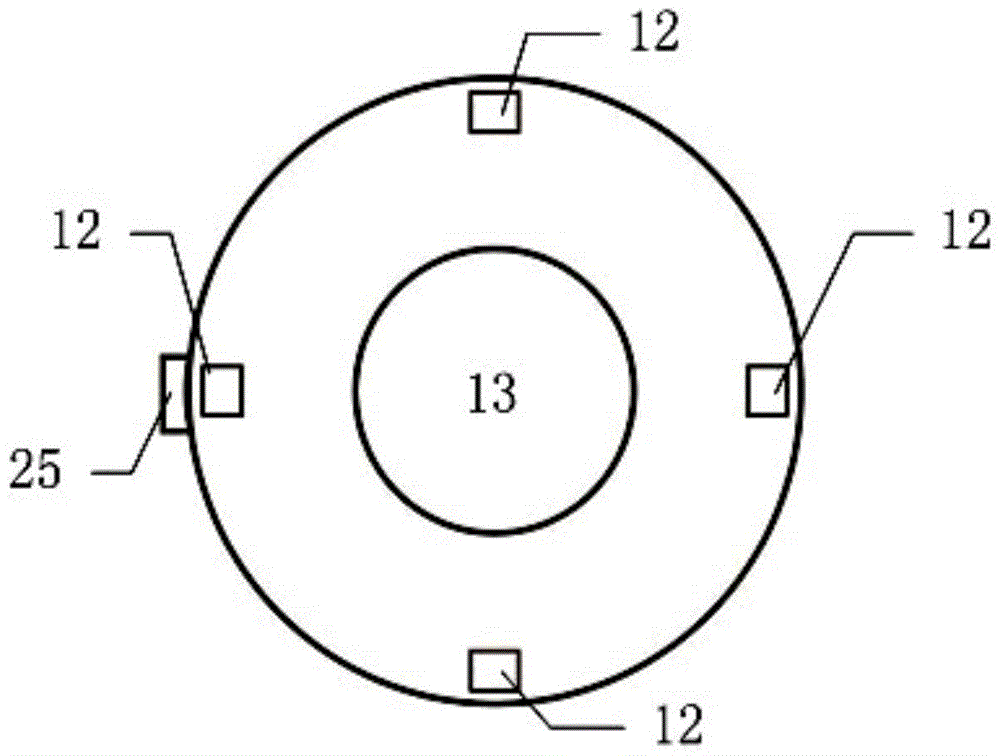

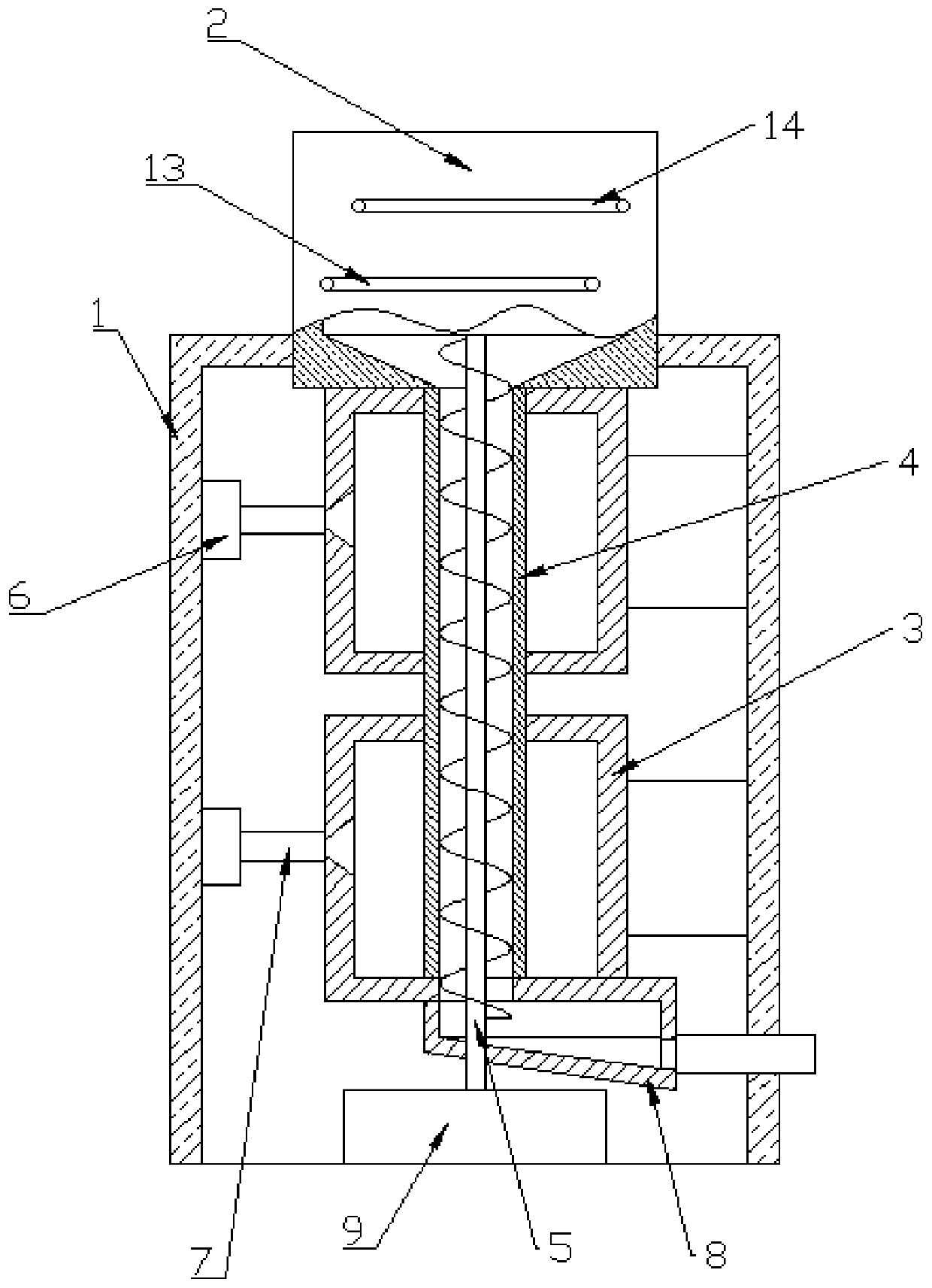

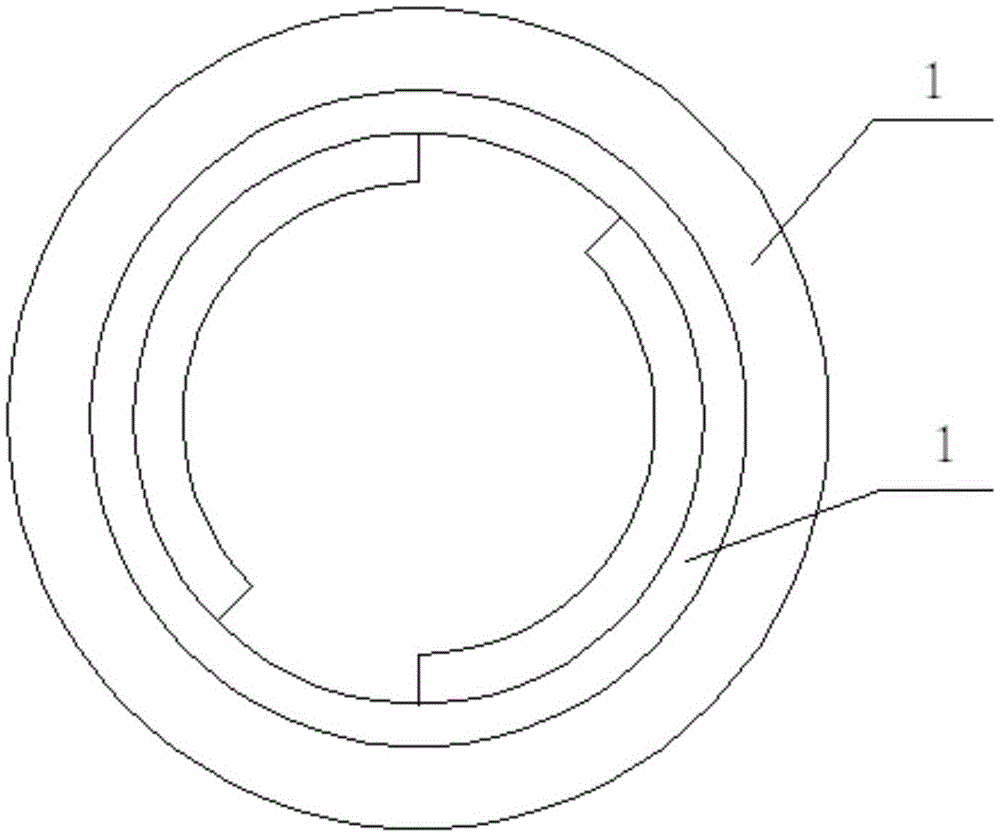

Tobacco suction system based on electromagnetic heating

The invention discloses a tobacco suction system based on electromagnetic heating, which is characterized in that it comprises an end cover (1), a heater (2) and an electromagnetic induction system, and the end cover (1) is detachably connected to the heater ( 2) above; the end cap (1) includes a round cover (11) and a filter tip (13); the heater (2) includes a shell (21), an inner tank (23) and a chassis (24) and a cylindrical Iron core (25); the electromagnetic induction system includes a heating liner (23), a chassis (24), a cylindrical iron core (25), an induction coil and a temperature control circuit. The present invention can increase the heating speed and high thermal efficiency through the electromagnetic induction system to heat the liner, the chassis and the cylindrical iron core, and can also realize instantaneous heating, so as to better meet the needs of the suction taste; the cylindrical iron core The setting can realize the uniform heating of the tobacco products, so that the tobacco products can be fully heated, which can prevent the waste caused by insufficient heating of the tobacco products, and is suitable for popularization and use.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

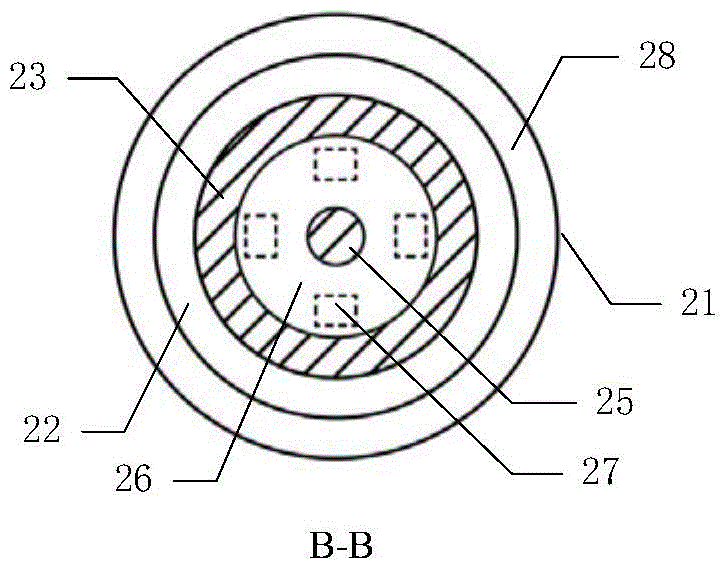

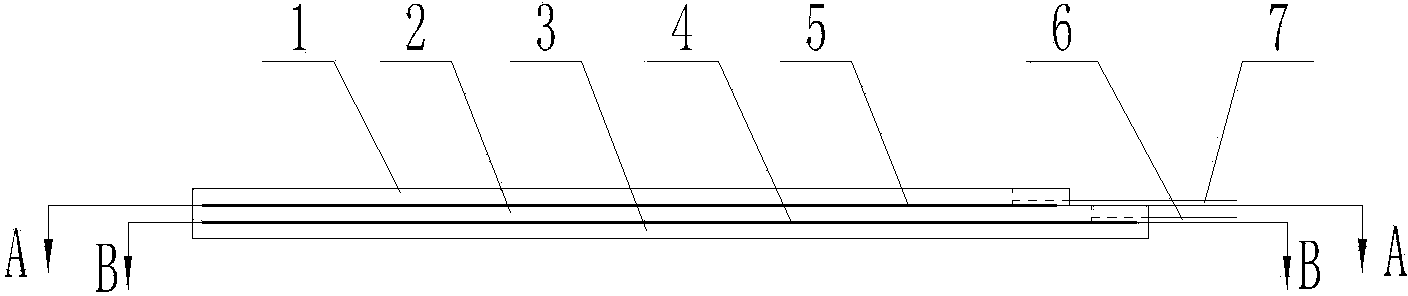

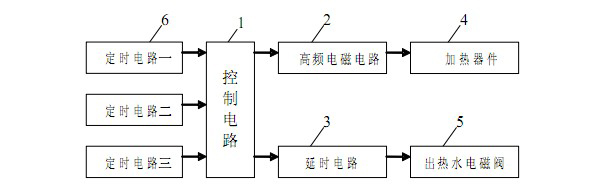

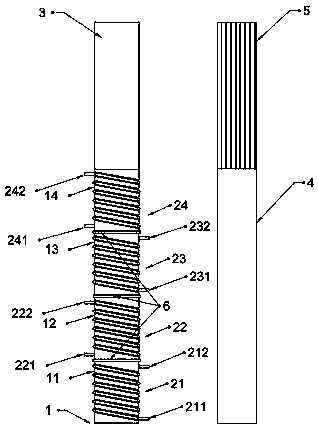

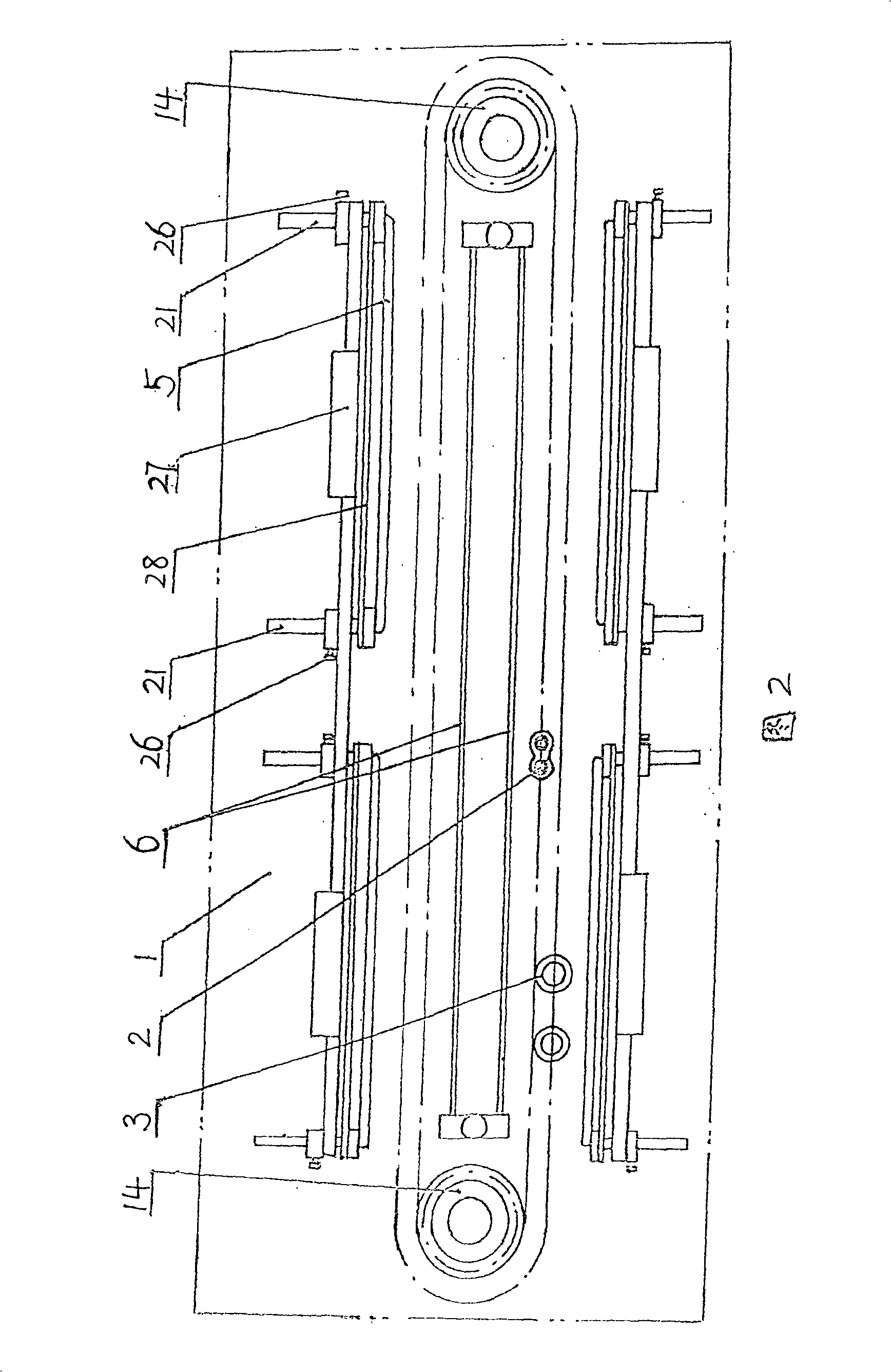

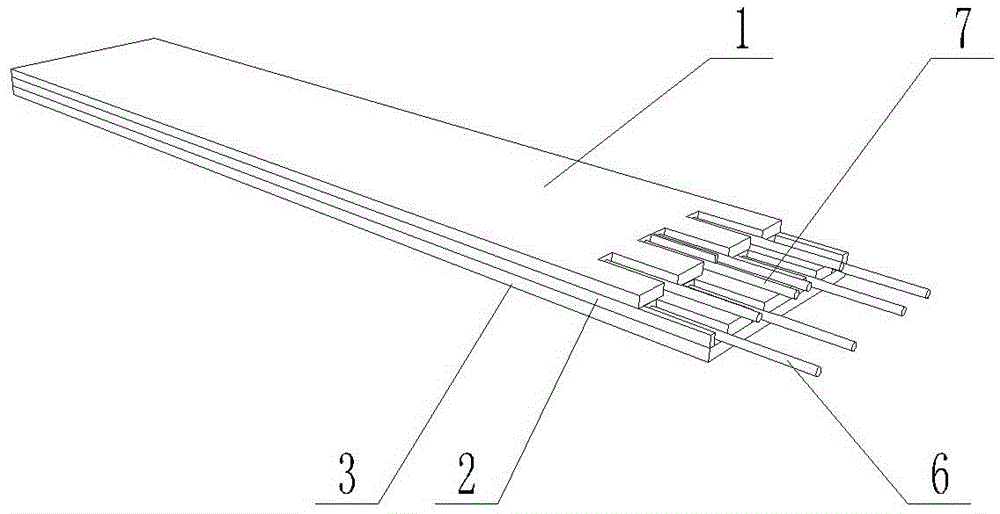

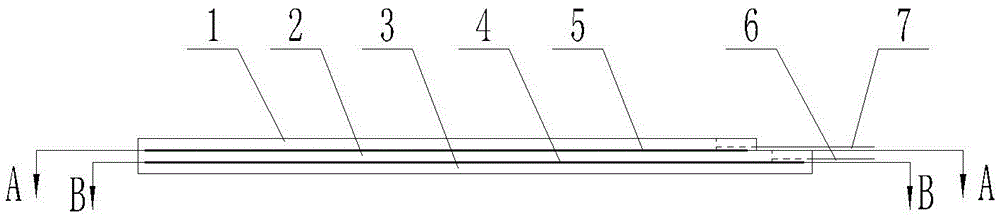

Temperature-control ceramic heating piece

ActiveCN103874243AMeet the purpose of heating a large areaClosely arrangedOhmic-resistance heating detailsElectricityTemperature control

The invention discloses a temperature-control ceramic heating piece which is of a plate-shaped structure composed of an upper ceramic piece 1, a middle ceramic piece 2, a lower ceramic piece 3, heating resistors, temperature control resistors, heating leads 6 and temperature control leads 7. The ceramic piece 1, the middle ceramic piece 2 and the lower ceramic piece 3 are sequentially stacked, the heating resistors are multiple in number, each heating resistor is electrically connected with one set of heating leads 6, and the temperature control resistors with the same number are correspondingly arranged. Each temperature control resistor is electrically connected with one set of temperature control leads 7, and the heating resistors and the temperature control resistors are located on the front face and the back face of the middle ceramic piece 2 respectively and are in one-to-one correspondence. According to the temperature-control ceramic heating piece, large-area heating can be achieved, heating efficiency is high, the heating resistors are arranged, and segmented heating and independent temperature control can be selectively achieved.

Owner:FUJIAN MINHANG ELECTRONICS

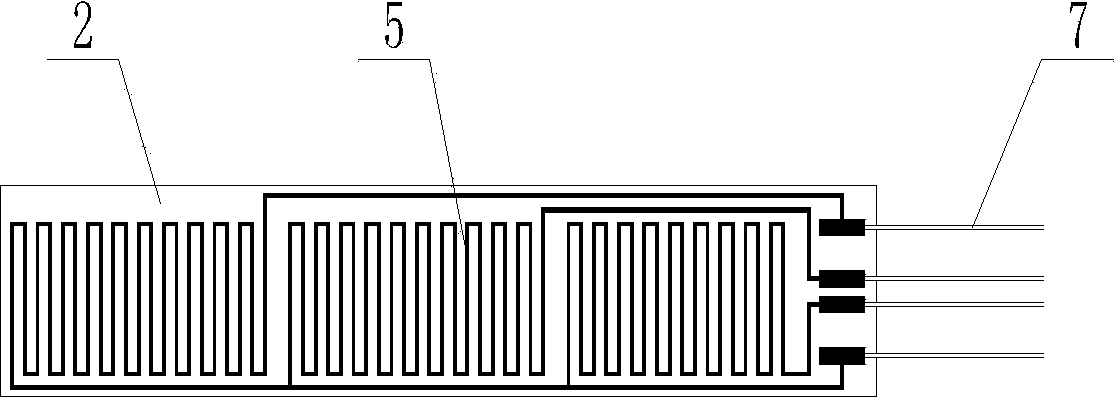

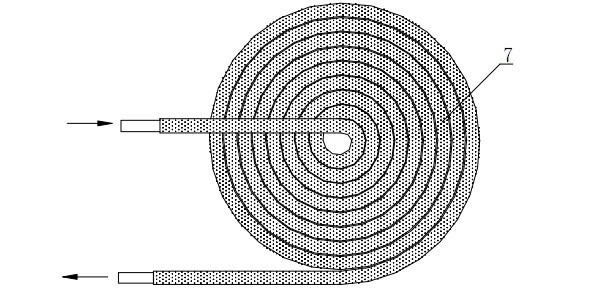

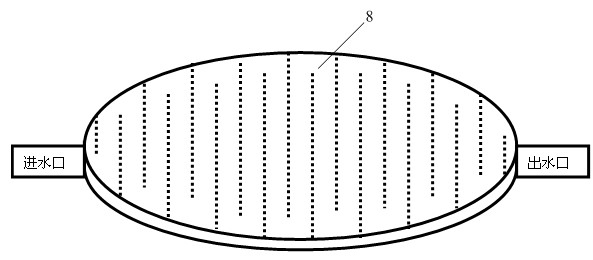

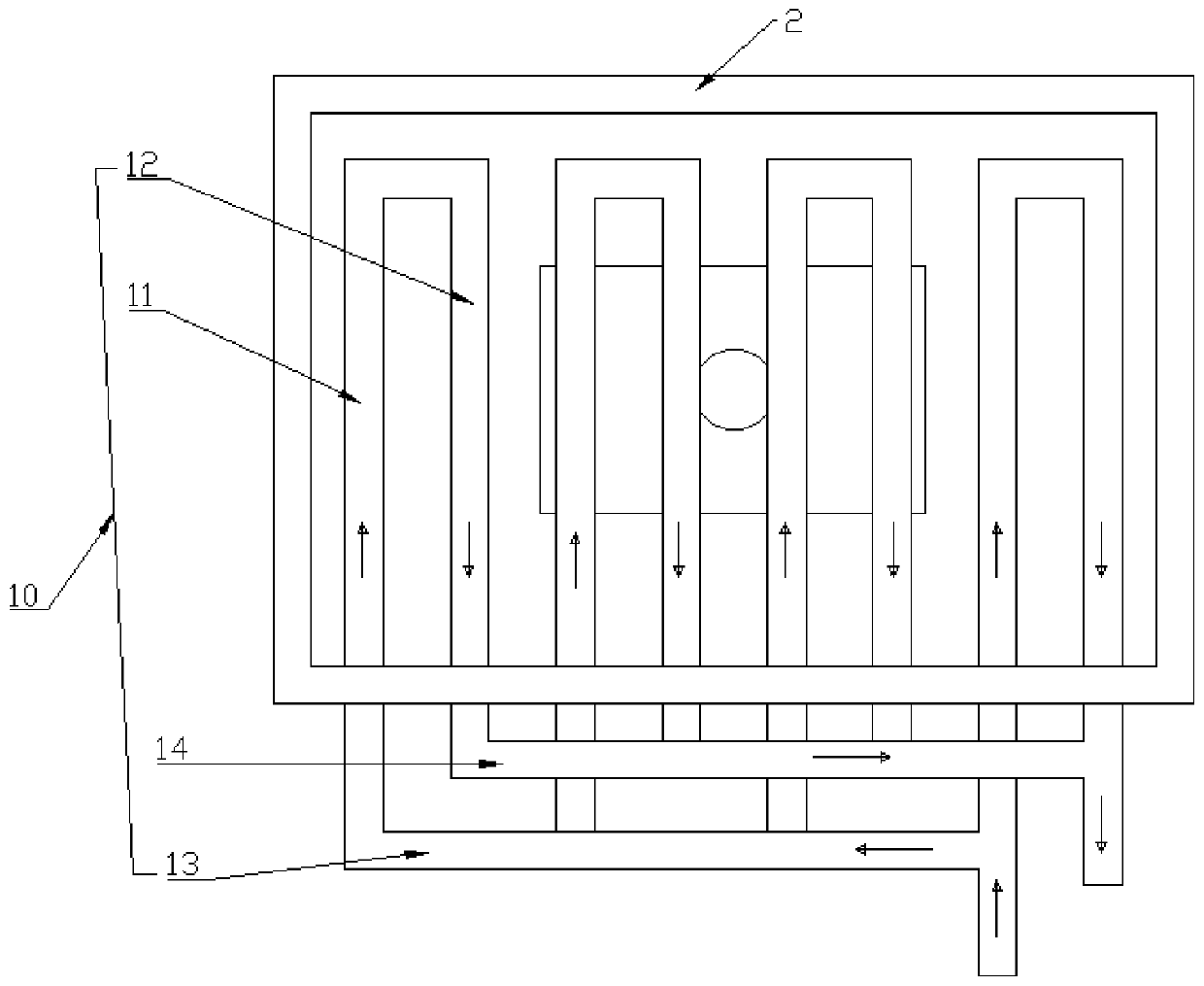

Energy-saving electromagnetic water dispenser

ActiveCN102151085AHigh heat conversion efficiencyTo achieve the purpose of continuous water supplyBeverage vesselsElectromagnetic valveStop signal

The invention discloses an energy-saving electromagnetic water dispenser. The energy-saving electromagnetic water dispenser comprises a water storage chamber; two paths of water outlets are formed on the water storage chamber; one path of the water outlets is connected with the water inlet end of a heating instrument; the water outlet of the heating instrument is connected with a hot water outlet electromagnetic valve; the heating instrument is arranged on a heating coil disc of a high-frequency electromagnetic circuit; the heating section of the heating coil disc is controlled by the intensity of a magnetic field generated in the high-frequency electromagnetic circuit; the high-frequency electromagnetic circuit is controlled by a control circuit which is connected with a time delay circuit; the hot water outlet electromagnetic valve is connected with the time delay circuit; the control circuit is connected with a timing circuit which is connected with a button on an external panel; when receiving a corresponding button press-down signal, the timing circuit feeds back a corresponding heating time signal to the control circuit; the control circuit sends a starting signal and the heating time signal to the high-frequency electromagnetic circuit, and sends the starting signal to the time delay circuit at the same time; and the time delay circuit feeds back a time delay starting and stopping signal to the hot water outlet electromagnetic valve.

Owner:ZHEJIANG UNIV OF TECH

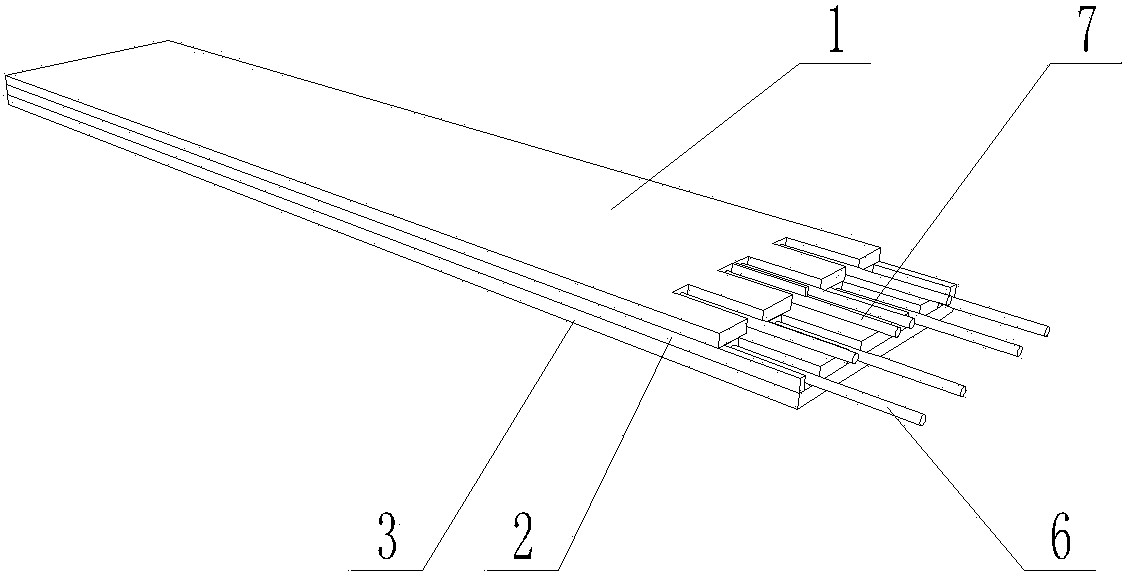

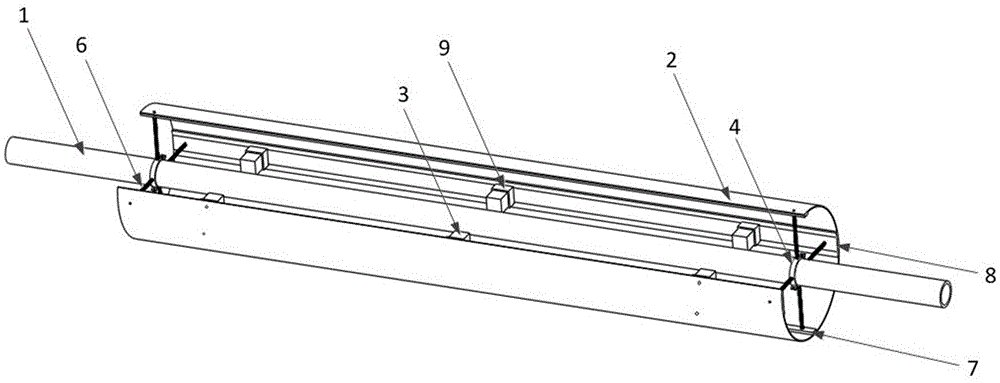

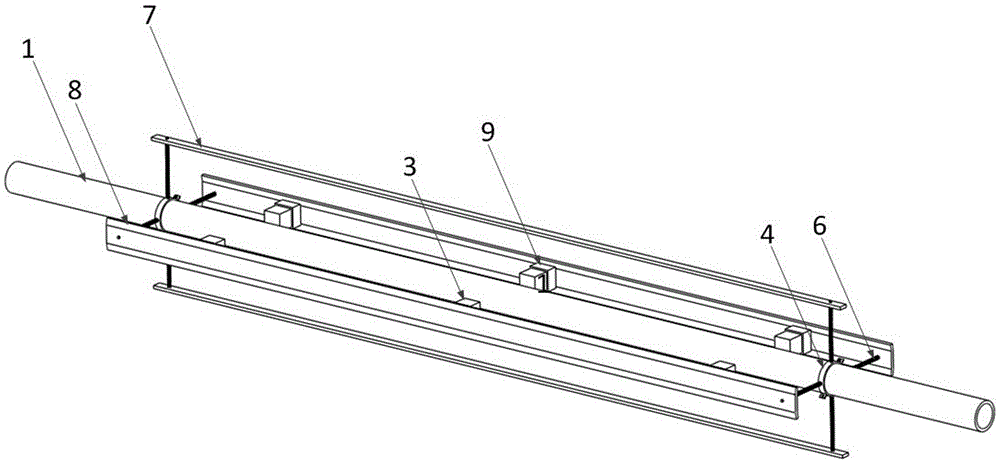

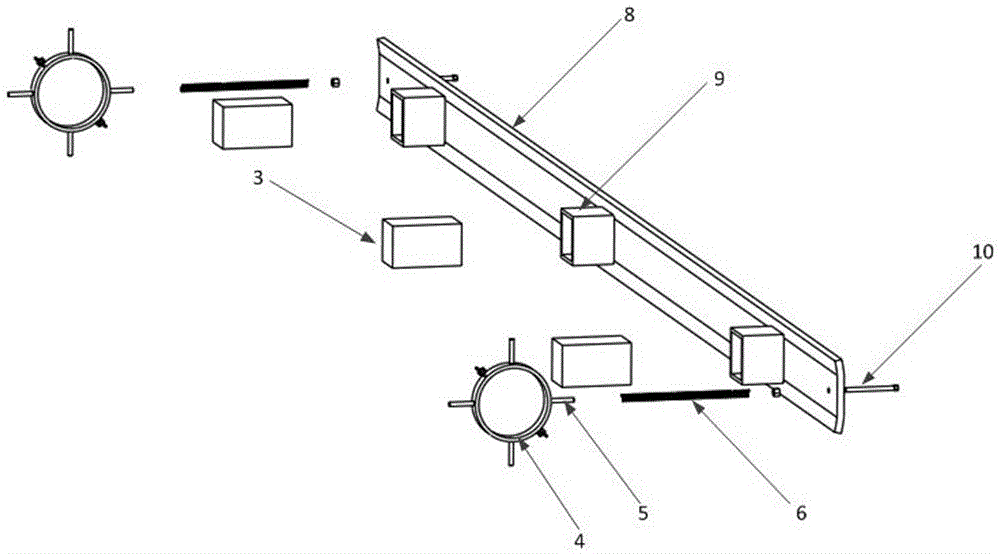

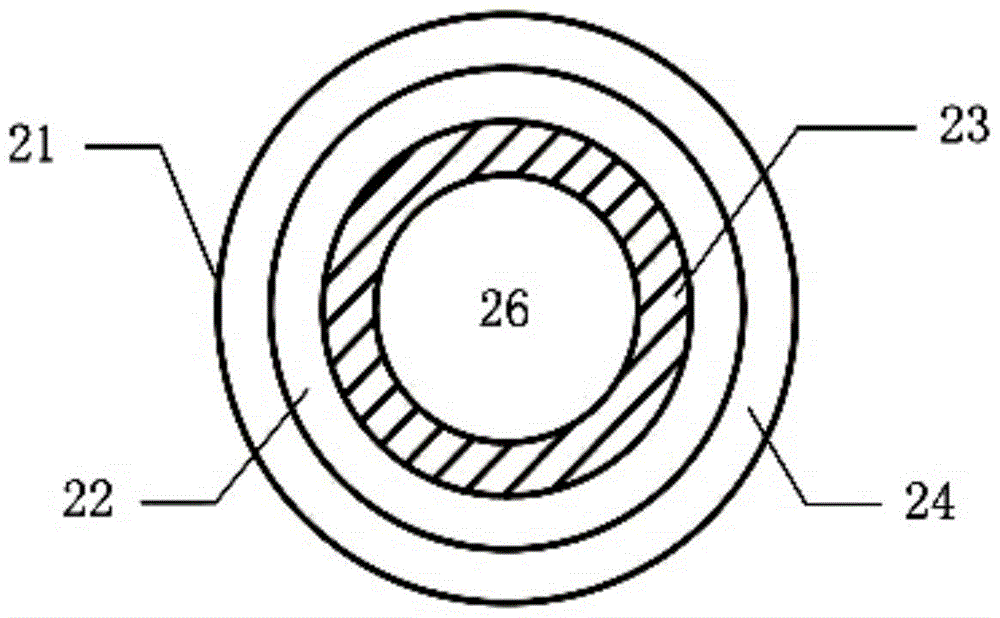

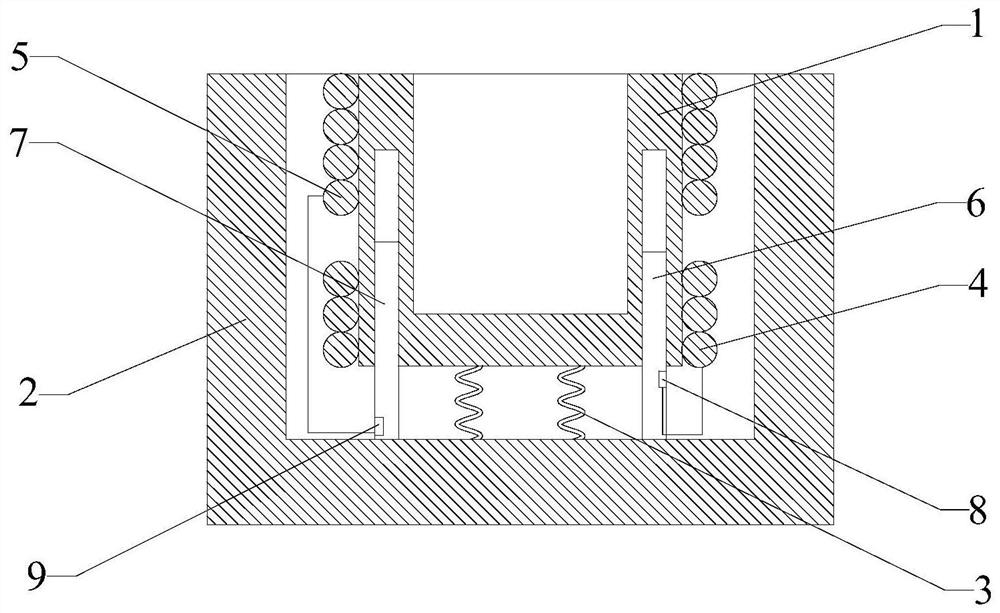

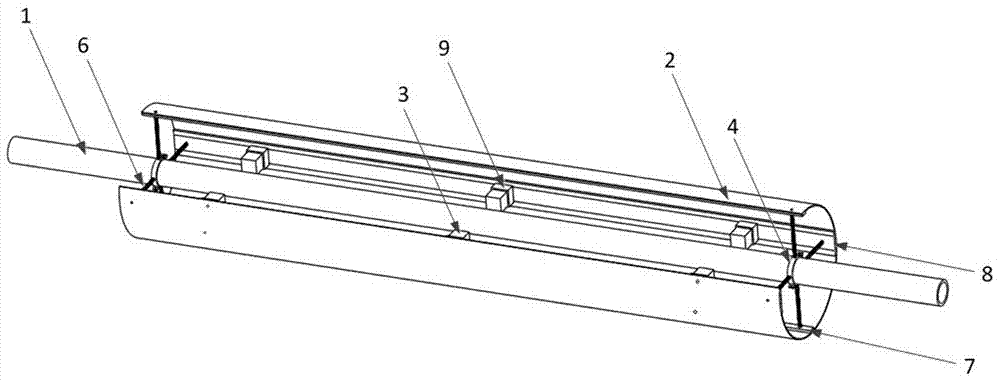

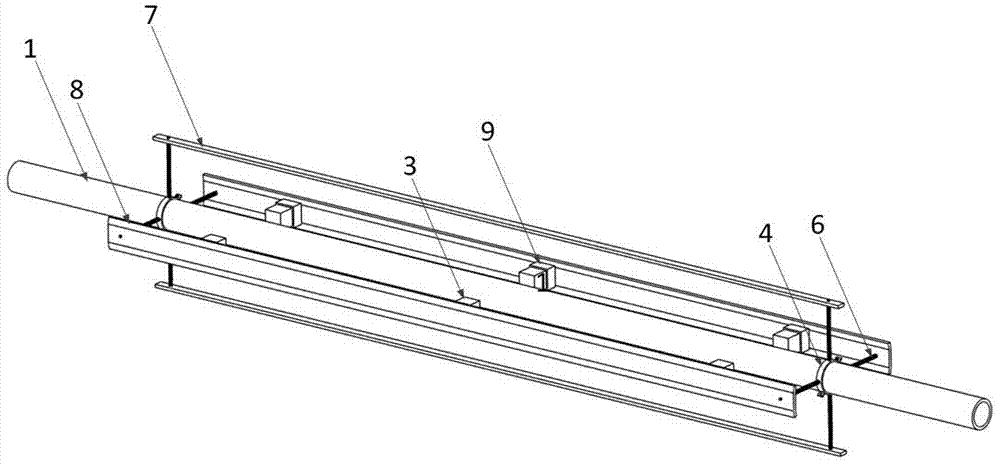

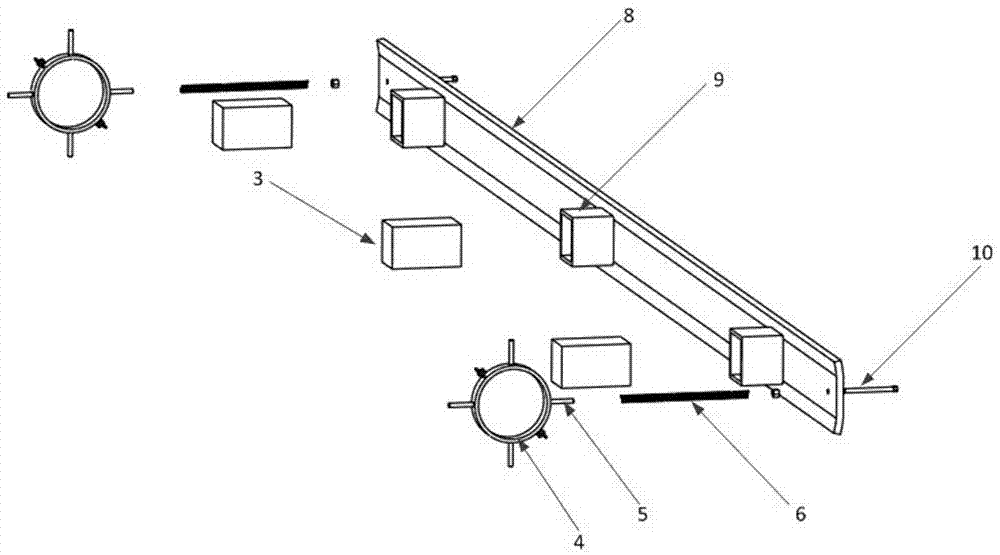

Device and method for realizing undersea oil pipeline flow damping through vortex-induced vibration

InactiveCN105546262ARealize segmental heatingLow costBatteries circuit arrangementsPipe heating/coolingElectricityOcean bottom

The invention relates to a device and method for realizing undersea oil pipeline flow damping through vortex-induced vibration. The device is composed of a vibration system, a magnetic field system and an electrogenic heat tracing system. The vibration system is composed of an outer barrel, supporting plates, supporting lantern rings, springs and long bolts and is used for producing vibration responses under the ocean current action. The magnetic field system is composed of magnet clamping grooves and magnets and arranged on the wide supporting plate of the inner wall of the outer barrel and used for constructing a magnetic field. The electrogenic heat tracing system comprises wires, an electrical conductor layer and an inner insulation layer, and an oil pipeline is transformed to be of a six-layer pipeline structure which is composed of a steel pipe, the inner insulation layer, the electrical conductor layer, the wires, a heat preservation layer and an outer insulation layer from inside to outside in sequence. According to the device for realizing undersea oil pipeline flow damping through the vortex-induced vibration, the wires are driven by the vibration to cut magnetic induction lines under the ocean current action, and heat generated by electricity enables the viscosity and the resistance of an oil flow to be reduced, so that the low cost and zero energy consumption are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Segmented differential electric heating cable

InactiveCN104254155ARealize centralized heatingImprove the heating effectInsulationHeating element shapesElectricityConstant power

The invention provides a segmented differential electric heating cable which comprises an upper pump cable and a lower pump cable which are respectively arranged above and below an annular pump in a shaft in a crude oil lifting process, wherein the heating power per meter of the lower pump cable is greater than that of the upper pump cable to form upper and lower segmented differential heating; the heating power of the lower pump cable is at least three times the power per meter of the upper pump cable; the upper pump cable comprises a cable housing and a cable core; the cable core is made of copper; the lower pump cable comprises a cable housing and a cable core; and the cable core is made of nichrome. According to the segmented differential electric heating cable, segmented heating is performed in different positions of the shaft, so that the heating power near the shaft is effectively improved under the condition of constant power consumption, a viscosity reduction effect near the shaft is improved, the defects of the prior art are overcome, and the problem that crude oil in an extremely-viscous block oil well difficultly enters the pump is effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

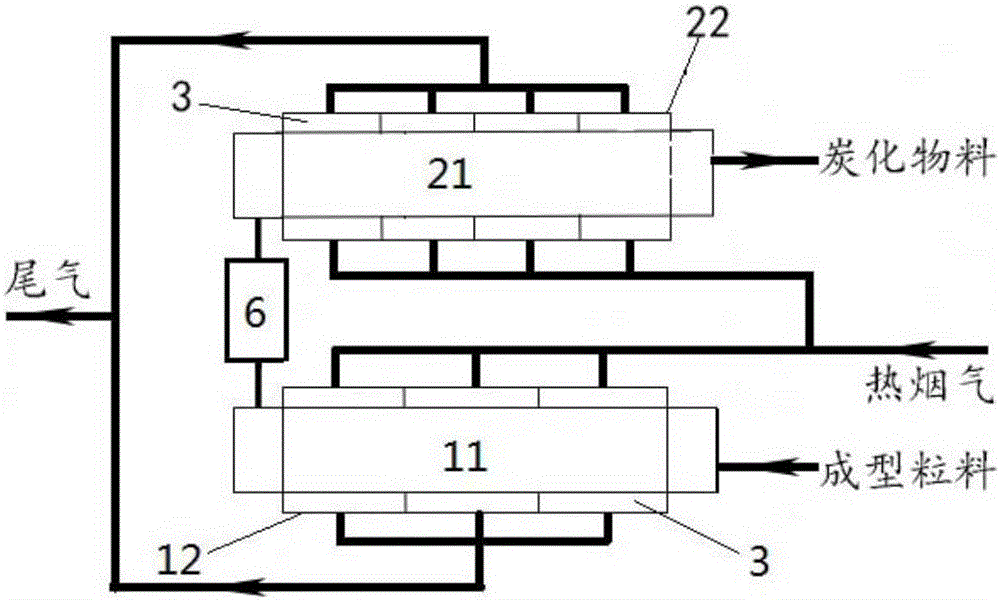

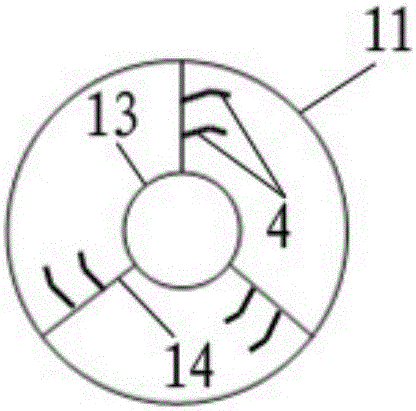

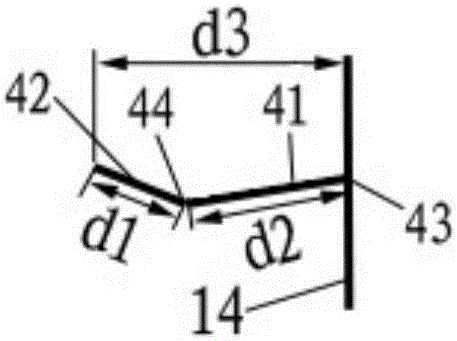

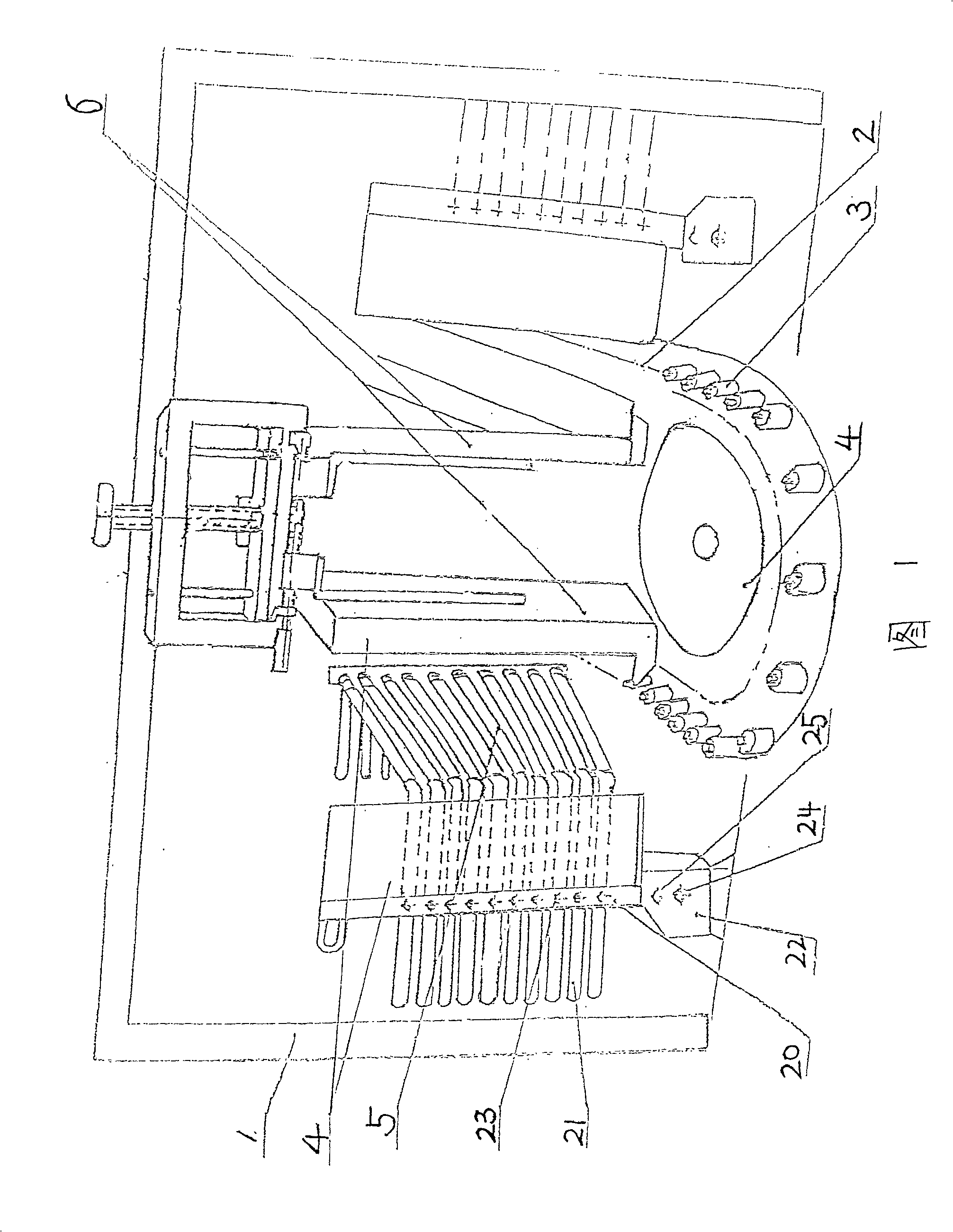

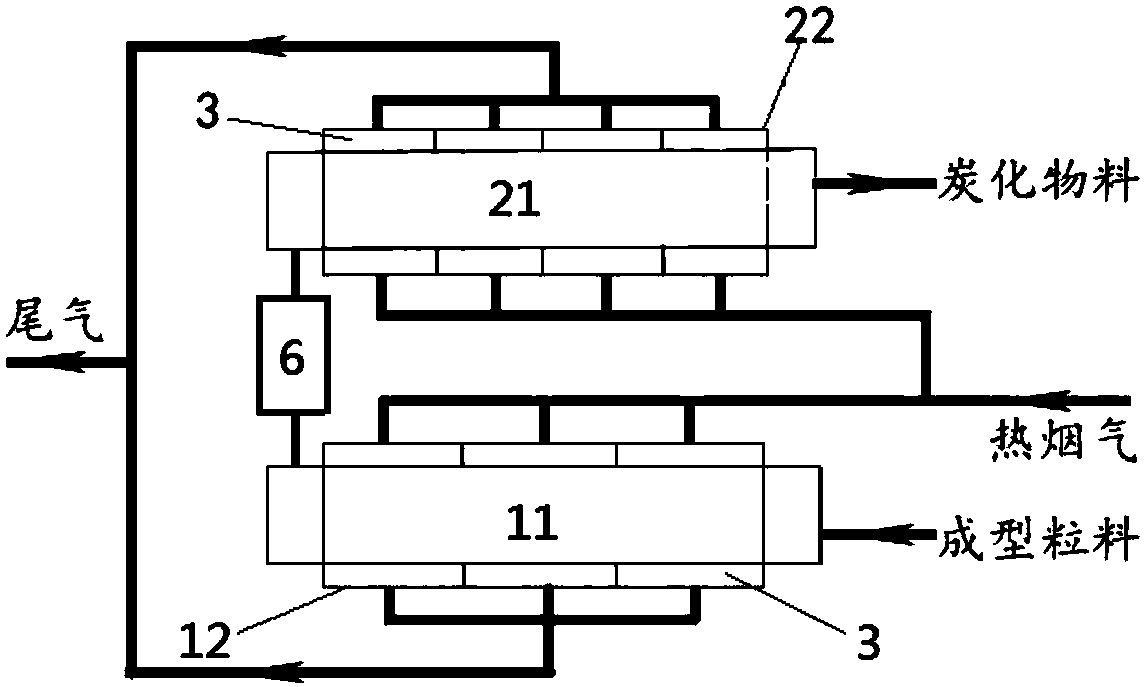

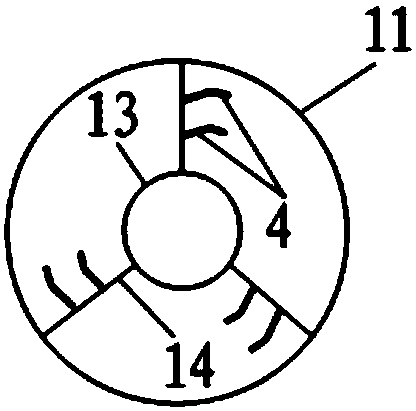

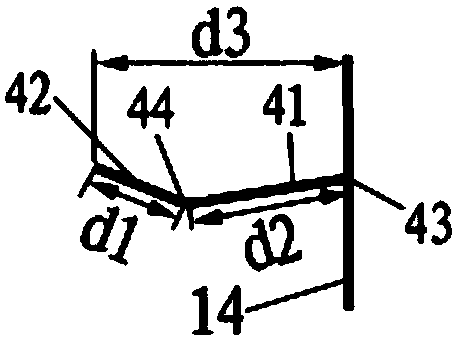

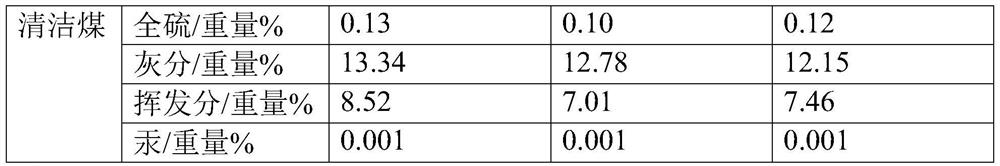

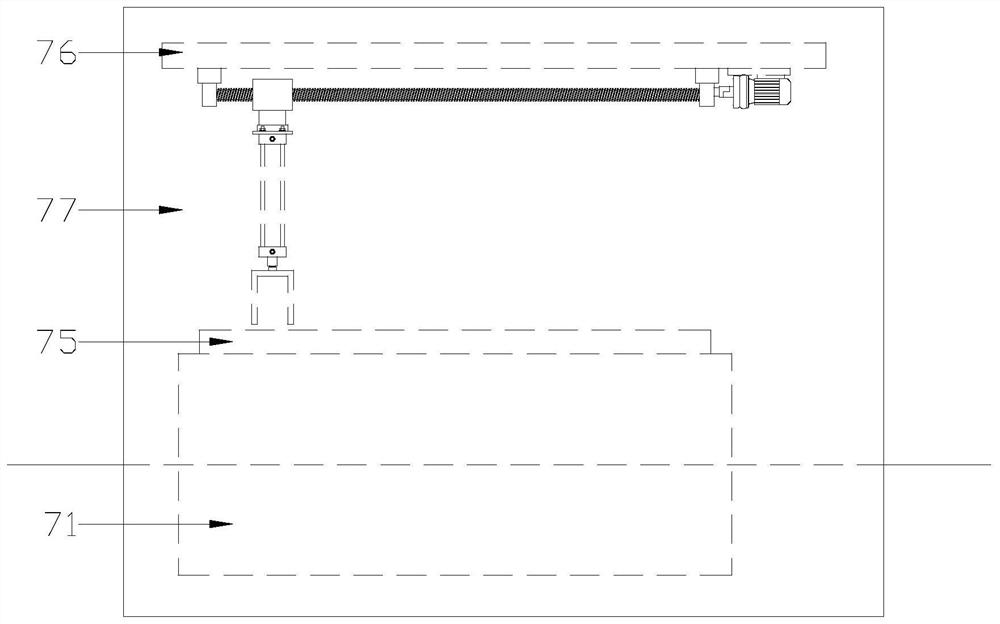

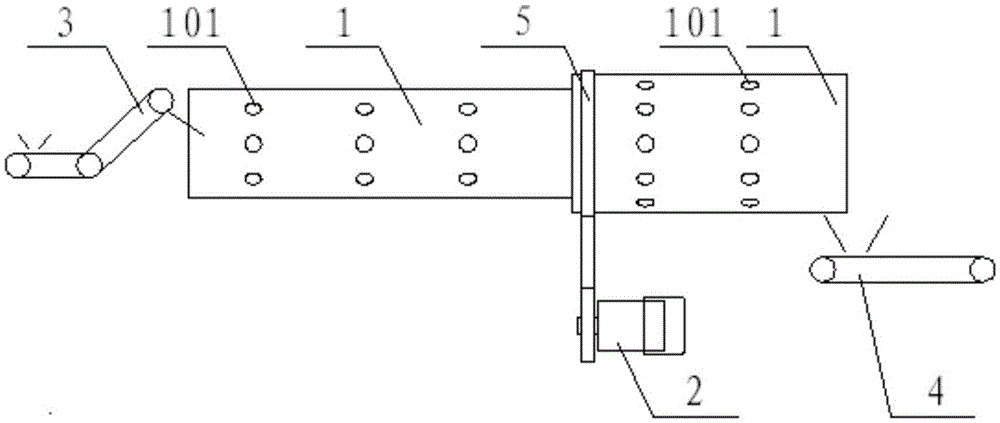

Oxidation carbonization device and method of coal-base activated carbon

The invention discloses an oxidation carbonization device of coal-base activated carbon. The device comprises a first external-heating rotary kiln, a second external-heating rotary kiln and a conveyer, wherein a core tube, a plurality of partition boards and a plurality of material grabbing plates are arranged in a first cylinder of the first external-heating rotary kiln. The invention also discloses an oxidation carbonization method by using the oxidation carbonization device. The inside of the first cylinder is divided into a plurality of reaction bins, the material grabbing plates in the reaction bins are adjusted, and the raw material coal formed particles are subjected to preoxidation treatment, thereby effectively reducing the material crushing, and enhancing the yield and strength of the coal formed particles after oxidation carbonization.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Electromagnetically heated smoking device for heat-not-burn cigarettes

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

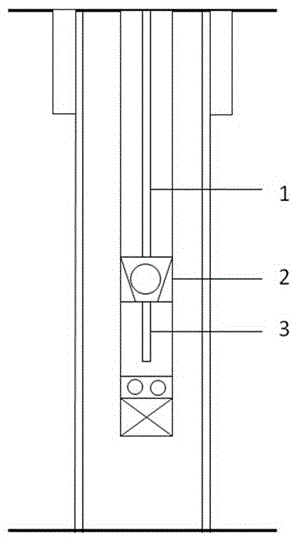

Combined electromagnetic induction aerosol heating device

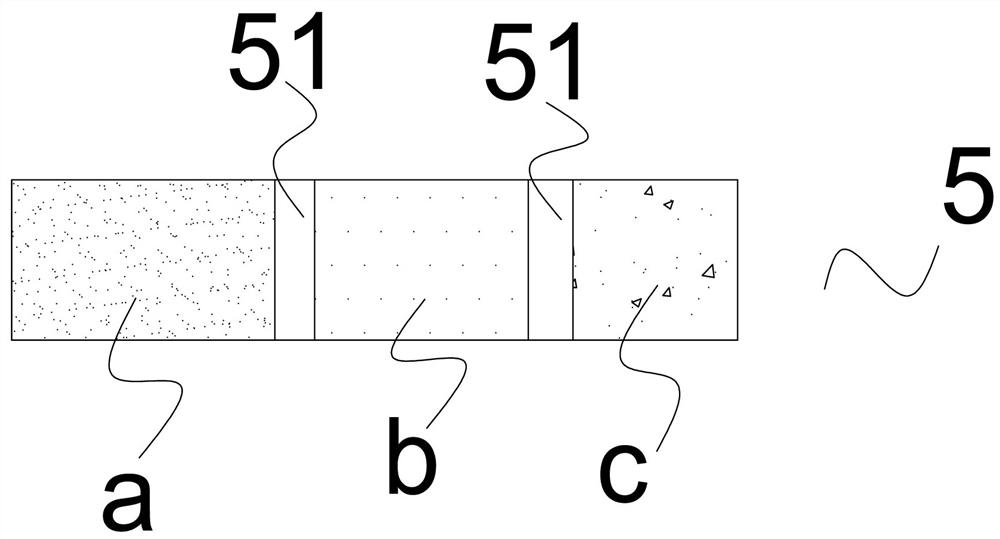

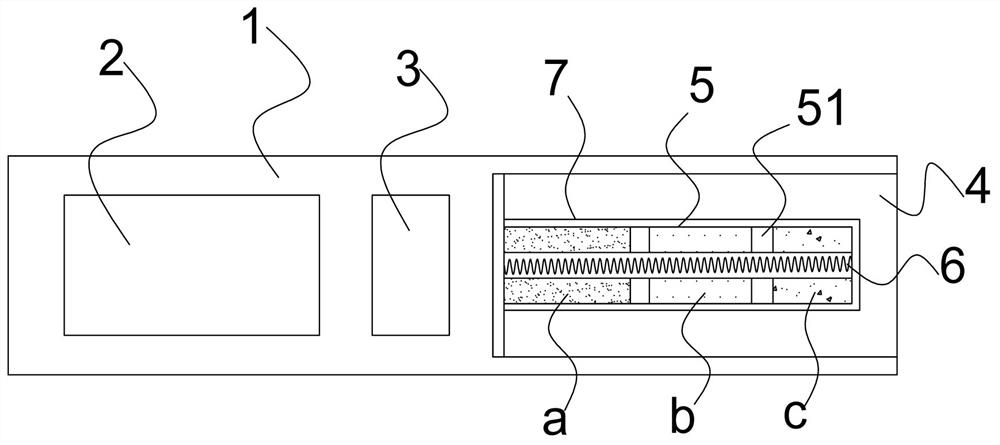

PendingCN113679114ARealize segmental heatingImprove practicalityScreening apparatusTobacco devicesMagnetic heatingEddy current

The invention provides a combined electromagnetic induction aerosol heating device. The combined electromagnetic induction aerosol heating device comprises a shell, a heating cavity arranged in the shell, an electromagnetic heating coil used for generating an alternating magnetic field and an electromagnetic heating magnetized body. The electromagnetic heating magnetized body is placed in an alternating magnetic field generated by the electromagnetic heating coil and used for generating eddy current and raising the temperature, and the electromagnetic heating magnetized body is provided with a plurality of magnetized areas with different magnetic permeability in the axial direction of the electromagnetic heating coil, so that different magnetized areas generate different electromagnetic heating amounts. The electromagnetic heating magnetized body is composed of magnetized areas with at least two magnetic conductivities, and a heat insulation ring for preventing heat conduction is arranged between every two adjacent magnetized areas. The induced electromotive force produced by the magnetized region with different permeability in the same alternating magnetic field is different, so that the electromagnetic heating magnetized body composed of the plurality of magnetized areas with different magnetic conductivities can generate a plurality of heating sections with different temperatures so as to realize segmented heating of an aerosol generating substrate.

Owner:HUBEI CHINA TOBACCO IND

Device for heating cigarettes

PendingCN109222248AReduce the temperatureRealize the effect of cooling and reducing cokeTobacco devicesEngineeringHeat transfer efficiency

The invention belongs to the field related to cigarette processing, and relates to a cigarette heating device which can be used for heating or baking cigarettes, in particular to a tubular heating device for heating cigarettes, which can heat cigarettes and emit a large amount of smoke. A cigarette heating apparatus includes a heating tube, A lumen inside that heat tube is a heating lumen, At least one set of thread grooves is arrange on that outer wall of the heating pipe, a set of heating wire matched with the threaded grooves is wound on each set of threaded grooves, each set of heating wire is controlled by an independent circuit, the heating wire is wrapped by an insulating and heat conductive material, and the heating pipe is made of a heat conductive material. The device has the advantages of strong applicability, simple manufacturing process, convenient assembly and maintenance, more uniform heating and higher heat transfer efficiency.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

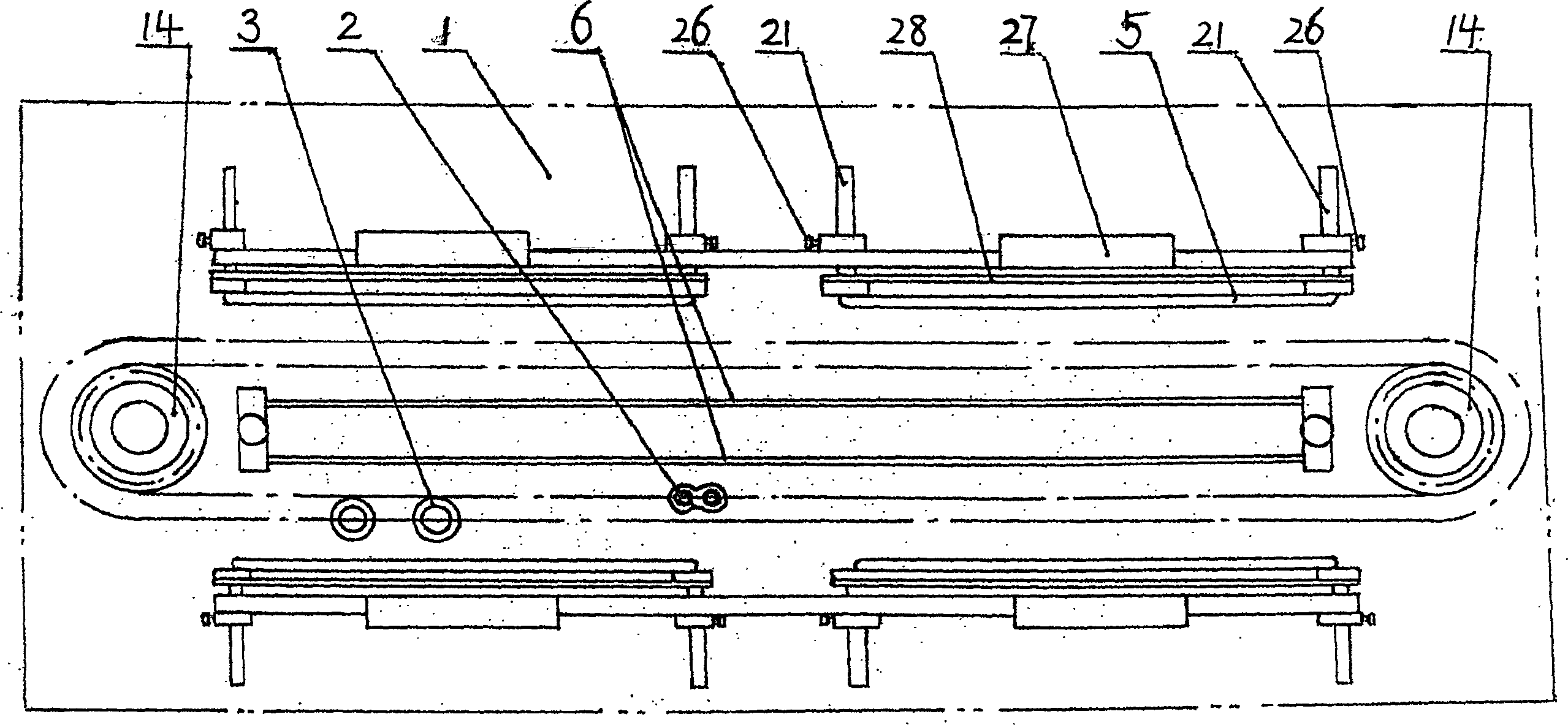

New type heater for roughcast of plastic bottle

A heater for plastic bottle blank is composed of machine frame, heating case containing heating lamp tubes and reflecting plates, an endless chain driven by a chain wheel to pass through said heating case, and plastic bottle blank holders arranged on said chain. Its lamp tubes and reflecting plates are adjustable.

Owner:林钇伽

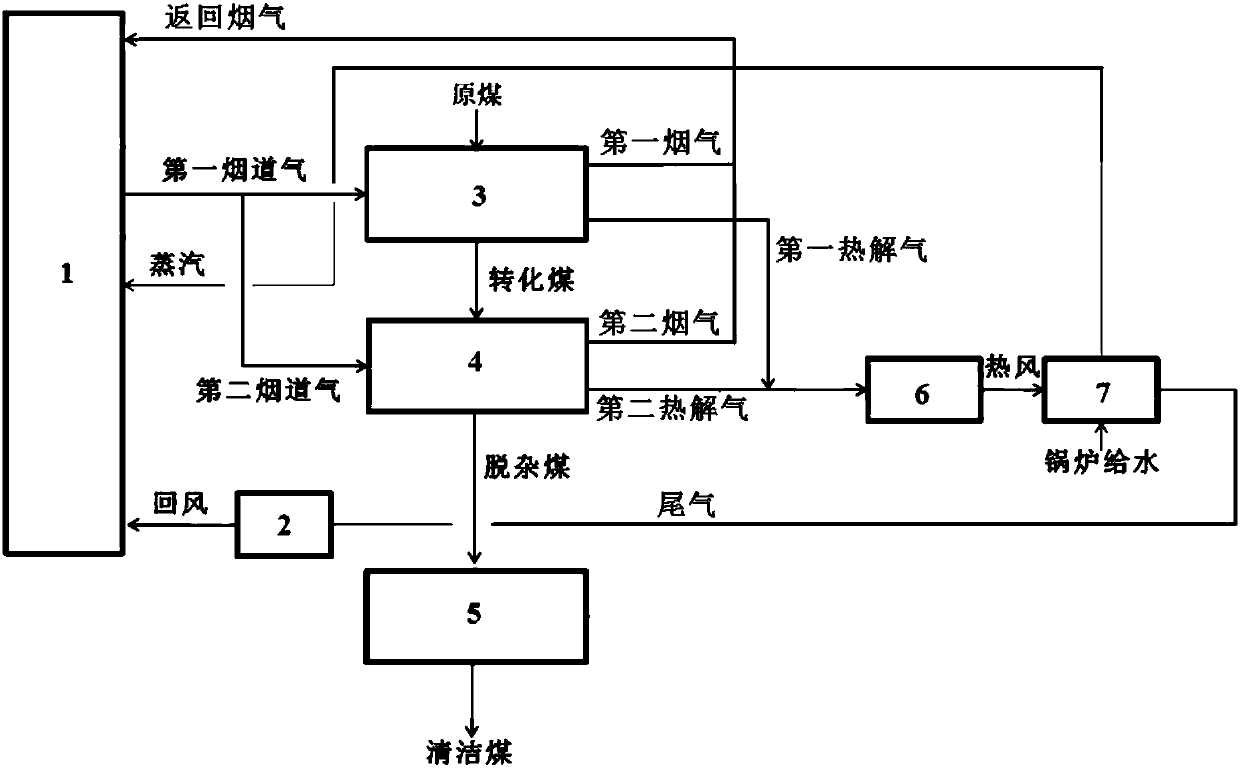

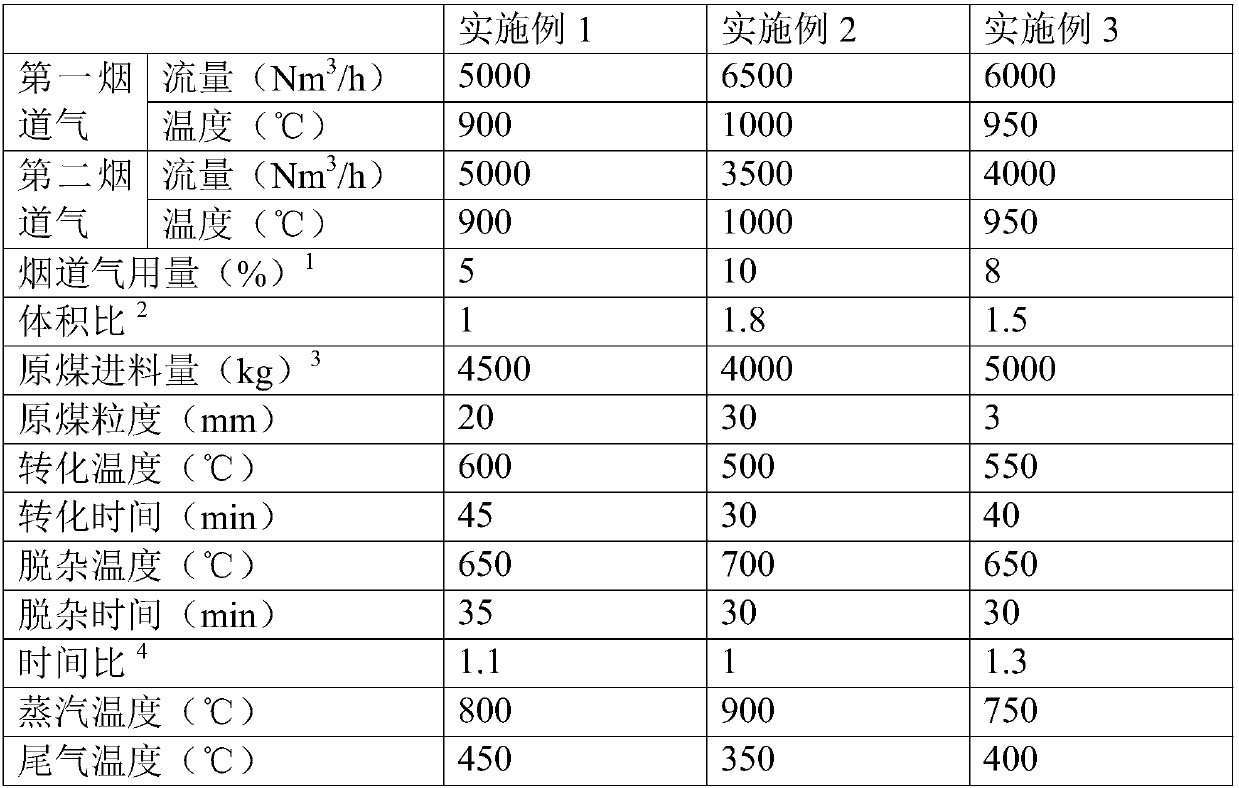

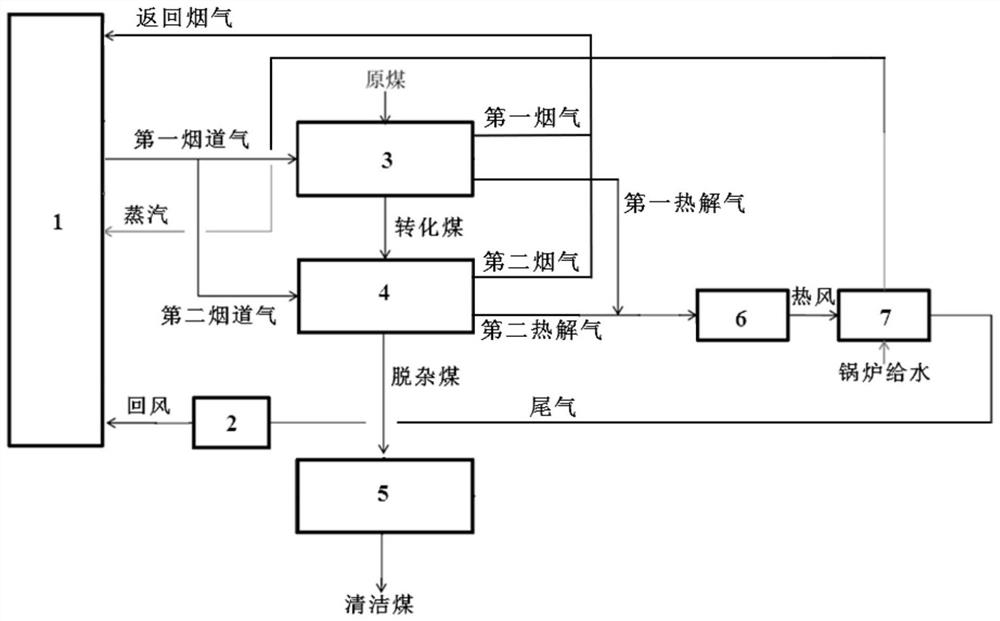

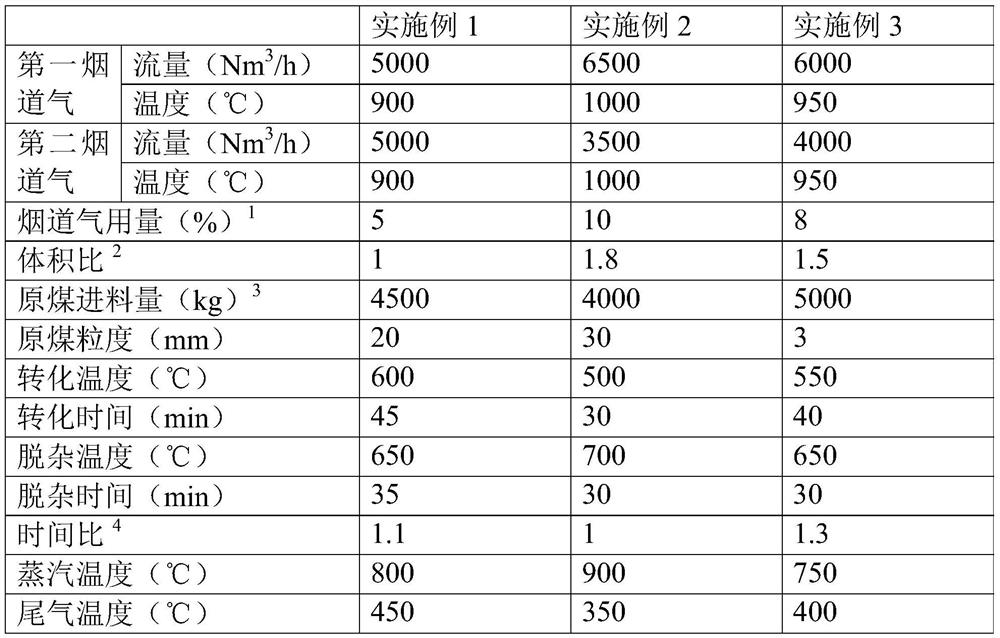

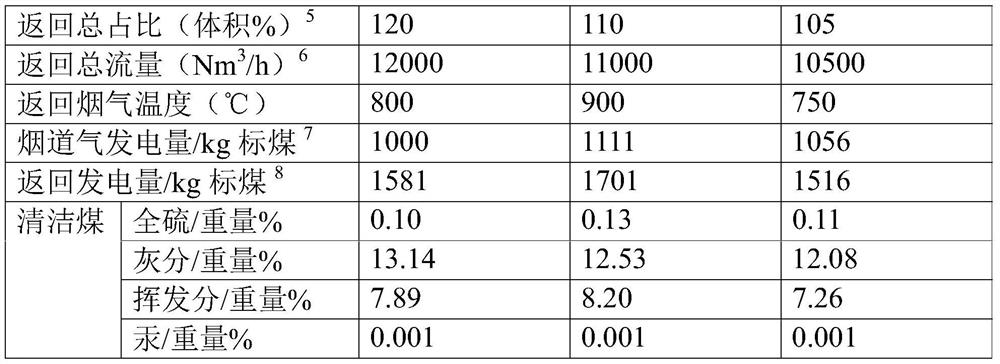

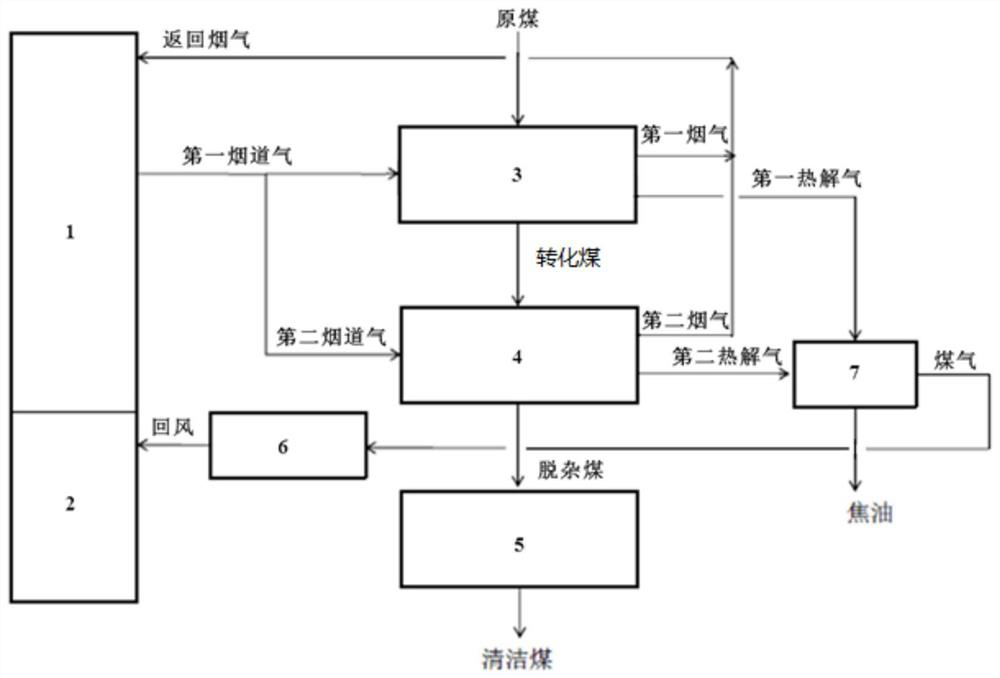

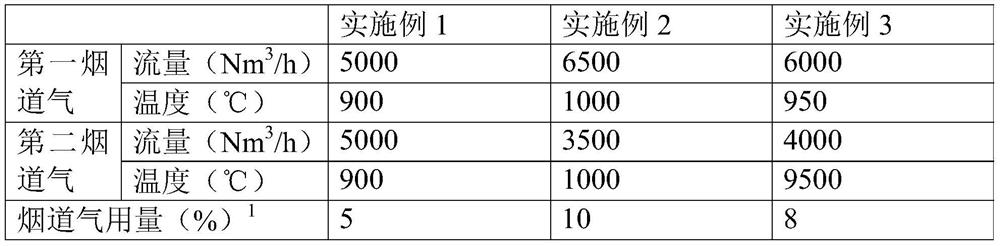

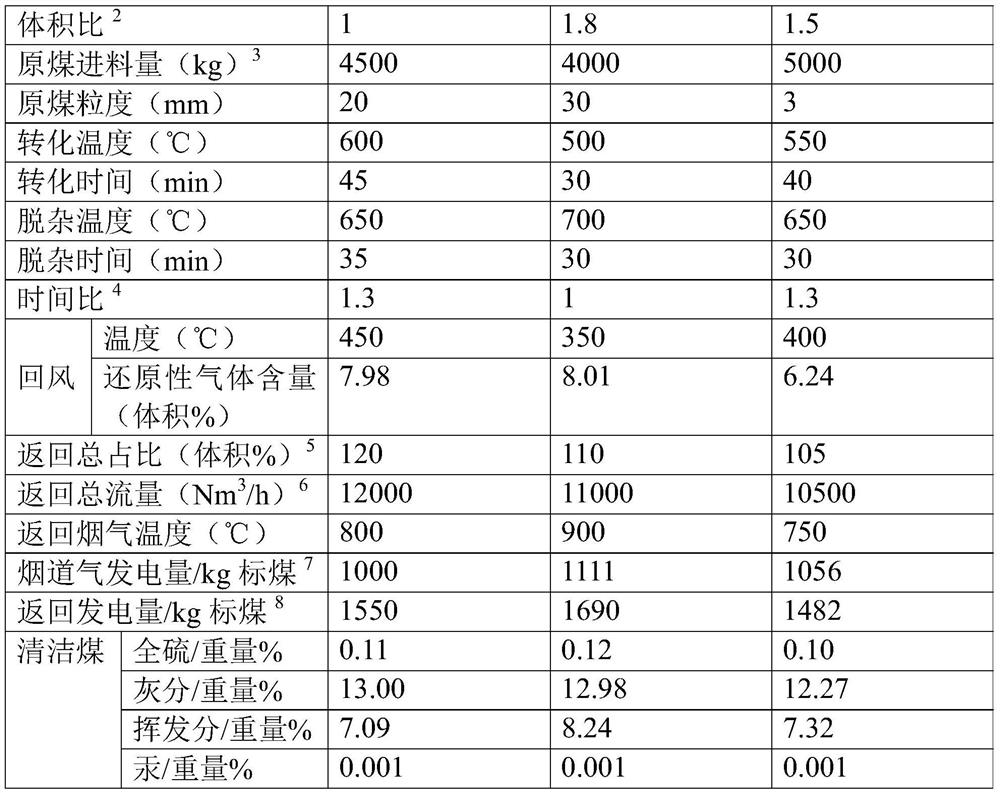

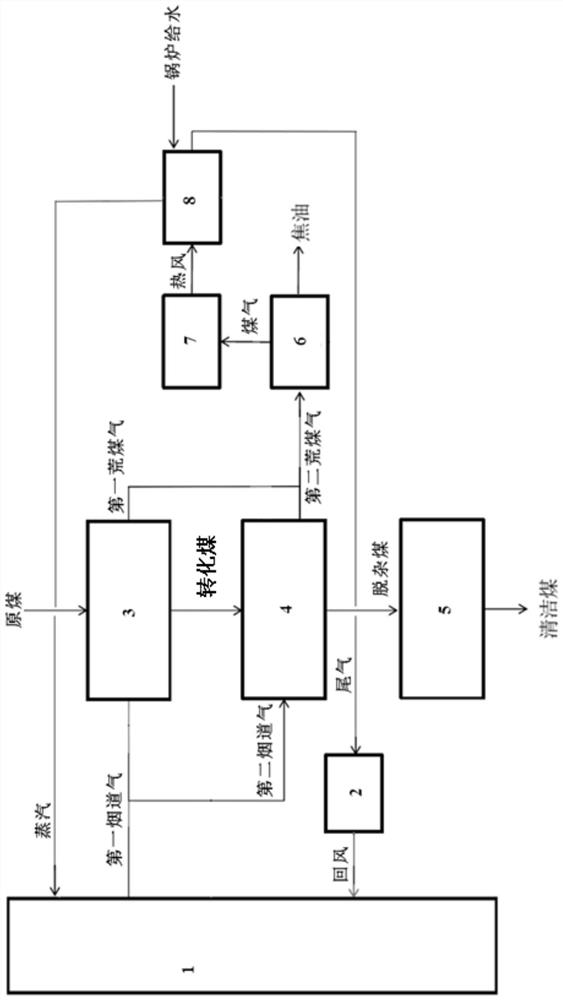

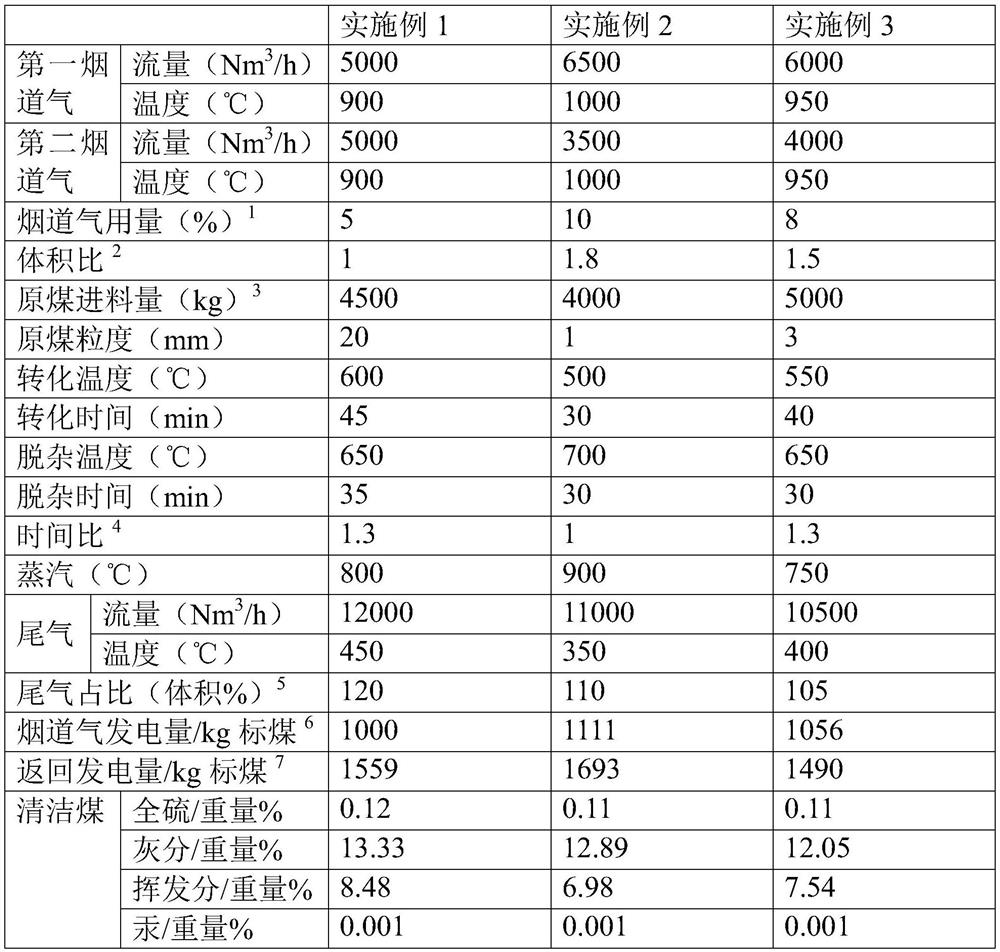

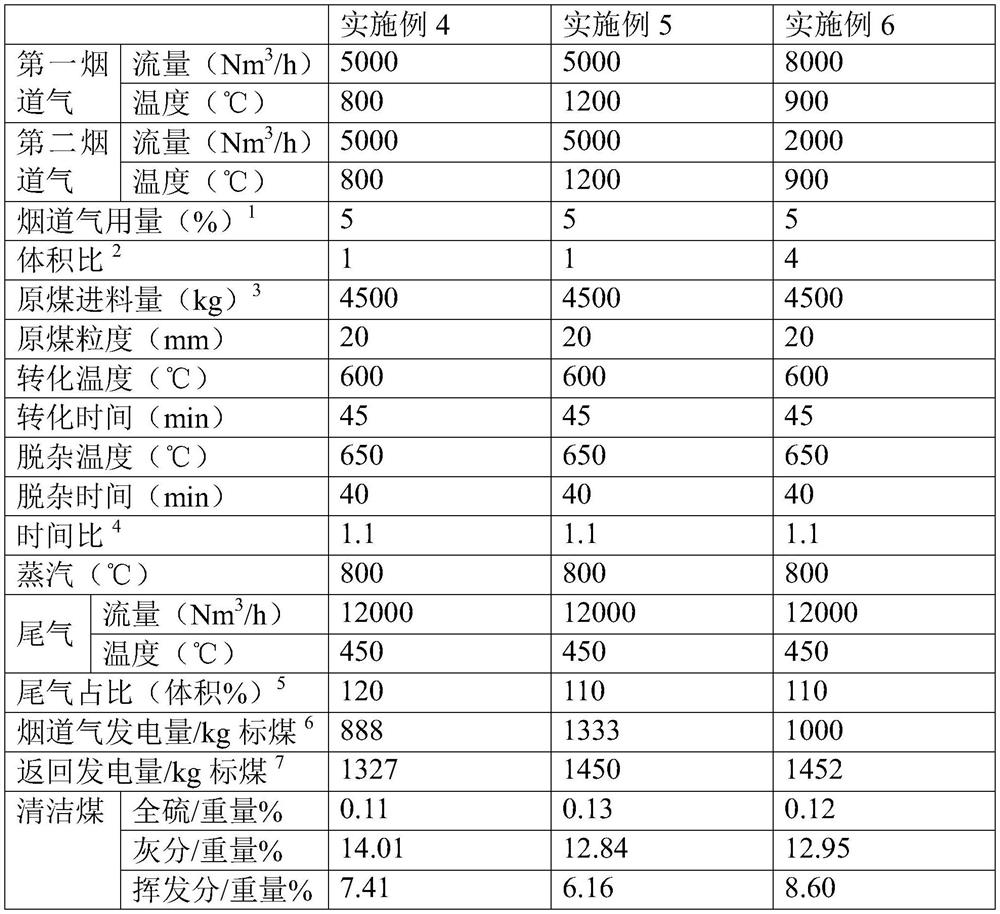

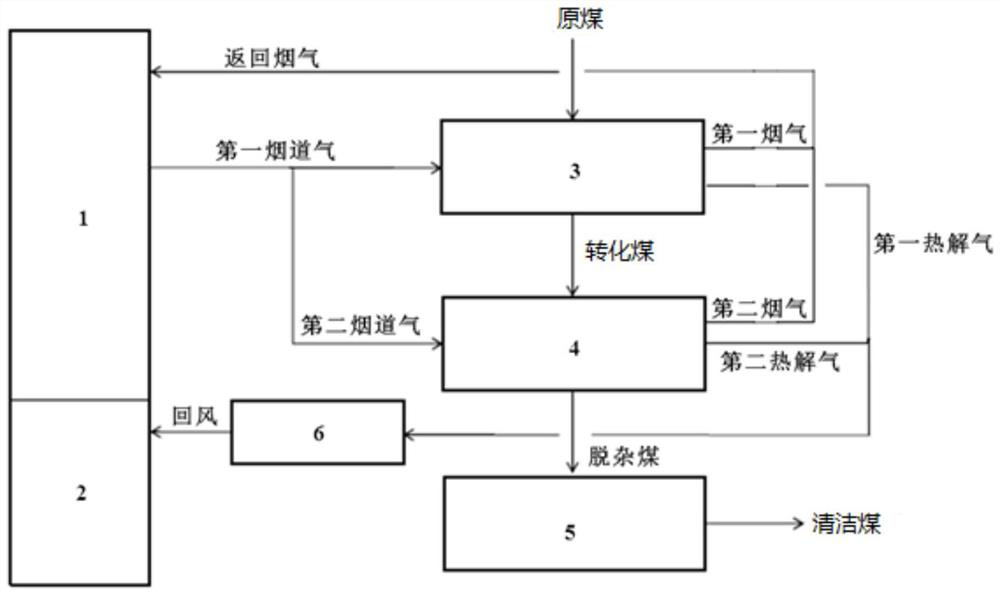

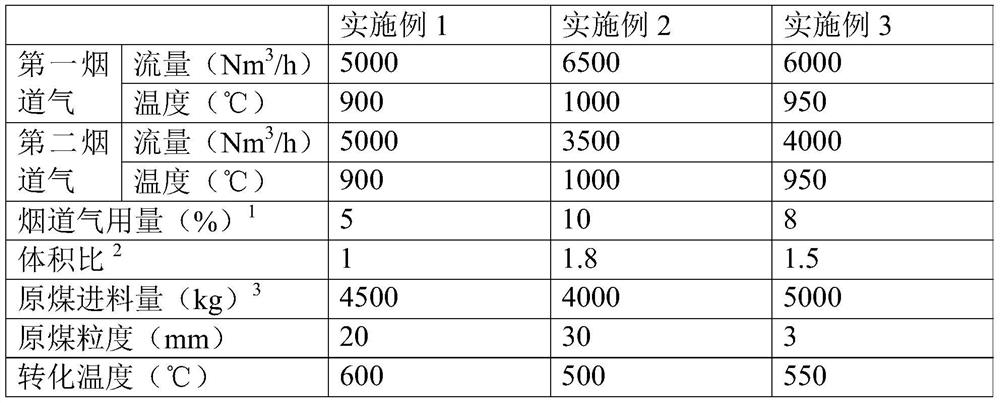

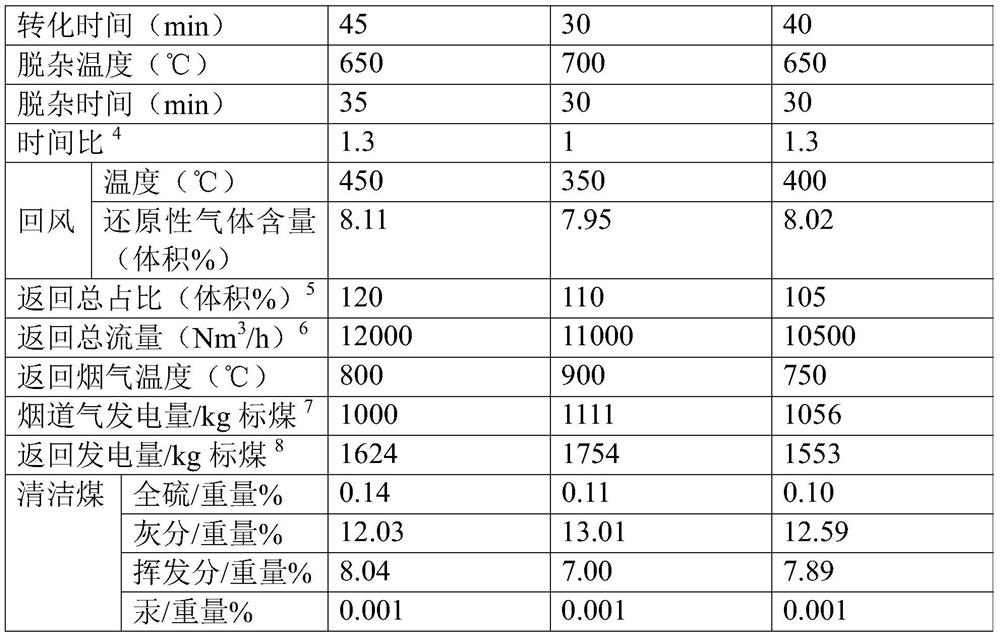

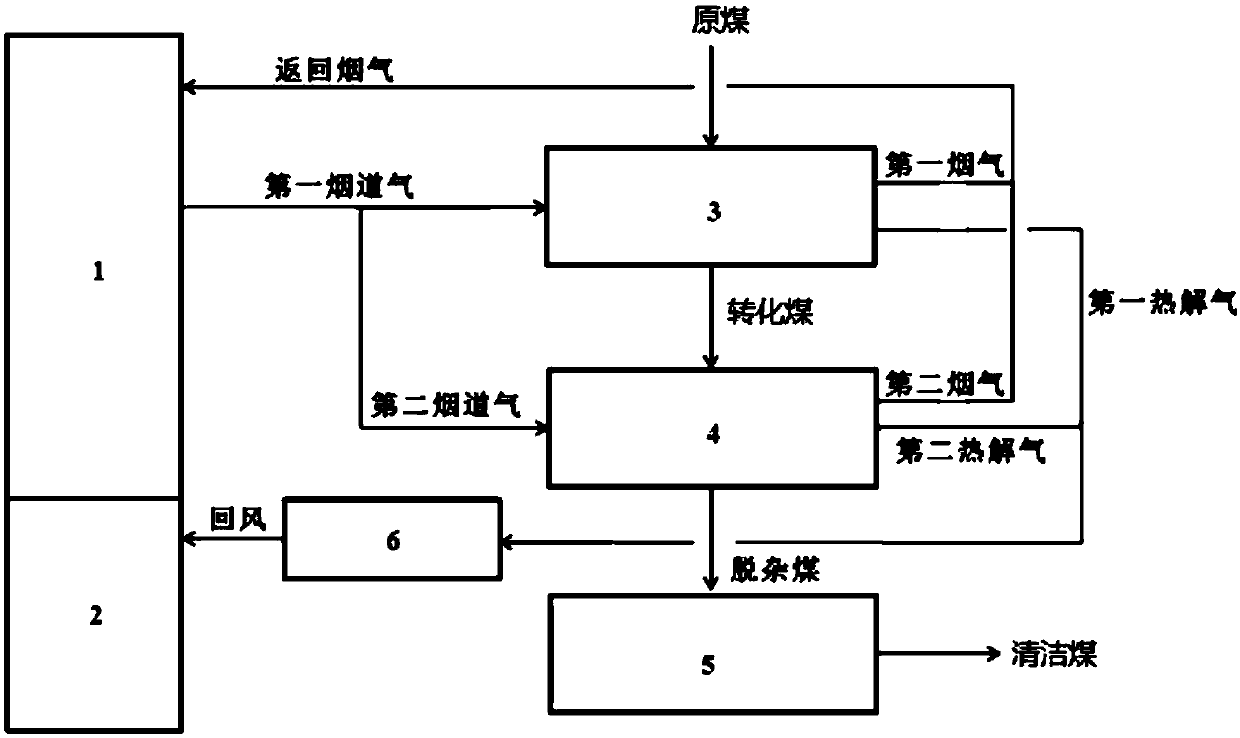

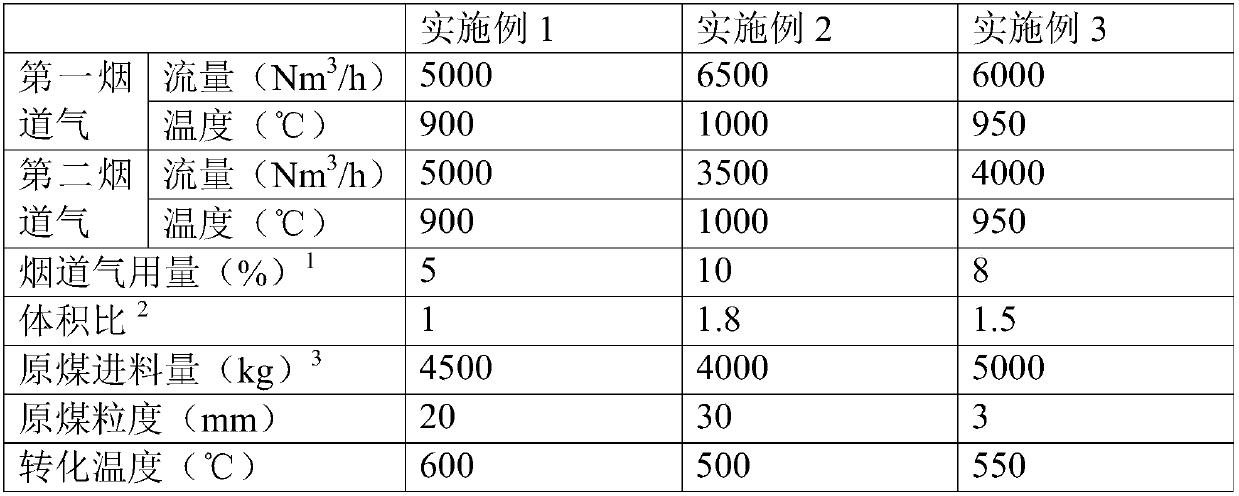

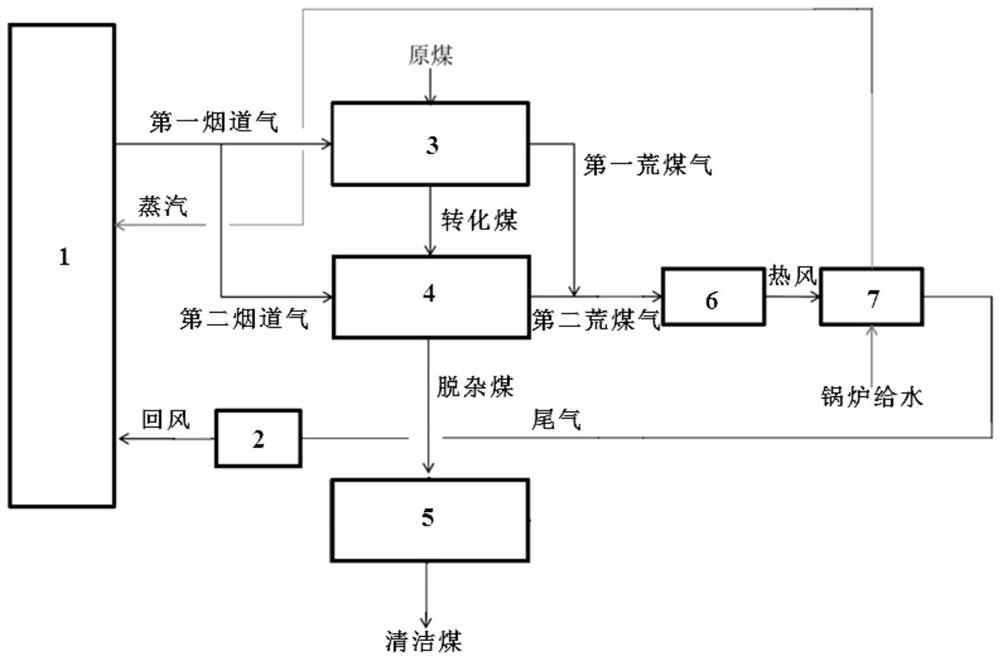

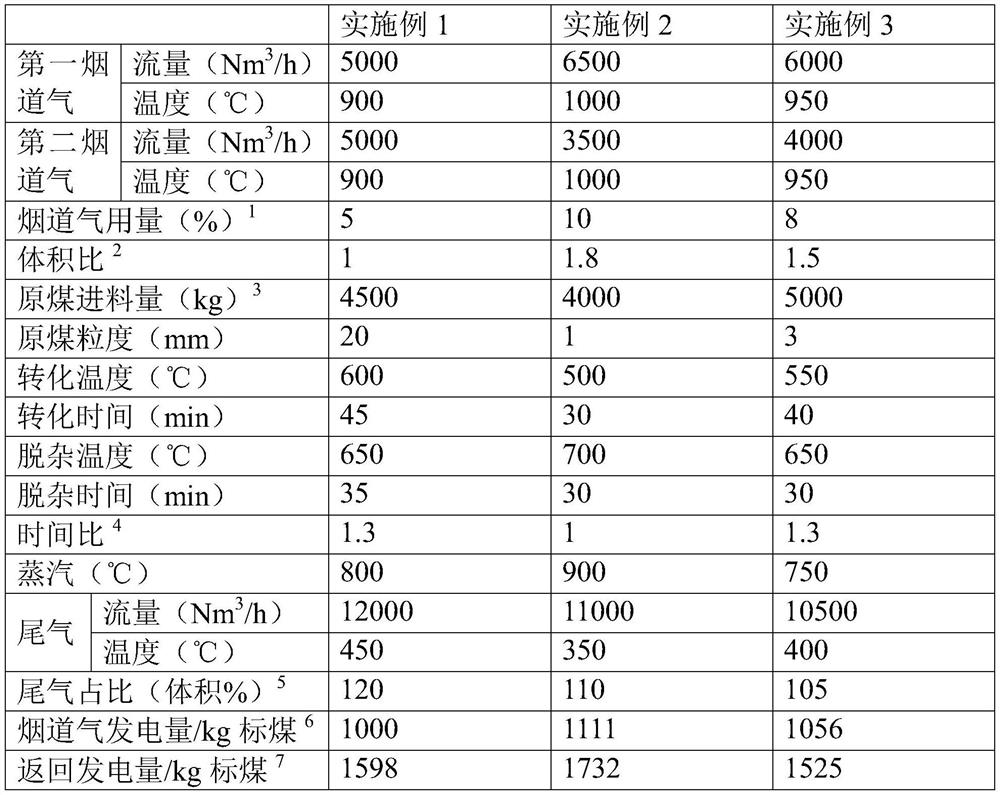

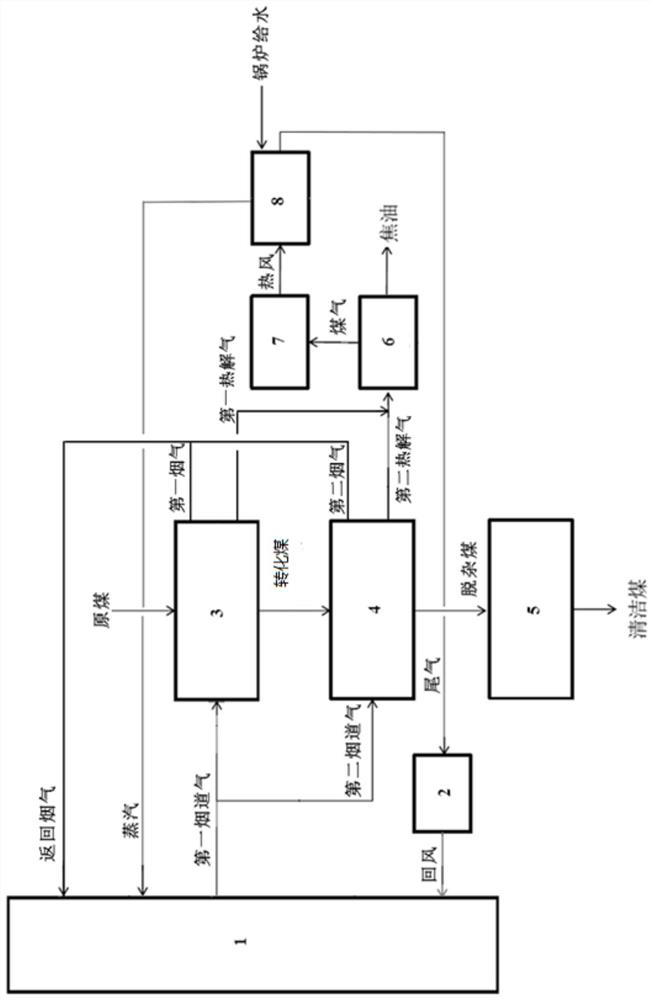

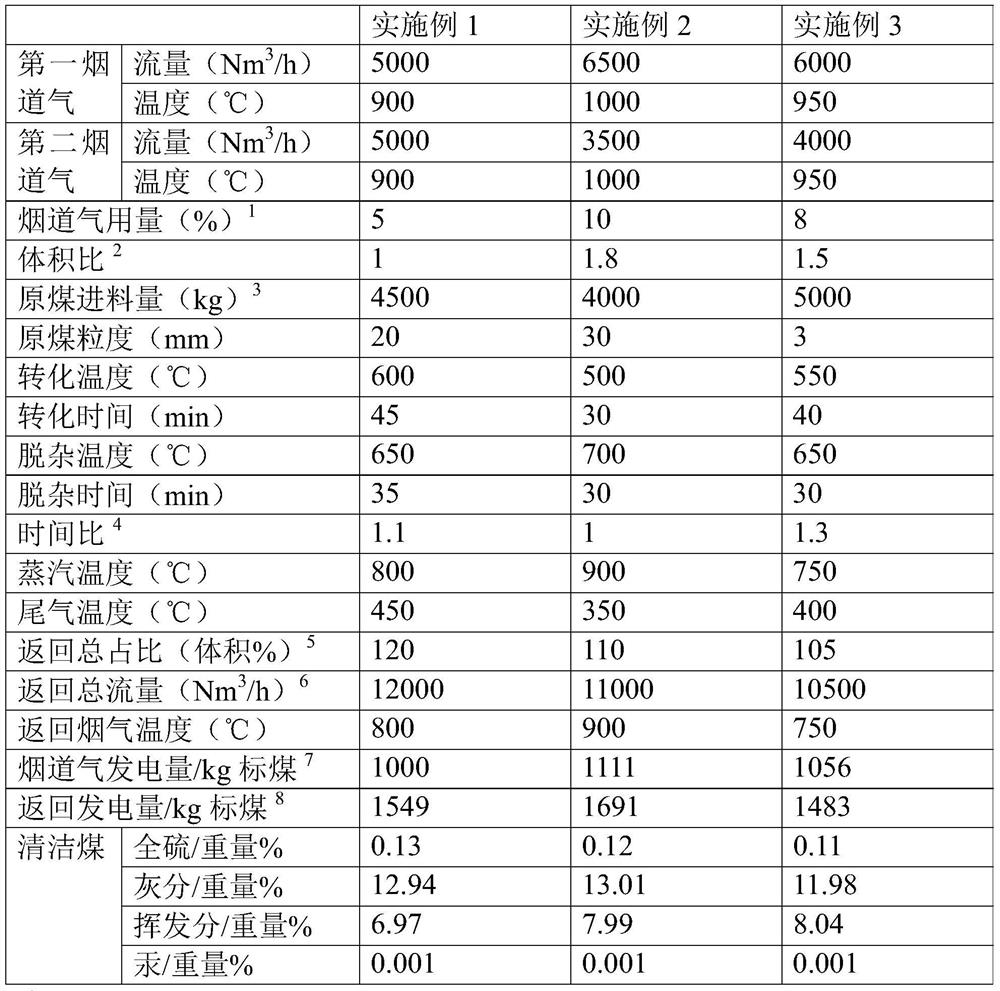

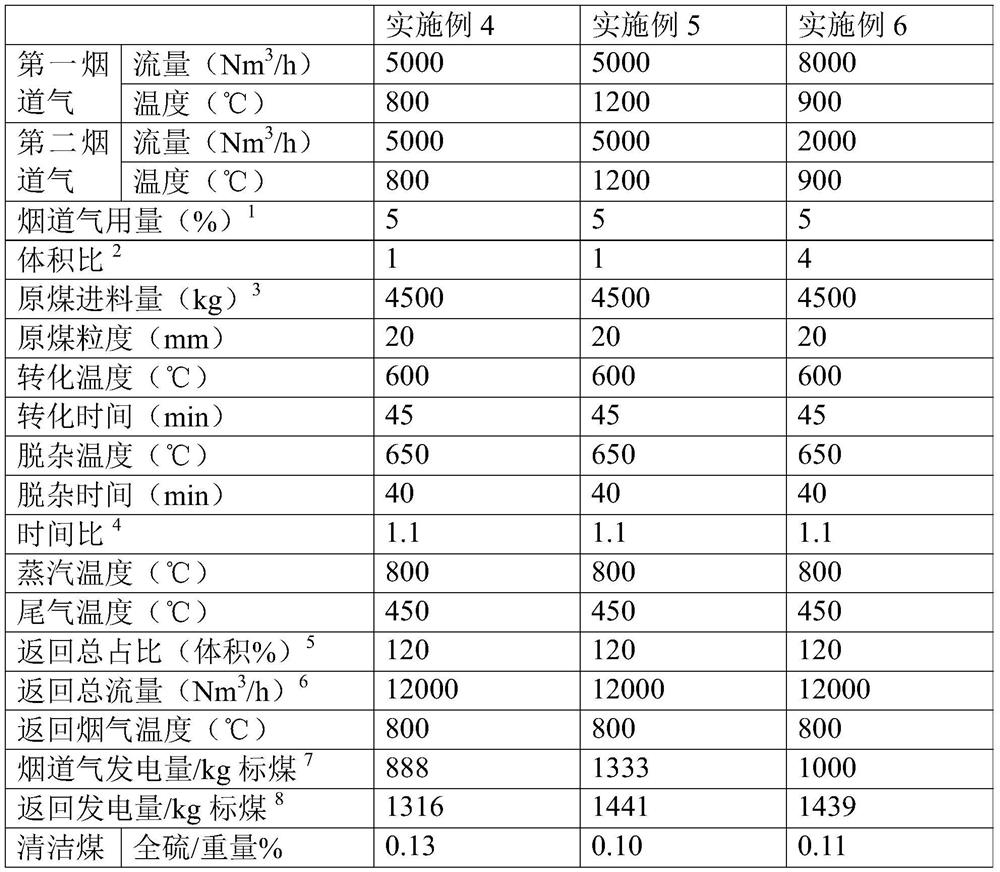

Method and system for coupling power plant power generation and clean coal production

ActiveCN109929572ARealize segmental heatingEasy to produceDirect heating destructive distillationSolid fuelsCombustionCoupling

The invention relates to the field of coupling of power plant power generation and clean coal production, and discloses a method and a system for coupling power plant power generation and clean coal production. The method comprises: (1) indirectly heating raw coal by using first flue channel gas from a power plant boiler, and carrying out coal conversion to obtain first flue gas, first pyrolysis gas and converted coal, wherein the final conversion temperature is 500-640 DEG C, and the conversion time is 10-60 min; (2) indirectly heating the converted coal by using second flue channel gas fromthe power plant boiler, and carrying out coal impurity removing to obtain second flue gas, second pyrolysis gas and impurity removed coal, wherein the final impurity removing temperature is 650-750 DEG C, and the impurity removing time is 10-60 min; (3) merging the first flue gas and the second flue gas into return flue gas, feeding into the power plant boiler so as to be used for power generation, merging the first pyrolysis gas and the second pyrolysis gas, and sequentially carrying out combustion and heat exchange; and (4) carrying out dry cooling on the impurity removed coal to obtain clean coal. With the method and the system of the present invention, the normal power generation of the power plant is achieved while the low-grade raw coal is produced into the clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

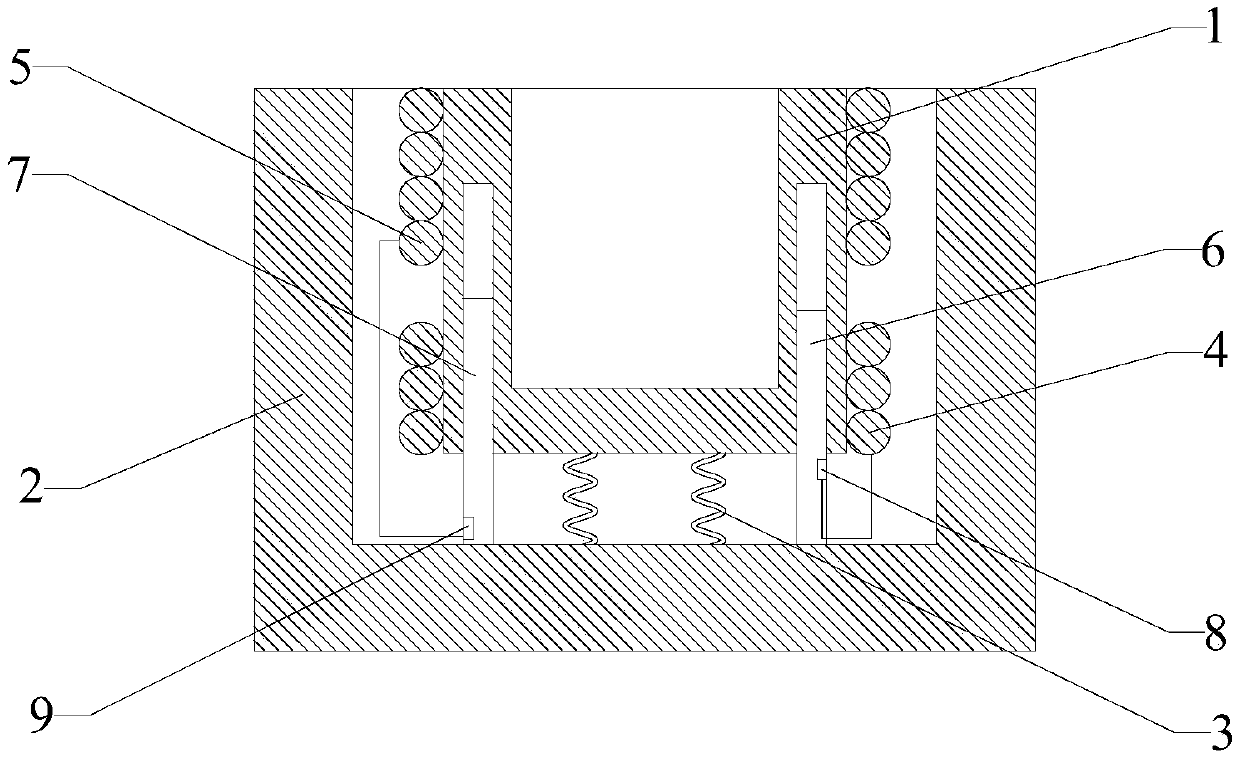

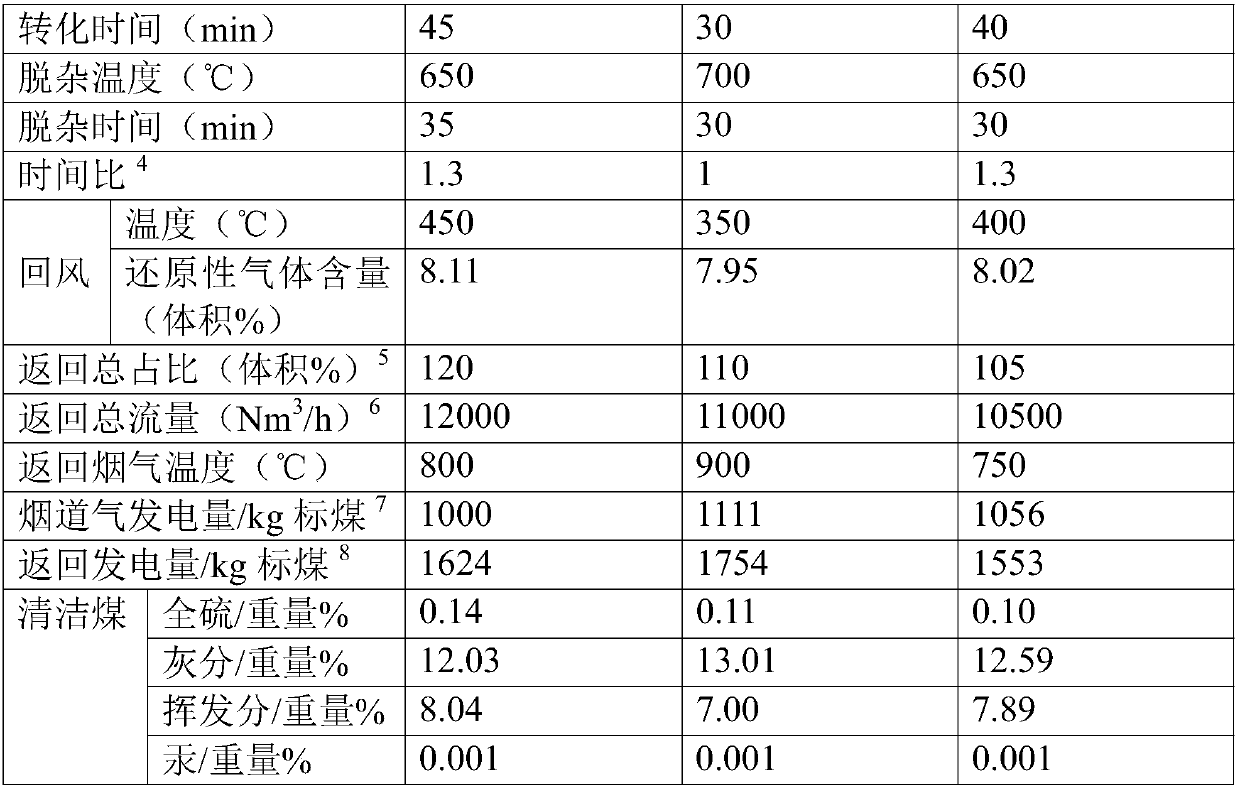

Casting mold of double-metal composite hammer

ActiveCN109570474AImprove liquidityGood molding effectFoundry mouldsFoundry coresElastomerTime delays

The invention relates to a casting mold of a double-metal composite hammer. The outer wall of the bottom of an inner cavity is connected with the inner wall of the bottom of an outer cavity through anelastic body, an inductance coil comprises a first inductance coil and a second inductance coil, a guide column comprises a first guide column and a second guide column, a contact type time delay switch comprises a first contact type time delay switch and a second contact type time delay switch, and first metal liquid and second metal liquid are subjected to segmented heating through the first inductance coil and the second inductance coil correspondingly.

Owner:罗源县白塔乡企业服务中心

Method and system for producing clean coal by coupling power generation in a power plant

ActiveCN109929572BRealize segmental heatingEasy to produceDirect heating destructive distillationSolid fuelsCombustionFlue gas

The invention relates to the field of coupling of power plant power generation and clean coal production, and discloses a method and a system for coupling power plant power generation and clean coal production. The method comprises: (1) indirectly heating raw coal by using first flue channel gas from a power plant boiler, and carrying out coal conversion to obtain first flue gas, first pyrolysis gas and converted coal, wherein the final conversion temperature is 500-640 DEG C, and the conversion time is 10-60 min; (2) indirectly heating the converted coal by using second flue channel gas fromthe power plant boiler, and carrying out coal impurity removing to obtain second flue gas, second pyrolysis gas and impurity removed coal, wherein the final impurity removing temperature is 650-750 DEG C, and the impurity removing time is 10-60 min; (3) merging the first flue gas and the second flue gas into return flue gas, feeding into the power plant boiler so as to be used for power generation, merging the first pyrolysis gas and the second pyrolysis gas, and sequentially carrying out combustion and heat exchange; and (4) carrying out dry cooling on the impurity removed coal to obtain clean coal. With the method and the system of the present invention, the normal power generation of the power plant is achieved while the low-grade raw coal is produced into the clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method and system for producing clean coal by coupling power generation in a power plant

ActiveCN109929571BRealize segmental heatingEasy to produceSolid fuelsIndirect heating destructive distillationCombustorFlue gas

The invention relates to the field of power generation coupling of power plants and clean coal production, and discloses a method and system for power generation coupling production of clean coal in power plants. The method comprises: (1) indirectly heating the raw coal with the first flue gas at 800-1200° C. The second flue gas at 800-1200°C of the power plant boiler indirectly heats the converted coal to remove impurities from the coal to obtain the second flue gas, the second pyrolysis gas and the impurity-removed coal; (3) the first pyrolysis gas After merging with the second pyrolysis gas, tar is removed to obtain tar and coal gas; the coal gas is returned to the burner of the power plant boiler in the form of return air, and the first flue gas and the second flue gas are combined into return flue gas and sent to the power plant boiler Used for power generation; (4) dry-cooling the de-miscellaneous coal to obtain clean coal. While realizing the normal power generation and production of the power plant, low-rank raw coal is produced into clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method and system for producing clean coal by coupling power generation in a power plant

ActiveCN109929575BRealize segmental heatingEasy to produceEnergy inputSteam generation using hot heat carriersFlue gasCoal conversion

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

New type heater for roughcast of plastic bottle

A heater for plastic bottle blank is composed of machine frame, heating case containing heating lamp tubes and reflecting plates, an endless chain driven by a chain wheel to pass through said heating case, and plastic bottle blank holders arranged on said chain. Its lamp tubes and reflecting plates are adjustable.

Owner:林钇伽

Systems and methods for power plant coupling to produce clean coal

ActiveCN109929574BRealize segmental heatingEasy to produceSteam generation using hot heat carriersFlue gasProcess engineering

The invention relates to the field of coupling power generation and coal-burning clean production in power plants, and discloses a system and method for coupling power plants to produce clean coal. The method comprises: (1) indirectly heating the raw coal with the first flue gas of 800-1200°C from the power plant boiler to carry out coal conversion, the final conversion temperature of the coal conversion is 500-640°C, and the conversion time is 10-60min , to obtain the first flue gas, the first pyrolysis gas and the converted coal; (2) use the second flue gas from the power plant boiler to indirectly heat the converted coal to remove impurities from the coal, and the final removal of impurities from the coal The impurity temperature is 650-750°C, and the impurity removal time is 10-60 minutes to obtain the second flue gas, the second pyrolysis gas and the de-impurity coal; (3) the first pyrolysis gas and the second pyrolysis gas are merged into a The wind returns to the boiler of the power plant; (4) dry-cooling the de-miscellaneous coal to obtain clean coal. Realize the normal power generation and production of power plants, and at the same time produce low-rank raw coal into clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method and system for coupling power plant power generation and clean coal production

ActiveCN109929574ARealize segmental heatingEasy to produceSolid fuelsIndirect heating destructive distillationCouplingFlue gas

The invention relates to the field of coupling of power plant power generation and clean production of fired coal, and discloses a method and a system for coupling power plant power generation and clean coal production. The method comprises: (1) indirectly heating raw coal by using first flue channel gas with a temperature of 800-1200 DEG C from a power plant boiler, and carrying out coal conversion to obtain first flue gas, first pyrolysis gas and converted coal, wherein the final conversion temperature of the coal conversion is 500-640 DEG C, and the conversion time is 10-60 min; (2) indirectly heating the converted coal by using second flue channel gas with a temperature of 800-1200 DEG C from the power plant boiler, and carrying out coal impurity removing to obtain second flue gas, second pyrolysis gas and impurity removed coal, wherein the final impurity removing temperature of the coal impurity removing is 650-750 DEG C, and the impurity removing time is 10-60 min; (3) merging the first pyrolysis gas and the second pyrolysis gas into return air, and returning to the power plant boiler; and (4) carrying out dry cooling on the impurity removed coal to obtain clean coal. With the method and the system of the present invention, the normal power generation of the power plant is achieved while the low-grade raw coal is produced into the clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A casting mold for bimetal composite hammer head

ActiveCN109570474BImprove liquidityGood molding effectFoundry mouldsFoundry coresEngineeringCasting mold

The invention relates to a casting mold of a double-metal composite hammer. The outer wall of the bottom of an inner cavity is connected with the inner wall of the bottom of an outer cavity through anelastic body, an inductance coil comprises a first inductance coil and a second inductance coil, a guide column comprises a first guide column and a second guide column, a contact type time delay switch comprises a first contact type time delay switch and a second contact type time delay switch, and first metal liquid and second metal liquid are subjected to segmented heating through the first inductance coil and the second inductance coil correspondingly.

Owner:罗源县白塔乡企业服务中心

Segmented Differential Electric Heating Cable

InactiveCN104254155BImprove the heating effectRealize centralized heatingInsulationHeating element shapesConstant powerNichrome

Owner:CHINA PETROLEUM & CHEM CORP +1

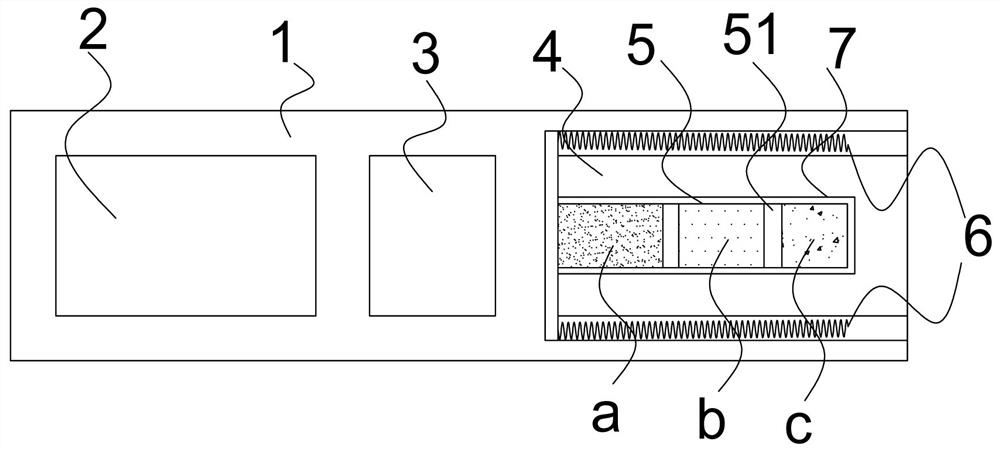

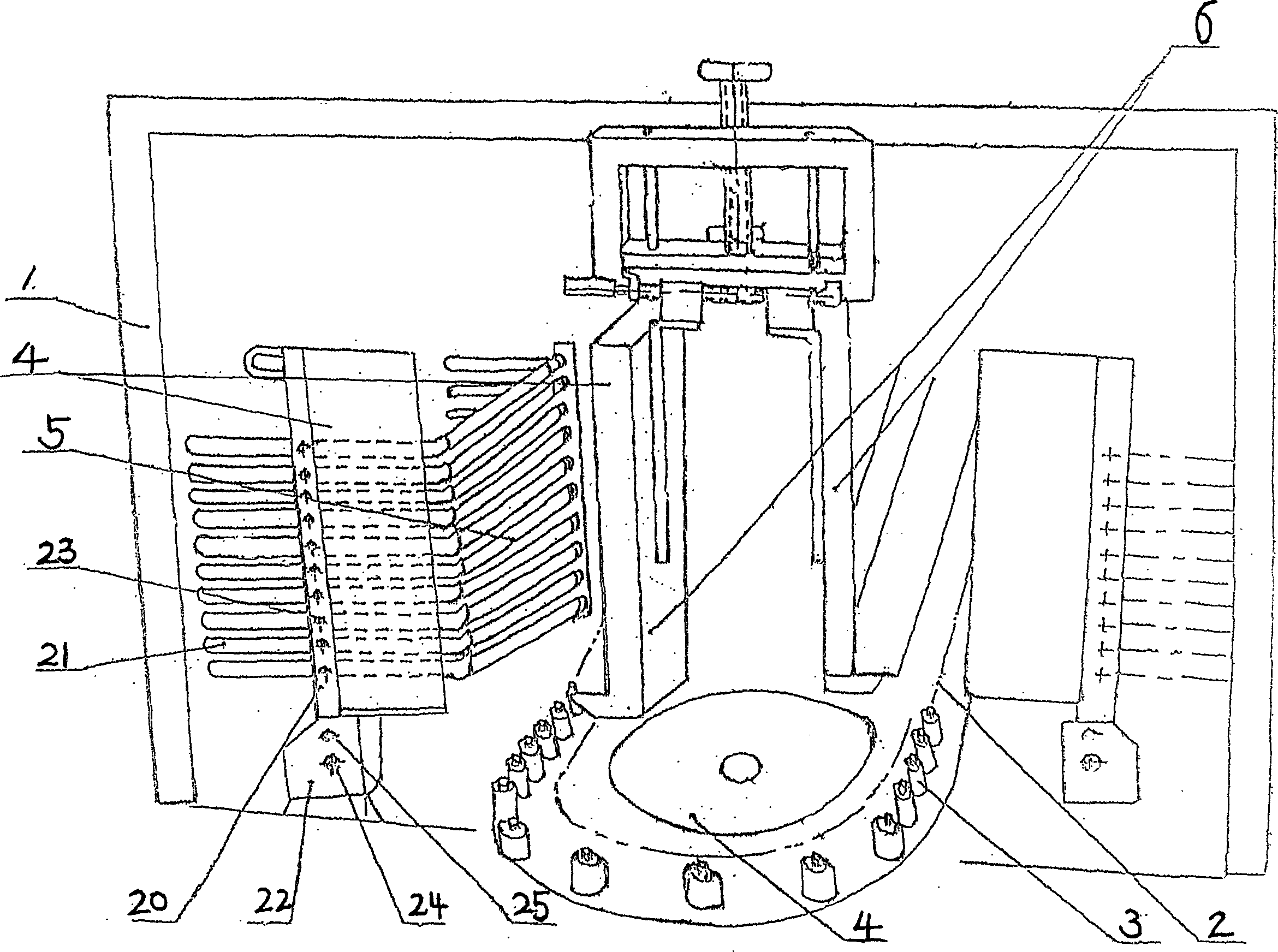

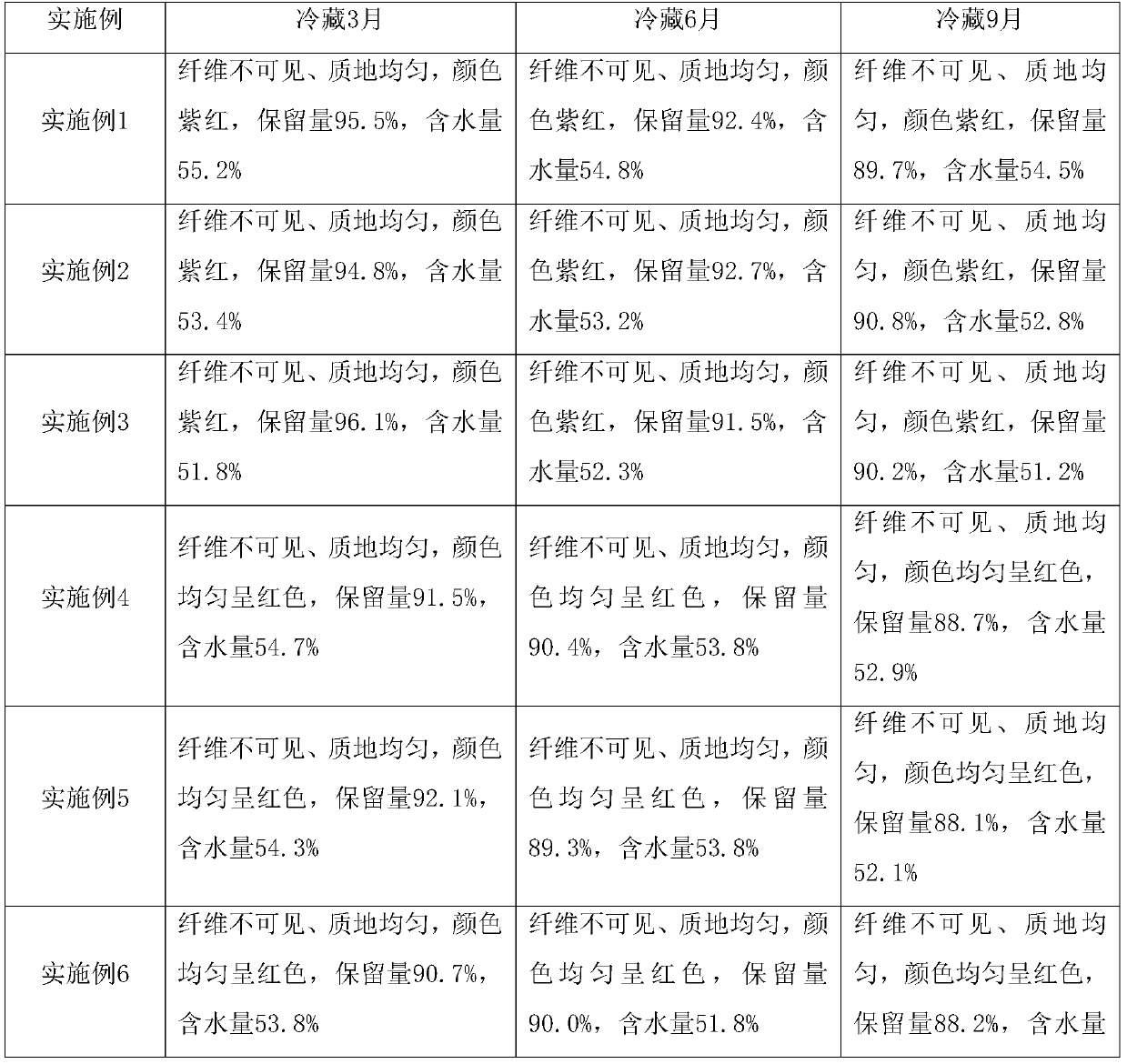

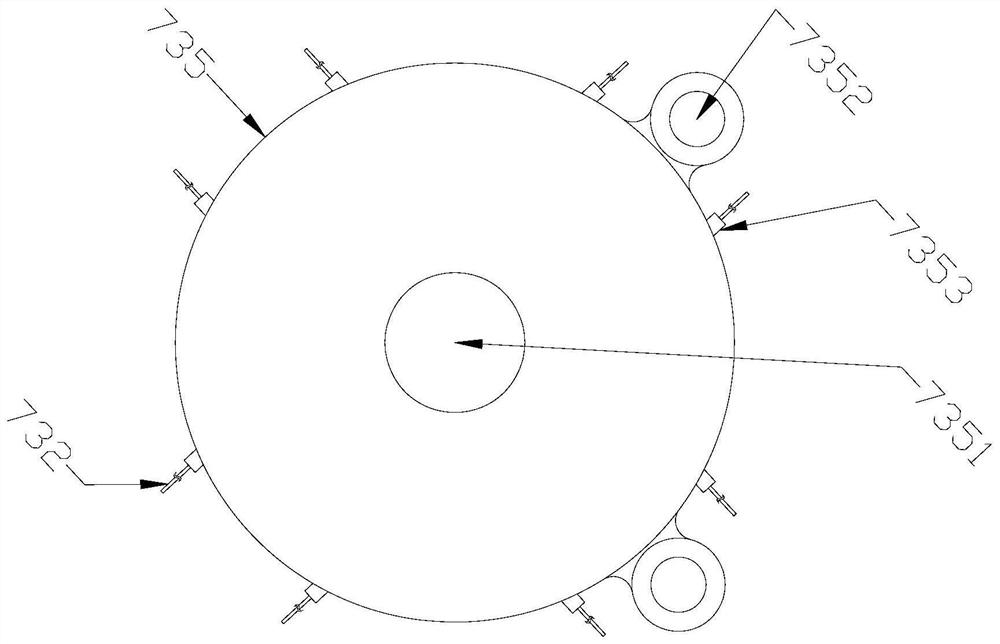

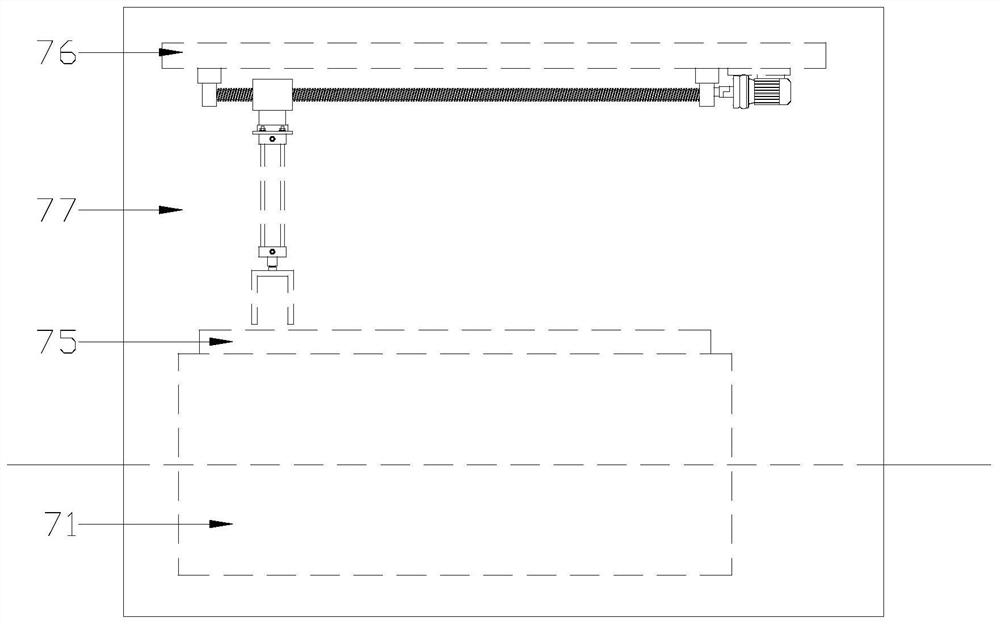

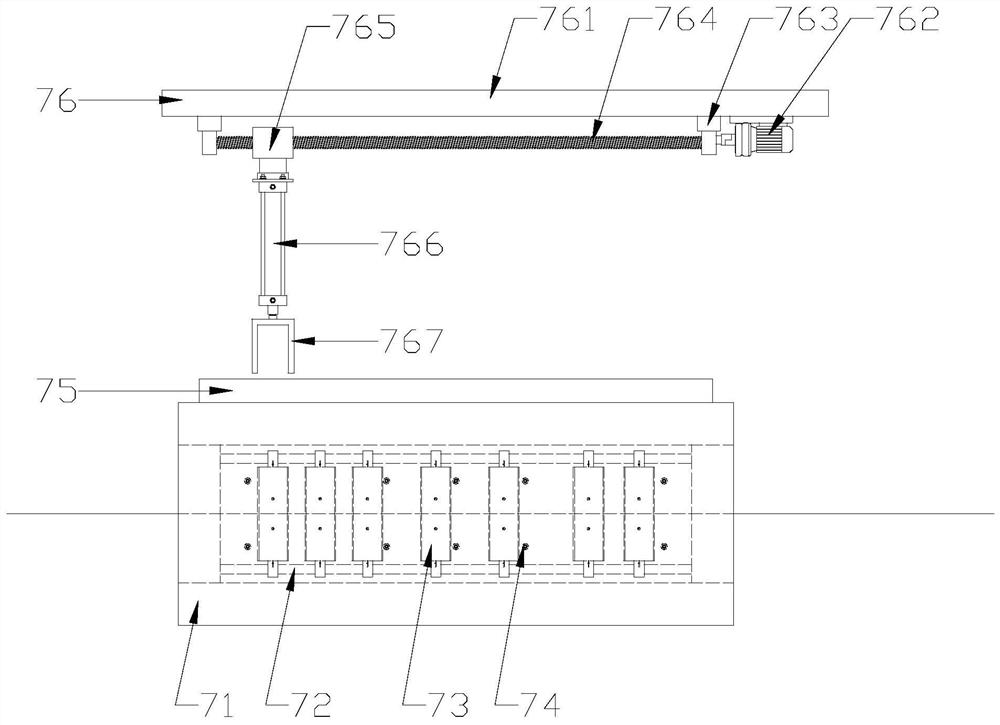

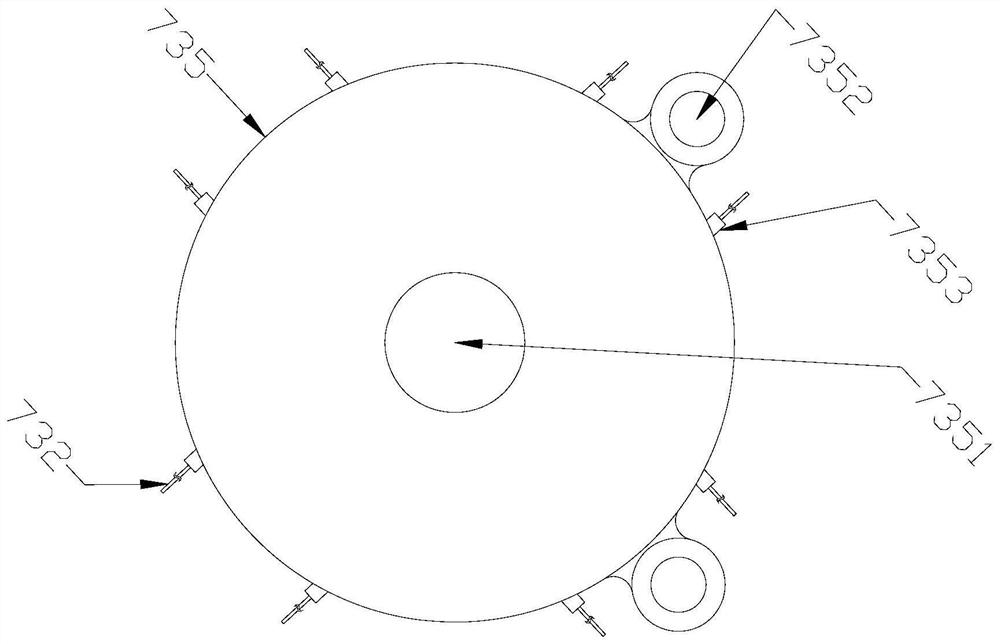

Processing technology of high-pigment mashed potatoes and mashed potato microwave heating system

PendingCN111000172ACompensation for dehydration effectShort timeFood thermal treatmentMicrowave heatingProcess engineeringNutrient content

The invention relates to a processing technology of high-pigment mashed potatoes. The processing technology comprises the steps of S1 mashing: cleaning high-pigment sweet potatoes, slicing and steaming over water for 10 to 20 minutes to obtain cooked slices, fully mixing the cooked slices, and adjusting the water content of the cooked slices to 80 to 85% to obtain pre-cooked mashed potatoes; S2 microwave curing: heating the pre-cooked mashed potatoes to 130 to 150 DEG C in sections, maintaining the temperature for 20 to 40 seconds, and then performing forced cooling to 30 to 40 DEG C by usinga tubular heat exchange tube to obtain mashed potatoes; and S3 packaging: performing aseptic packaging on the mashed potatoes cooled in the S2, and then performing storage in an environment of 0 to 6DEG C. The invention further provides a system for realizing segmented heating, and provides a new processing and eating mode of high-pigment sweet potatoes. The high-pigment sweet potatoes are processed into mashed potatoes, so that nutritional ingredients can be reserved to a greater extent, and the mashed potatoes have better storage performance and better flavor, and meanwhile, other safety risk threats (risks of cancerogens and the like generated by processing such as frying and the like) do not exist.

Owner:ZHEJIANG FORESTRY UNIVERSITY

A ceramic heating sheet with temperature control

ActiveCN103874243BMeet the purpose of heating a large areaClosely arrangedOhmic-resistance heating detailsElectricityTemperature control

Owner:FUJIAN MINHANG ELECTRONICS

A device and method for realizing flow drag reduction of submarine oil pipeline by using vortex-induced vibration

InactiveCN105546262BRealize segmental heatingLow costBatteries circuit arrangementsPipe heating/coolingOcean bottomElectricity

The invention relates to a device and method for realizing undersea oil pipeline flow damping through vortex-induced vibration. The device is composed of a vibration system, a magnetic field system and an electrogenic heat tracing system. The vibration system is composed of an outer barrel, supporting plates, supporting lantern rings, springs and long bolts and is used for producing vibration responses under the ocean current action. The magnetic field system is composed of magnet clamping grooves and magnets and arranged on the wide supporting plate of the inner wall of the outer barrel and used for constructing a magnetic field. The electrogenic heat tracing system comprises wires, an electrical conductor layer and an inner insulation layer, and an oil pipeline is transformed to be of a six-layer pipeline structure which is composed of a steel pipe, the inner insulation layer, the electrical conductor layer, the wires, a heat preservation layer and an outer insulation layer from inside to outside in sequence. According to the device for realizing undersea oil pipeline flow damping through the vortex-induced vibration, the wires are driven by the vibration to cut magnetic induction lines under the ocean current action, and heat generated by electricity enables the viscosity and the resistance of an oil flow to be reduced, so that the low cost and zero energy consumption are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Oxidative carbonization device and method for coal-based activated carbon

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method and system for producing clean coal by coupling power generation in a power plant

ActiveCN109929570BRealize segmental heatingEasy to produceDirect heating destructive distillationEnergy inputCoal conversionDirect heating

The invention relates to the field of power generation coupling of power plants and clean coal production, and discloses a method and system for power generation coupling production of clean coal in power plants. The method comprises: (1) directly heating the raw coal with the first flue gas from the power plant boiler at 800-1200°C to carry out coal conversion, the final conversion temperature of the coal conversion is 500-640°C, and the conversion time is 10-60 minutes, Obtain the first raw gas and converted coal; (2) directly heat the converted coal with the second flue gas from the power plant boiler at 800-1200°C for coal removal, and the final removal temperature of coal removal is 650-750°C , the impurity removal time is 10-60 minutes, and the second raw gas and the second raw coal are obtained; (3) the first raw gas and the second raw gas are burned, and the hot air obtained is passed into the waste heat boiler to generate steam and tail gas, and returns to the power plant The boiler is used for power generation; (4) dry-cooling the de-miscellaneous coal to obtain clean coal. It realizes the normal power generation production of the power plant and at the same time produces low-rank raw coal into clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Induction heating device for producing complex brass

The invention discloses an induction heating device for producing complex brass. The induction heating device comprises an inner furnace body, a plurality of slide rods, a heating block, a temperatureinductor, a movable door, a block body mover, an outer furnace body and a central controller, wherein the top end of the inner furnace body is equipped with an opening, and is sealed or opened by themovable door; the inner furnace body, the movable door and the block body mover are separately arranged in an inner cavity of the outer furnace body; the slide rods, the heating block and the temperature inductor are separately arranged in the inner cavity of the inner furnace body; the heating block sleeves the slide rods, and is driven by the block body mover to move left and right along the slide rods; the center of the heating block is provided with a wire passing hole for allowing a brass raw material wire to pass through; left and right ends of each of the inner furnace body and the outer furnace body are separately provided with discharge holes for allowing the brass raw material to get in and get out; and the central controller is electrically connected to the heating block, the temperature inductor, the movable door and the block body mover separately. The induction heating device can realize sectioned heating in the inner furnace body as well as length regulating at each temperature stage.

Owner:嘉兴市利富通新材料科技有限公司

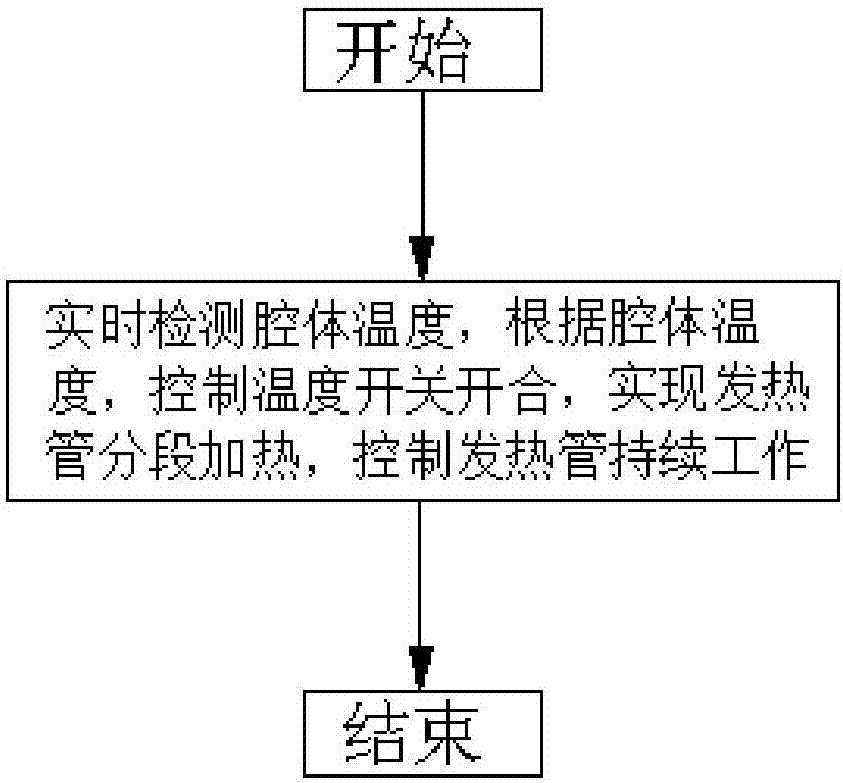

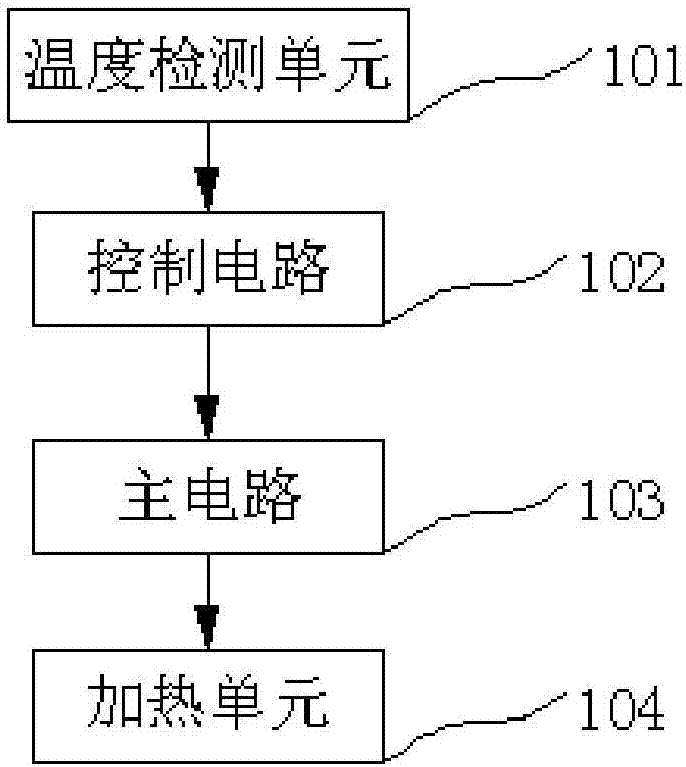

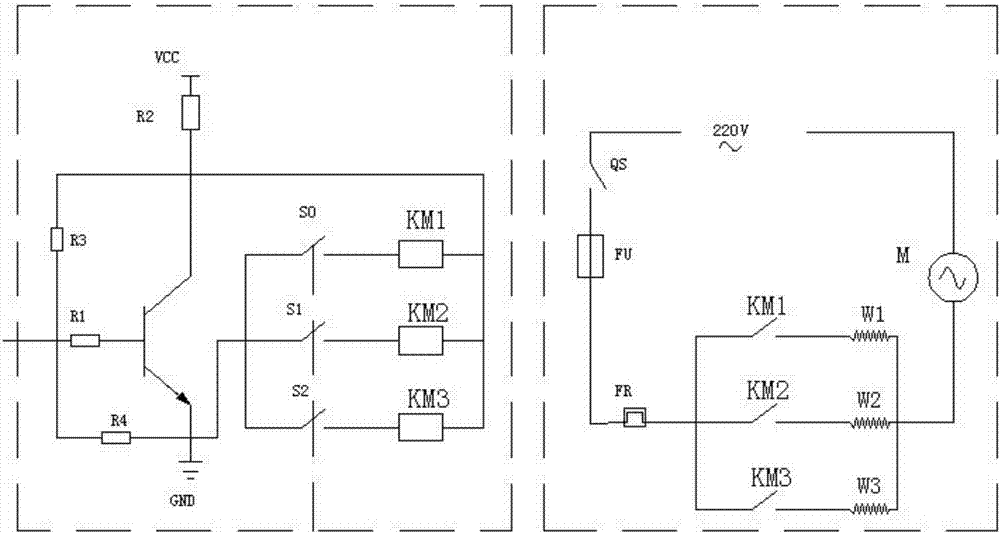

Energy-saving control method and system of microwave oven

InactiveCN107504526ARealize segmental heatingHeat stableDomestic stoves or rangesLighting and heating apparatusMicrowave ovenTransmitted power

The invention relates to the technical field of microwave ovens, in particular to an energy-saving control method and system of a microwave oven. The control method comprises the steps of (1) detecting the temperature of a cavity of the microwave oven in real time when receiving an instruction for starting the microwave oven; and (2) controlling turn-on and turn-off of different temperature switches to conduct automatic sectional control on the transmitted power of heating tubes of the microwave oven so as to control the temperature of the cavity in the continuous operating process of the heating tube. By means of the energy-saving control method and system, sectional heating of the heating tubes is realized through setting temperature intervals; heating is stable; control is accurate; the control stability is improved; meanwhile, through sectional heating control and continuous heating of the heating tubes, energy consumption is reduced while food tastiness is guaranteed.

Owner:NINGBO DUNHE TECH CO LTD

Method and system for coupling power generation in power plants to produce clean coal

ActiveCN109929573BRealize segmental heatingEasy to produceEnergy inputCombustion technology mitigationFlue gasProcess engineering

The invention relates to the field of power generation coupling of power plants and clean coal production, and discloses a method and system for power generation coupling production of clean coal in power plants. The method includes: (1) using the first flue gas from the power plant boiler to indirectly heat the raw coal for coal conversion, the final conversion temperature is 500-640°C, and the conversion time is 10-60 minutes to obtain the first flue gas, the first pyrolysis (2) Use the second flue gas from the power plant boiler to indirectly heat the dried coal to remove impurities from the coal. The final removal temperature is 650-750°C, and the removal time is 10-60 minutes to obtain the second flue gas , the second pyrolysis gas and the removal of miscellaneous coal; (3) remove the tar from the pyrolysis gas to obtain tar and coal gas; (4) burn the coal gas and exchange heat, and return the steam and tail gas obtained to the power plant boiler for power generation ; Combine the first flue gas and the second flue gas and return to the power plant boiler. While realizing the normal power generation and production of the power plant, low-rank raw coal is produced into clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Combustion kiln system

InactiveCN105526798AImprove combustion efficiencyAvoid the problem of low combustion efficiencyCharge composition/stateFurnace typesElectricityCombustion chamber

The invention discloses a combustion kiln system. The combustion kiln system comprises a plurality of combustion kiln chambers sequentially communicated end to end, a drive device for driving combustion kilns of the combustion kiln system to rotate, a control device electrically connected to the combustion kiln system drive device, a temperature detecting device, and a heating device, wherein control device for the combustion kiln system can regulate rotation speed of the combustion kiln system drive device; the temperature detecting device is used for determining the temperature of the inner parts of the combustion kiln chambers; the temperature detecting device for the combustion kiln system is electrically connected to the control device for the combustion kiln system; and the heating device is used for heating each combustion kiln of the combustion kiln system. In use, the control device controls the drive device to drive the combustion kilns to rotate so as to control the rotation speed, and the combustion kiln system comprises the plurality of the combustion kiln chambers, and therefore, the plurality of the combustion kiln chambers can be respectively heated, difference of the inner temperatures of the plurality of the combustion kiln chambers and retention time of blank is realized, different temperature needs, at each stage, of the blank are met, sectional heating effect is realized, and the combustion efficiency of the combustion kiln system is improved.

Owner:CHONGQING SHENGSHANGYUAN ENVIRONMENTAL GOVERNANCE CO LTD

An induction heating device for the production of complex brass

The invention discloses an induction heating device for producing complex brass, which comprises an inner furnace body, a sliding rod, a heating block, a temperature sensor, a movable door, a block mover, an outer furnace body and a central controller, the inner furnace body The top of the body is provided with an opening and is closed or opened by a movable door. The inner furnace body, movable door and block mover are respectively arranged in the inner cavity of the outer furnace body. The heaters are respectively arranged in the inner chamber of the inner furnace body. The heating block is sleeved on the slide bar and driven by the block mover to move left and right along the slide bar. The center of the heating block is provided with a brass raw material The threading hole through which the wire rod passes, the left and right ends of the inner furnace body and the outer furnace body are respectively provided with material ports for the brass raw material wire rod to enter and exit, and the central controller is respectively connected with the heating block, temperature sensor, movable door and The block mover is electrically connected, enabling segmental heating in the inner furnace body and length adjustment of each temperature stage.

Owner:嘉兴市利富通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com