An induction heating device for the production of complex brass

An induction heating device, a technology for complex brass, applied in the induction heating device for producing complex brass, in the field of brass production, it can solve the problem of segmented temperature regulation, the inability to control the length of the temperature stage, and the inability to accurately control the temperature of the brass raw material wire, etc. problems, to reduce the workshop temperature, avoid heat loss, and enhance the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

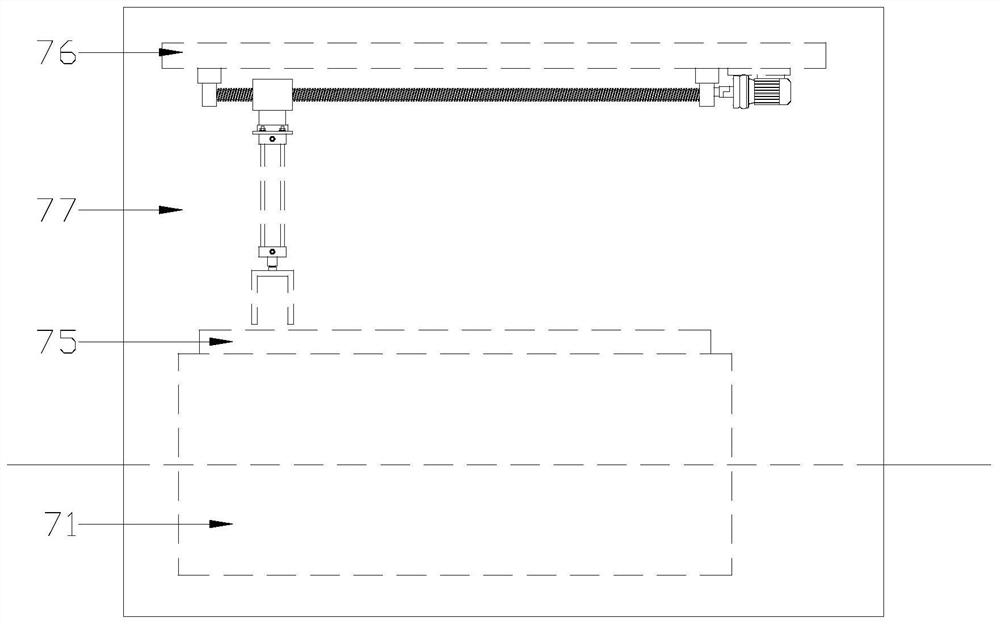

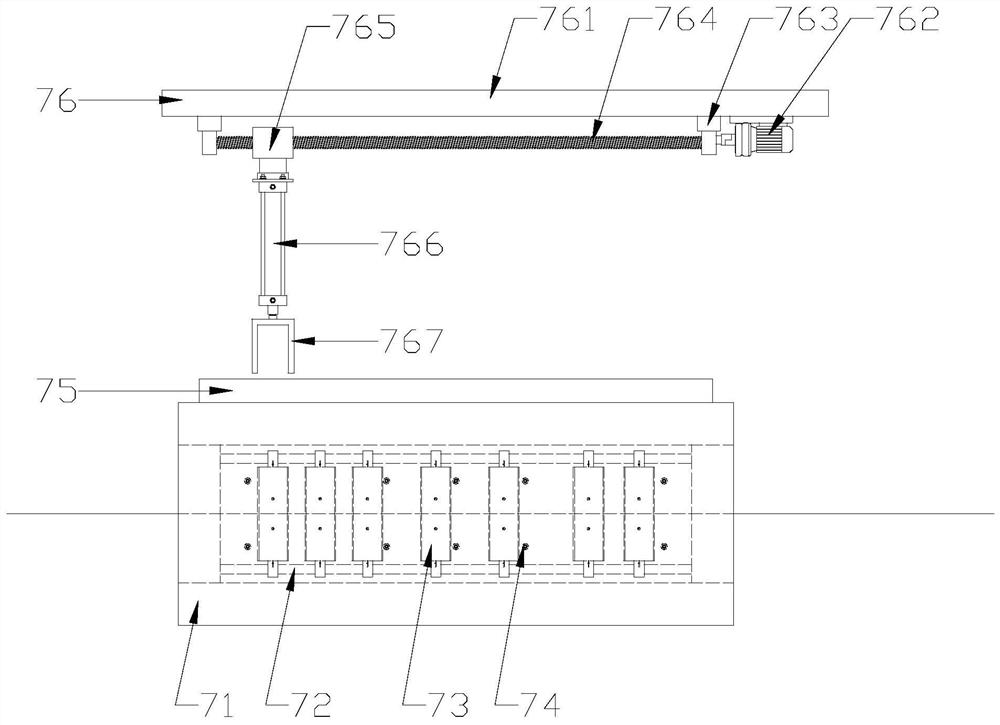

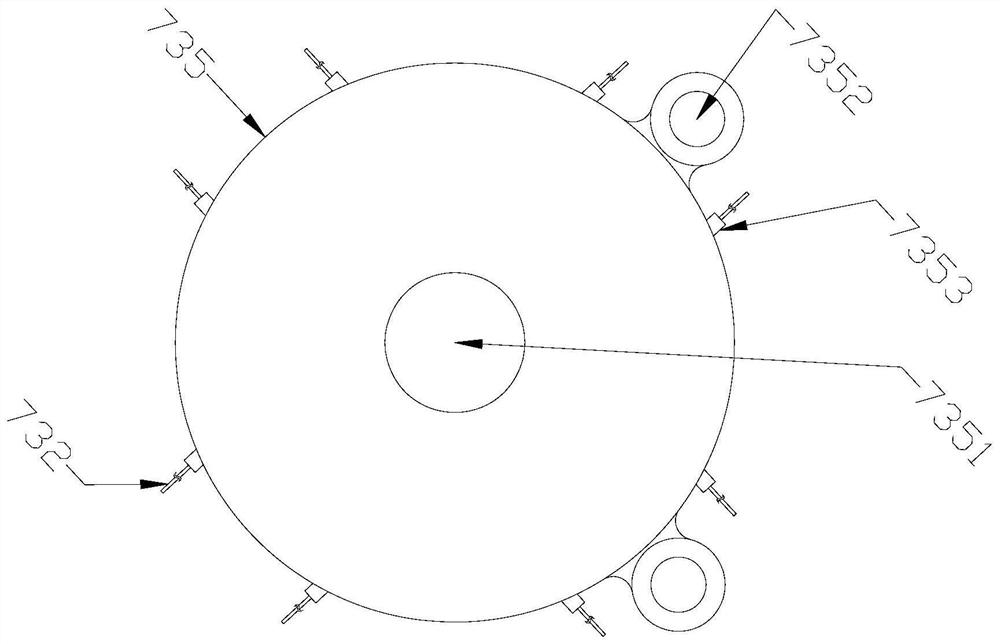

[0020] refer to Figure 1 to Figure 5 , an induction heating device for producing complex brass in the present invention, comprising an inner furnace body 71, a slide bar 72, a heating block 73, a temperature sensor 74, a movable door 75, a block mover 76, an outer furnace body 77 and a central control The top of the inner furnace body 71 is provided with an opening and is closed or opened by a movable door 75. The inner furnace body 71, the movable door 75 and the block mover 76 are respectively arranged in the inner cavity of the outer furnace body 77, The plurality of slide bars 72, heating blocks 73 and temperature sensors 74 are respectively arranged in the inner cavity of the inner furnace body 71, and the heating blocks 73 are sleeved on the slide bars 72 and driven by the block mover 76 Moving left and right along the slide bar 72, the center of the heating block 73 is provided with a threading hole for the brass raw material wire to pass through, and the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com