Device and method for realizing undersea oil pipeline flow damping through vortex-induced vibration

A technology of oil pipeline and vortex-induced vibration, which is applied in circuit devices, transportation and packaging, battery circuit devices, etc., can solve the problems of huge cost of marine heavy oil exploitation and increased work burden, and achieve low cost, low cost and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

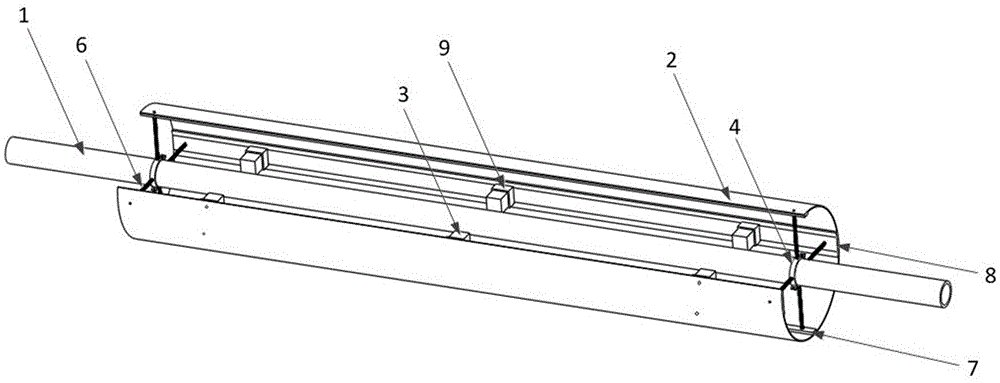

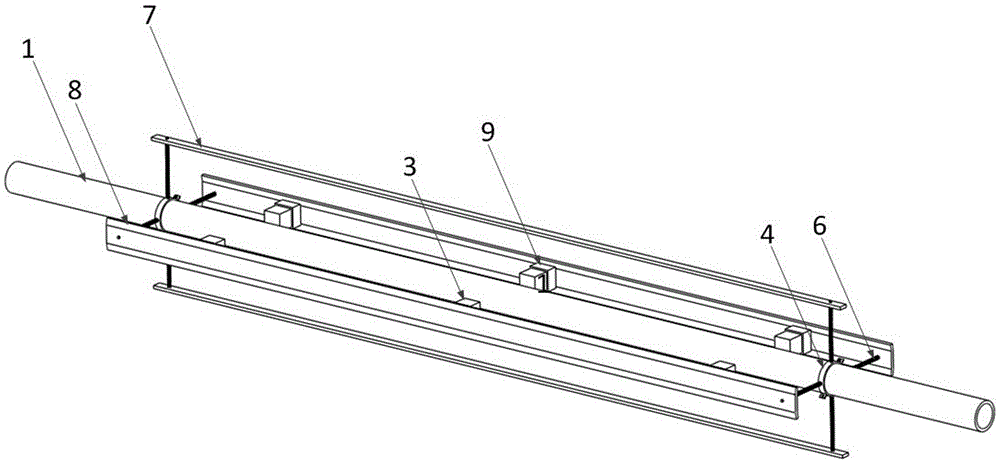

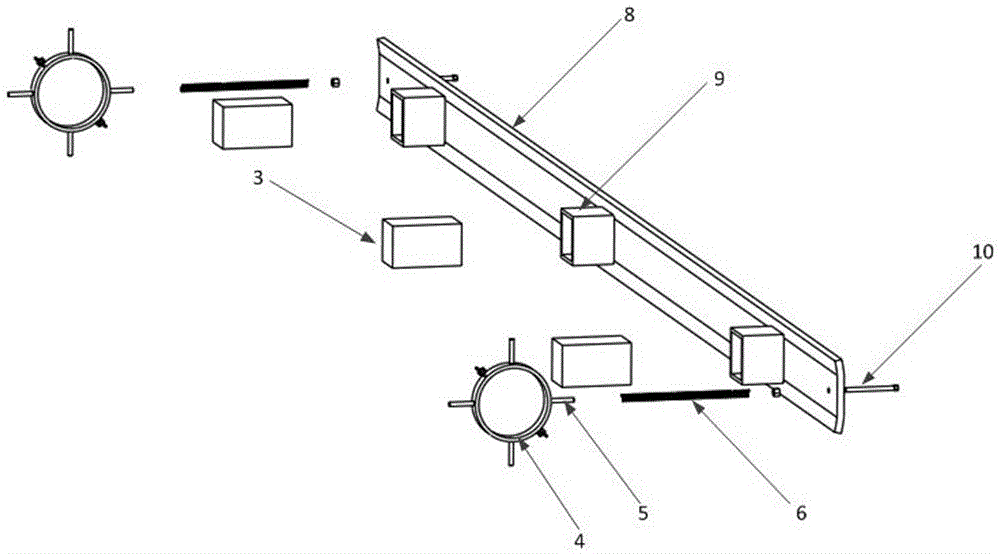

[0029] In actual use, the device of the present invention can be arranged at a certain interval as required. When the device of the present invention is installed, the oil pipeline 1 must first be transformed, and the pipeline to be transformed can be selected according to the root, and a layer of inner insulating layer 13 is added outside the steel pipe of the oil pipeline 1, and a layer of electrical conductor is arranged outside the inner insulating layer 13. Layer 12, and wires 11 are arranged outside the electrical conductor layer 12 to form a six-layer pipeline structure consisting of steel pipes, inner insulating layers 13, electrical conductor layers 12, wires 11, insulation layers and outer insulating layers from inside to outside, and make The wire 11 and the electrical conductor layer 12 form a closed electrical circuit. Then, install and fix the two support collars 4 on the oil pipeline 1 according to the interval between the openings at both ends of the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com