Combustion kiln system

A kiln chamber and control device technology, applied in the field of combustion kiln, can solve the problems of low combustion efficiency of the combustion kiln, achieve the effect of avoiding uncontrollable heating temperature and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

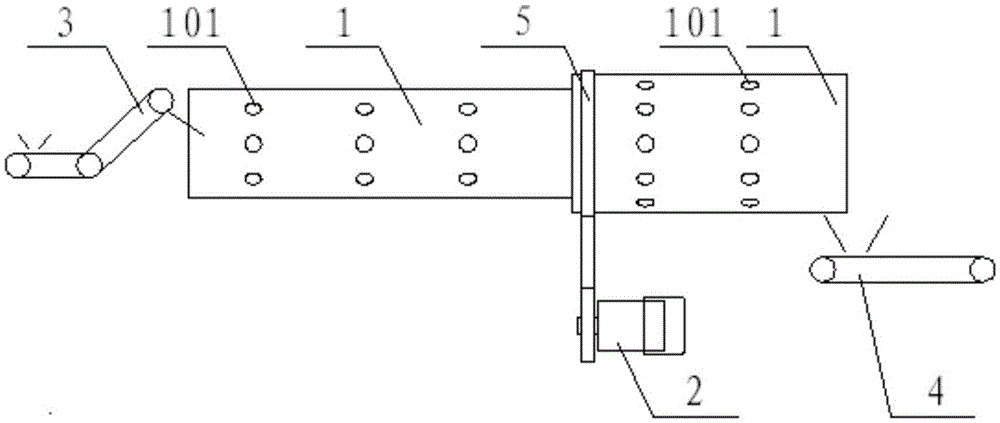

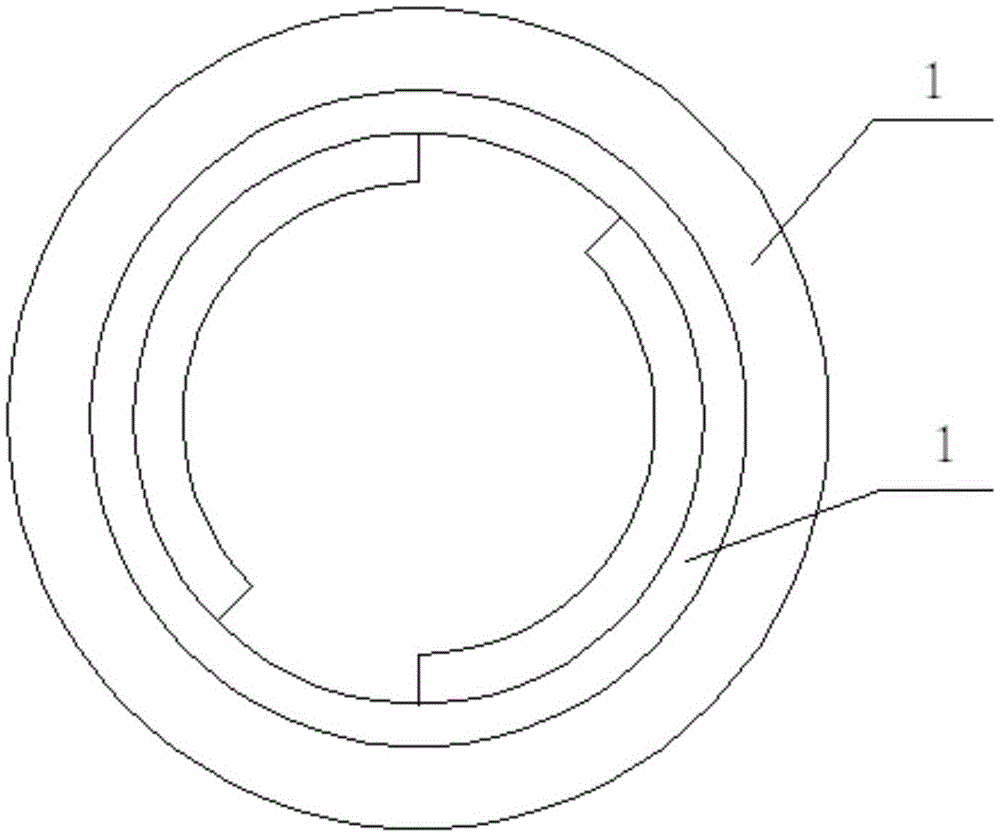

[0029] see Figure 1-2 , is a schematic structural diagram of the combustion kiln system provided by the present invention.

[0030] The present invention provides a combustion kiln system, comprising: a plurality of combustion kiln chambers 1 connected end-to-end in sequence, the inlets and outlets of adjacent combustion kiln chambers 1 are connected; a driving device 2 for driving a plurality of combustion kiln chambers 1 to rotate; and The drive device 2 is electrically connected to the control device, the control device can adjust the rotating speed of the drive device 2; the combustion kiln chamber 1 is provided with a temperature detection point for detecting the internal temperature of the combustion kiln chamber 1, the temperature detection device is electrically connected to the control device, and the temperature detection device The detected temperature signal can be transmitted to the control device, and the control device controls the size of the feed amount accor...

Embodiment 2

[0034] In yet another embodiment provided by the present invention, the structure of the combustion kiln system in this embodiment is similar to that in Embodiment 1, and the similarities will not be repeated, and only the differences will be introduced.

[0035] In this embodiment, the present invention discloses that the combustion kiln system also includes a feed device 3; The device is electrically connected, and the control device can control the feeding amount of the feeding device 3 by controlling the rotating speed of the power device, thereby reducing the intensity of manual operation. Specifically, the present invention discloses that the feeding device 3 is a conveyor belt device.

[0036] In order to further reduce the labor intensity and improve the degree of automation, the present invention also discloses that the combustion kiln system also includes a discharge device 4; the discharge device 4 is used to receive the materials output from the discharge port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com