Oxidative carbonization device and method for coal-based activated carbon

A technology for oxidizing carbon and chemical devices, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of increased crushing rate, decreased yield, and decreased strength of molded particles, and achieves reduction of crushing and powder. , the effect of increasing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

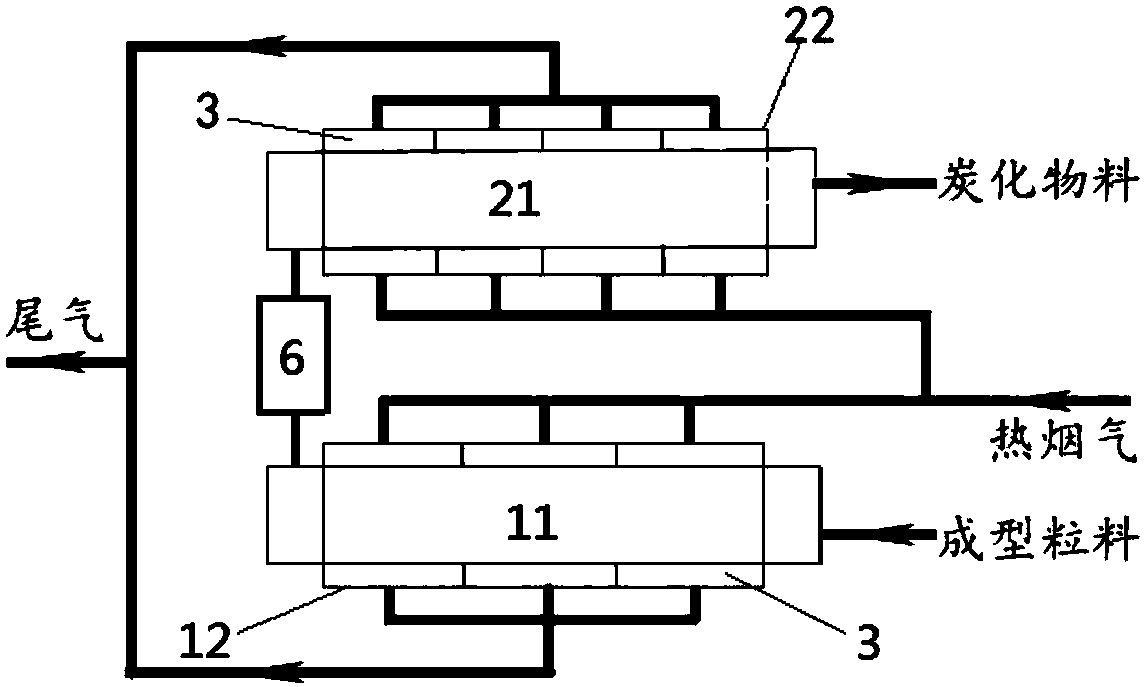

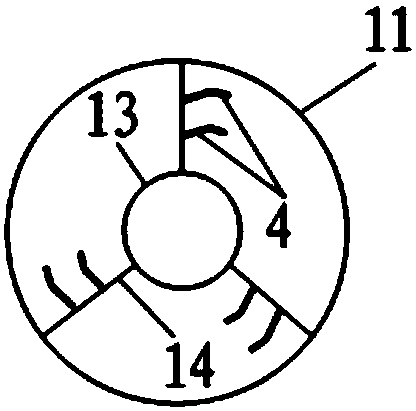

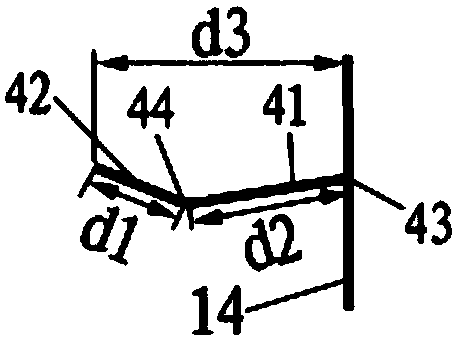

[0039] use as figure 1 The shown oxidative carbonization device performs oxidative carbonization treatment on the shaped pellets of raw coal, wherein the internal structure of the first cylinder is as follows figure 2 Shown; the second cylinder is provided with a copy board with the same structure. In addition, the first outer heating jacket and the second outer heating jacket are each provided with 6 segmented jackets.

[0040] The briquette is crushed and granulated to obtain granules with a particle diameter between 6.7 mm and 8 mm. During the oxidation treatment, the inner temperature of the cylinder corresponding to the first segmented jacket of the first external heating jacket is controlled to be 150-170°C, and the temperature inside the cylinder corresponding to the sixth segmented jacket is 200-220°C, during which the temperature rise rate is 0.2~0.5°C / min; use air as the oxidant to oxidize for 2.5 hours to obtain the oxidized material.

[0041] Then send the oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com