Processing technology of high-pigment mashed potatoes and mashed potato microwave heating system

A processing technology, microwave heating technology, applied in microwave heating, lighting and heating equipment, food heat treatment, etc., can solve problems such as loss of nutrients, storage technology limitations, unsafe factors of leisure food, etc., to shorten time-consuming and ensure flavor , the effect of compensating for the dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

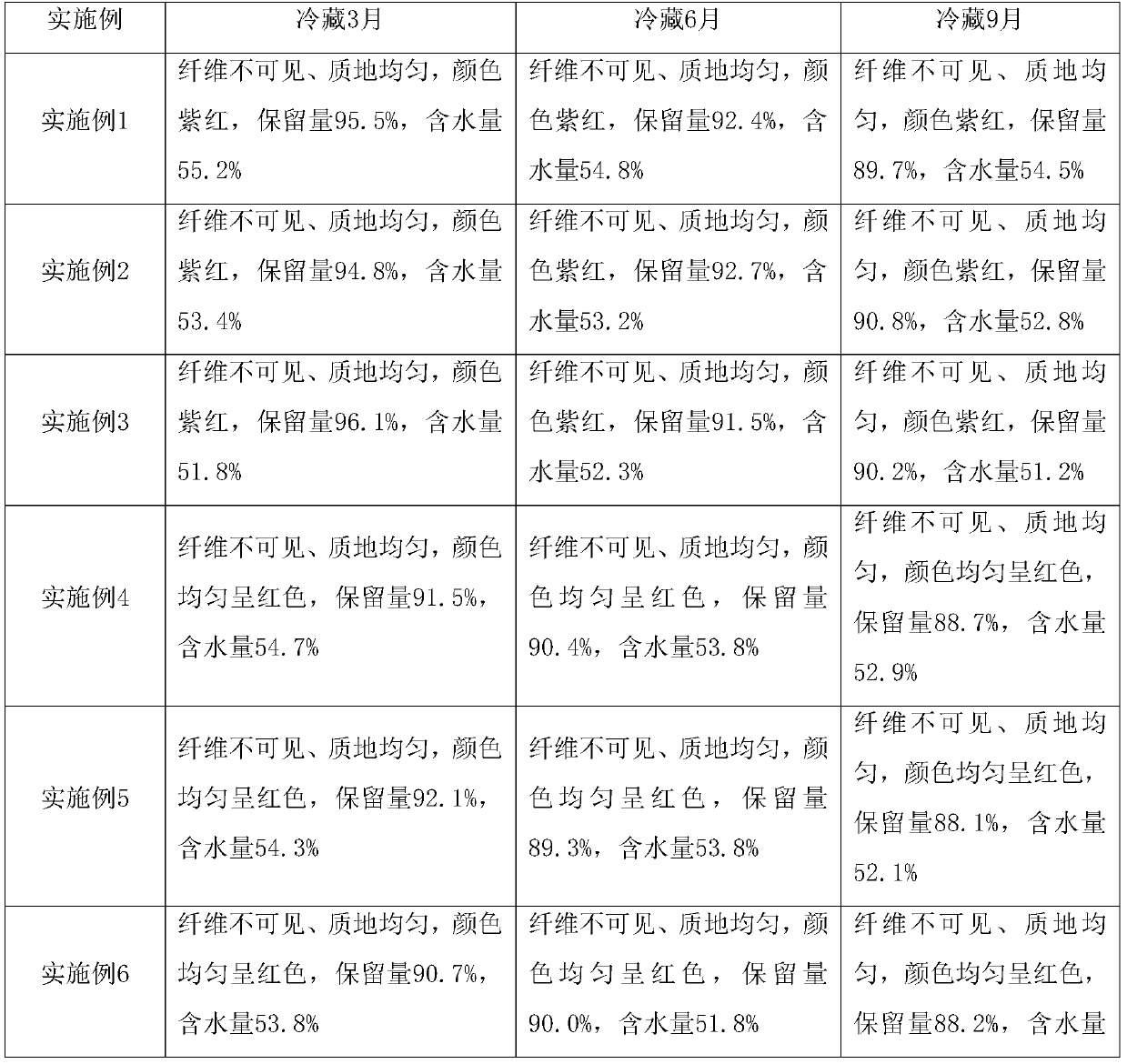

Embodiment 1

[0050] A processing technology of high-pigment mash potato, comprising the following steps:

[0051] S1 into mud:

[0052] Wash the purple sweet potato and slice it, and steam it for 10 minutes to get cooked slices, collect the steaming water for later use, then use a ribbon mixer to fully mix the cooked slices, and use steaming water to adjust its water content at the same time to 85%, and then processed by a hammer crusher to obtain precooked mud;

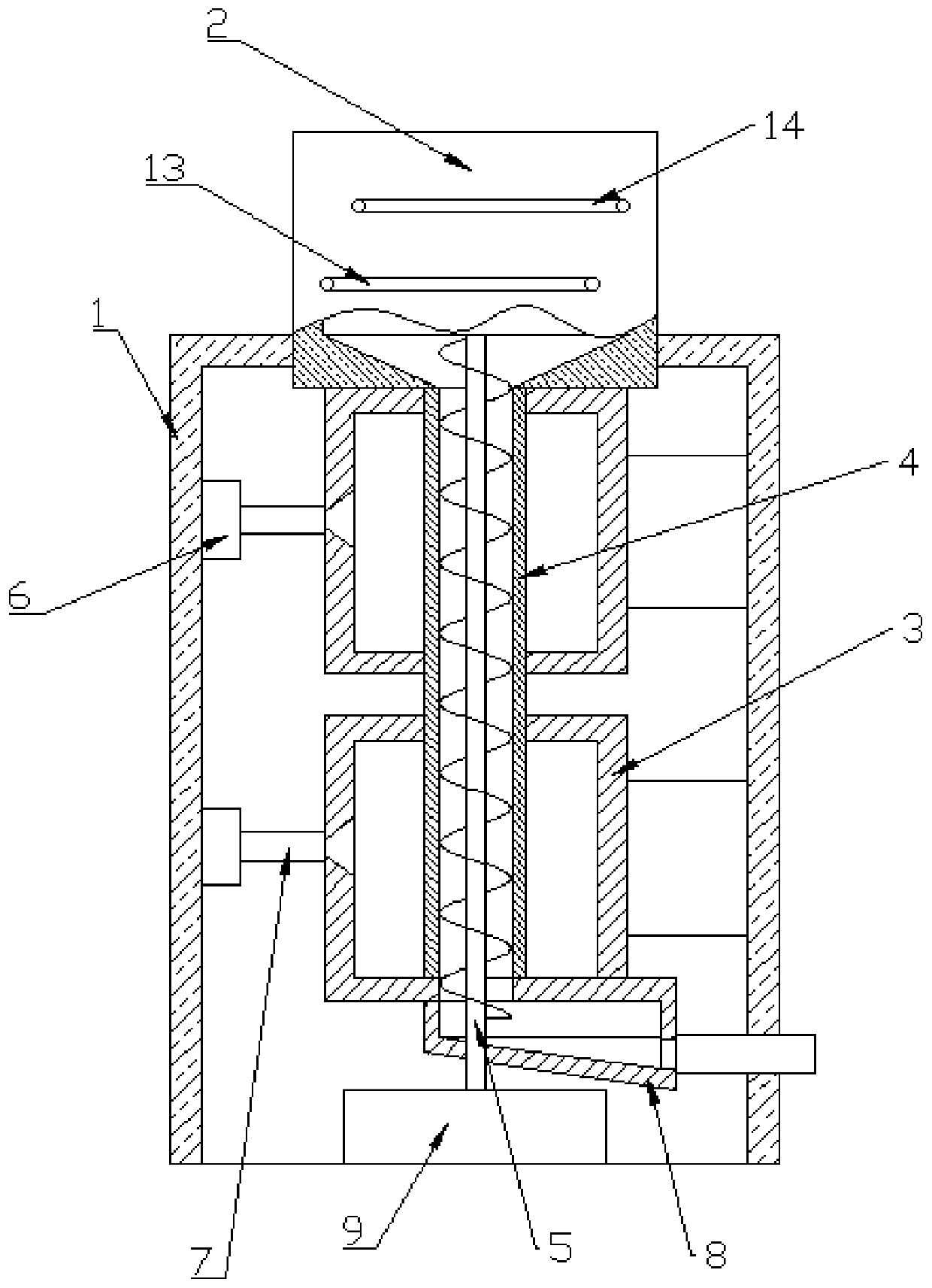

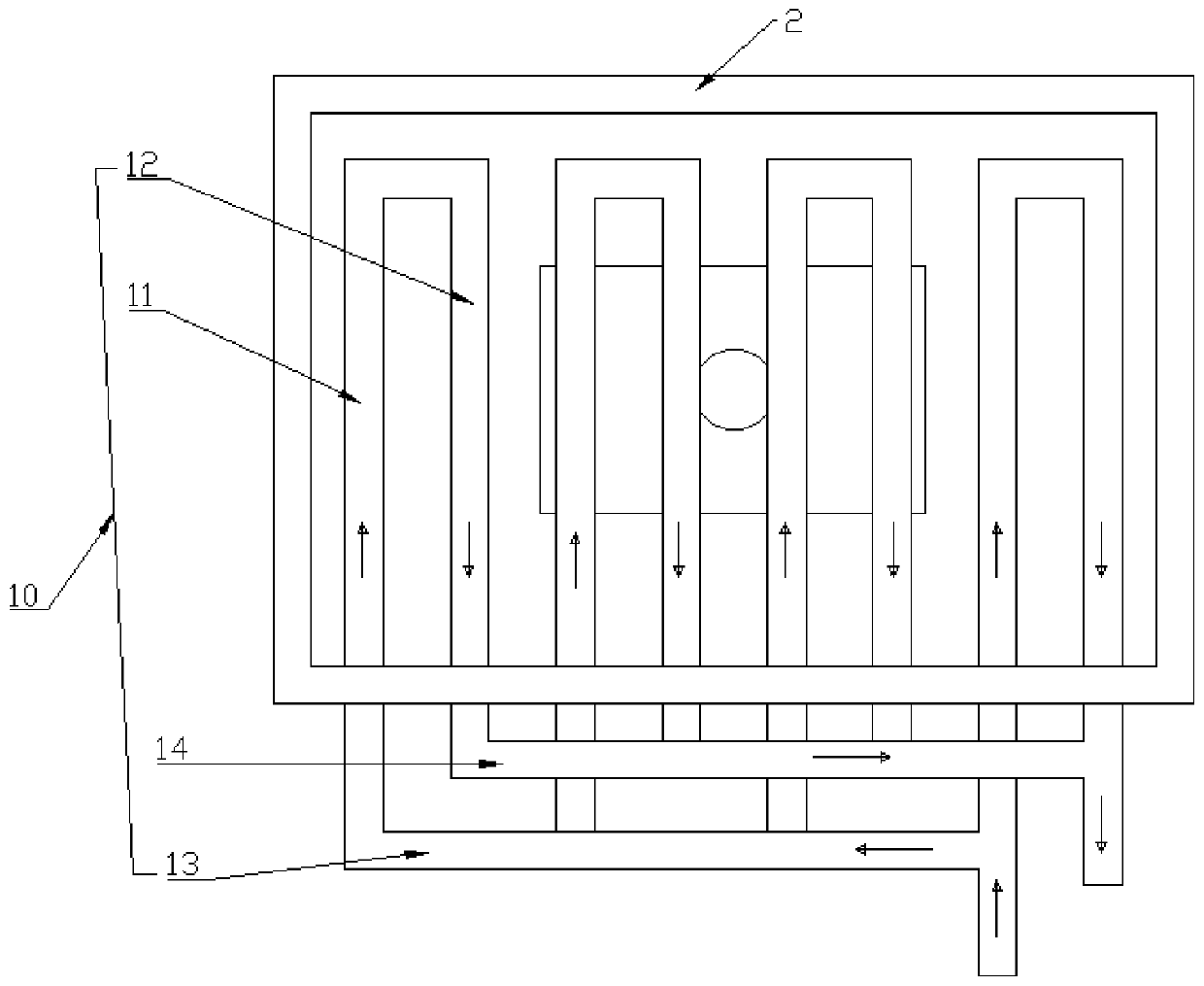

[0053] S2 microwave curing:

[0054] The precooked mud is subjected to the following subsection heating:

[0055] The first stage: from room temperature to 60°C, using a tubular heat exchange tube: the temperature of the medium (water) in the tube is 80°C, and the precooked mud is placed outside the tube;

[0056] The second stage: to 90°C, using microwave heating: the pre-cooked mud obtained in the first stage is introduced into the feeding pipe in a microwave environment with a power of 55kw for heating;

[0057] The third ...

Embodiment 2

[0062] A processing technology of high-pigment mash potato, comprising the following steps:

[0063] S1 into mud:

[0064] Wash the purple sweet potato and slice it, and steam it for 15 minutes to get cooked slices, collect steaming water for later use, then use a ribbon mixer to fully mix the cooked slices, and use steaming water to adjust its water content at the same time to 82%, and then processed by a hammer crusher to obtain pre-cooked mud;

[0065] S2 microwave curing:

[0066] The precooked mud is subjected to the following subsection heating:

[0067] The first stage: from room temperature to 65°C, using a tubular heat exchange tube: the temperature of the medium (water) in the tube is 85°C, and the precooked mud is placed outside the tube;

[0068] The second stage: to 95°C, using microwave heating: the pre-cooked mud obtained in the first stage is introduced into the feeding pipe in a microwave environment with a power of 60kw for heating;

[0069] The third sta...

Embodiment 3

[0074] A processing technology of high-pigment mash potato, comprising the following steps:

[0075] S1 into mud:

[0076] Wash the purple sweet potato and slice it, and steam it for 20 minutes to get cooked slices, collect the steaming water for later use, then use a ribbon mixer to fully mix the cooked slices, and use steaming water to adjust its water content at the same time to 80%, and then processed by a hammer crusher to obtain precooked mud;

[0077] S2 microwave curing:

[0078] The precooked mud is subjected to the following subsection heating:

[0079] The first stage: from room temperature to 70°C, using a tubular heat exchange tube: the temperature of the medium (water) in the tube is 90°C, and the precooked mud is placed outside the tube;

[0080] The second stage: to 100°C, using microwave heating: the precooked mud obtained in the first stage is introduced into the feeding pipe in a microwave environment with a power of 65kw for heating;

[0081] The third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com