Method and system for producing clean coal by coupling power generation in a power plant

A power plant, clean technology, applied in the direction of steam generation using heat carrier, energy input, etc., to achieve the effect of reducing pollutant emissions, reducing coal consumption, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

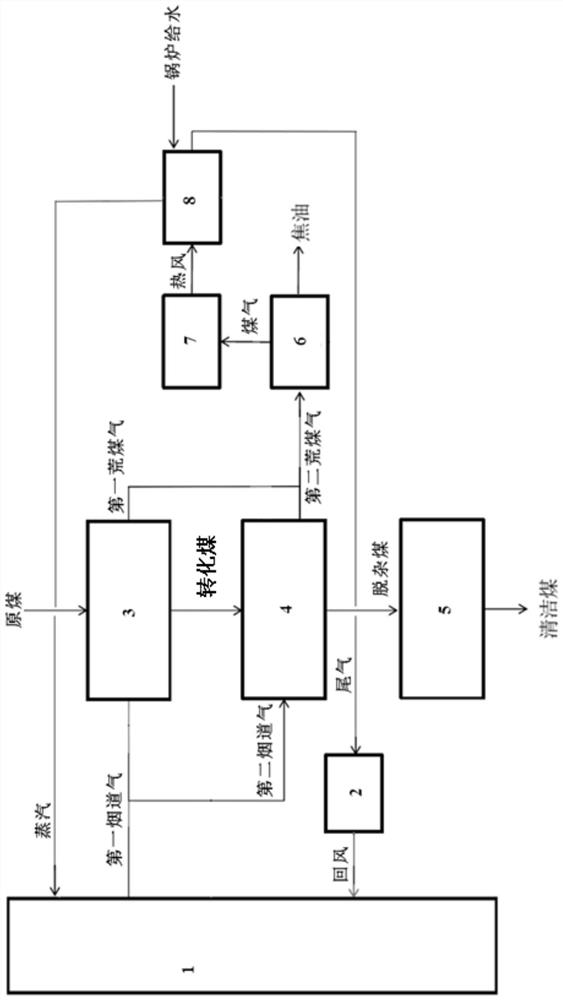

Method used

Image

Examples

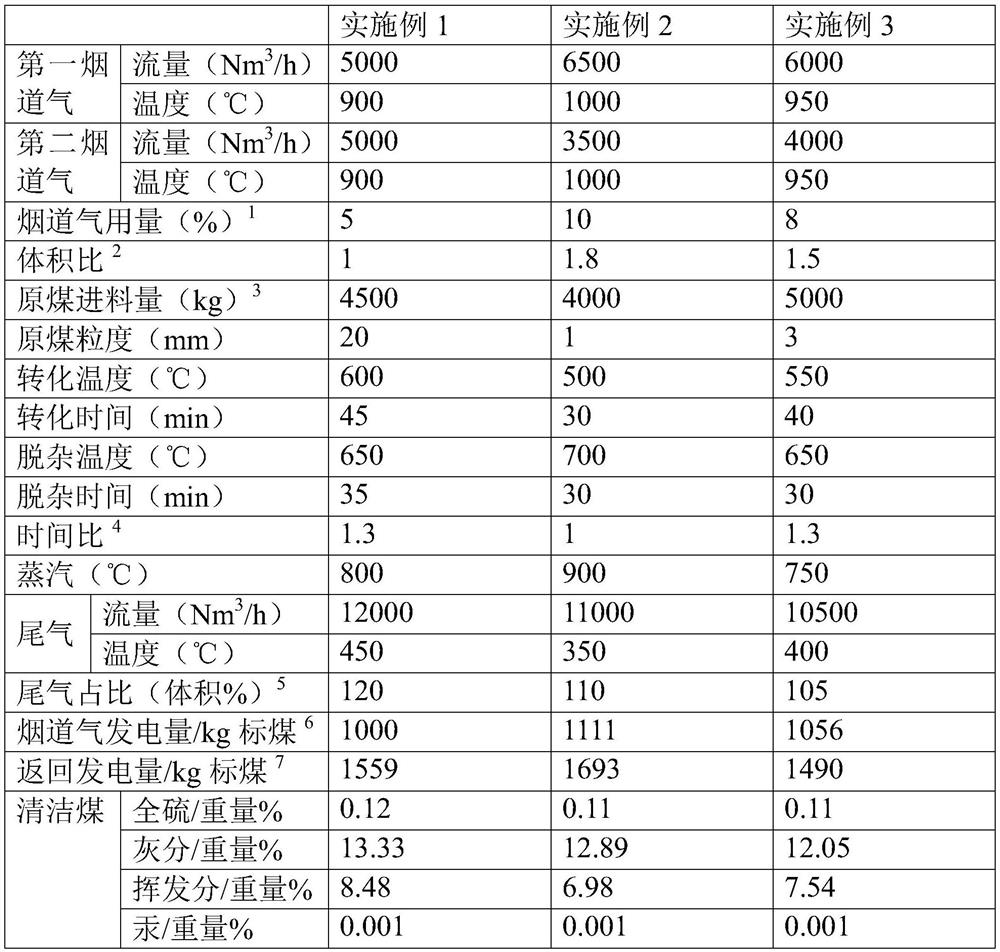

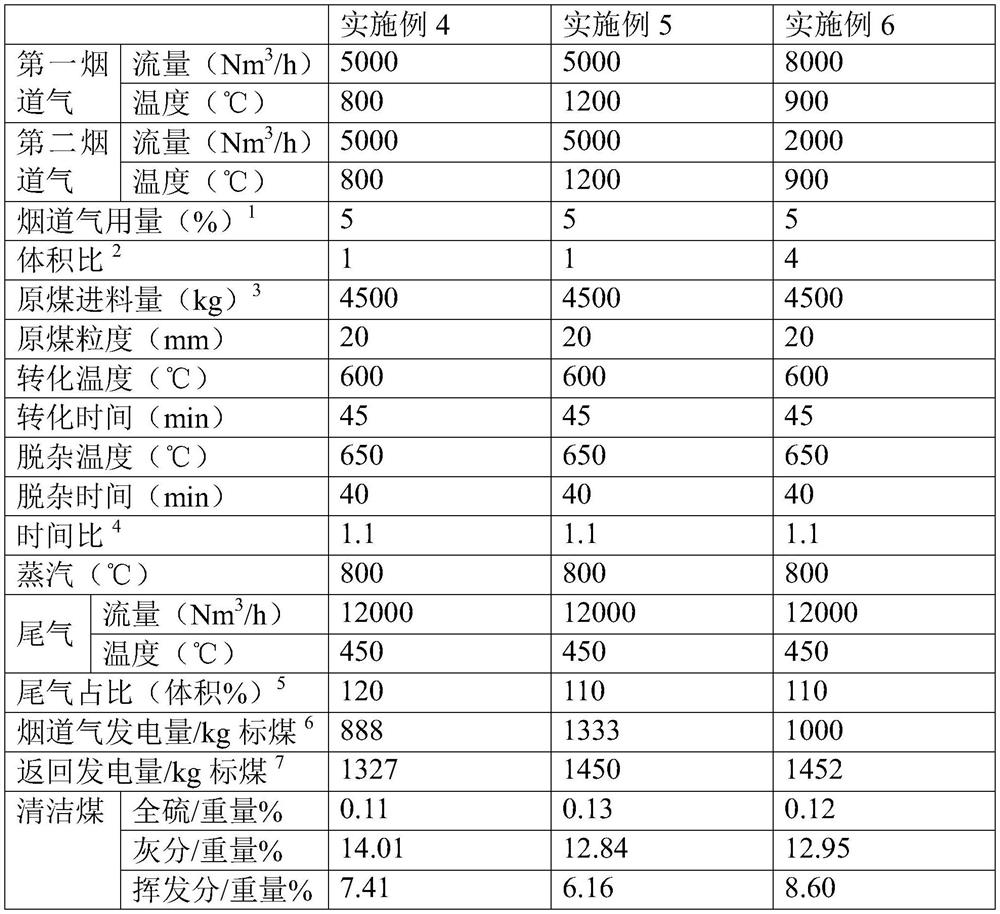

Embodiment 1

[0075] (1) put 5000Nm 3 / h of the first flue gas (900°C) and 4500kg of raw coal (lignite, particle size 20mm) are directly contacted in a countercurrent manner in the rotary kiln, and the coal conversion is carried out for 45min, and the final conversion temperature is 600°C, and the first raw coal is obtained. gas and converted coal;

[0076] (2) put 5000Nm 3 The second flue gas (900°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 35 minutes. The final decontamination temperature is 650°C to obtain the second raw coal gas and decontaminated coal;

[0077] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0078] (4) After the first and second raw coal gas are combined, tar is removed to obtain a tar product; at the same time, the obtained coal gas is passed into a co-firing furnace for combustion, and the hot air obtained is passed into a waste heat boiler to generate ste...

Embodiment 2

[0082] (1) Will 6500Nm 3 / h of the first flue gas (1000°C) and 4000kg of raw coal (non-caking coal, particle size of 1mm) are directly contacted in a fluidized bed in a countercurrent manner, and the coal conversion is carried out for 30 minutes, and the final conversion temperature is 500°C. The first raw gas and converted coal;

[0083] (2) 3500Nm 3 The second flue gas (1000°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 30 minutes, and the final decontamination temperature is 700°C to obtain the second raw gas and decontaminated coal;

[0084] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0085] (4) After the first and second raw coal gas are combined, tar is removed to obtain a tar product; at the same time, the obtained coal gas is passed into a co-firing furnace for combustion, and the hot air obtained is passed into a waste heat boiler to generate steam and ...

Embodiment 3

[0089] (1) Will 6000Nm 3 / h of the first flue gas (950°C) and 5000kg of raw coal (long-flame coal, particle size 3mm) are directly contacted in a countercurrent manner in the moving bed, and the coal conversion is carried out for 40 minutes, and the final conversion temperature is 550°C, and the first - raw gas and converted coal;

[0090] (2) 4000Nm 3 The second flue gas (950°C) per hour is in direct contact with the converted coal in a countercurrent manner in the rotary kiln, and the coal is decontaminated for 30 minutes, and the final decontamination temperature is 650°C to obtain the second raw coal gas and decontaminated coal;

[0091] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0092] (4) After the first and second raw coal gas are combined, tar is removed to obtain a tar product; at the same time, the obtained coal gas is passed into a co-firing furnace for combustion, and the hot air obtained is passed into a waste heat boiler to generate steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com