Furnace temperature control method for coping with blast furnace thermal load fluctuation

A control method and technology of heat load, which is applied in the temperature control of blast furnace, and controls the temperature of blast furnace through the fluctuation of heat load of blast furnace, so as to achieve the effect of stabilizing the temperature of blast furnace and ensuring the quality of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention are further described below through examples, but the specific embodiments of the present invention are not limited to the following examples.

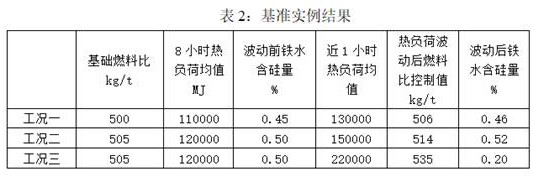

[0020] Firstly, the benchmark example is introduced. The benchmark example is the traditional measurement method, that is, the control method to stabilize the furnace temperature after the thermal load fluctuation of the blast furnace is determined according to the traditional experience.

[0021] Baseline Example

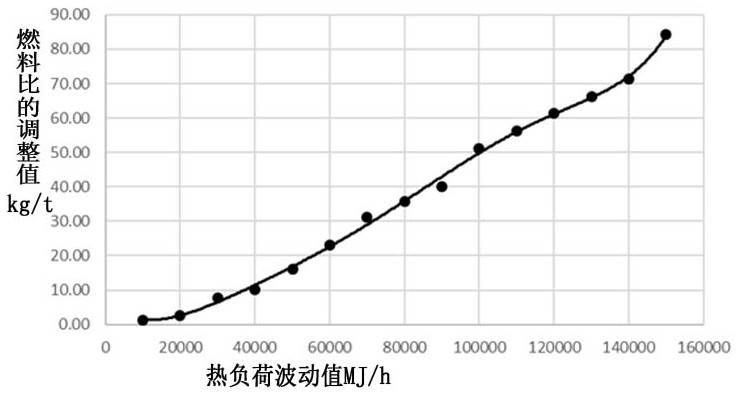

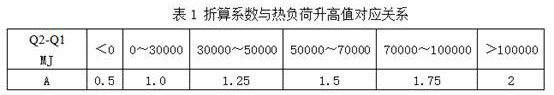

[0022] Under the known three different working conditions, adjust according to the traditional method, every time the heat load of blast furnace fluctuates by 10000MJ, adjust the fuel ratio by 3kg / t, among which working condition one is the normal furnace condition, and working conditions two and three are the occurrence of blast furnace heat load For the relatively fluctuating furnace conditions, the production levels under the three working conditions are the same....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com