Adjuster with accurate mixing ratio

A regulator and mixing ratio technology, which is used in machines/engines, oil supply devices, internal combustion piston engines, etc., can solve the problems of complex structure, large volume, and many connecting parts, achieve low production and maintenance costs, and optimize mixing. Effect, simple and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

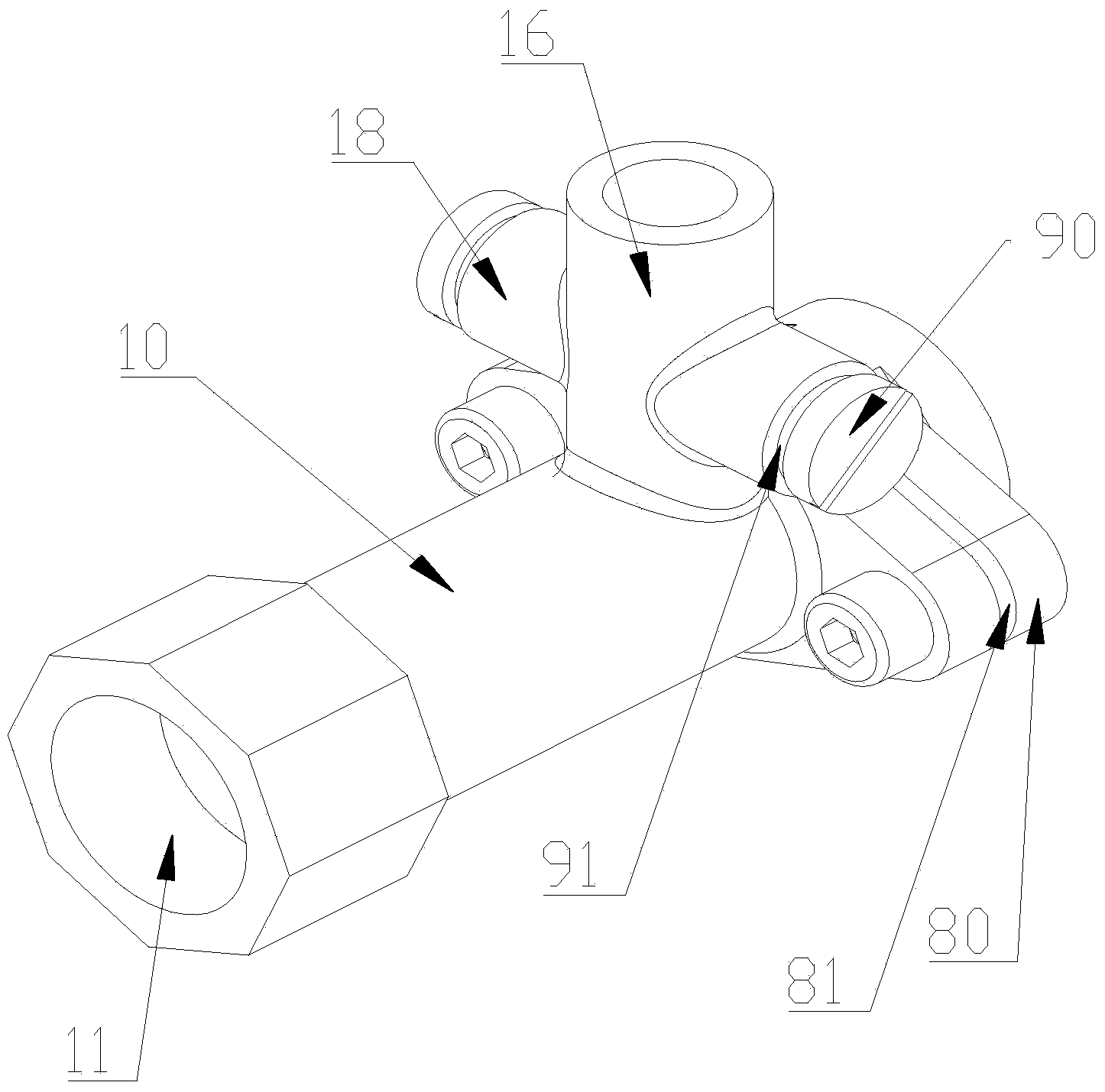

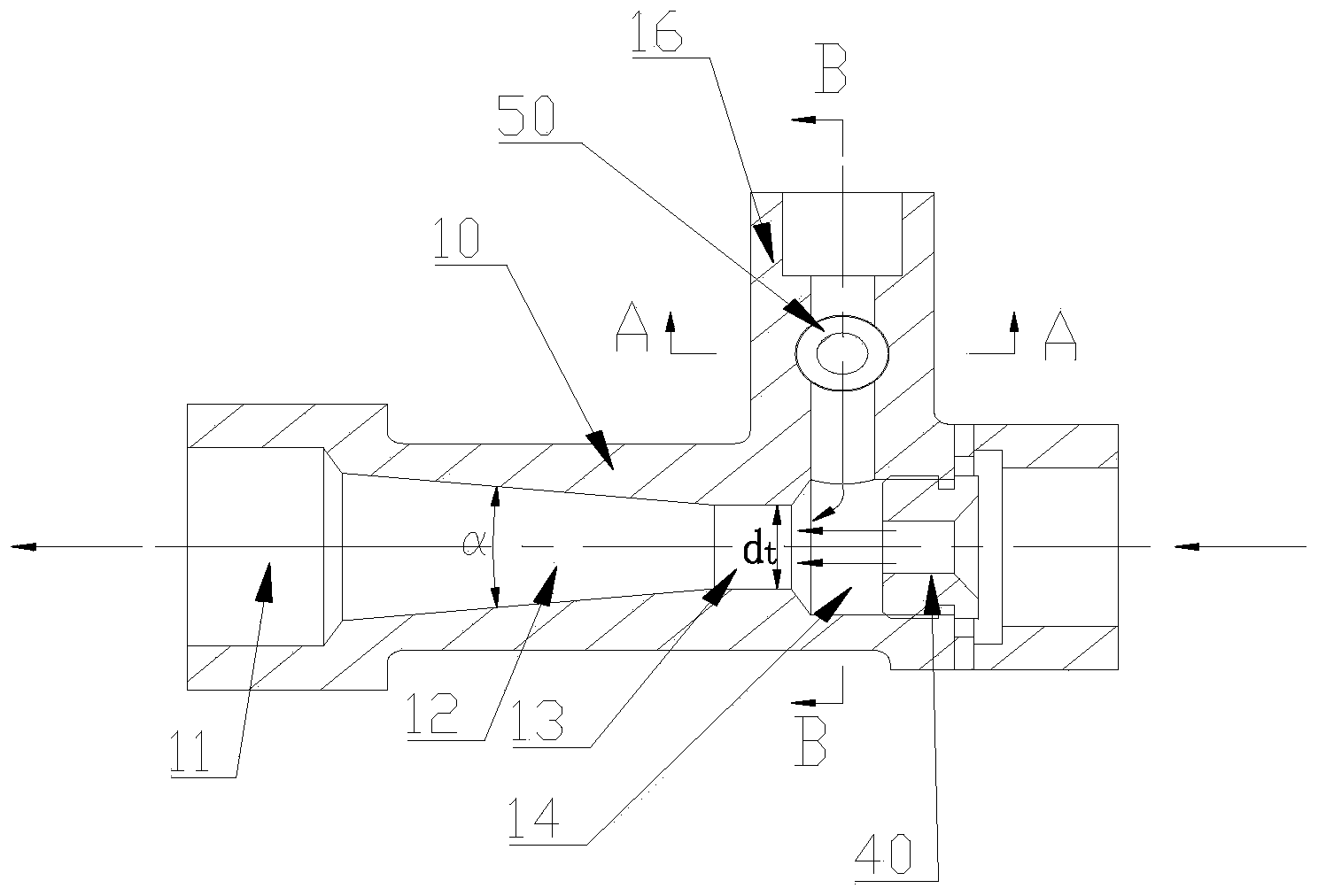

[0023] See Figure 1 to Figure 4 , the present invention relates to a precise mixing ratio regulator, and its preferred embodiment includes a housing 10 and an air nozzle 40 .

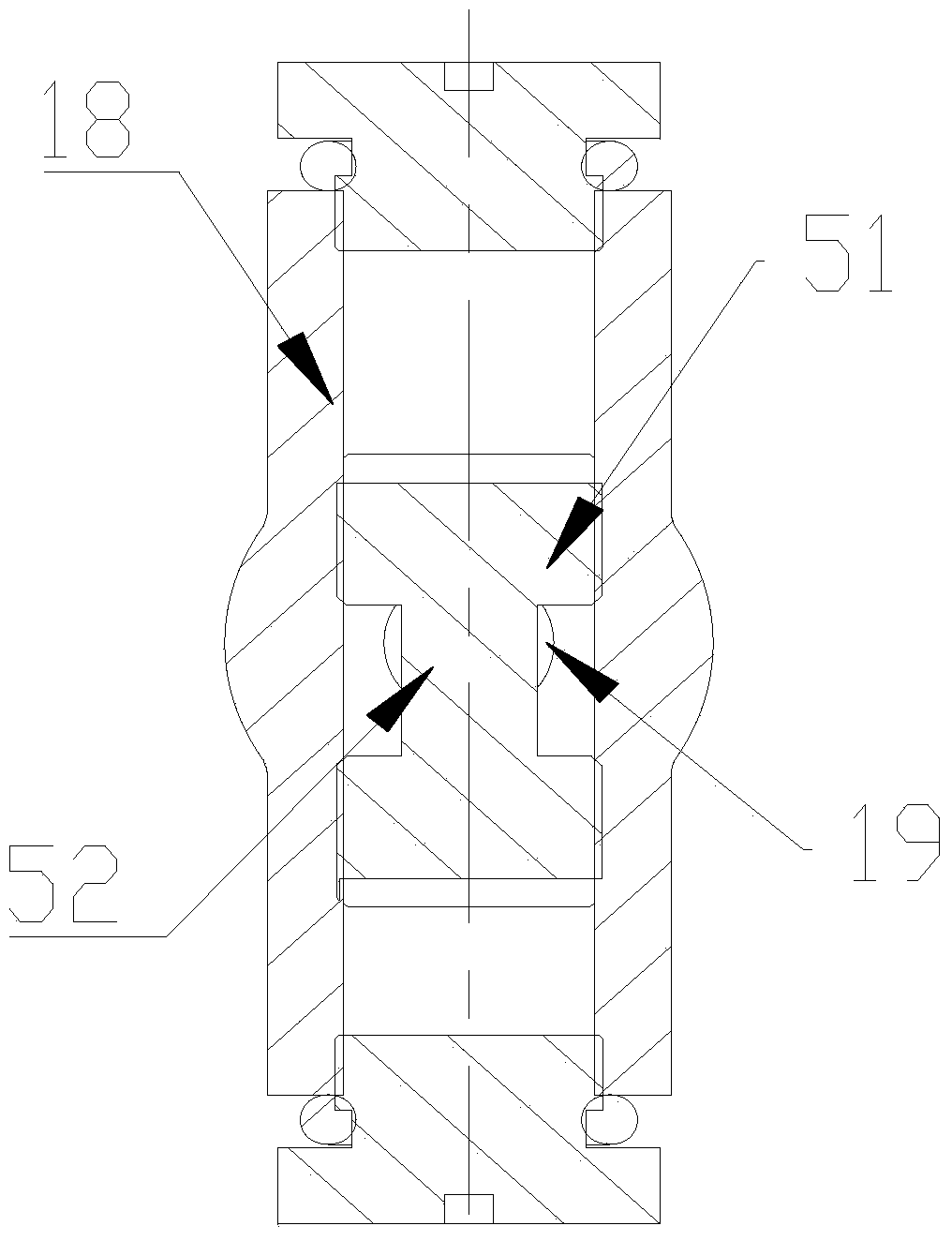

[0024] The housing 10 is provided with a mixed gas outlet 11 , a diffuser mixing chamber 12 , a mixing chamber 13 , a negative pressure chamber 14 and an air inlet which are connected in sequence from left to right. The air nozzle 40 is installed in the air inlet. The top wall of the casing 10 is provided with a gas inlet pipe 16 , and the gas inlet pipe 16 communicates with the negative pressure chamber 14 .

[0025] The air nozzle 40 is used to accelerate the air velocity and increase the air capacity, which can minimize the consumption of air. The air nozzle 40 converts the potential energy of the air into kinetic energy, and utilizes the ejection effect to further eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com