Patents

Literature

84 results about "Sequential injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sequential fuel injection is a type of multi-port fuel injection system in which each injection valve will open just before the cylinder intake valve opens. So in essence, the individual injectors work by themselves because they are fired individually.

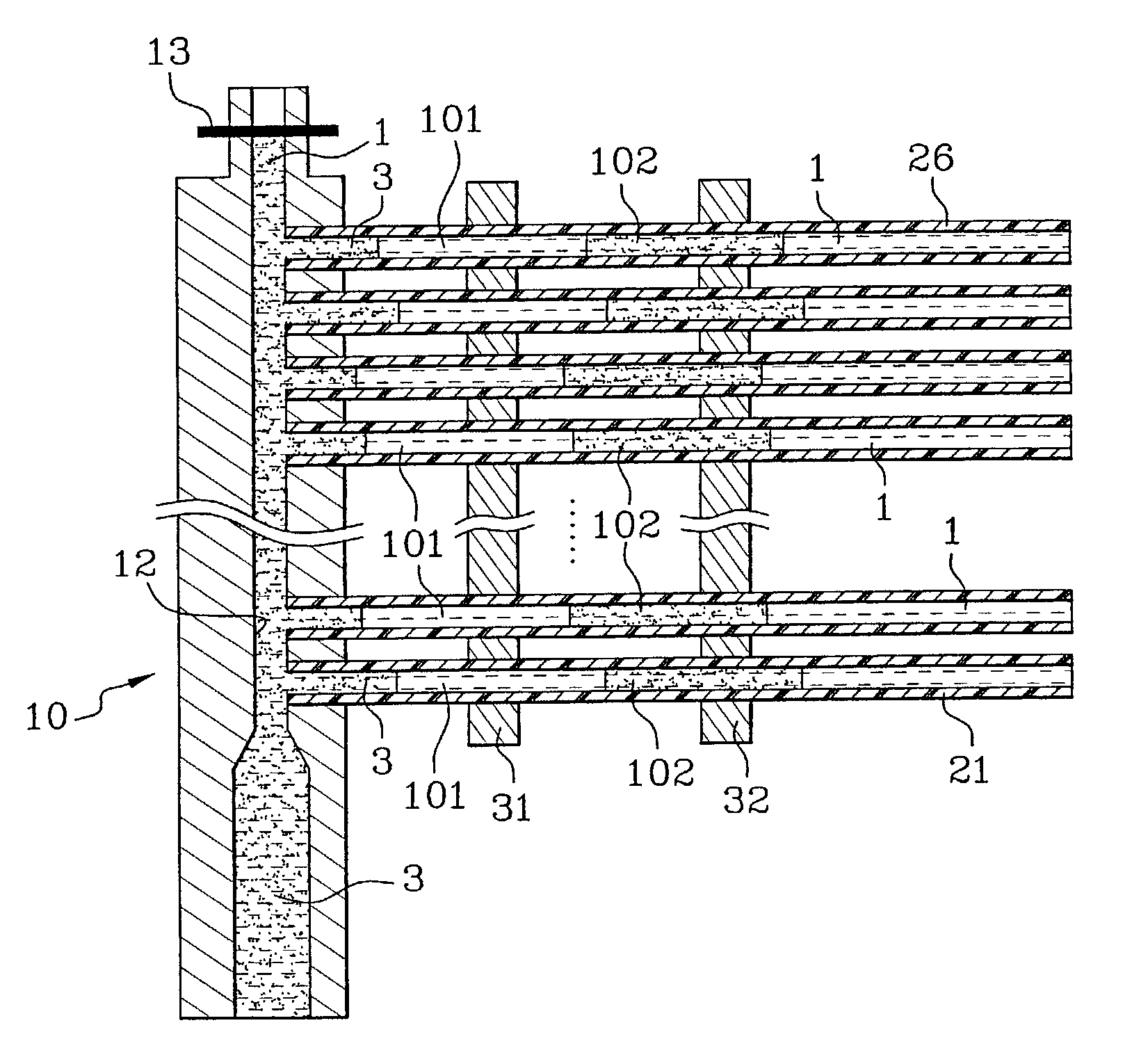

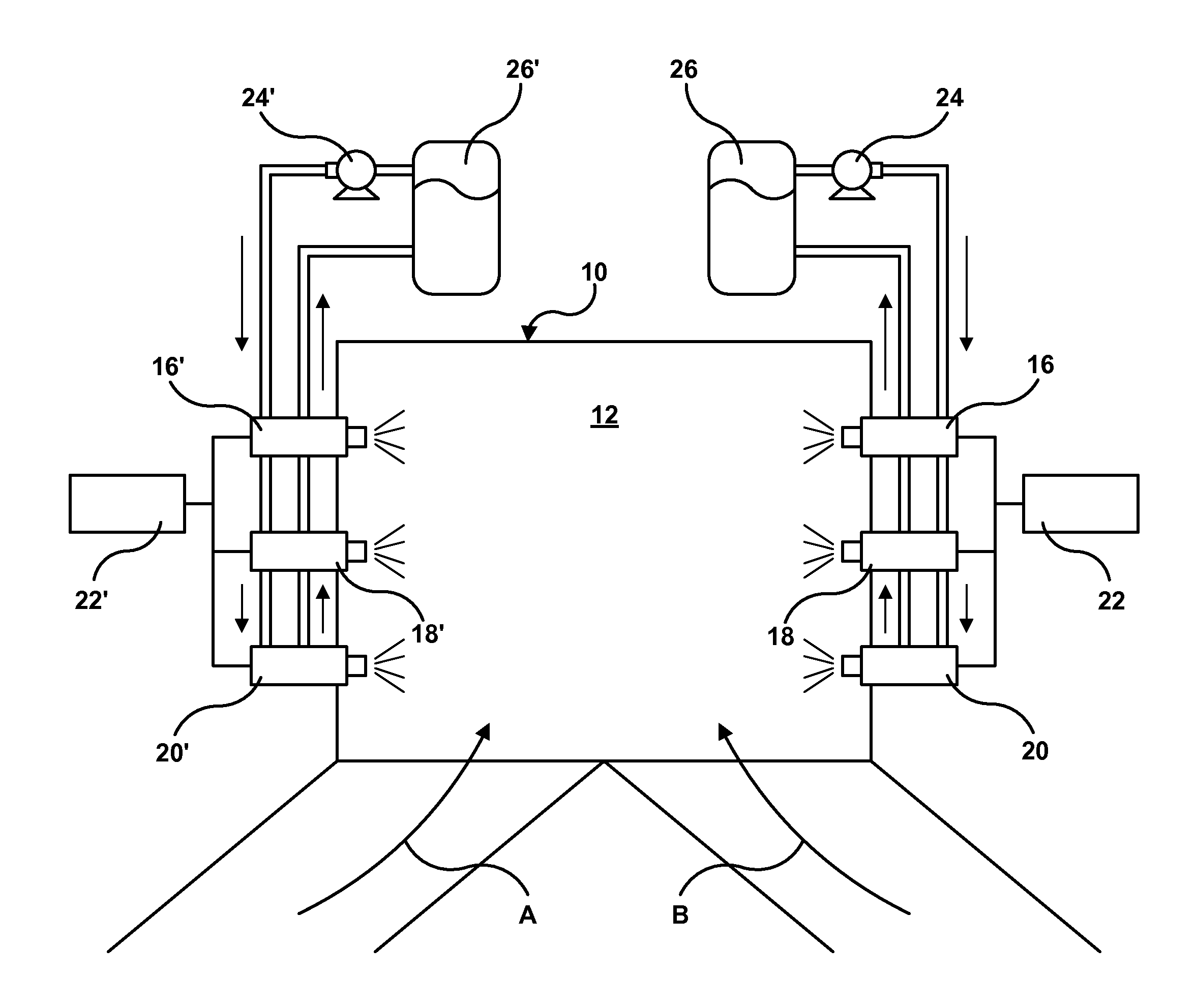

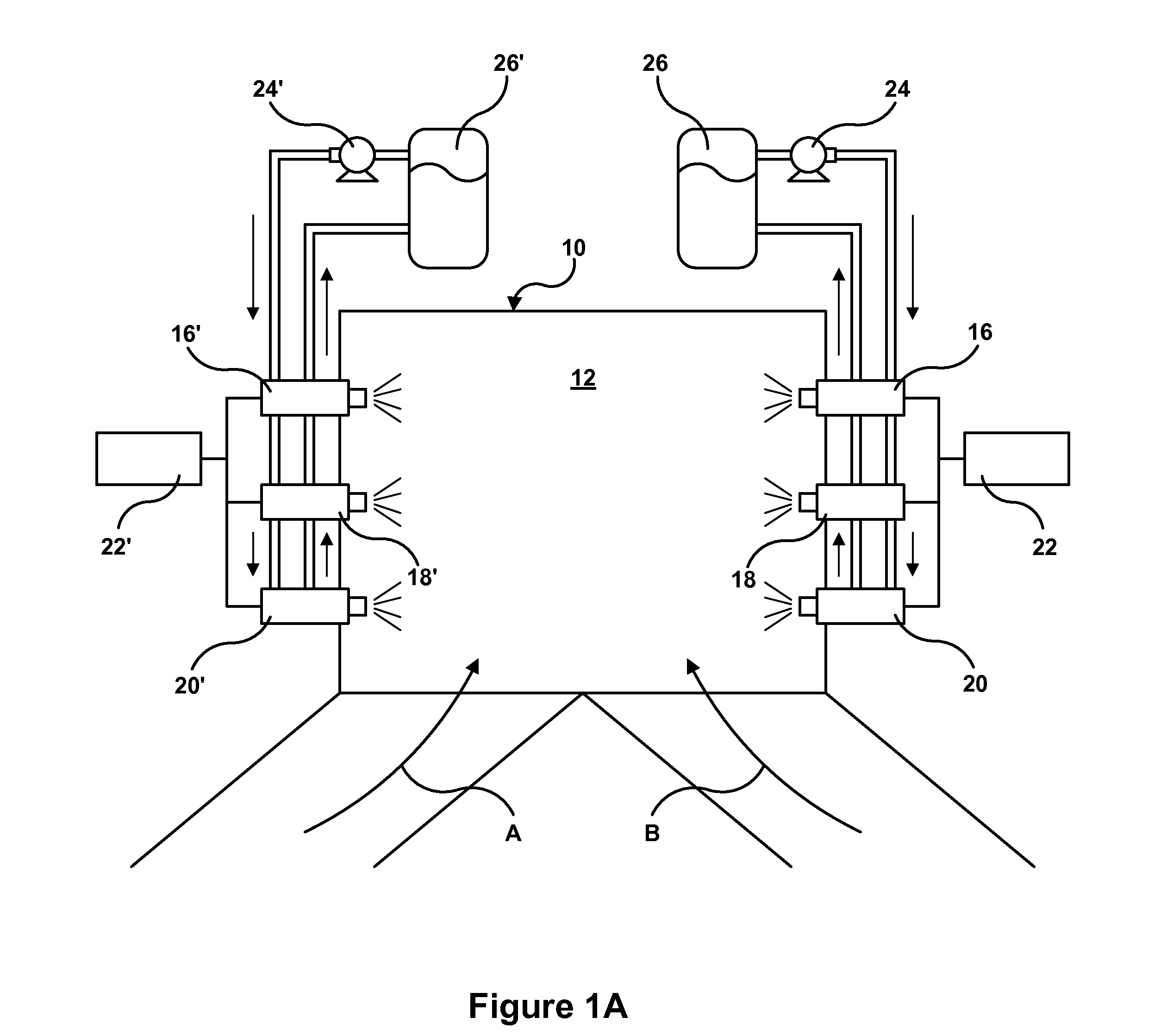

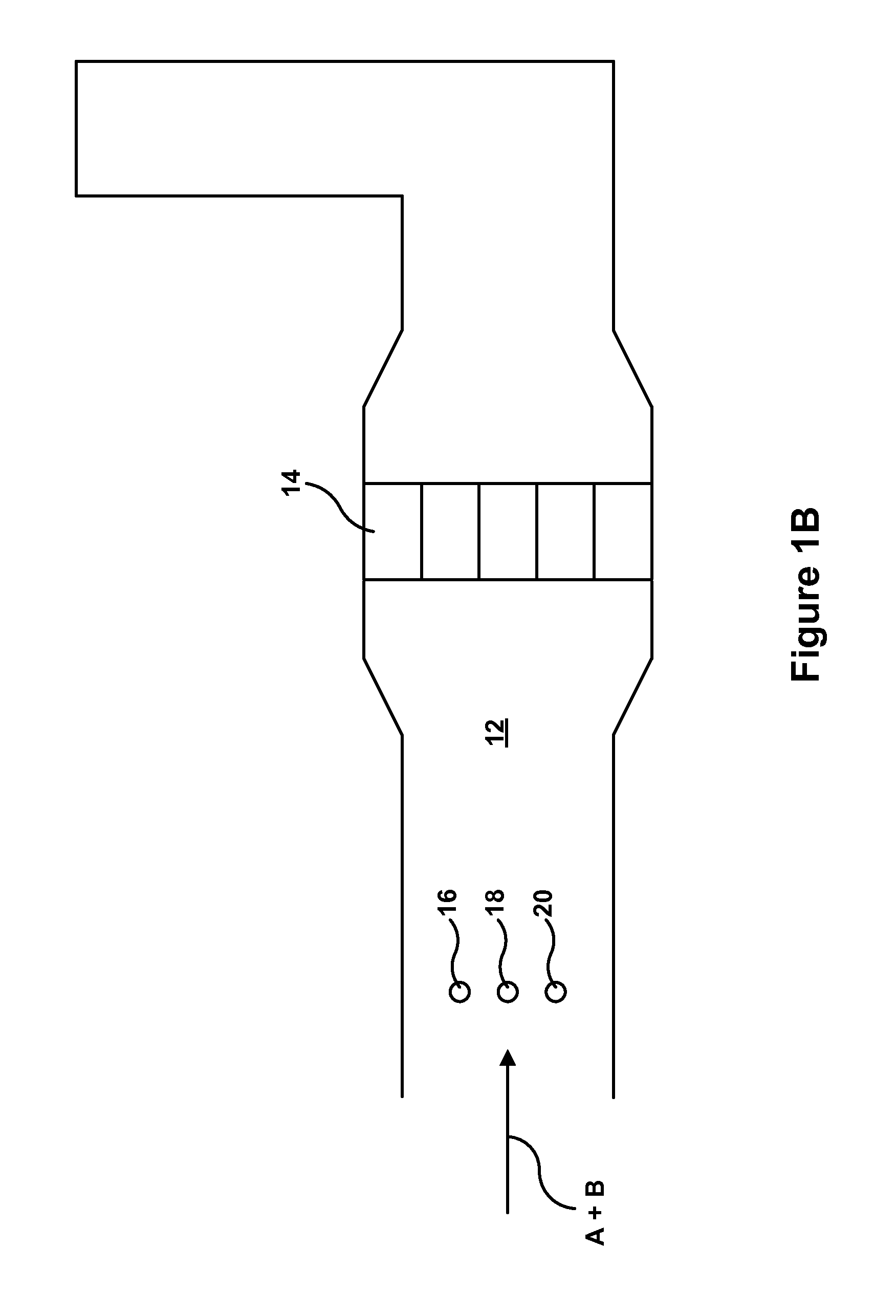

Device for parallel and synchronous injection for sequential injection of different reagents

InactiveUS20030082081A1Exhaust apparatusChemical/physical/physico-chemical microreactorsInjection volumeBiomedical engineering

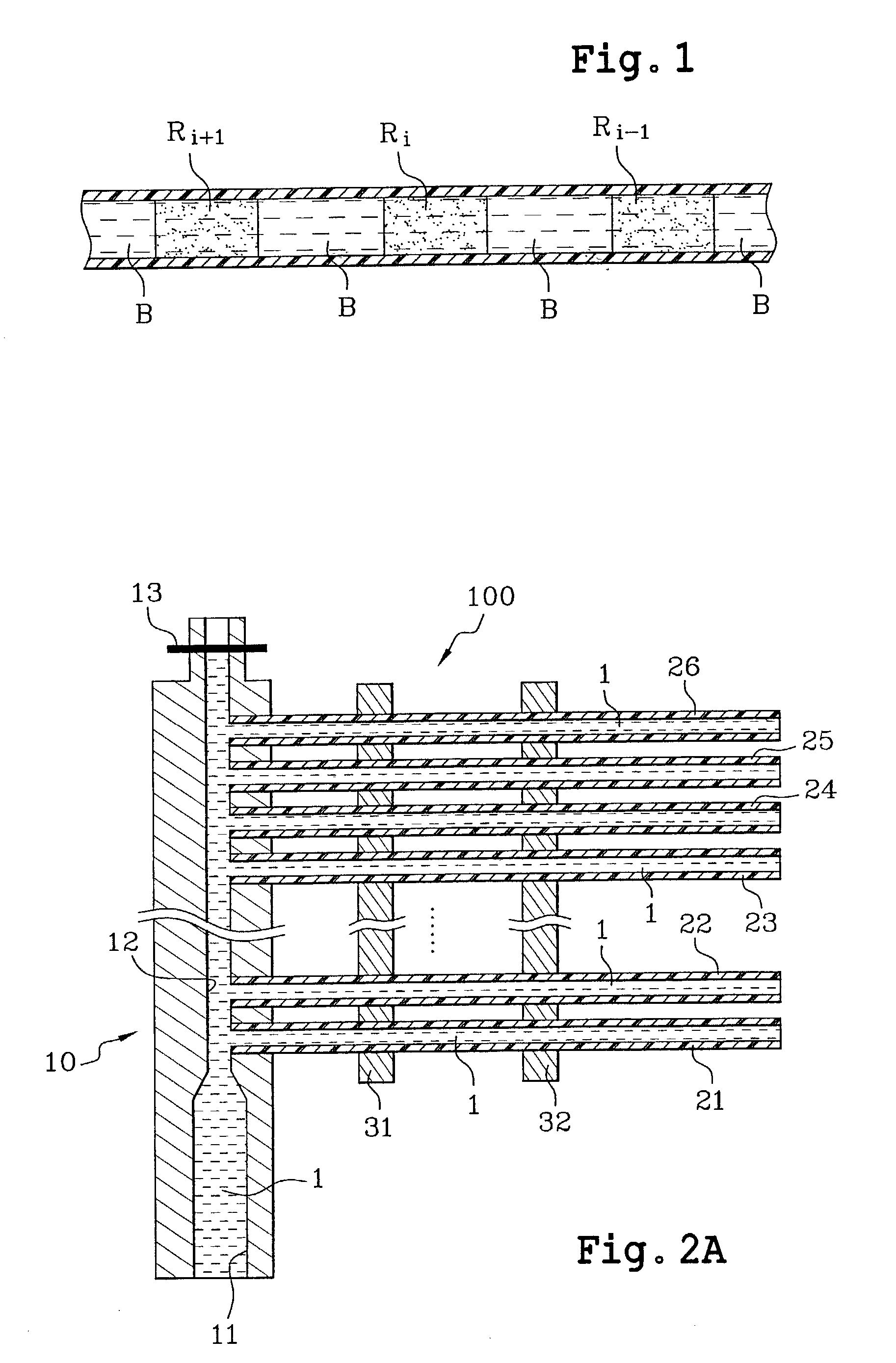

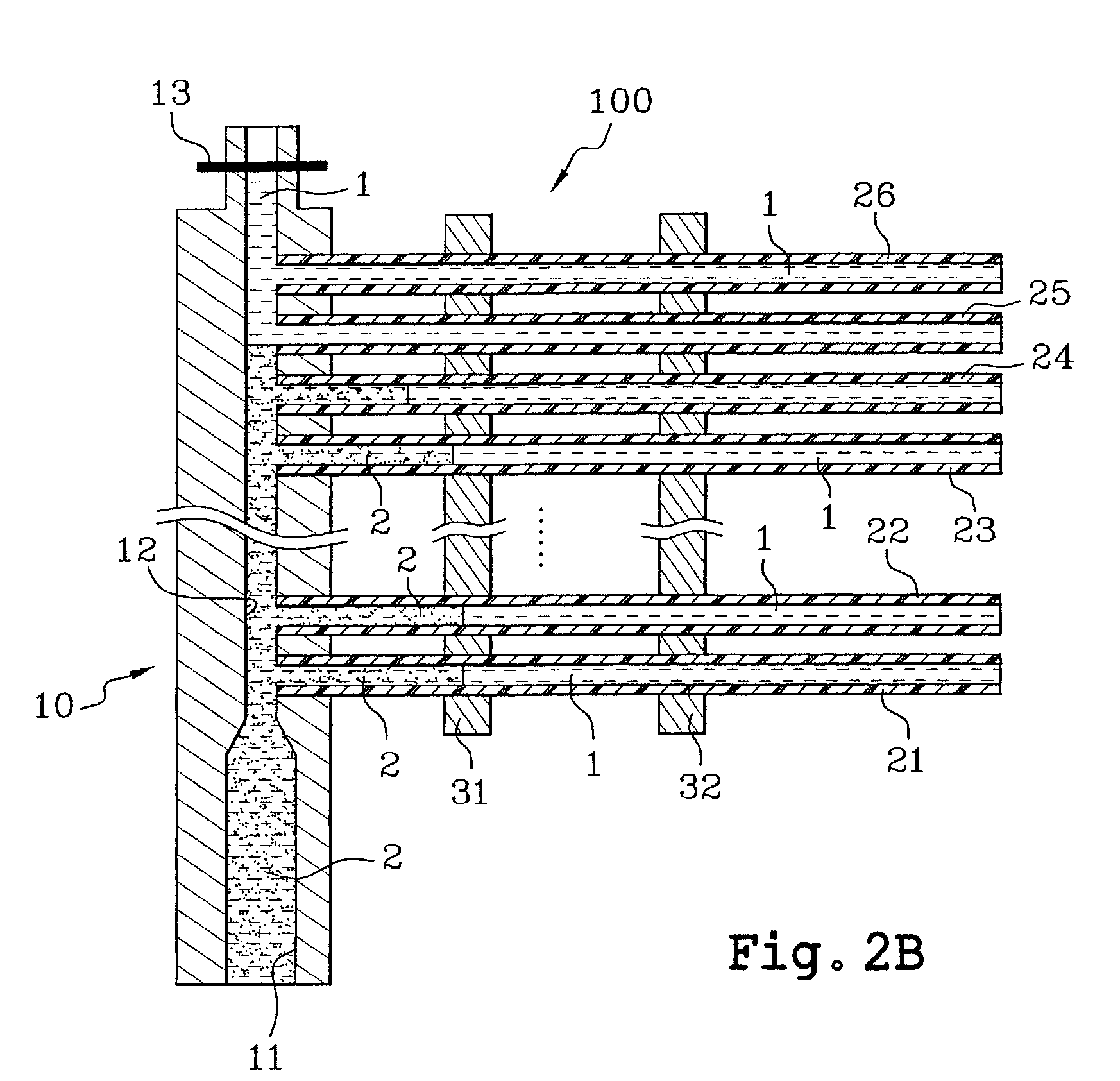

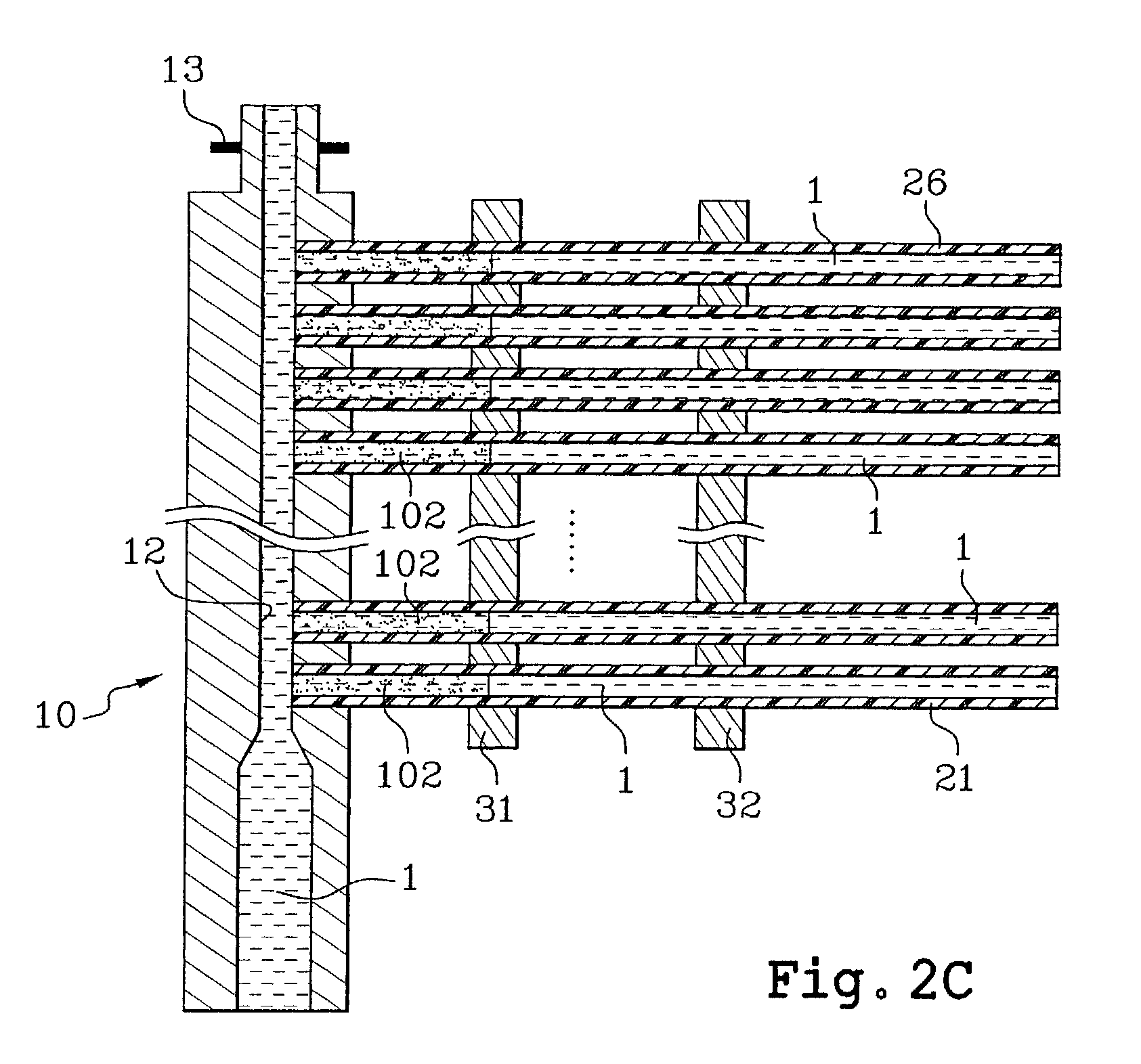

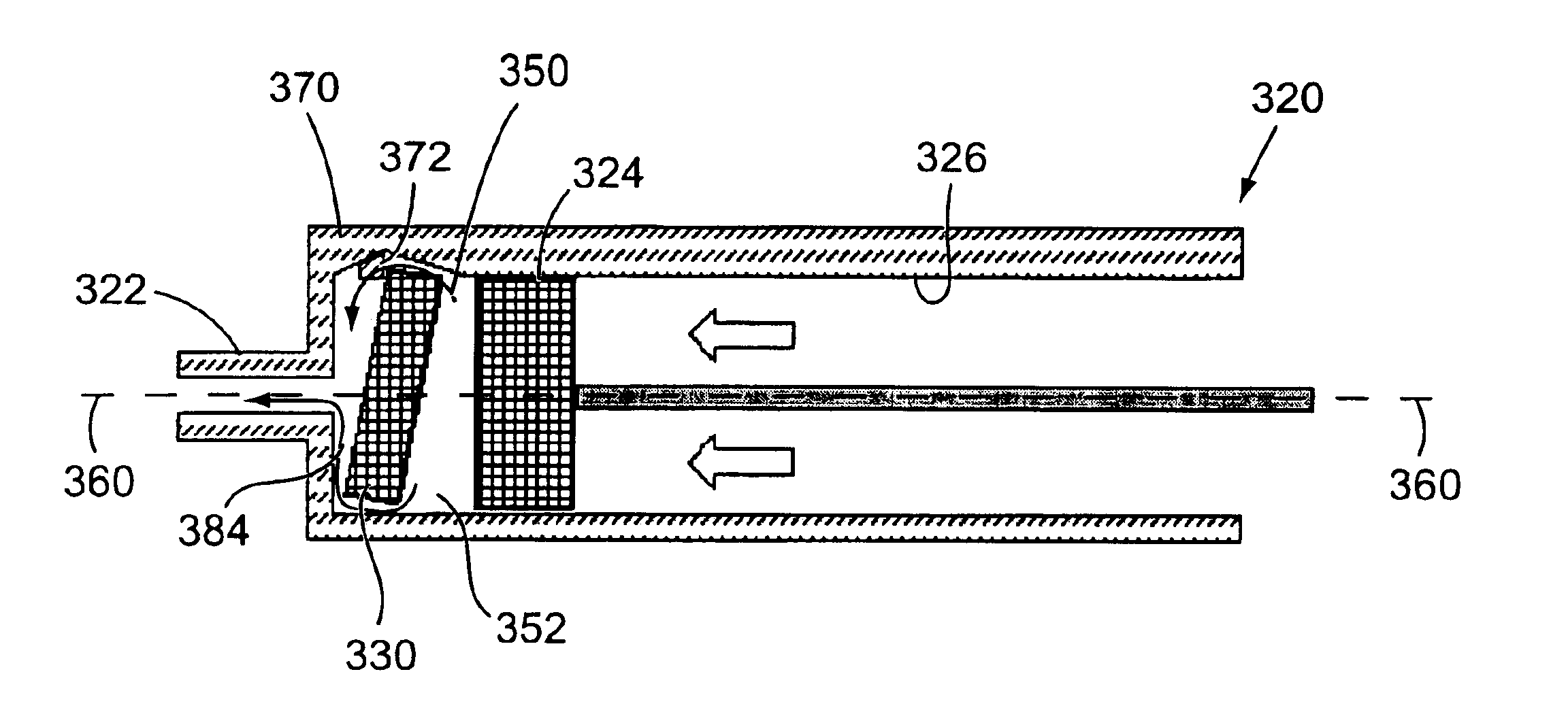

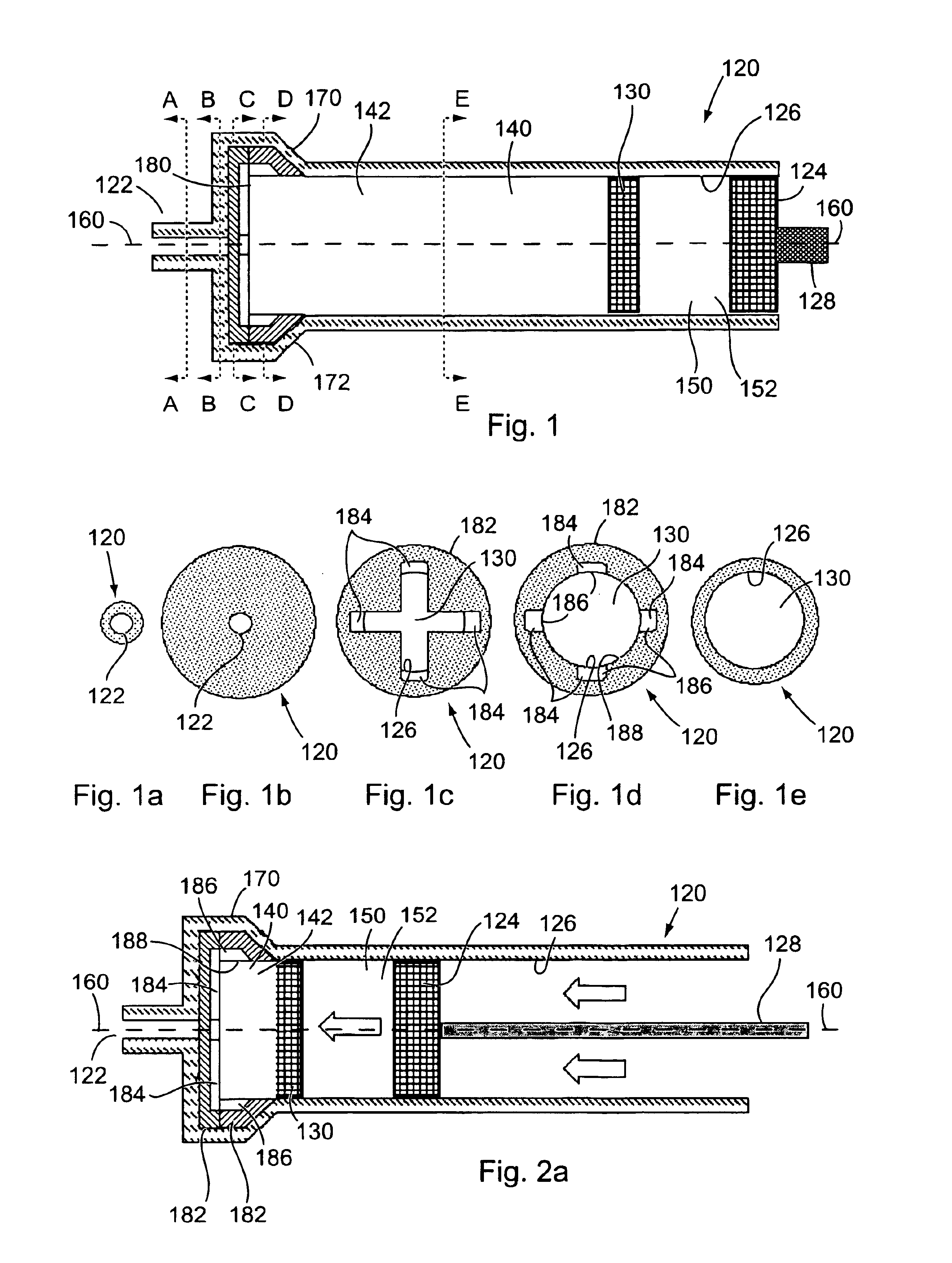

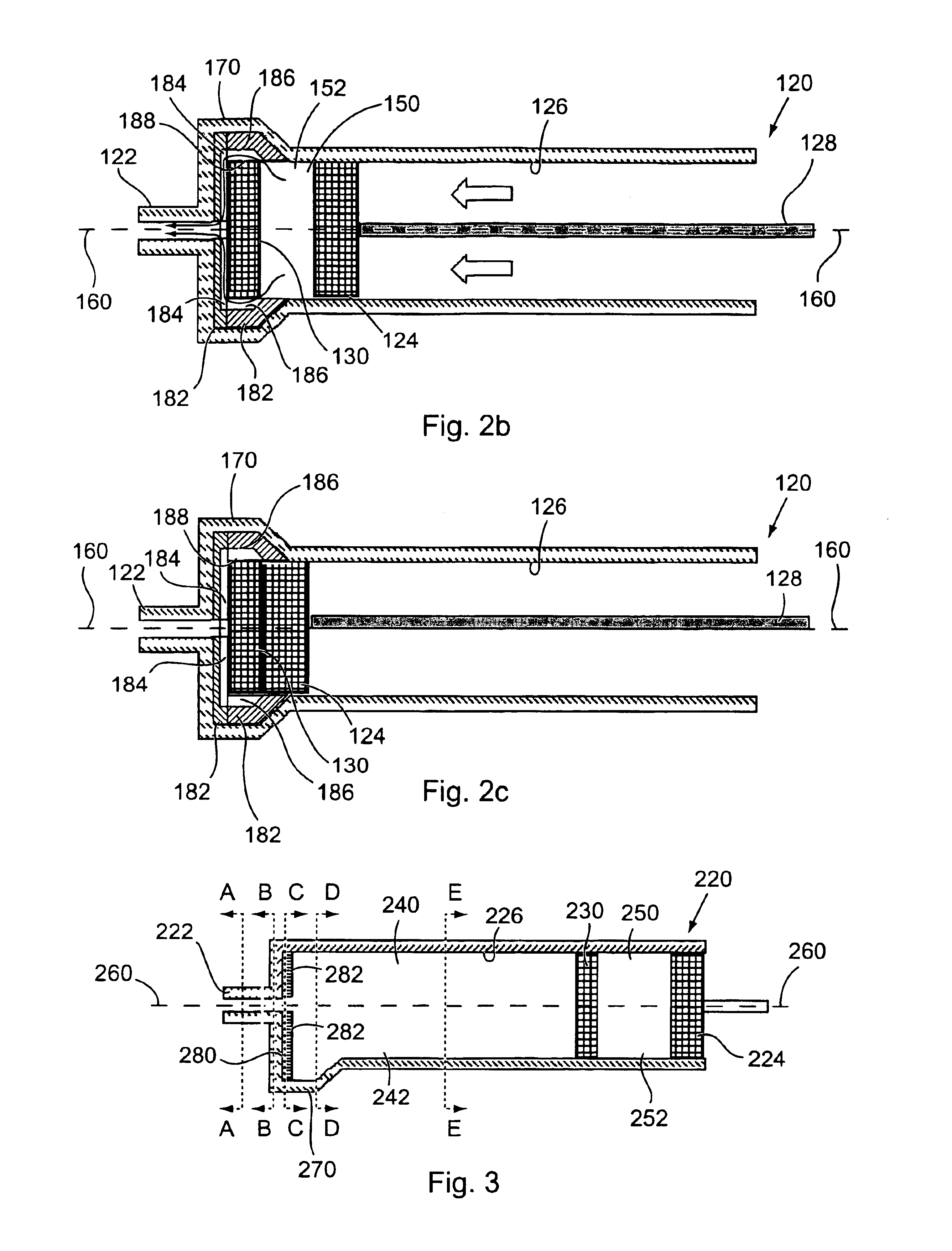

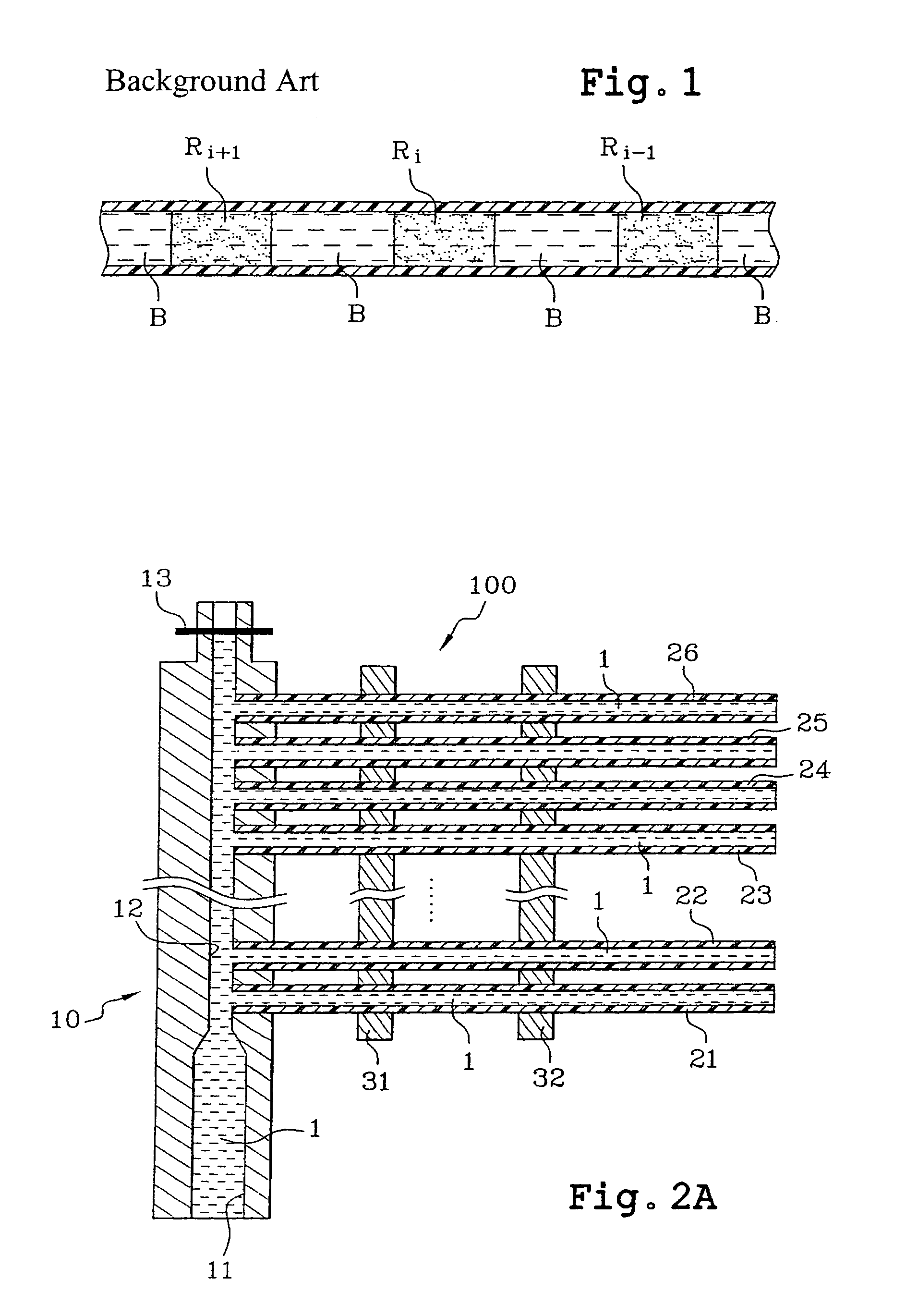

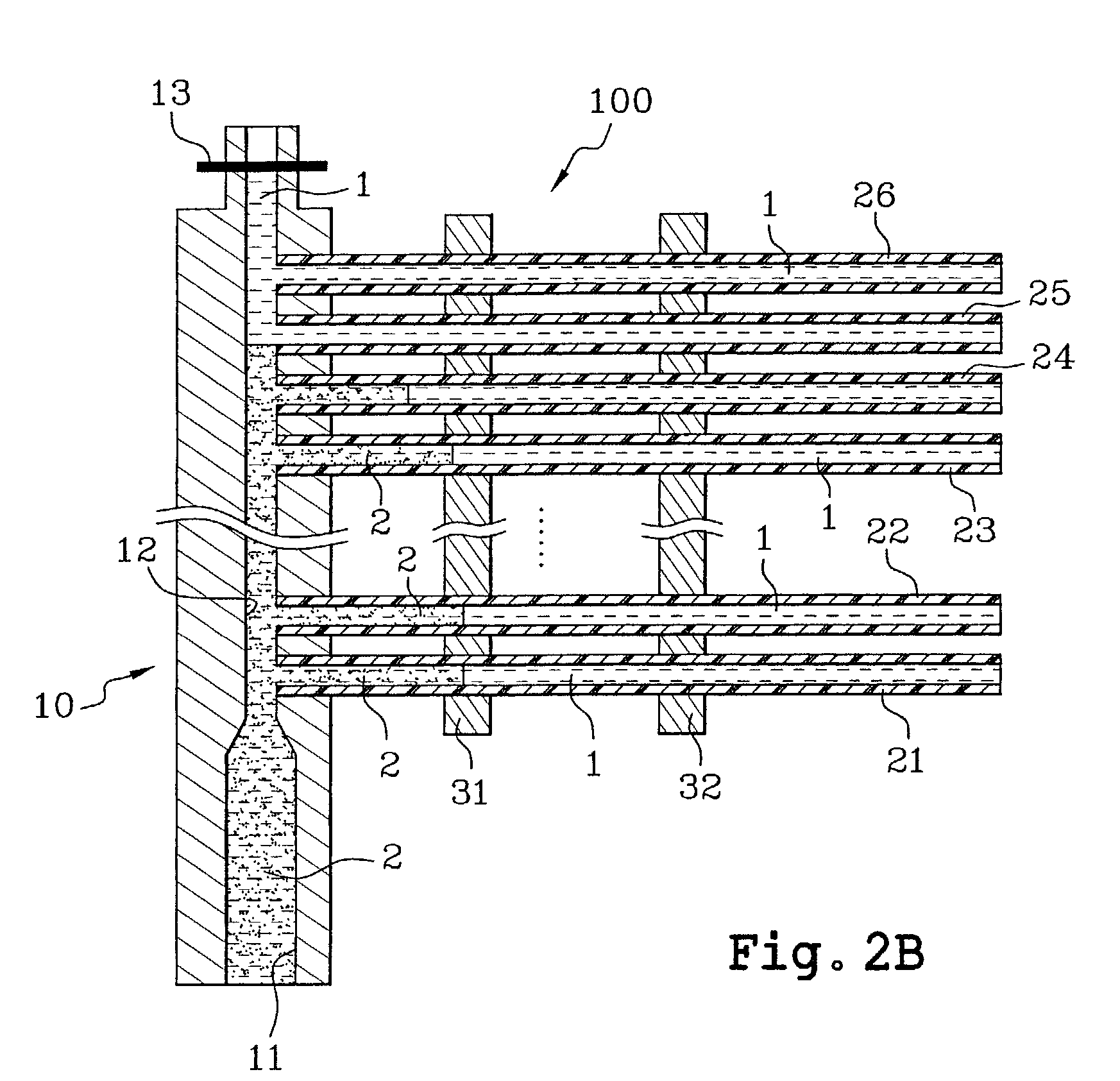

The invention relates to a microfluidic device for injecting series of mobile reaction chambers (102, 103) having non-miscible segmenters (101) in microchannels (21 to 26), comprising: injection means (10) for injecting into microreaction channels alternatingly and in parallel liquid to form mobile reaction chambers and liquid for forming the segmenters; means for controlling the progression of one of the two liquids, applied to act on one zone (31) of each microchannel delimiting an injection volume of said liquid; the control means being able to cause stopping or slowing of the progression of said liquid over the zone of each microchannel by exerting an action based on a physico-chemical property of the liquid and said action not affecting the other liquid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

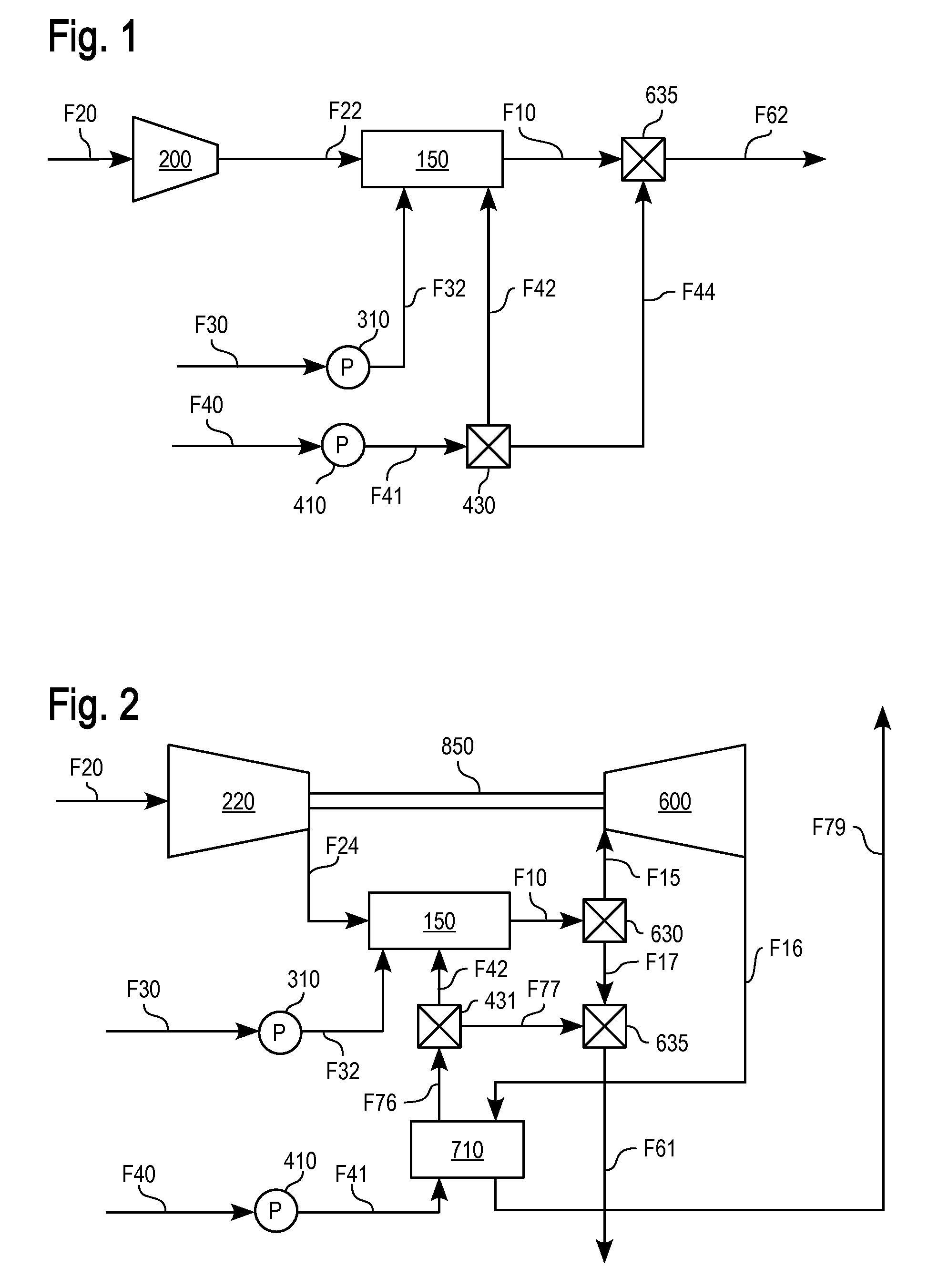

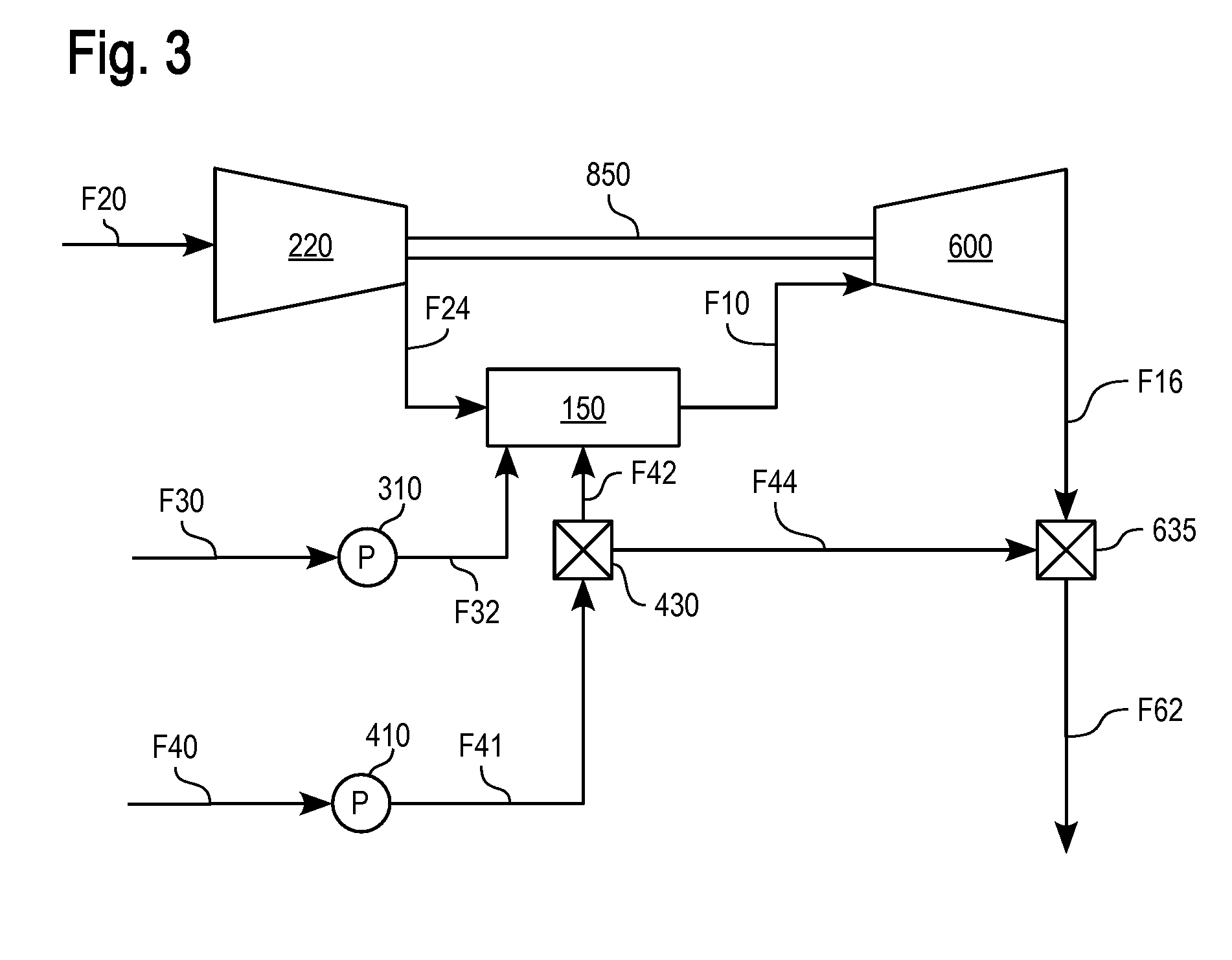

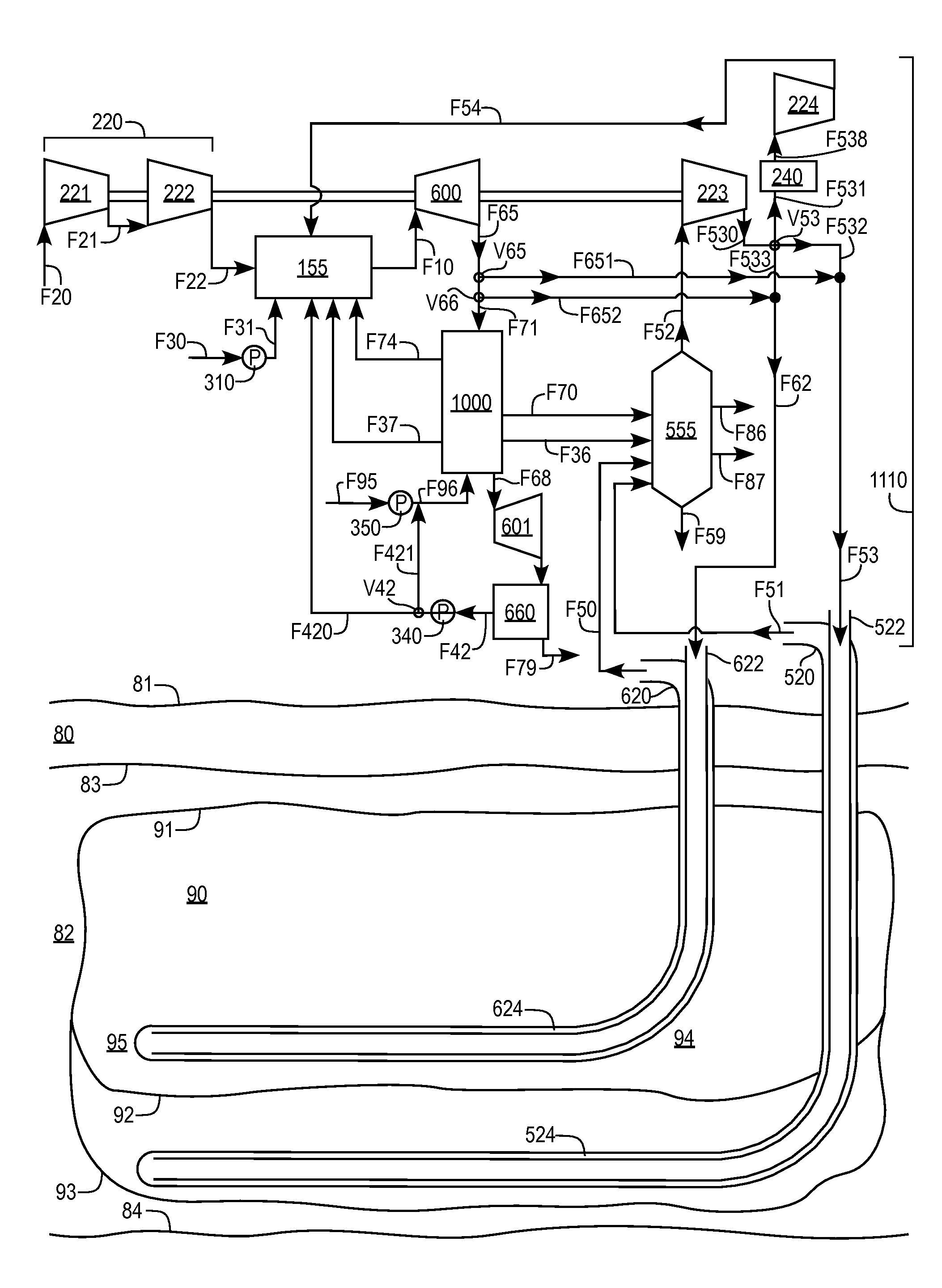

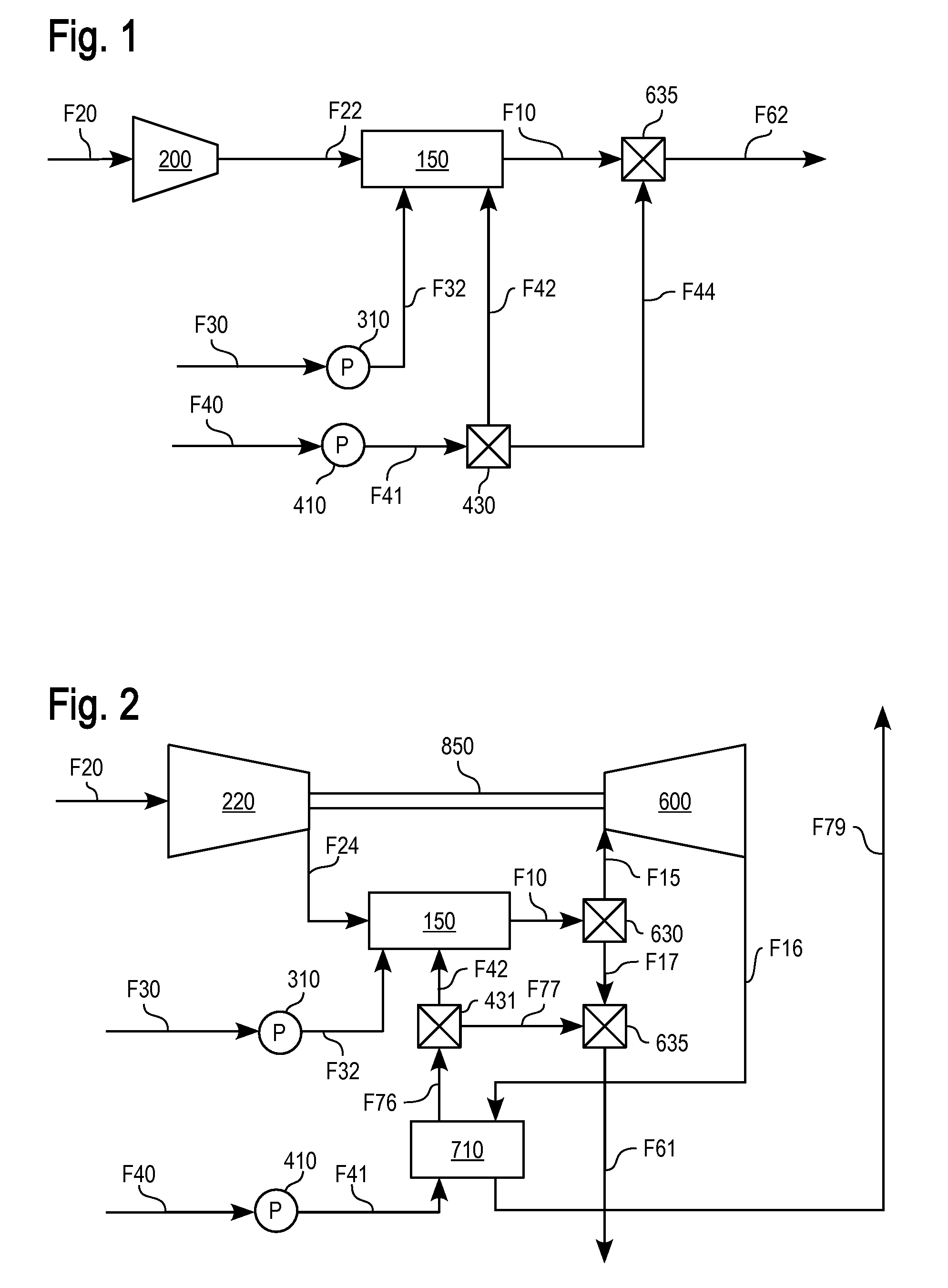

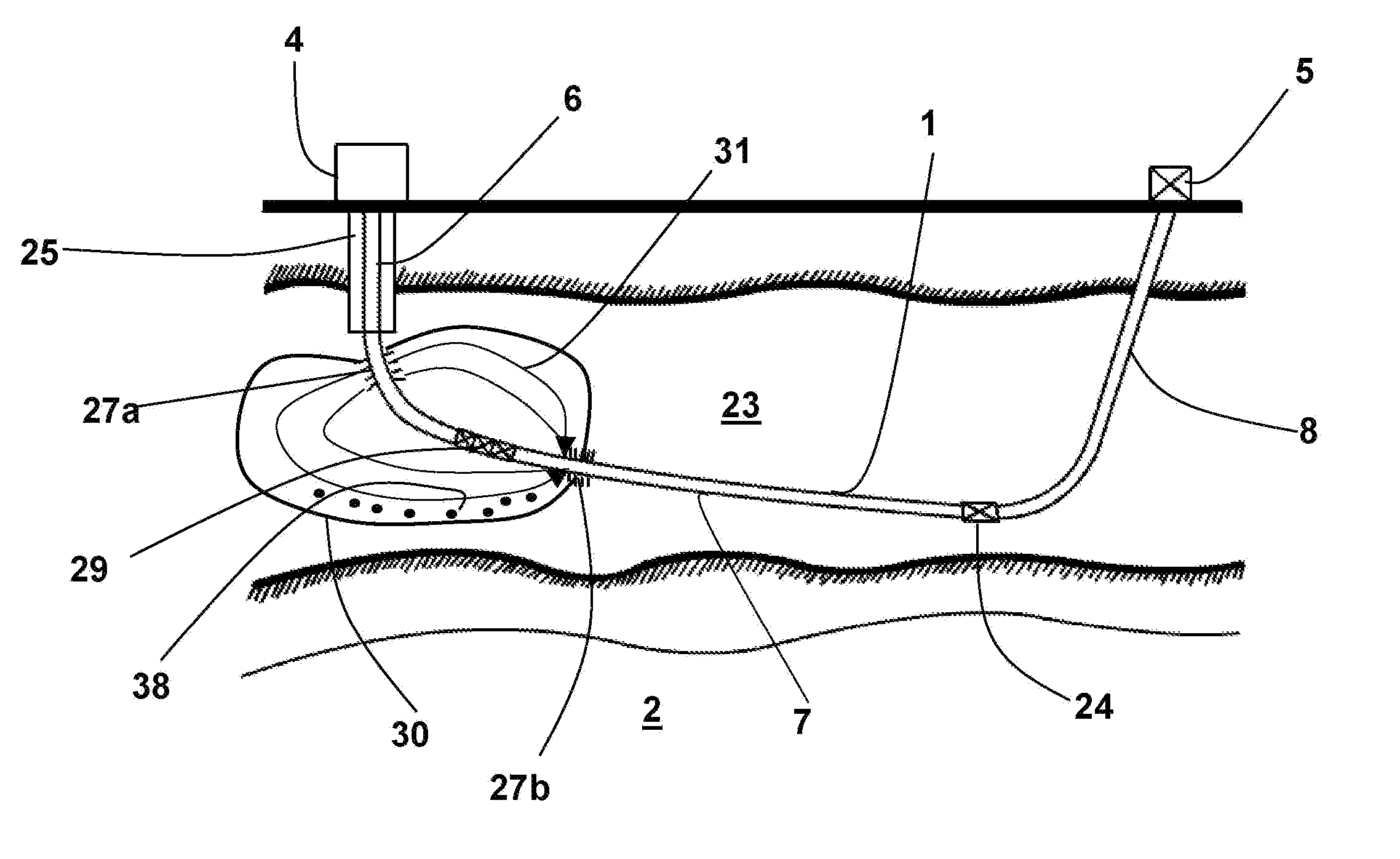

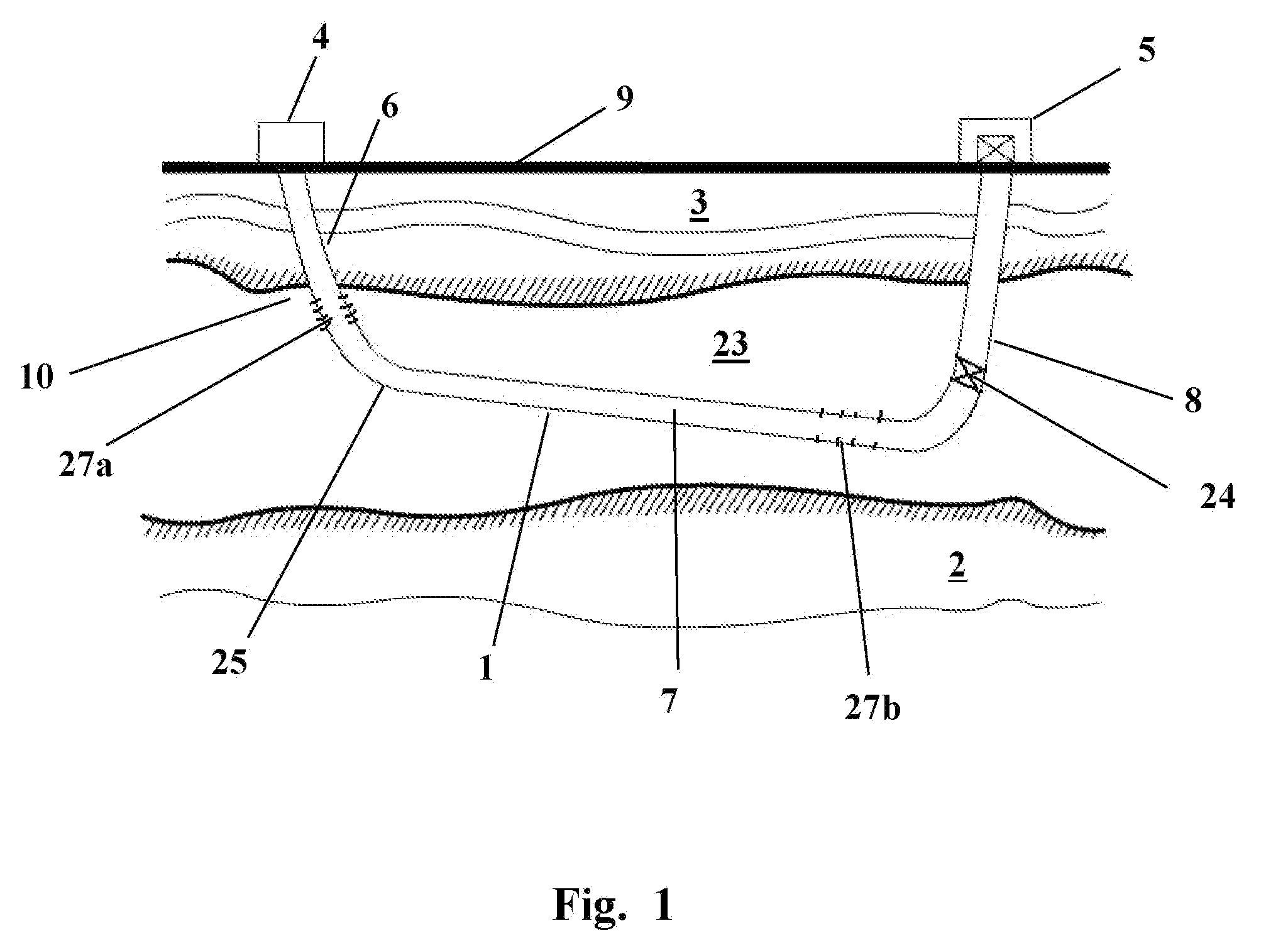

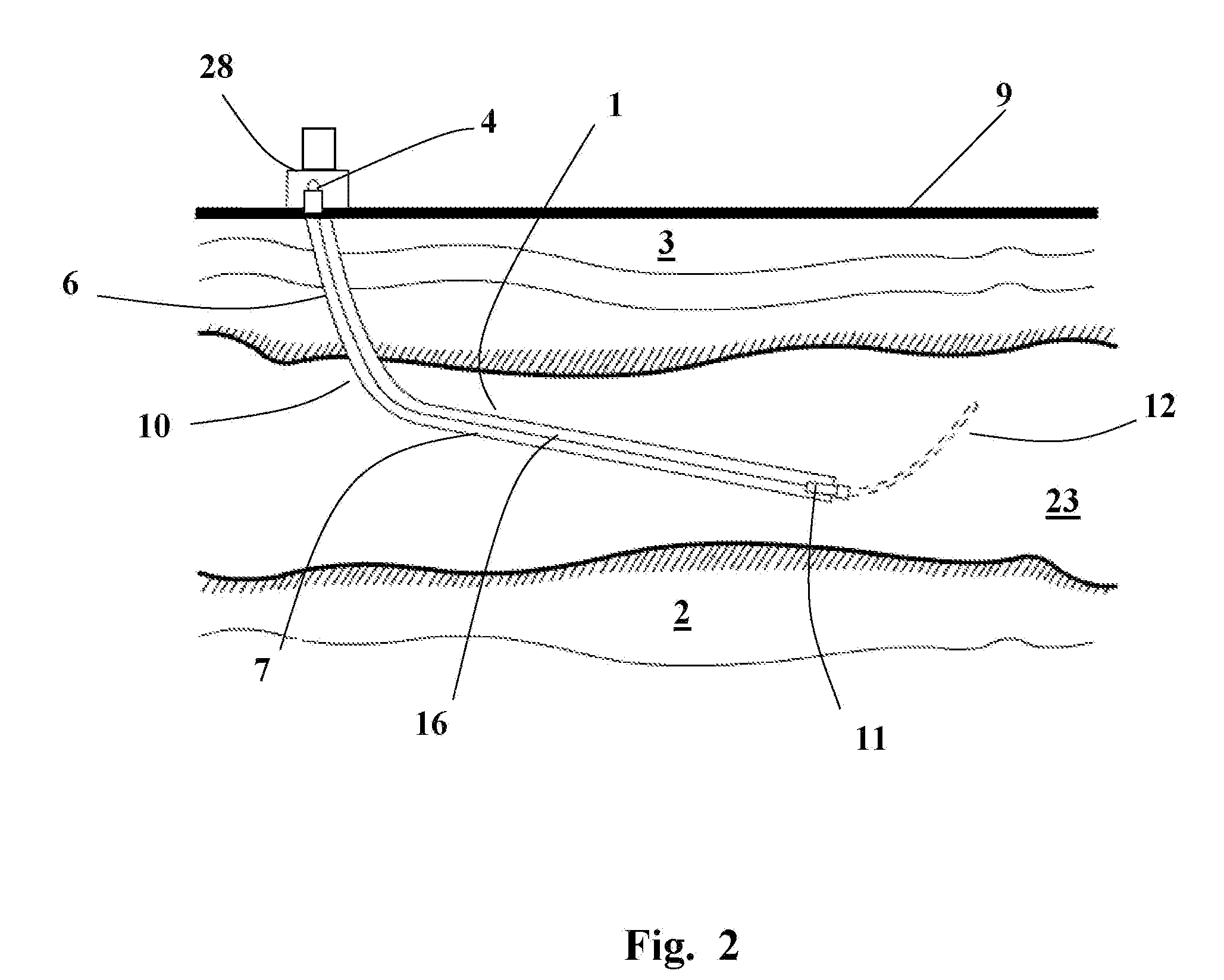

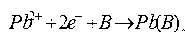

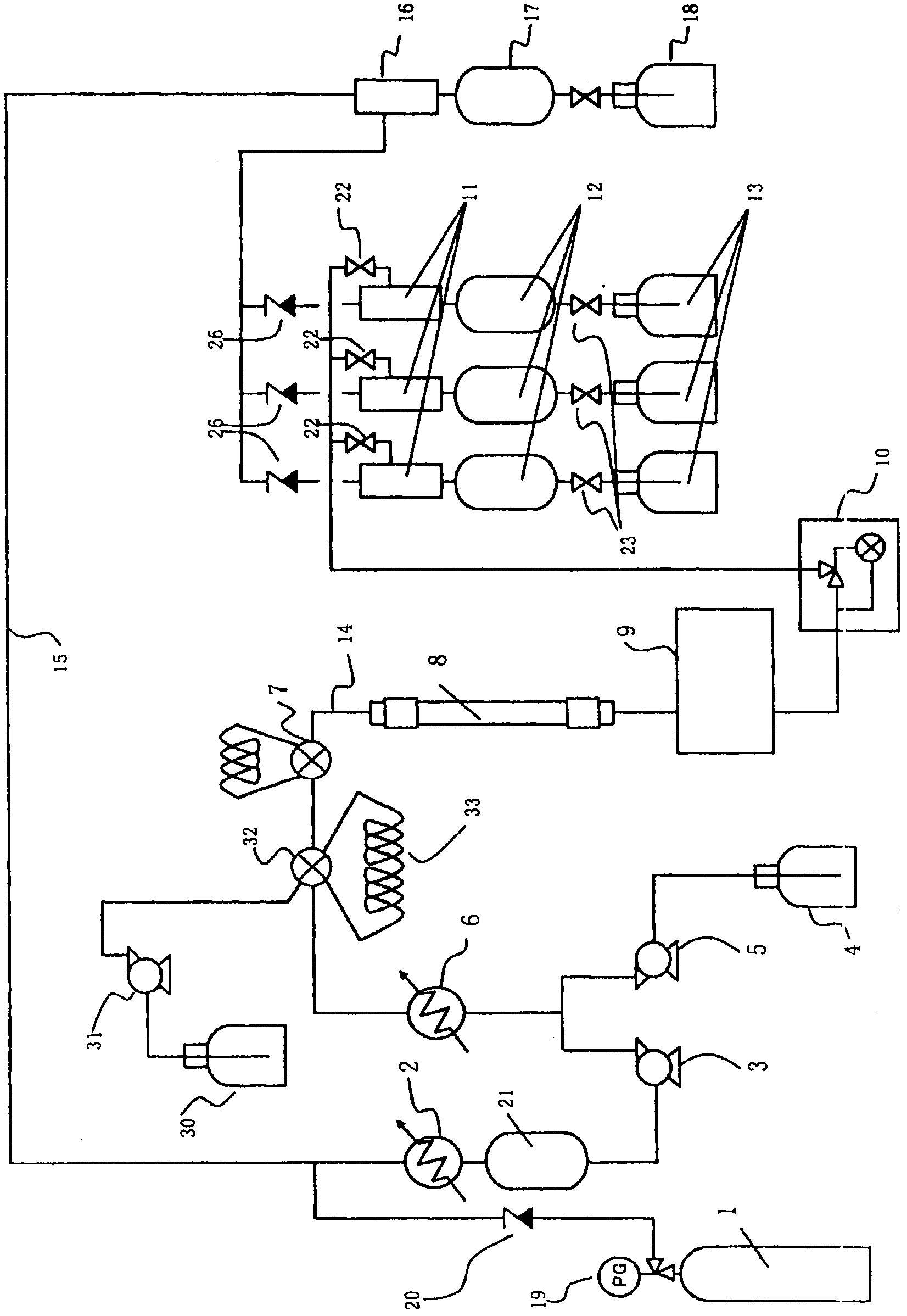

Heavy oil recovery with fluid water and carbon dioxide

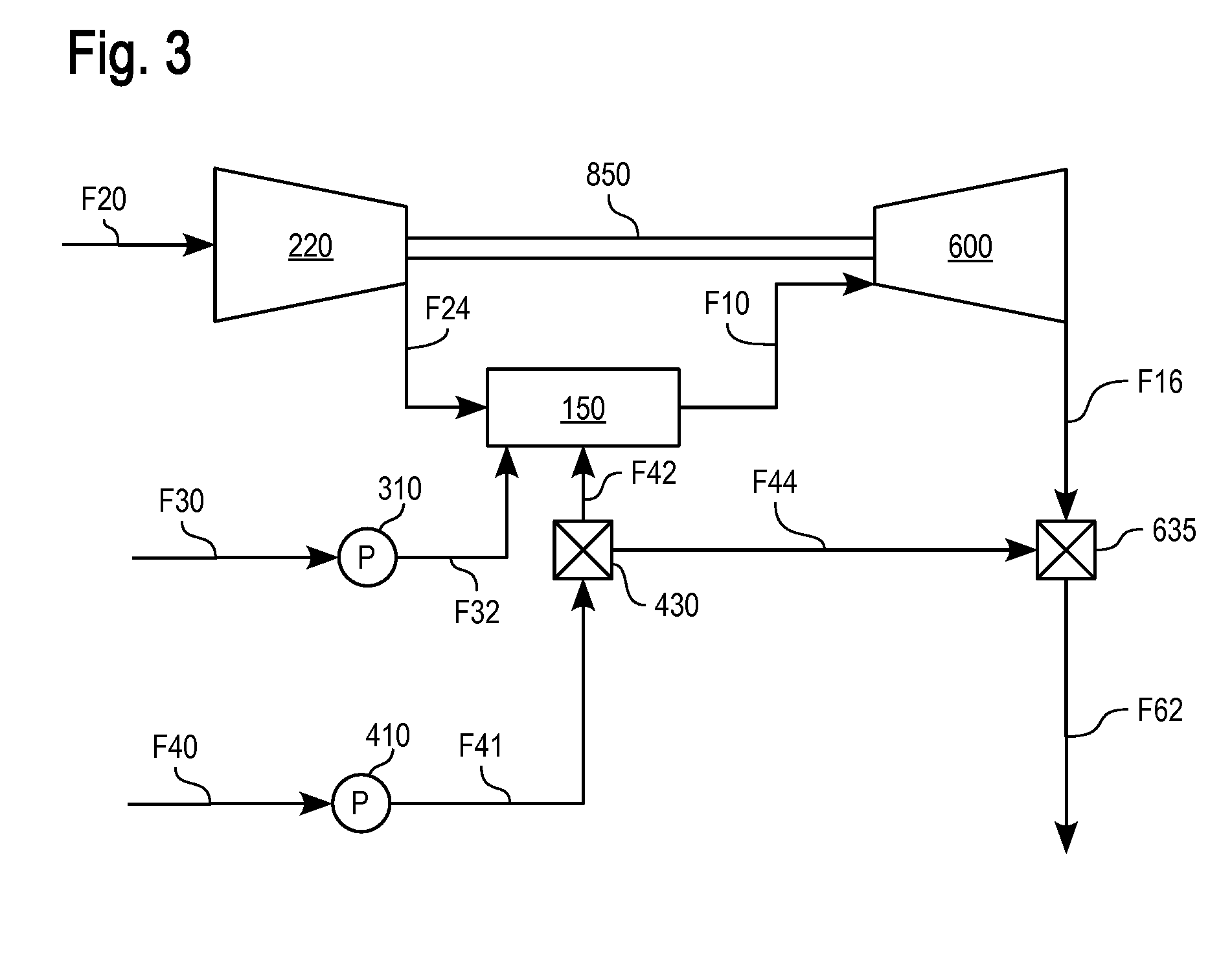

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

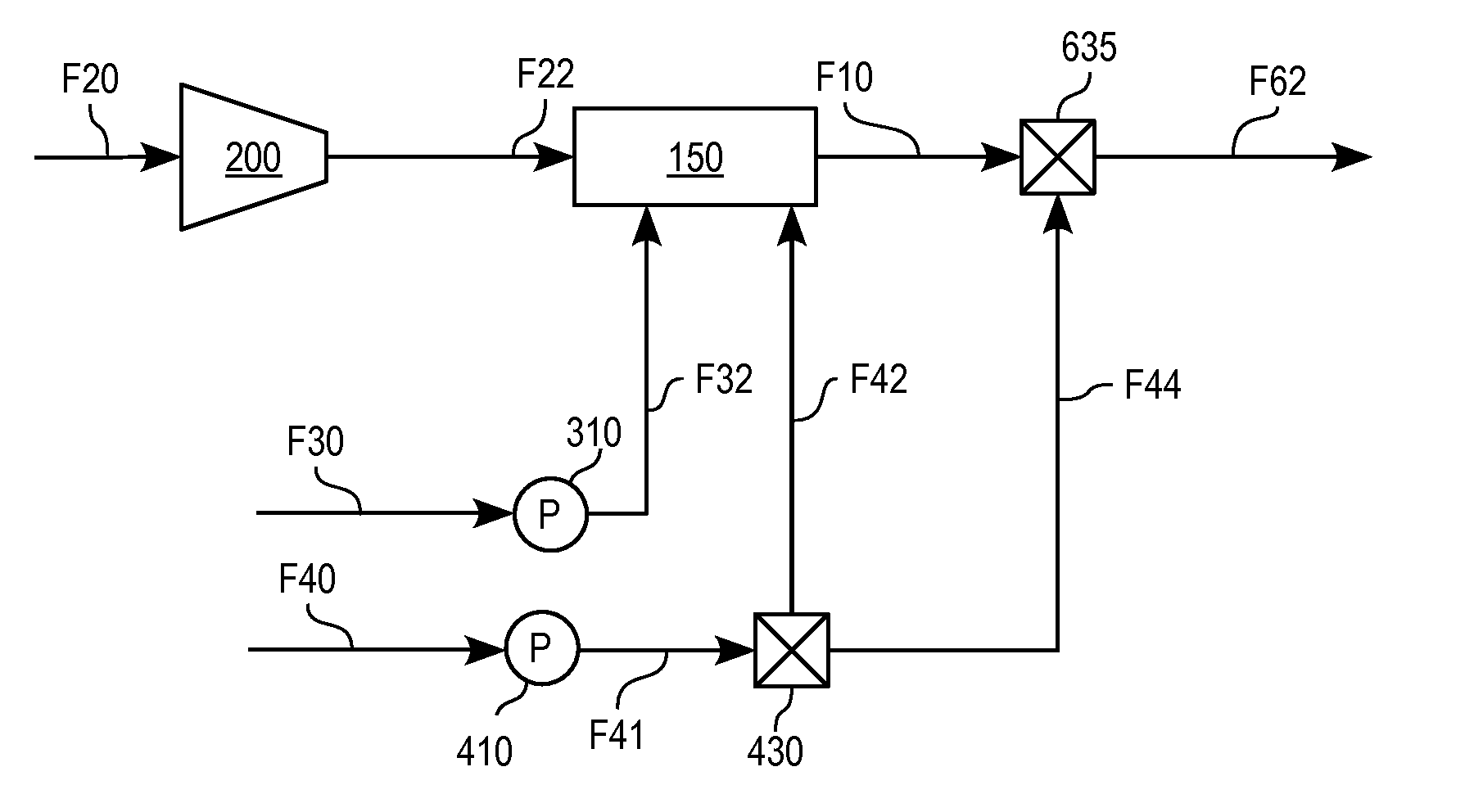

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Heavy oil recovery with fluid water and carbon dioxide

Diluted wet combustion forms a hot process fluid or VASTgas including carbon dioxide (CO2) and fluid water which is delivered to geologic formations and / or to surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be used to pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into a well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

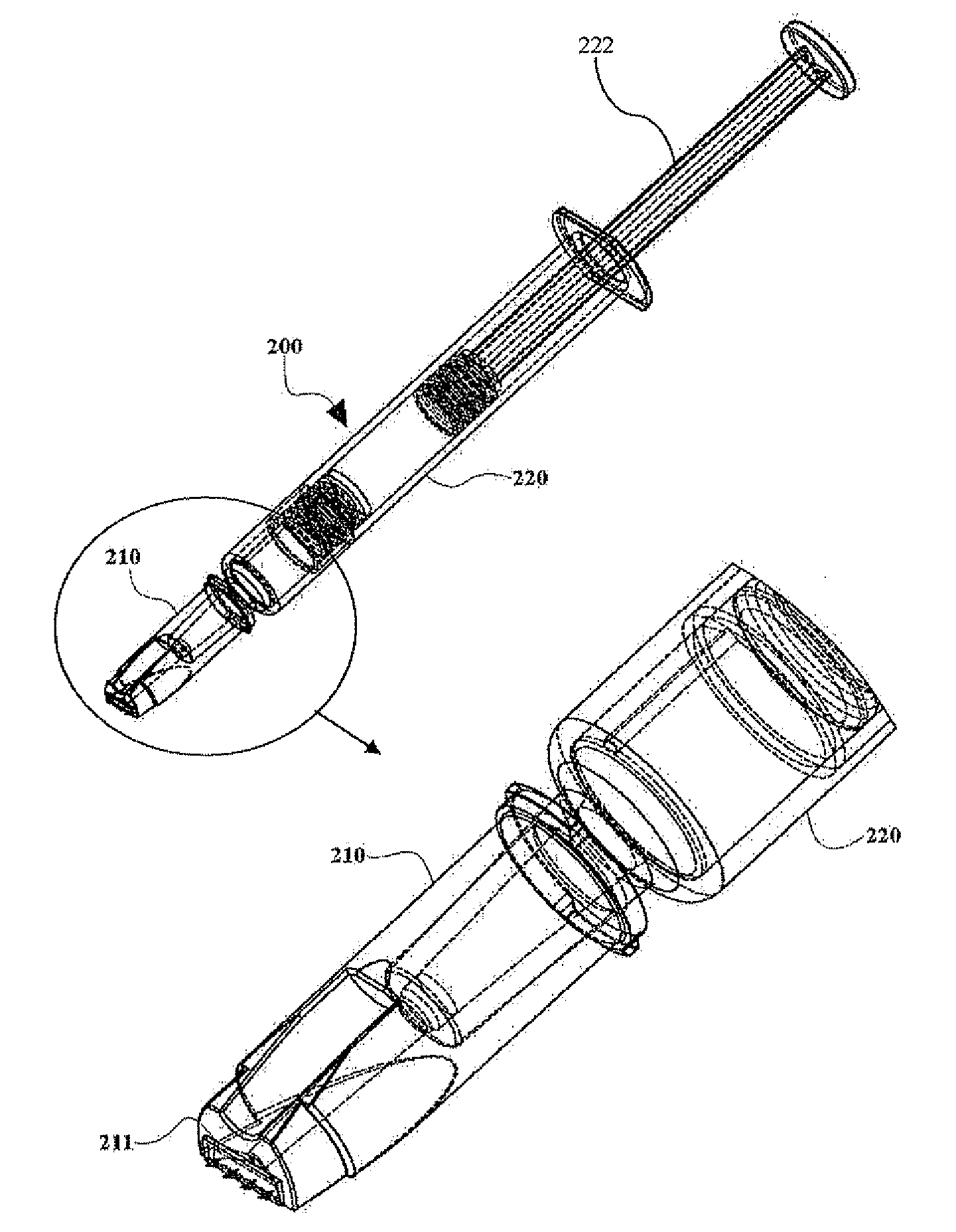

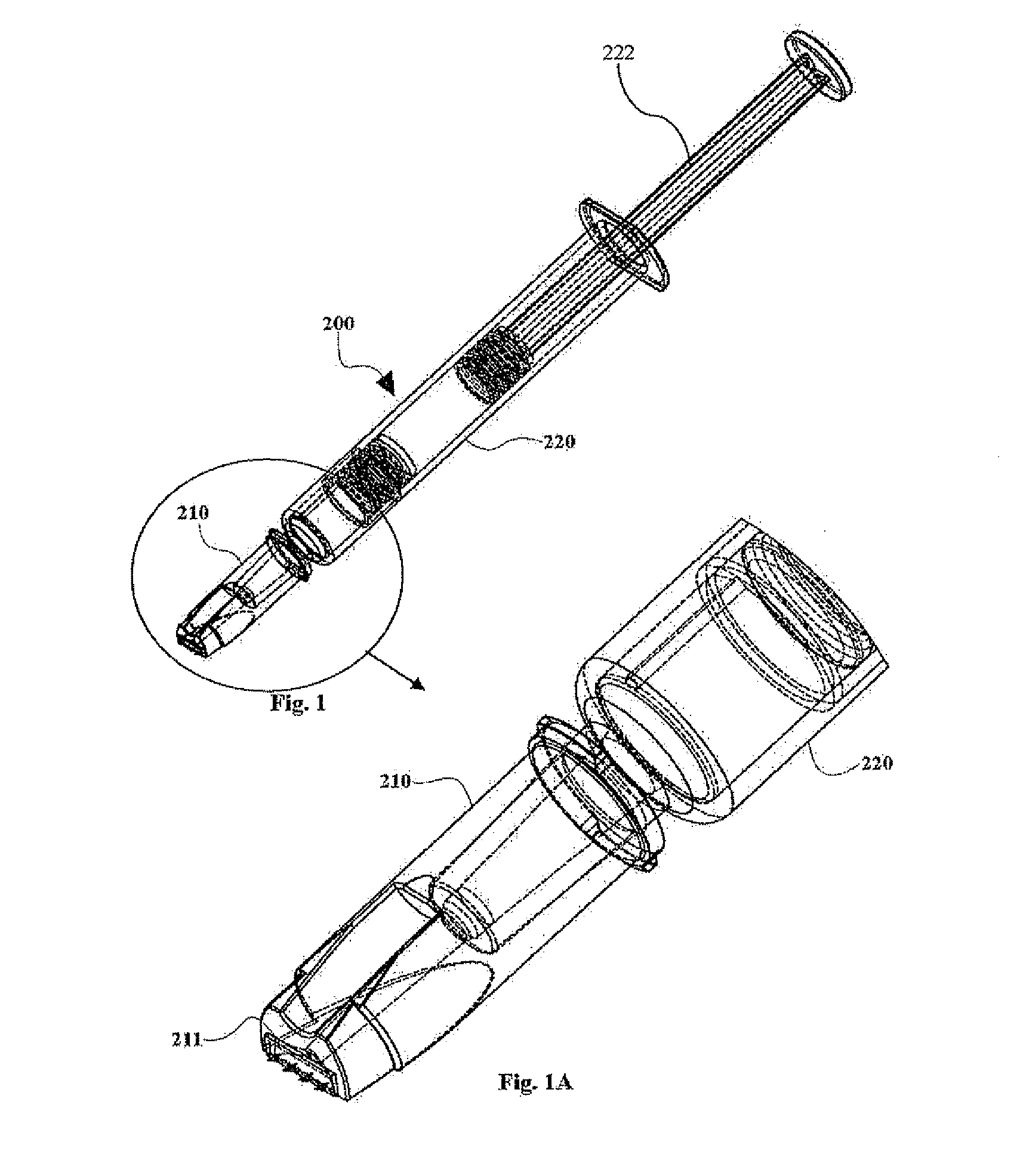

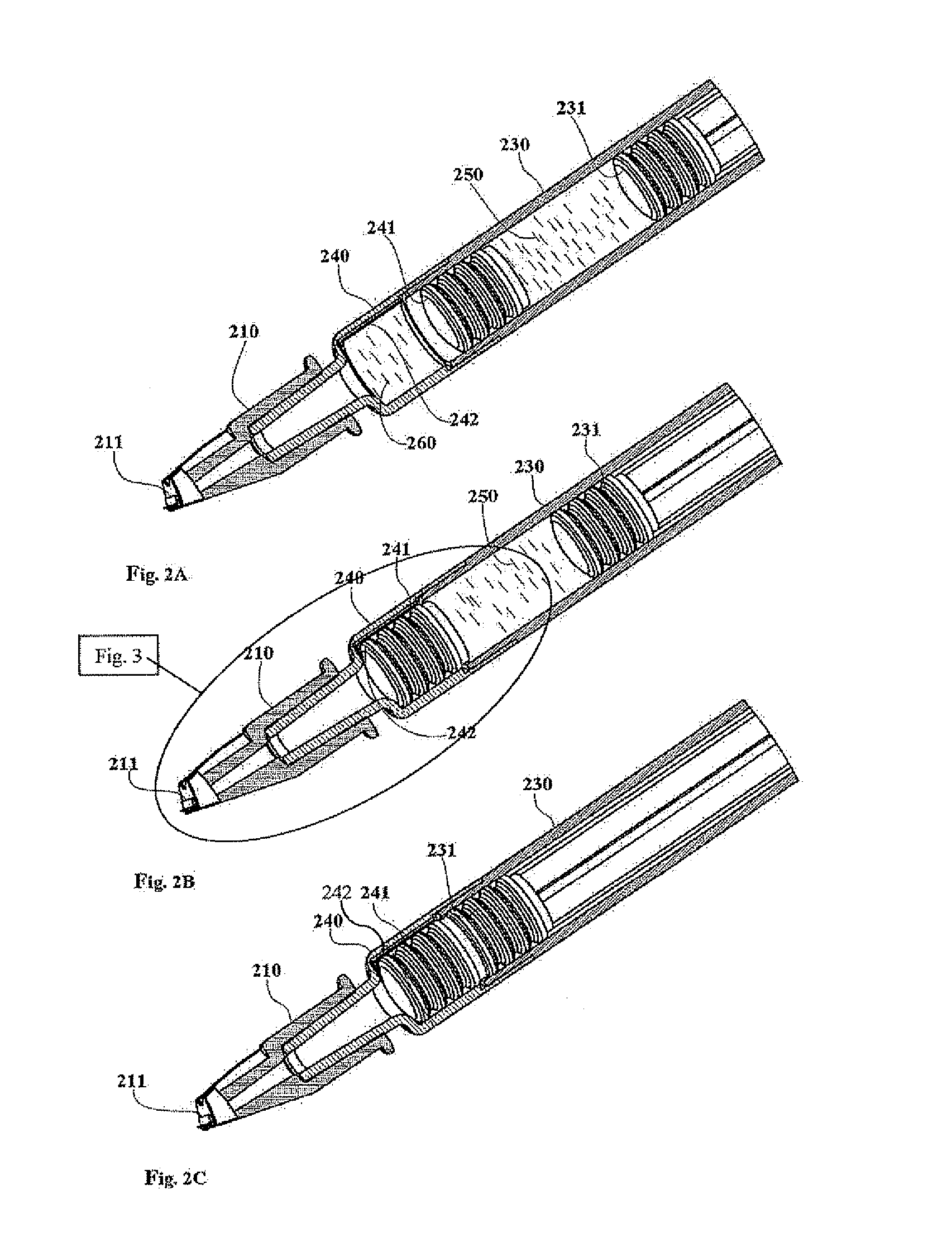

Method and apparatus for sequential delivery of multiple injectable substances stored in a prefilled syringe

A syringe, which may be pre-filled, and a method of using the syringe is disclosed to provide sequential injection of two different fluids without mixing thereof. The syringe comprises in a first version a plunger and an intermediate disc sealingly disposed within a generally cylindrical barrel, with an outlet portion distal of the barrel, the outlet portion being generally larger in diameter so that as the disc is advanced into it far enough to substantially inject the first fluid the disc loses sealing engagement and the second fluid is then expelled around the disc and through the syringe opening. Baffles are provided within the outlet portion to prevent the disc from inadvertently sealing the opening, and channels may be provided around the baffles. In a second version a bag is provided adjacent the plunger, with the first fluid being contained within the barrel and the second fluid being contained within the bag, and at least one barb is provided in the bottom of the syringe to burst the bag after the first fluid is expelled to thereby expel the second fluid.

Owner:BAE KYONGTAE T

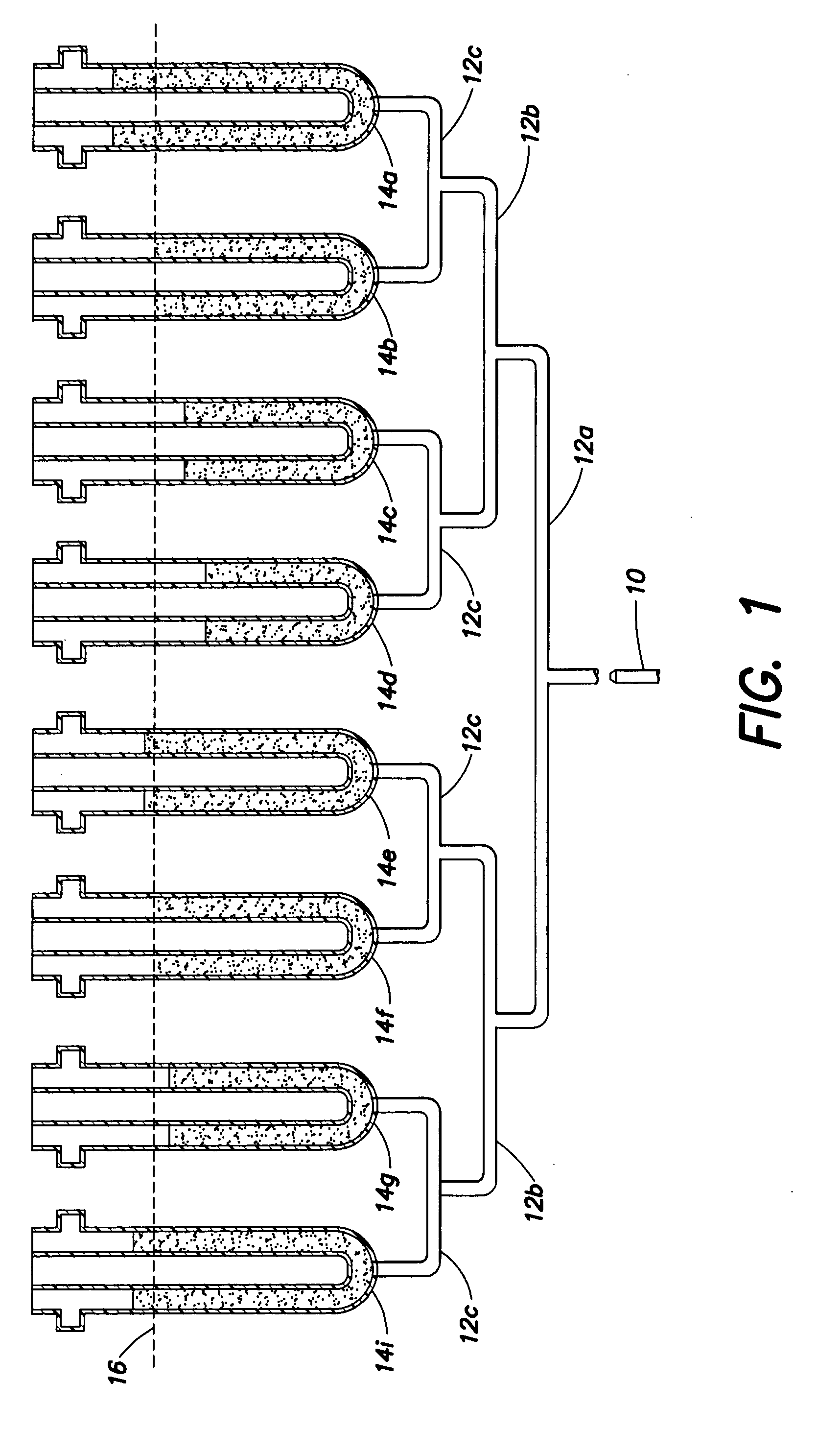

Method for Recovering Hydrocarbons from Subterranean Formations

InactiveUS20060175061A1Minimize damageLimited surfaceInsulationFluid removalWater productionTubes types

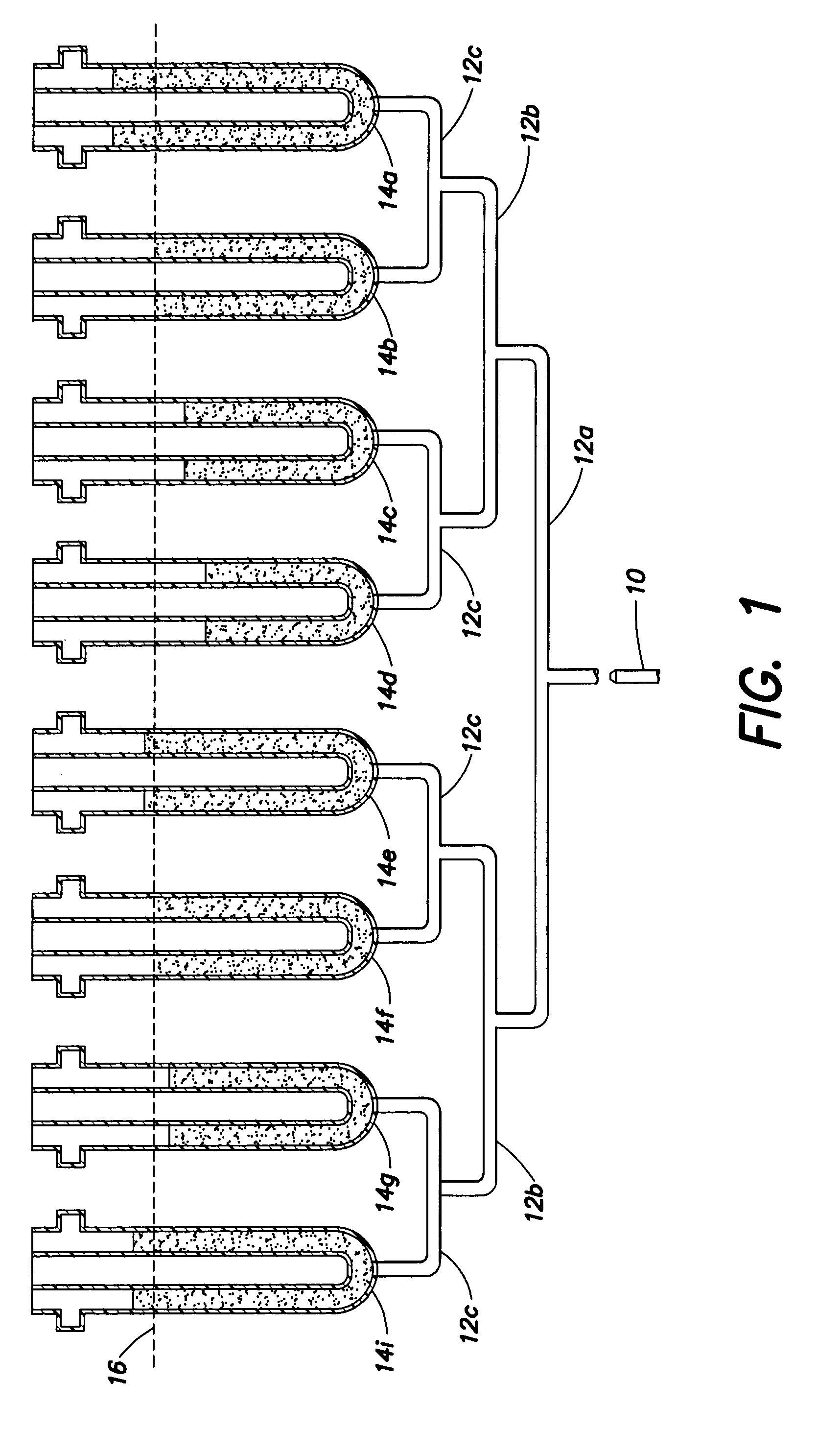

Recovery of viscous hydrocarbon from subterranean formations is assisted by using a plurality of novel U-tube type wells, each with dual wellheads, a moveable wellbore packer, a lateral section with a concentric communication zone and with sequential injection production perforations in which heat is injected into the proximal perforations and hot oil and produced fluids are produced from the distal perforations, the whole process being controlled by modulating the production flow where the wellbore fluids are controlled to act as a hydraulic seal to limit bypass of injected fluids. The injection-production displacement process moves axially along the wellbore in a sequential manner as hydrocarbon volumes are depleted by injected fluid displacement of oil and oil and water production.

Owner:CRICHLOW HENRY B

Device for parallel and synchronous injection for sequential injection of different reagents

InactiveUS7094379B2Exhaust apparatusChemical/physical/physico-chemical microreactorsInjection volumeBiomedical engineering

The invention relates to a microfluidic device for injecting series of mobile reaction chambers (102, 103) having non-miscible segmenters (101) in micro-channels (21 to 26), comprising:injection means (10) for injecting into microreaction channels alternatingly and in parallel liquid to form mobile reaction chambers and liquid for forming the segmenters;means for controlling the progression of one of the two liquids, applied to act on one zone (31) of each microchannel delimiting an injection volume of said liquid; the control means being able to cause stopping or slowing of the progression of said liquid over the zone of each microchannel by exerting an action based on a physico-chemical property of the liquid and said action not affecting the other liquid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Dual Chamber Injector Integrated With Micro-Needles

This invention relates to a medical injection system for the intradermal injection of two or more fluid substances via micro-needles, and most preferably via a linear array of micro-needles, although the array need not be linear. Injecting two fluid substances contained in two separate chambers of the delivery device can be done by various methods. These methods may be generally categorized as, a) sequential injection, b) simultaneous injection, c) parallel injection and d) closed-loop injection processes. The present invention includes devices configured to perform all three of these methods.

Owner:NANOPASS TECH LTD

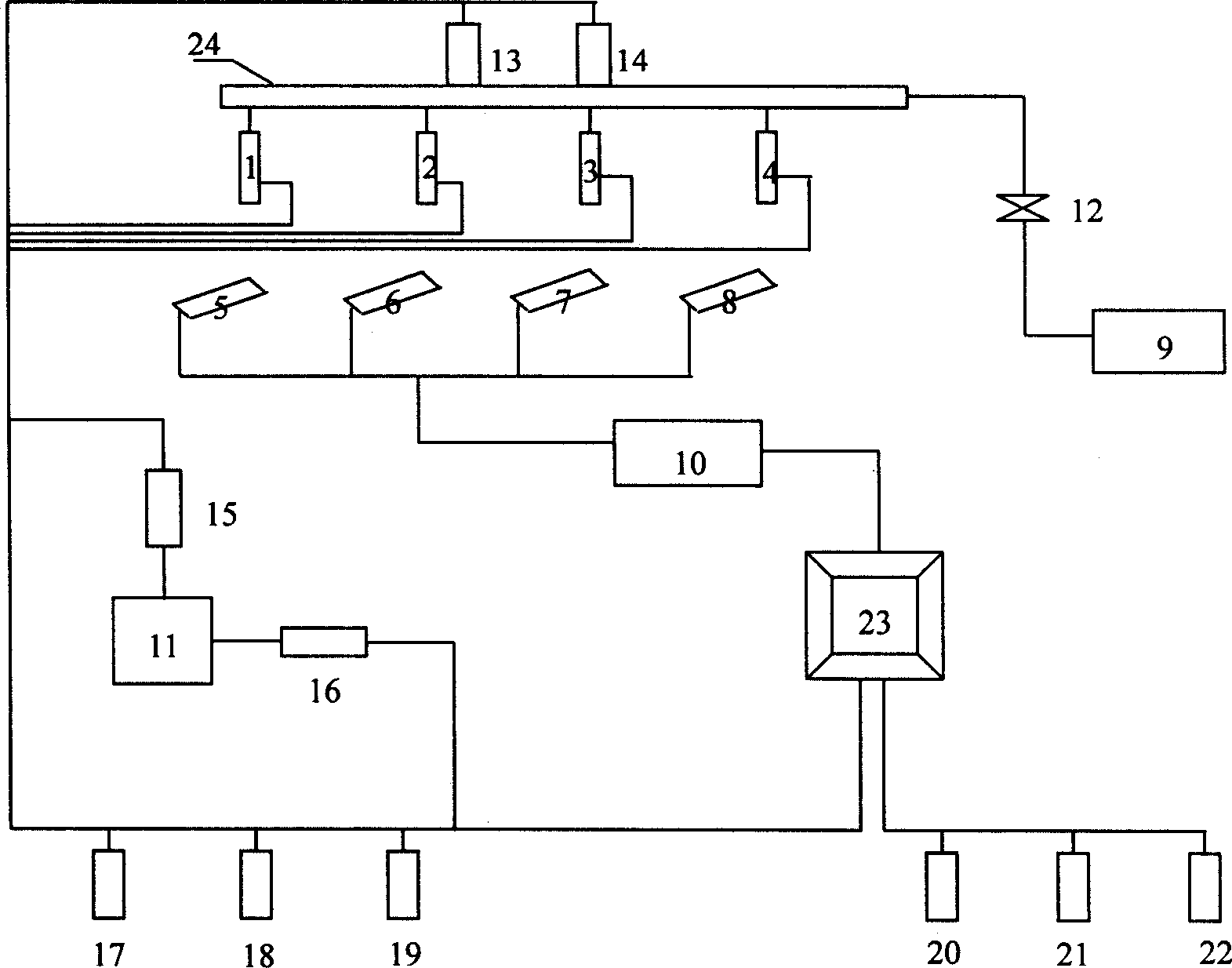

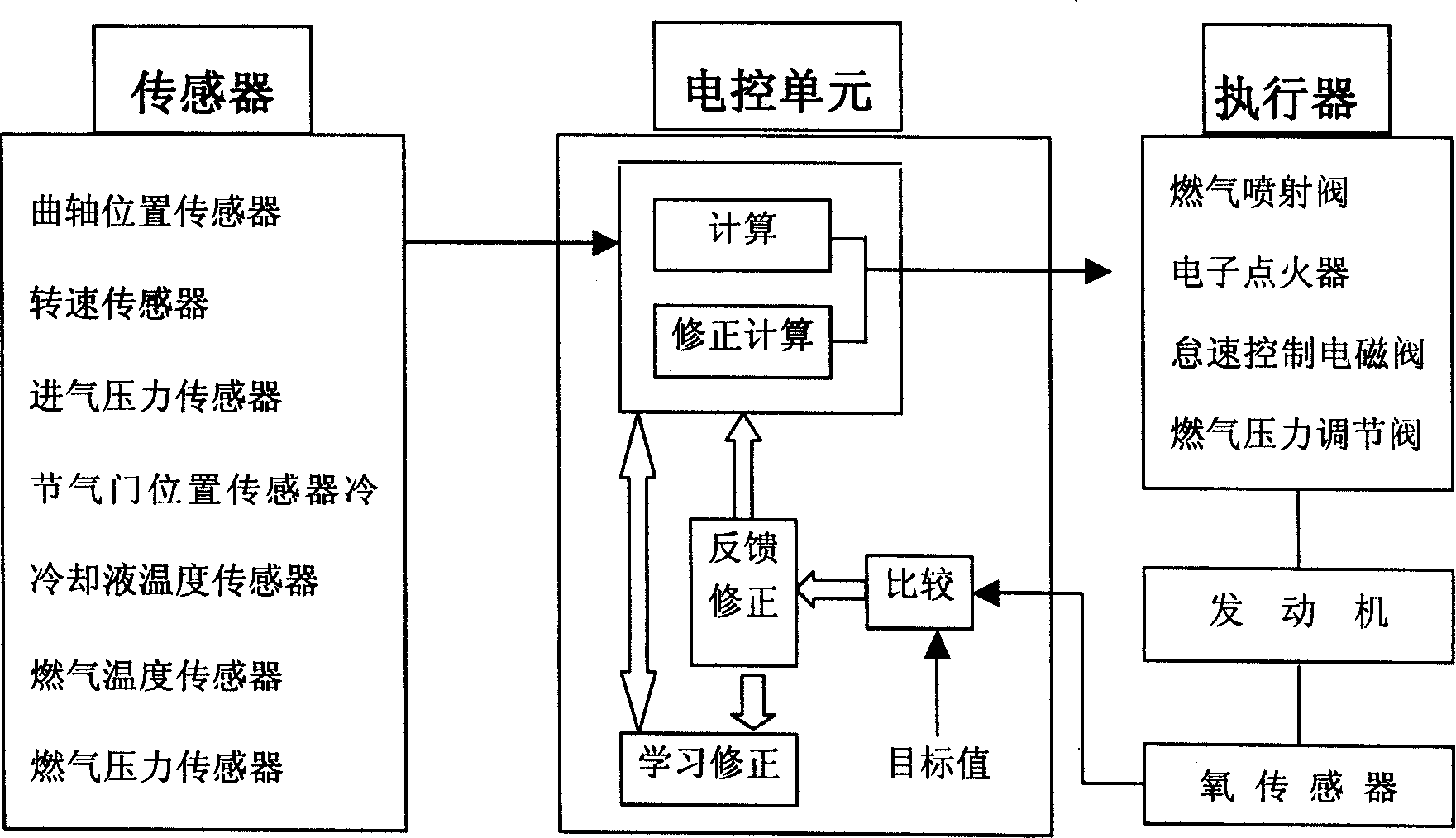

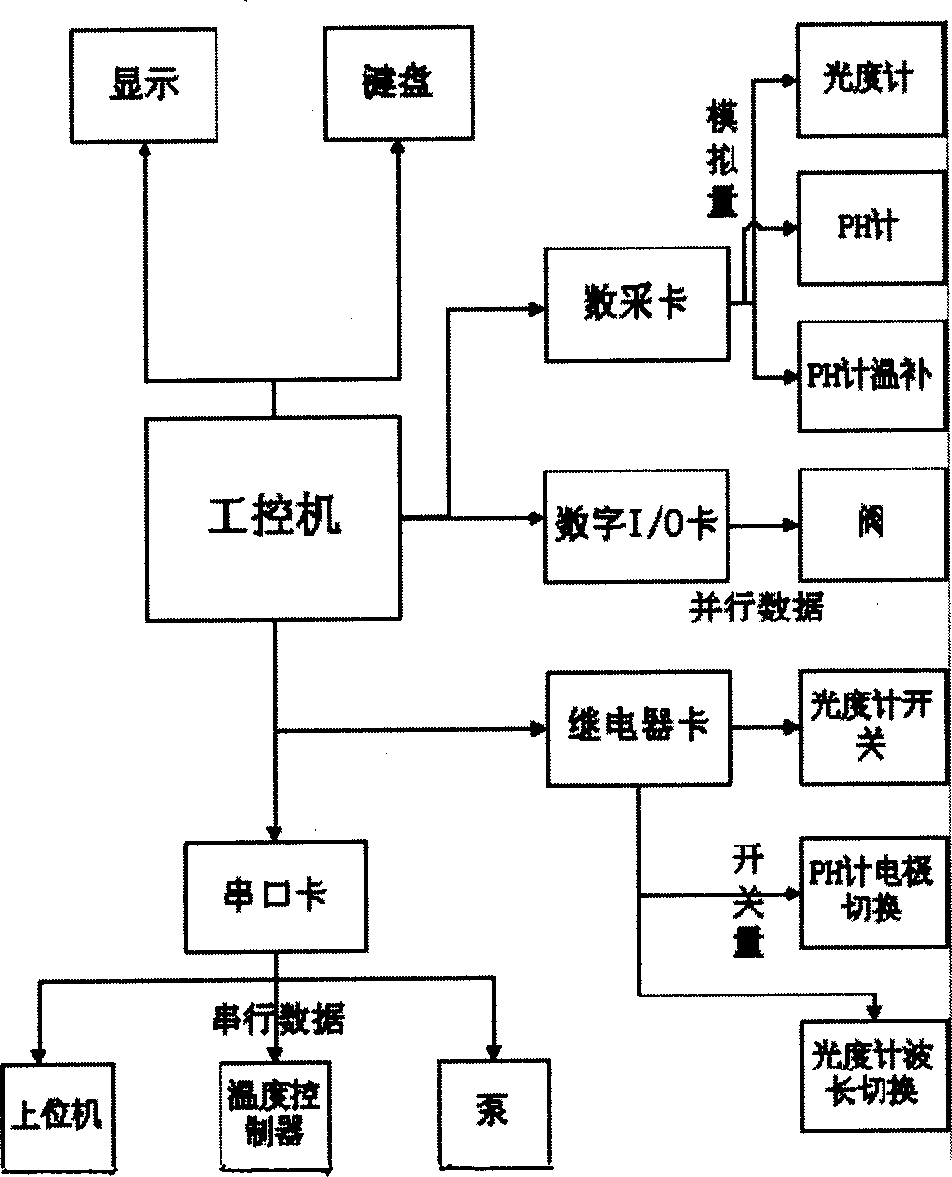

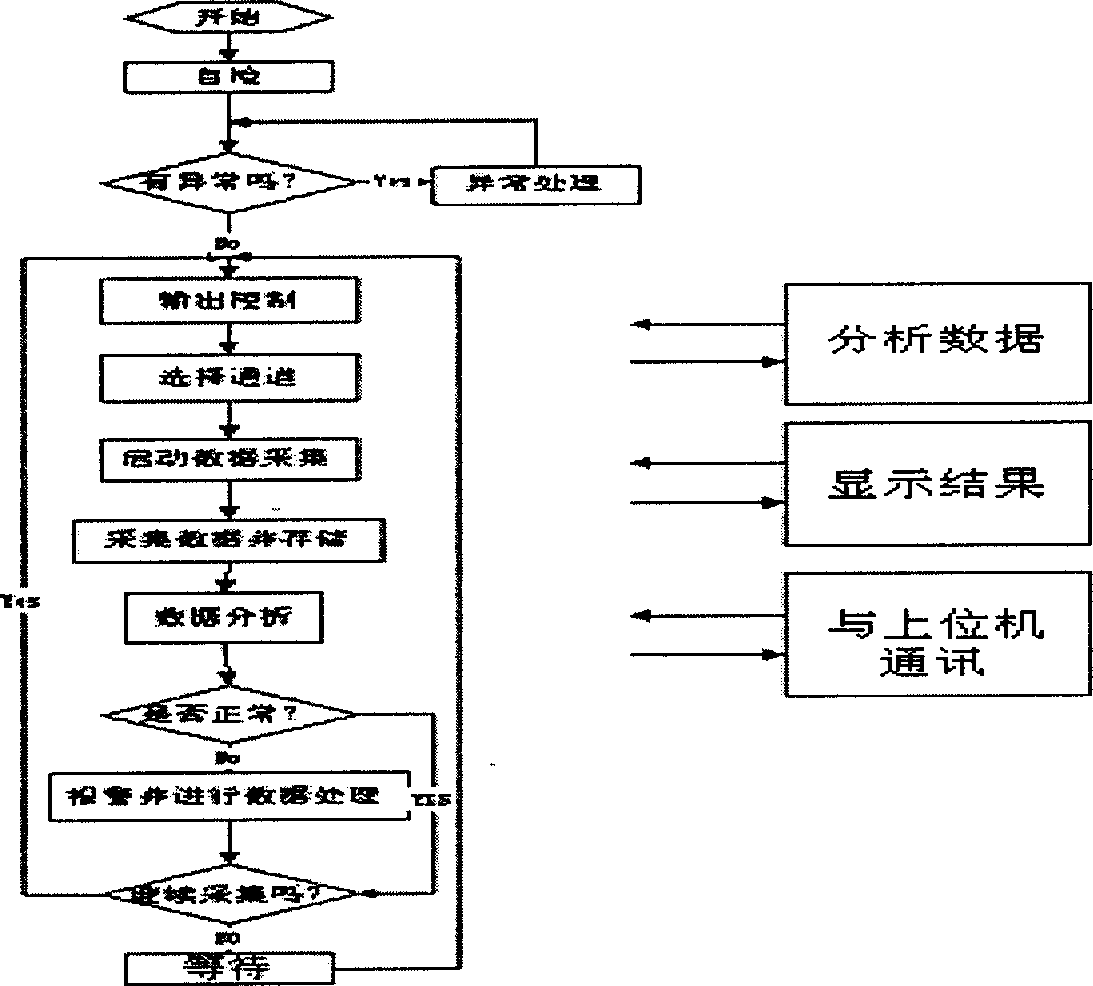

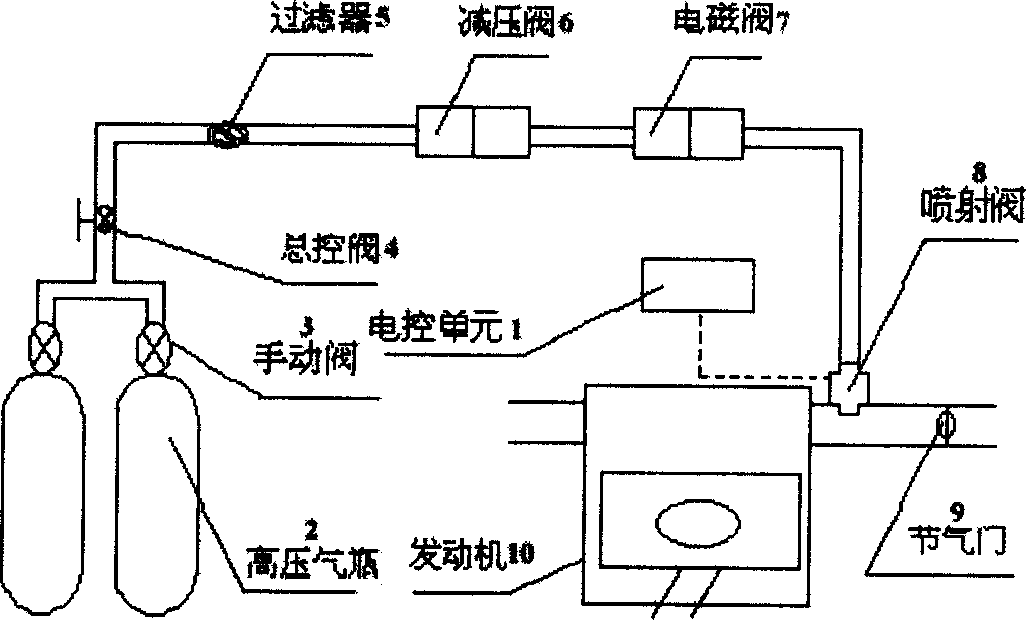

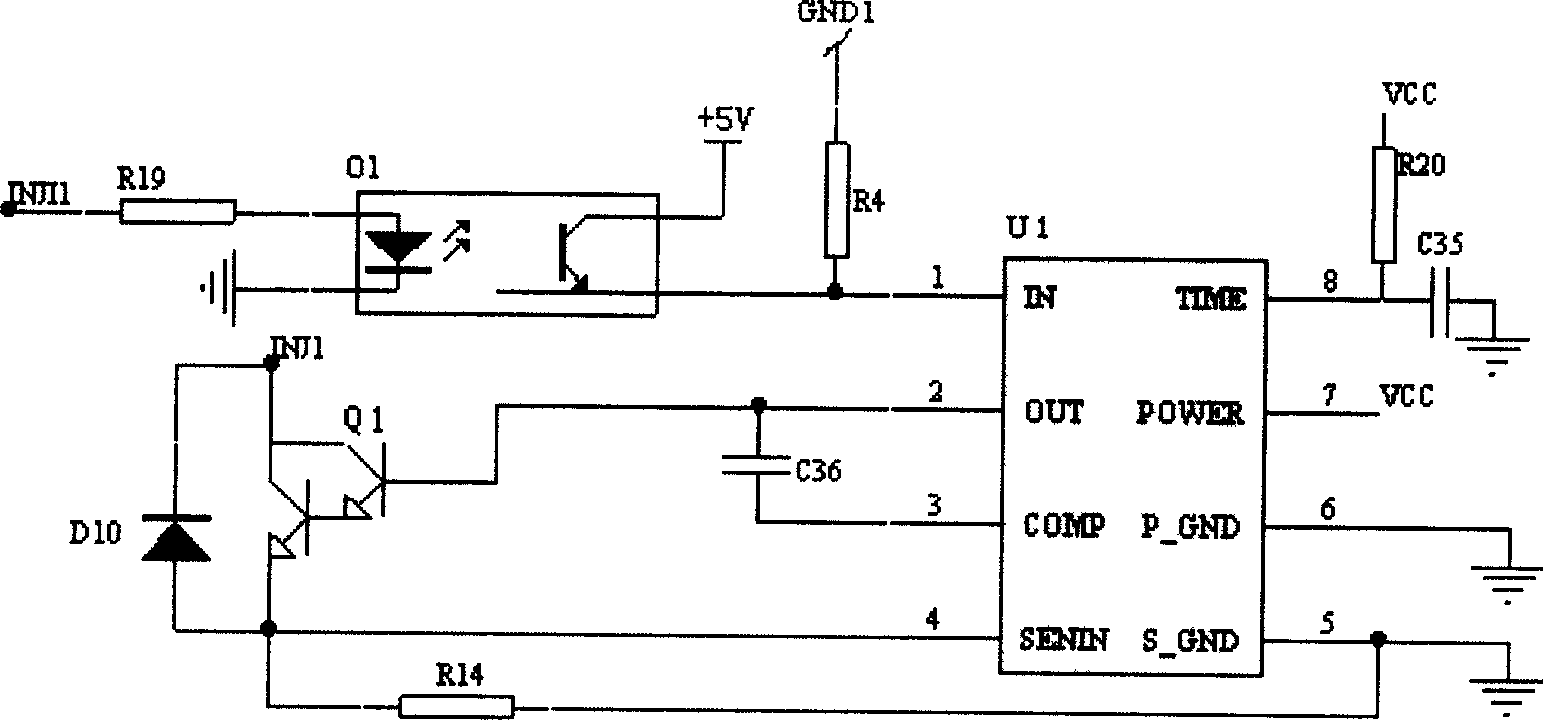

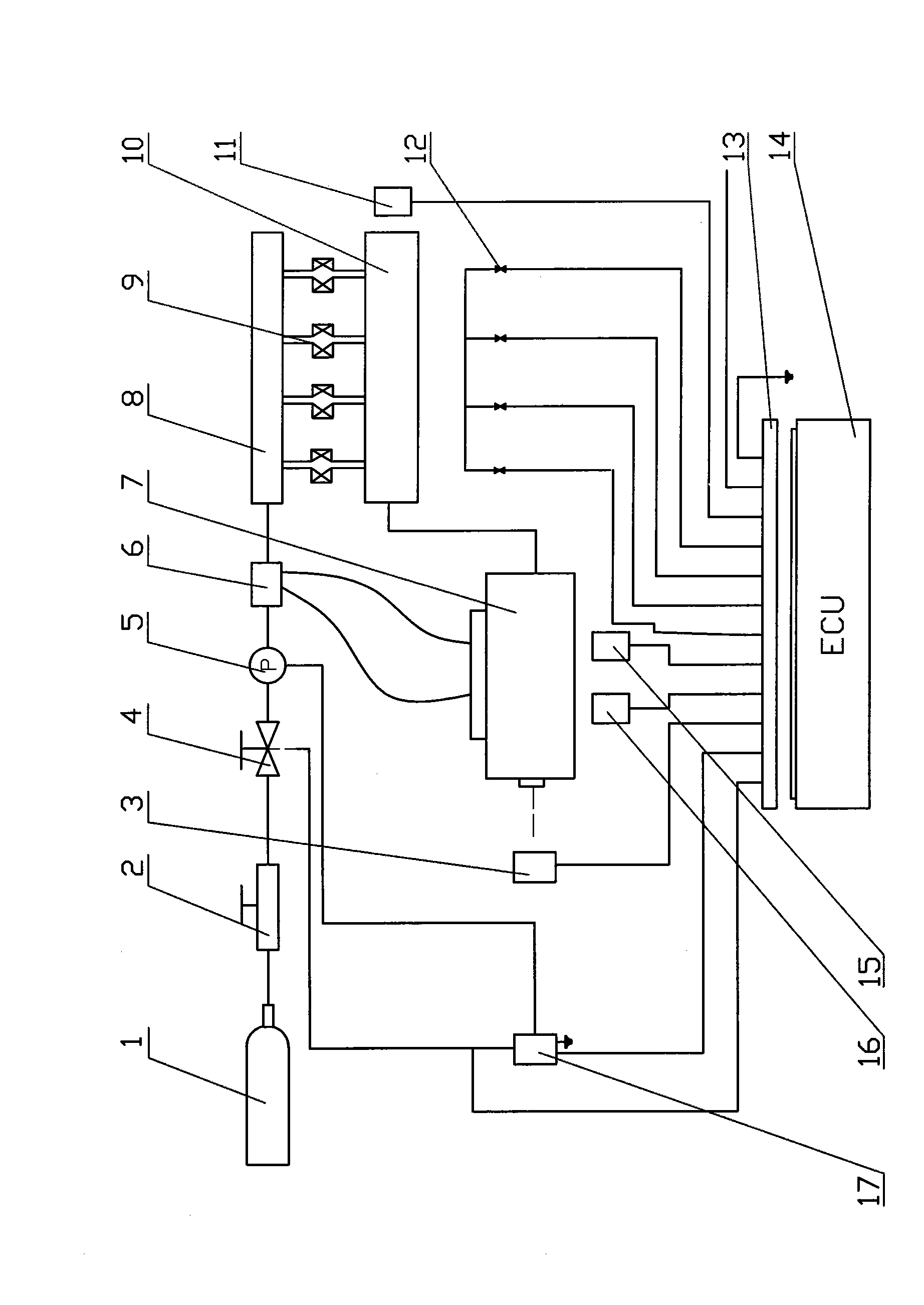

Multipoint sequential injection control system of gas fuel

InactiveCN1730926AEliminate wasteImprove consistencyElectrical controlInternal combustion piston enginesLoop controlElectric control

The enclosed loop control system for gas fuel to jet successively in several points includes three parts of sensors, enclosed control unit (ECU) and executing mechanism. The sensors collects signals and transmits the signals to the ECU, the ECU performs precise calculation to control the operation of the executors, and the executors perform the timely and quantitative fuel jetting. In the enclosed loop control system, the ECU compares the data the oxygen sensor obtains with target value, and performs self correction and feedback correction to raise air / fuel ratio controlling precision. The timely and quantitative gas supply can eliminate fuel gas backing and fuel waste caused by gas valve superposing angle, raise the mixed gas uniformity and work homogeneity of the cylinders, improve the mixed gas controlling precision of the engine and reduce tail gas exhaust.

Owner:HEBEI UNIV OF TECH

System and Method for Sequential Injection of Reagent to Reduce NOx from Combustion Sources

ActiveUS20140360168A1Short durationReduce pollutant emissionsInternal combustion piston enginesExhaust apparatusEngineeringDiesel engine

In a large exhaust duct from a lean burn combustion source, such as a boiler, diesel engine or gas turbine, multiple injectors can be used to inject a reagent, such as an aqueous solution of urea or ammonia, into the exhaust for use in the catalytic reduction of NOx in a process known in the art as selective catalytic reduction (SCR). When operating at low injection rates, such as during low combustor loads, the injectors are operated individually for short periods of time in a sequential manner.

Owner:CECO ENVIRONMENTAL IP INC

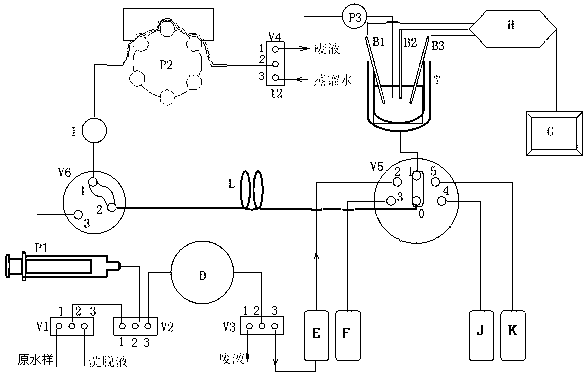

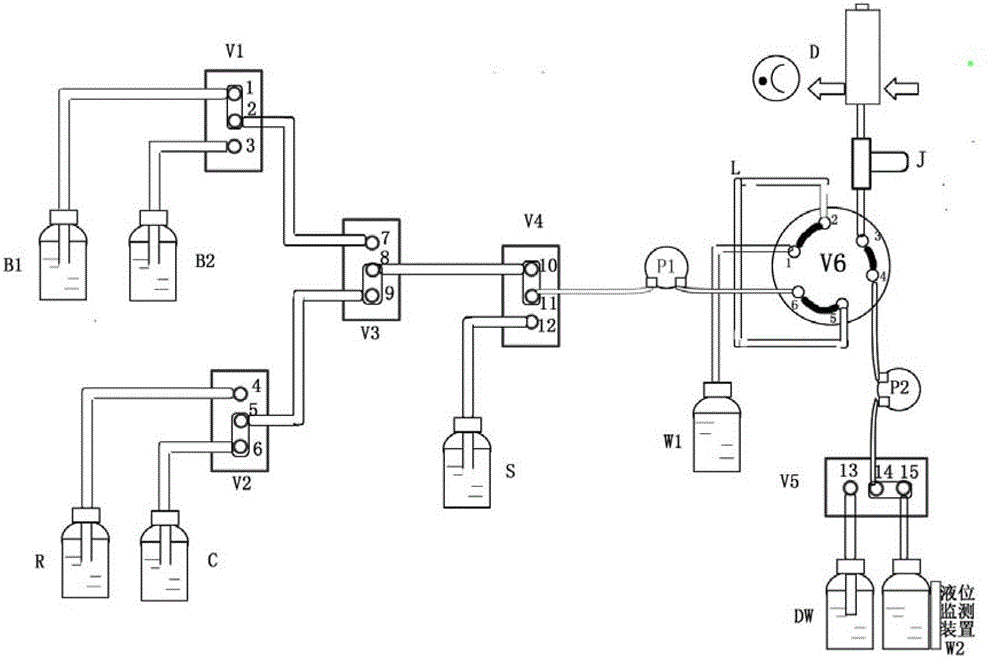

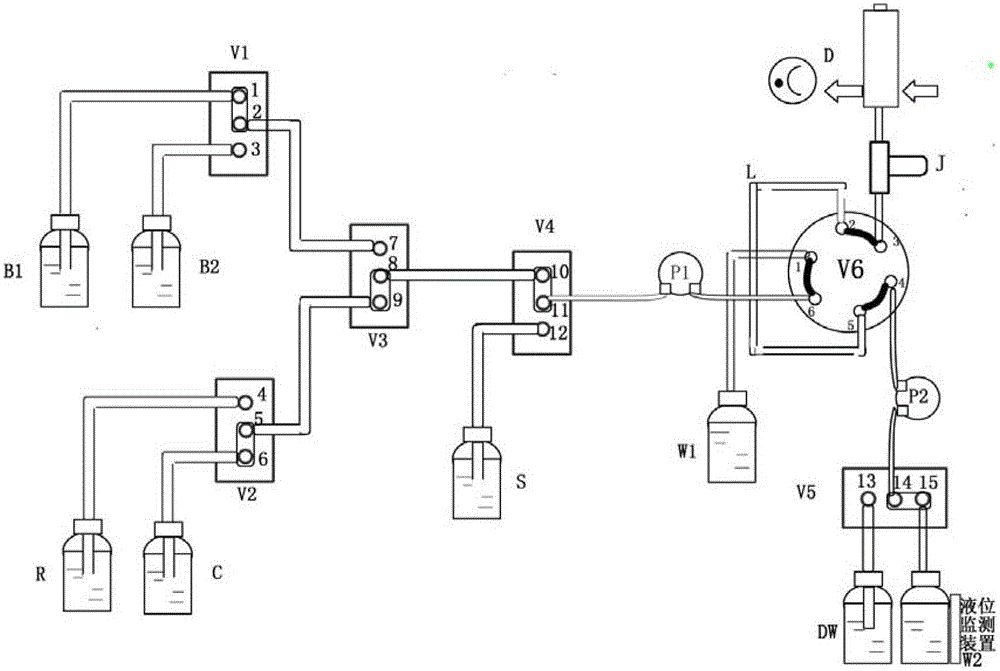

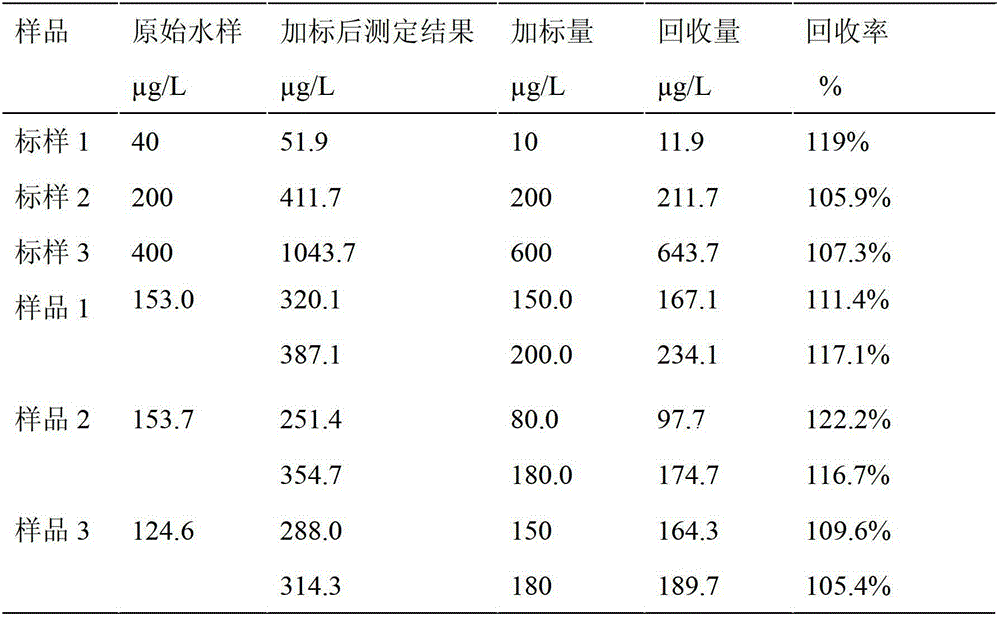

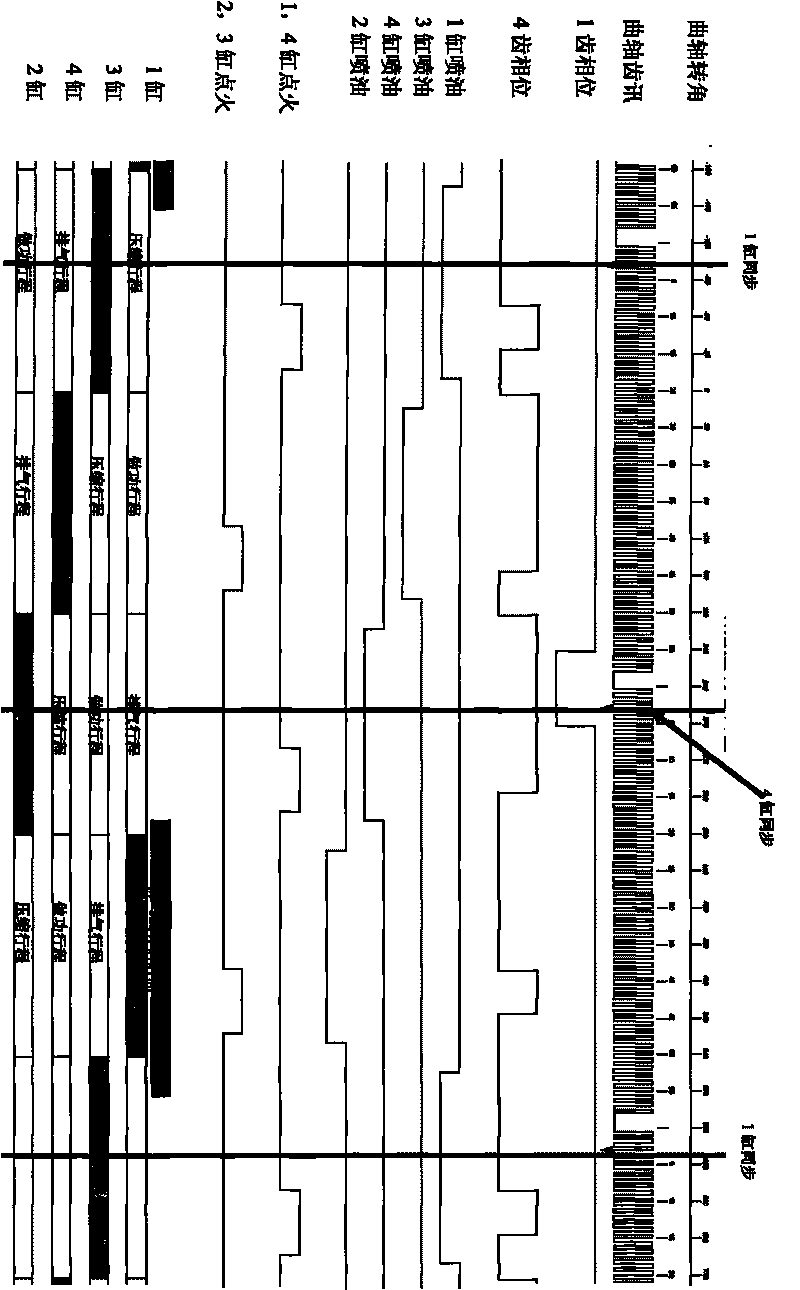

Sequential injection method for automatically monitoring COD, ammoniacal nitrogen and pH value of water and its integrated equipment

InactiveCN1366184AEasy accessRealize remote controlInvestigating moving fluids/granular solidsTesting waterWater qualityStop flow

The invention discloses a method and equipment for automatically monitoring the water quality by measuring COD, ammonia nitrogen and pH in water by using the sequential injection analysis (SIA). Based on SIA, COD is measured by using the combination of Ce oxidation process and stopped flow-SIA method; ammonia nitrogen is measured by using the SIA-indigo intensity method of blue light; pH is measured by using the spraying wall electrode method. The invention measures COD, ammonia nitrogen and pH at the same time by using the on-line SIA technique. The invention provides features of on-line monitoring, simple structure, good accuracy and repeatability.

Owner:XI AN JIAOTONG UNIV

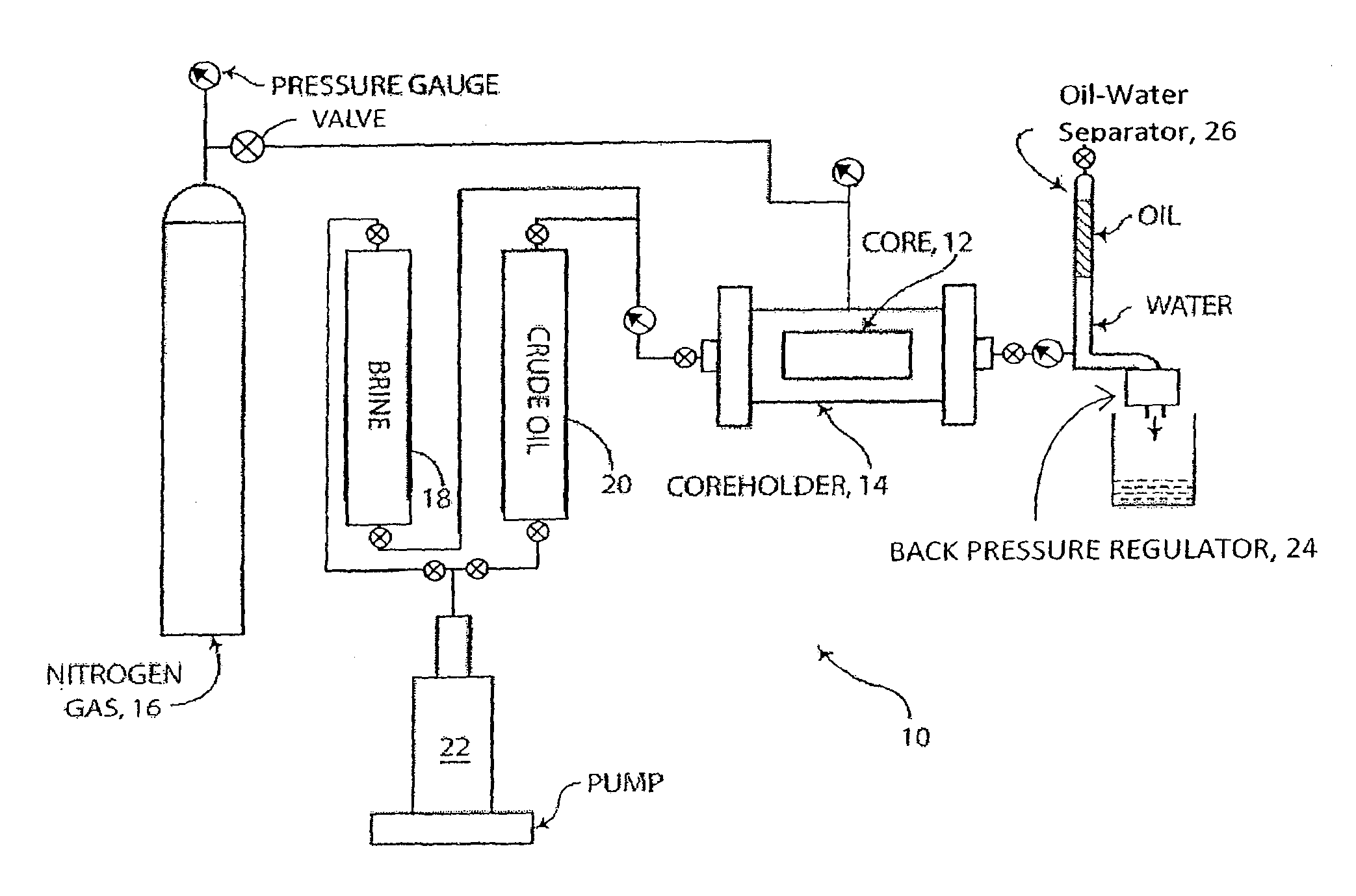

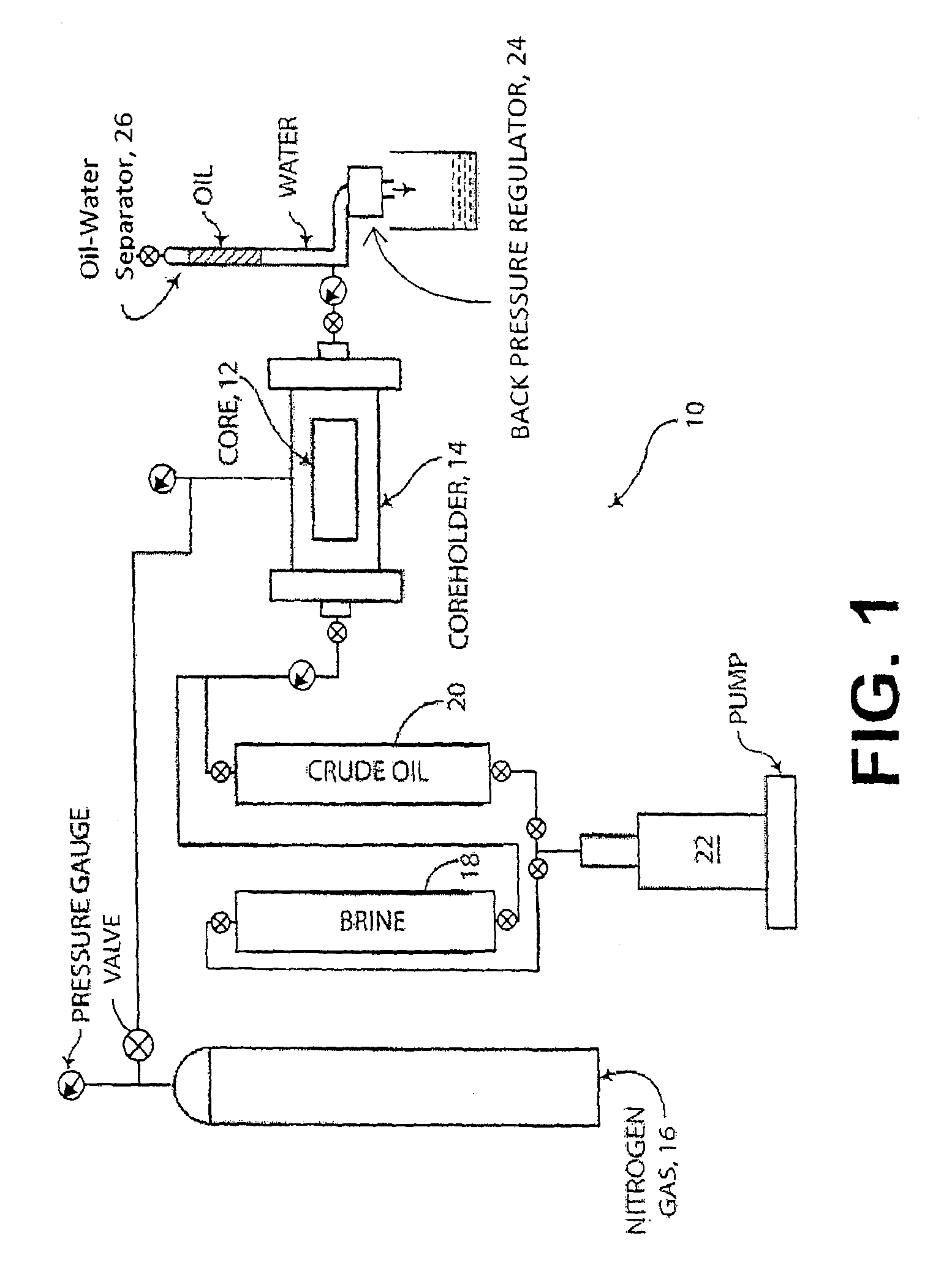

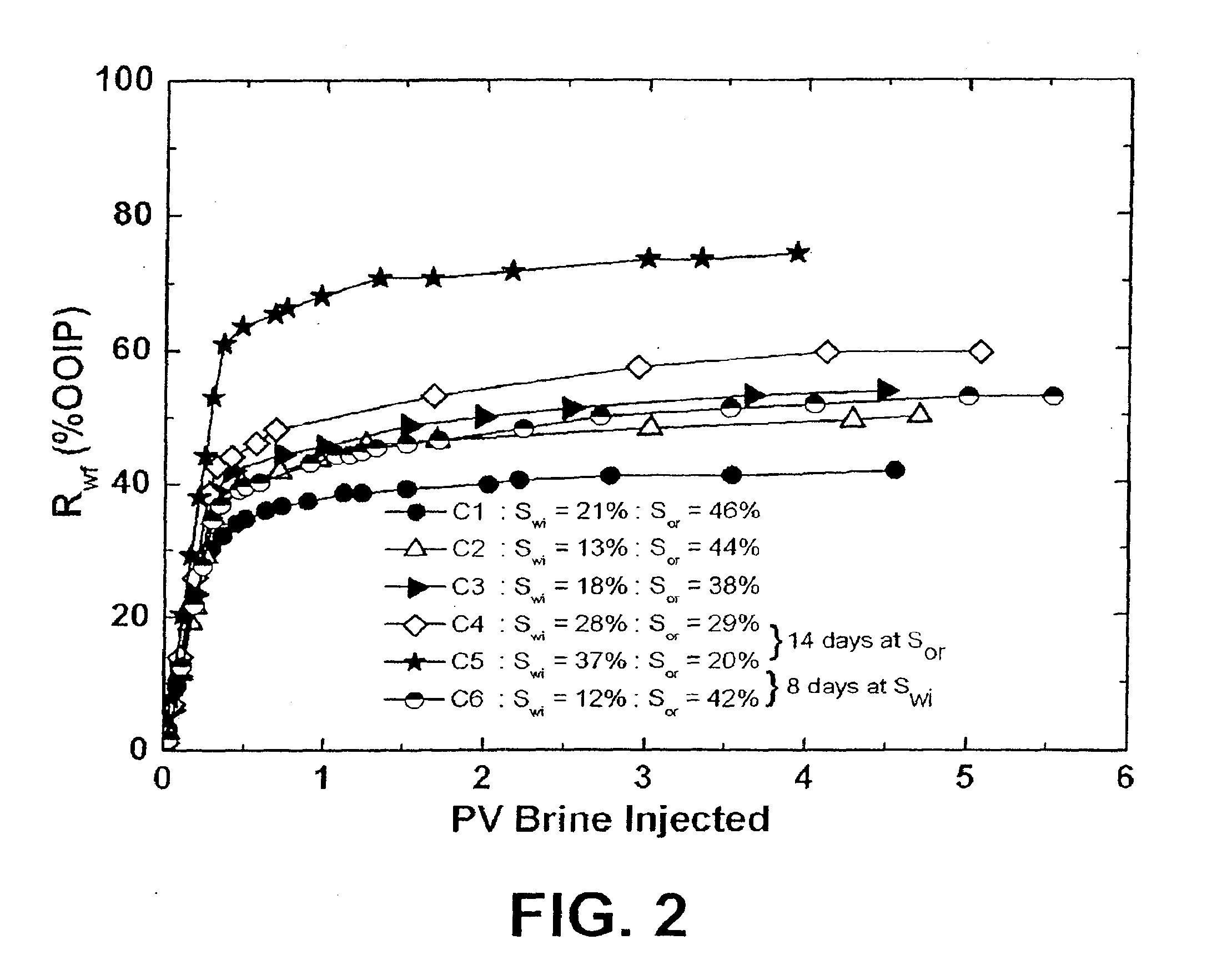

Single-well diagnostics and increased oil recovery by oil injection and sequential waterflooding

A method for residual oil recovery from oil reservoirs, and diagnostic tests for determining its efficiency using a single well are described. The method includes injecting oil into a well in a reservoir that has been previously waterflooded or an oil reservoir or zone of an oil reservoir which contains immobile oil at the time of discovery, and extracting the oil by waterflooding the charged zones by placing the injection well in production. The target zone from which oil is recovered may be increased by following injection of oil with injection of water to push an oil bank which grows in volume as a function of distance of propagation, because of the effect of waterflooding on residual oil. The well may then be placed in production and the oil bank volume will continue to increase in volume as it returns to the well, again because of the waterflooding effect. The oil bank is then produced at the surface. The double-sweep waterflooding process using a single well can be repeated by again charging with oil followed by waterflooding. Sequential injection of oil and water to generate more than one oil bank may also be used to increase oil recovery by multiple sequential waterfloods. Combinations of oil injection and sequential waterflooding also have application to reservoir diagnostics.

Owner:UNIVERSITY OF WYOMING

Automotive fuel cell hydrogen circulating system

The invention discloses an automotive fuel cell hydrogen circulating system, which is characterized by comprising a multi-point sequential injection system, a Venturi tube, a hydrogen flowmeter and a back pressure valve, wherein the multi-point sequential injection system and the Venturi tube are combined to realize fuel cell hydrogen circulation. The automotive fuel cell hydrogen circulating system has the advantages that: the multi-point sequential injection system is adopted to control the hydrogen flow, and is combined with the Venturi tube, so that the hydrogen is circulated, the hydrogen utilization rate is improved, the hydrogen side drainage is strengthened, the hydrogen side humidification is effectively improved, and the water in the fuel cell is effectively managed; and the device is simple, safe, reliable and low in cost, and can be used for vehicle-mounted environment.

Owner:SUNRISE POWER CO LTD

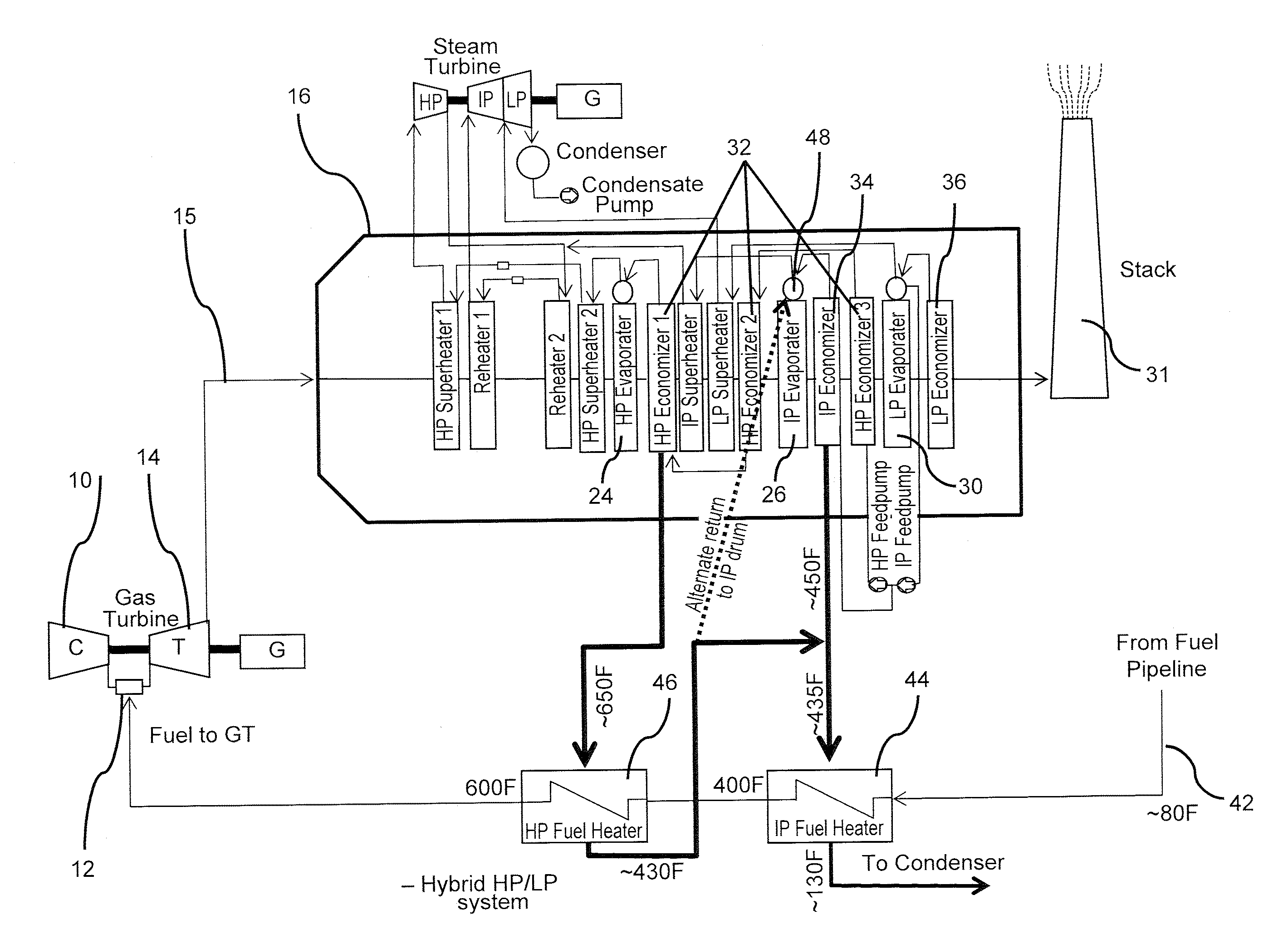

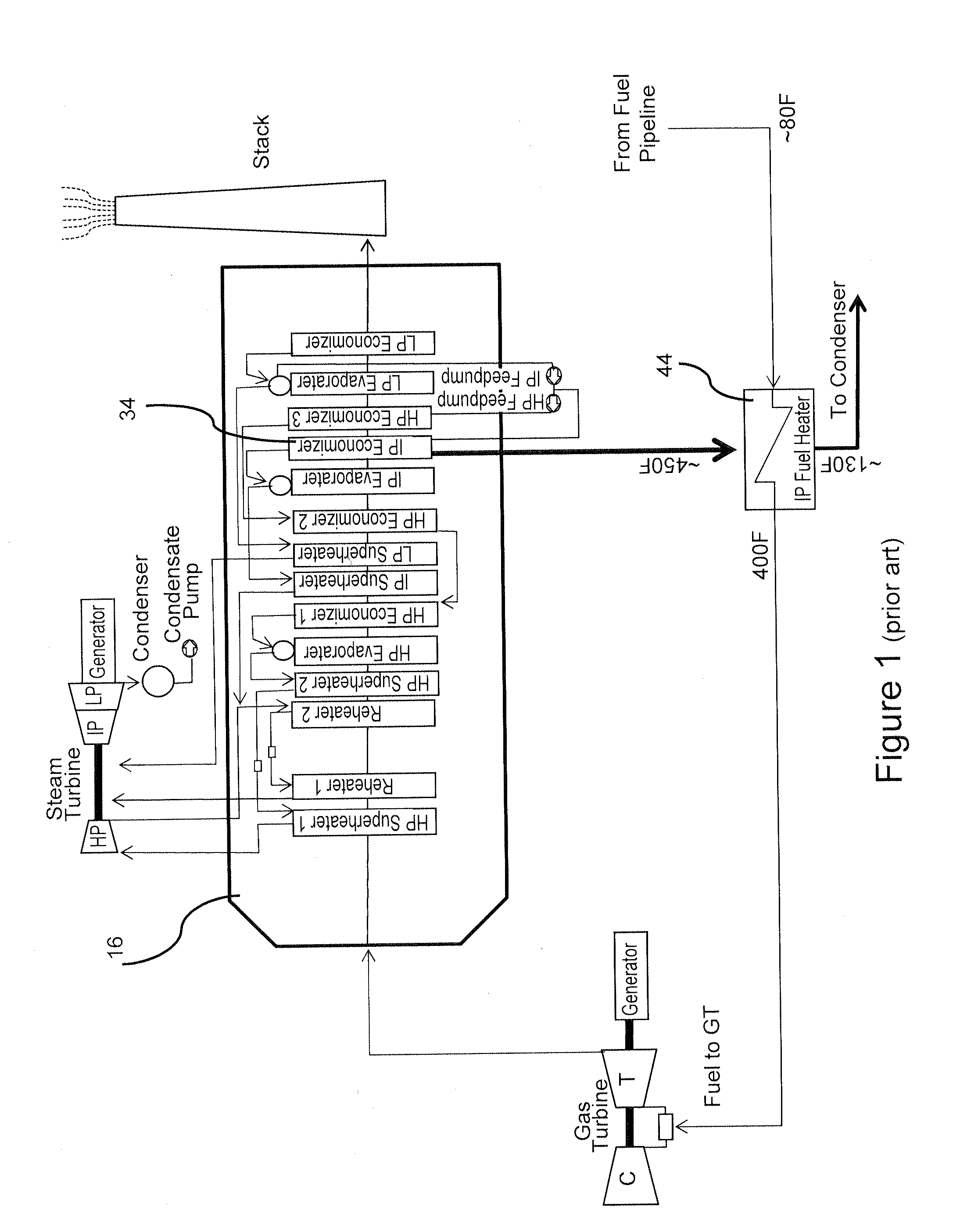

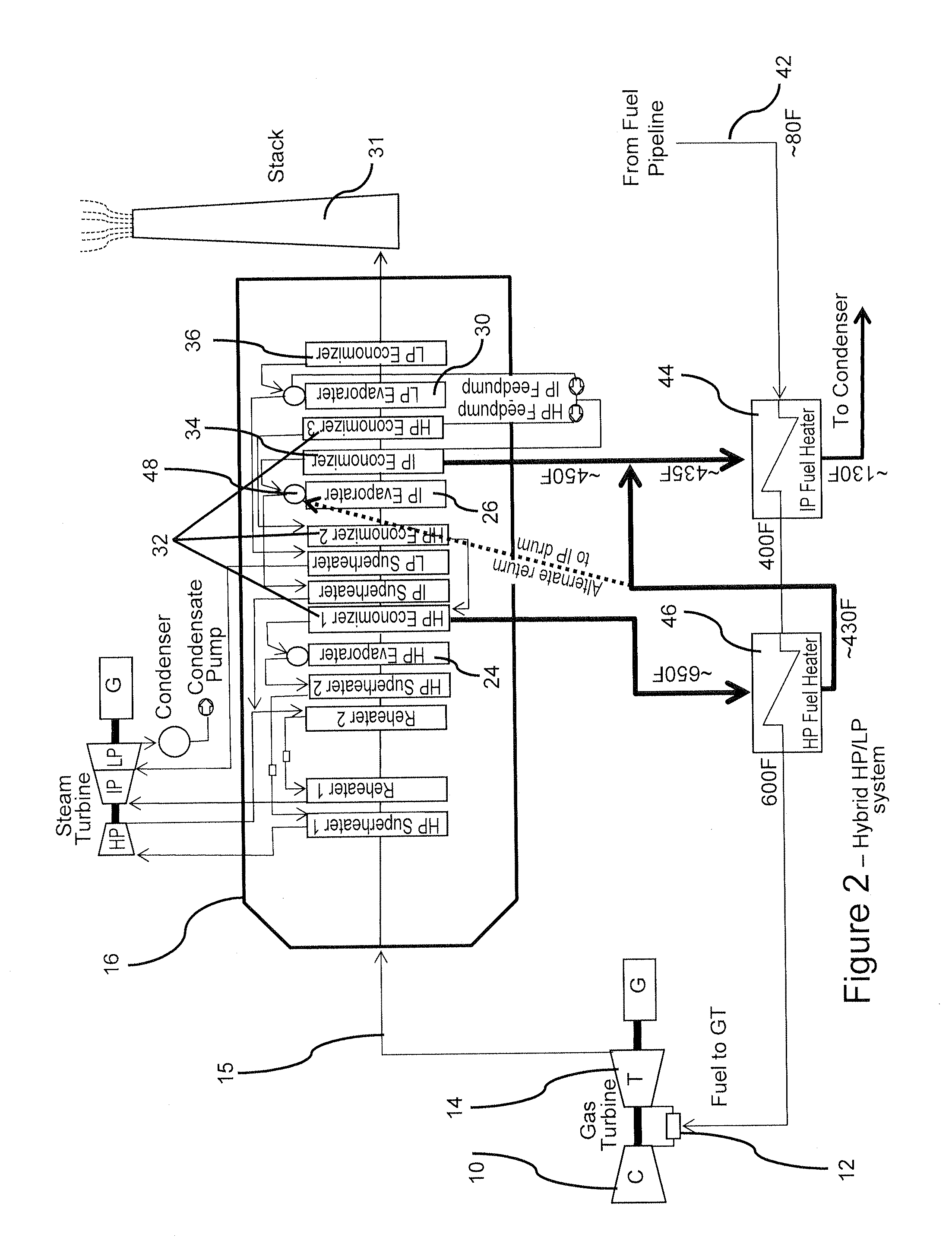

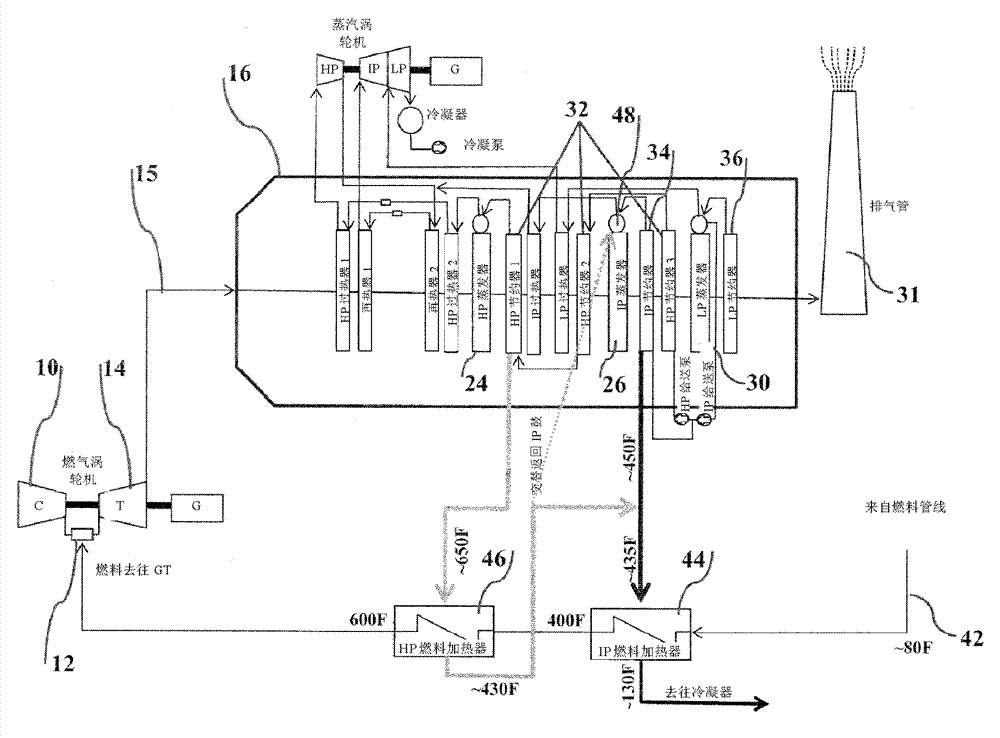

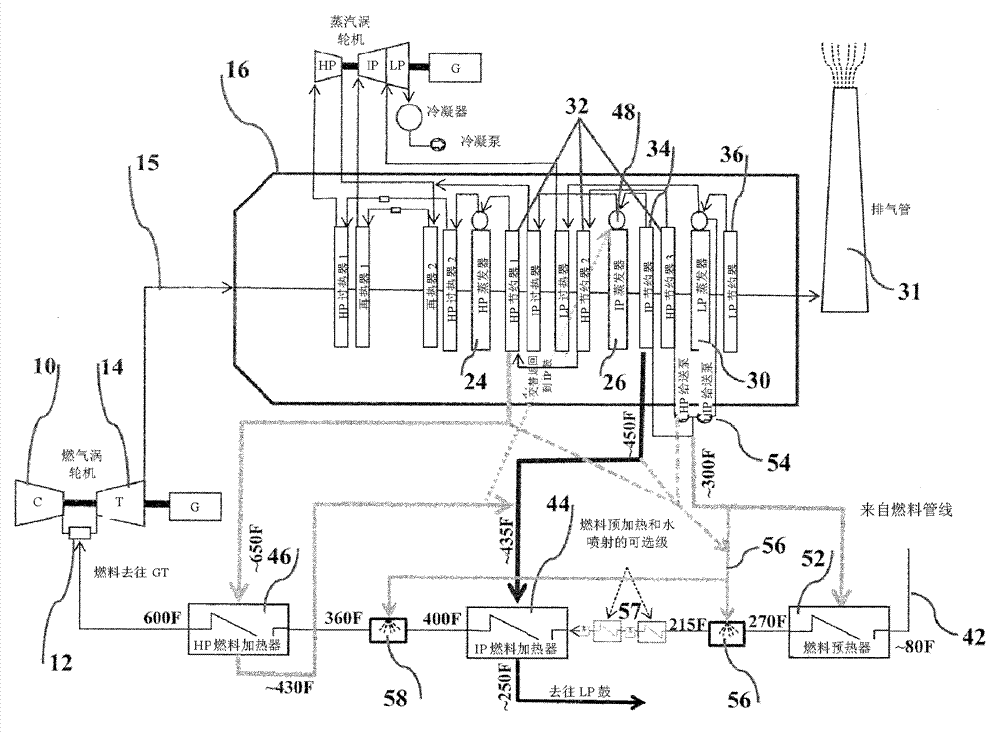

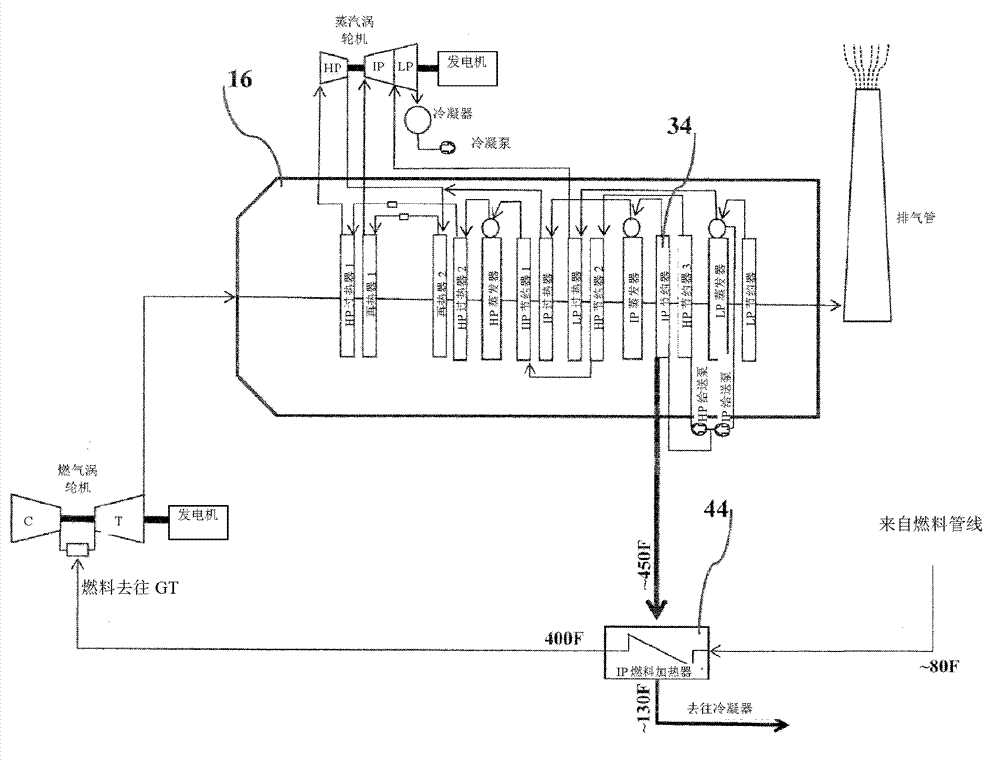

Fuel Heating in Combined Cycle Turbomachinery

InactiveUS20130074508A1Improve efficiencyGas turbine plantsTurbine/propulsion fuel heatingFuel lineThermal water

Combined cycle efficiency can be improved by heating fuel in a gas turbine fuel line in two stages using (i) hot water from an HP economizer of a heat recovery steam generator (HRSG) in a second stage and (ii) hot water from an IP economizer of the HRSG and water output flow from the second stage in a first stage. Efficiency may be further improved by adding one or more fuel preheaters using hot water from the IP feedpump and sequential injections of hot water into the fuel.

Owner:GENERAL ELECTRIC CO

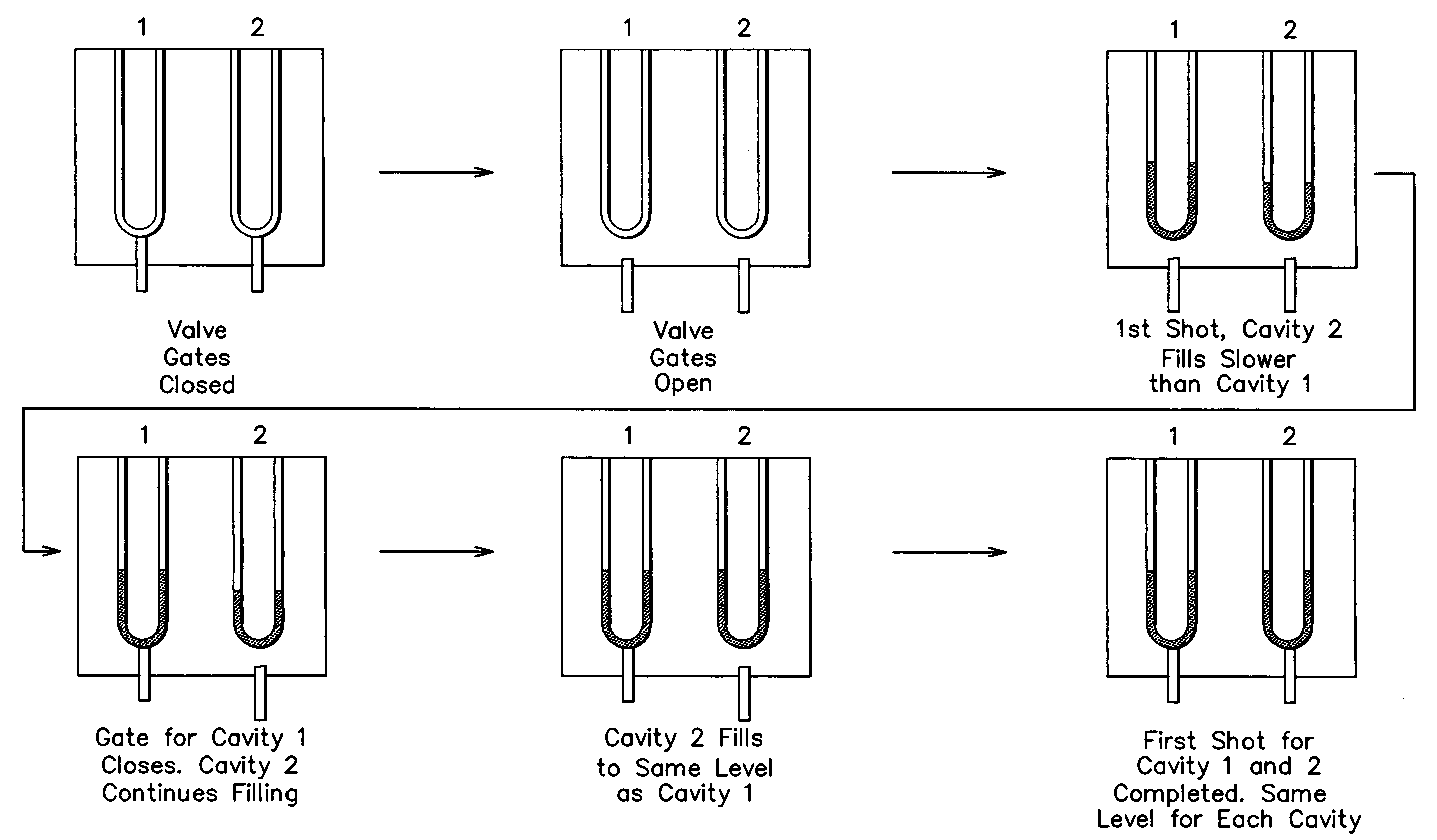

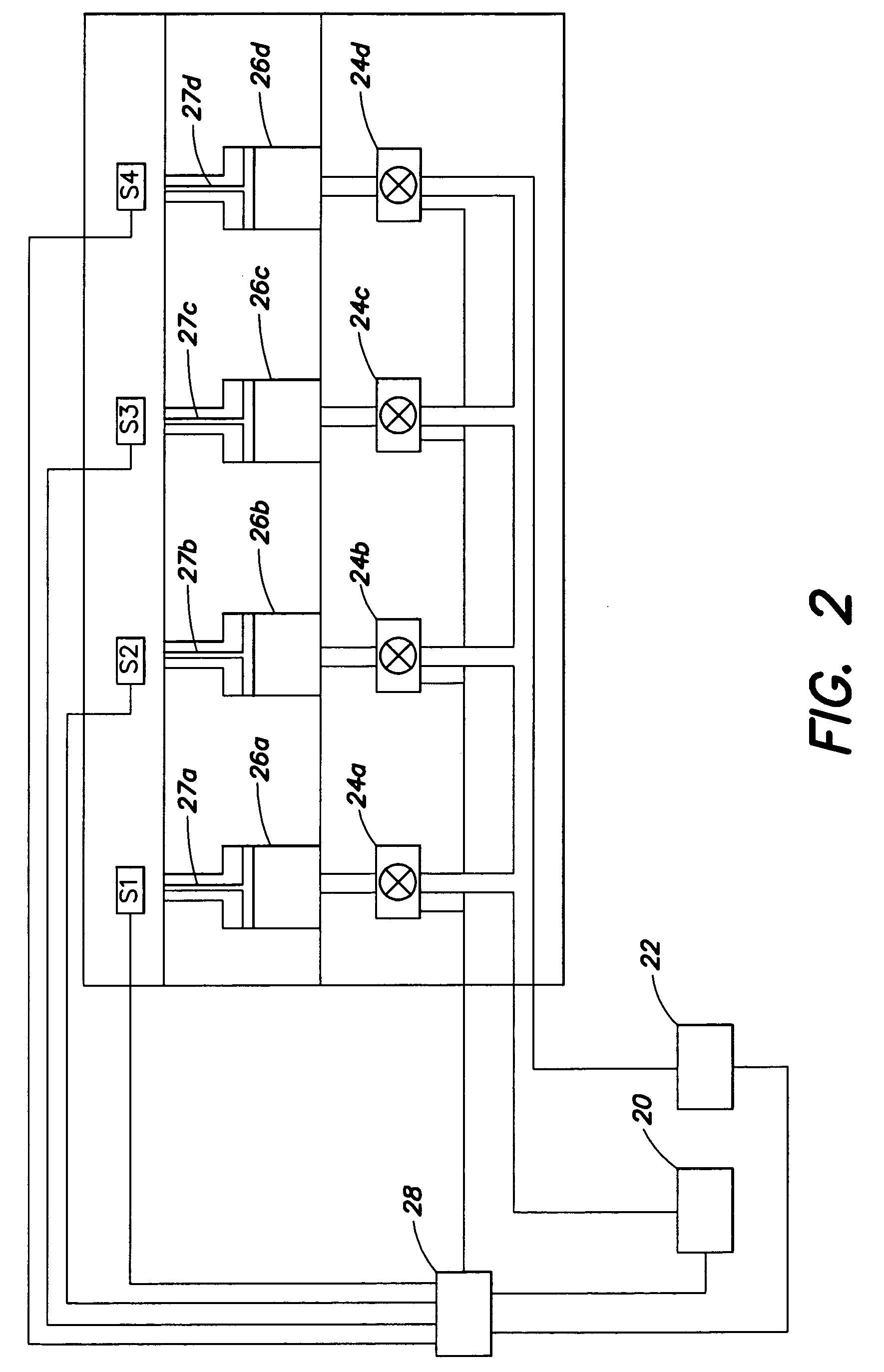

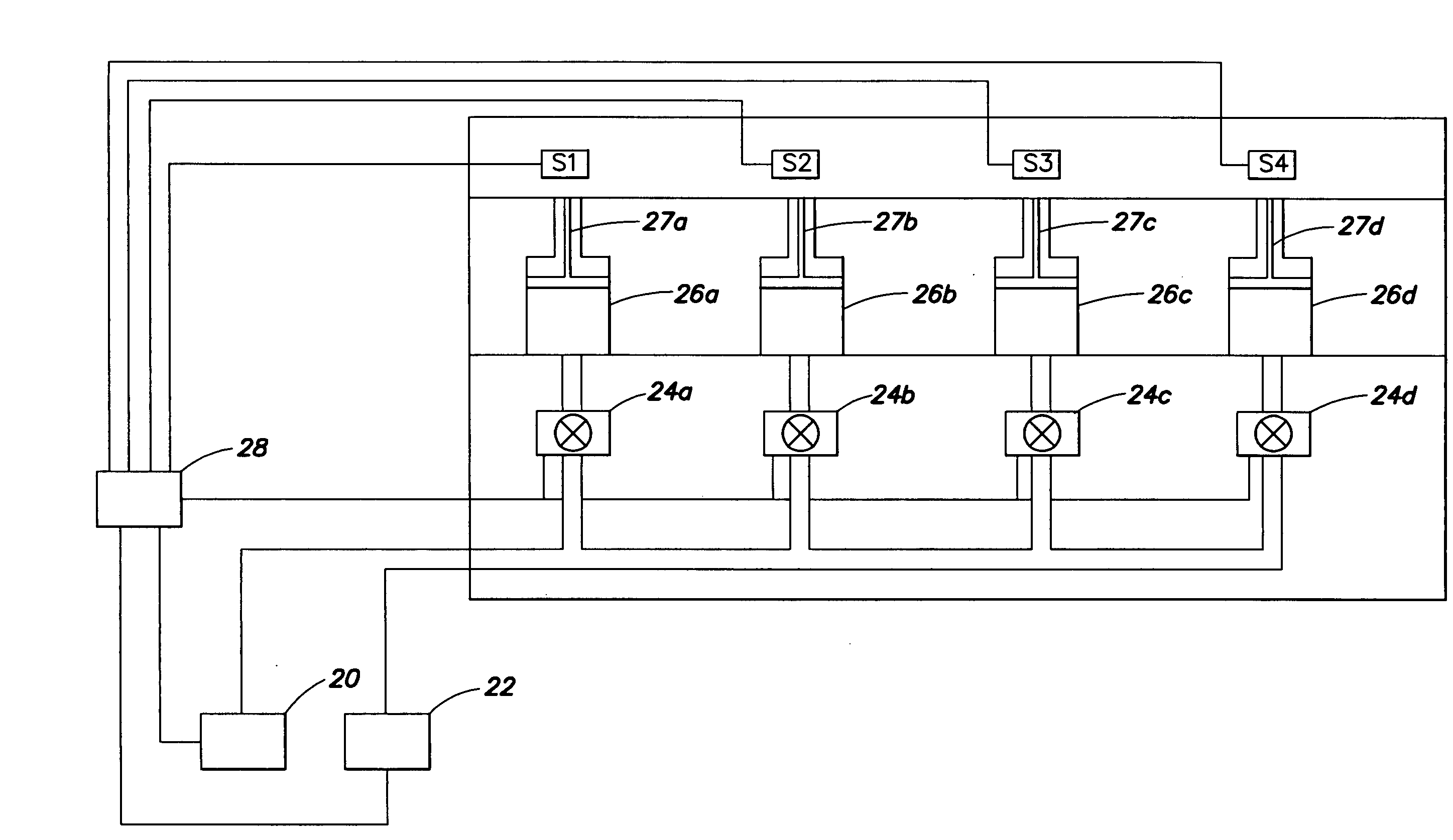

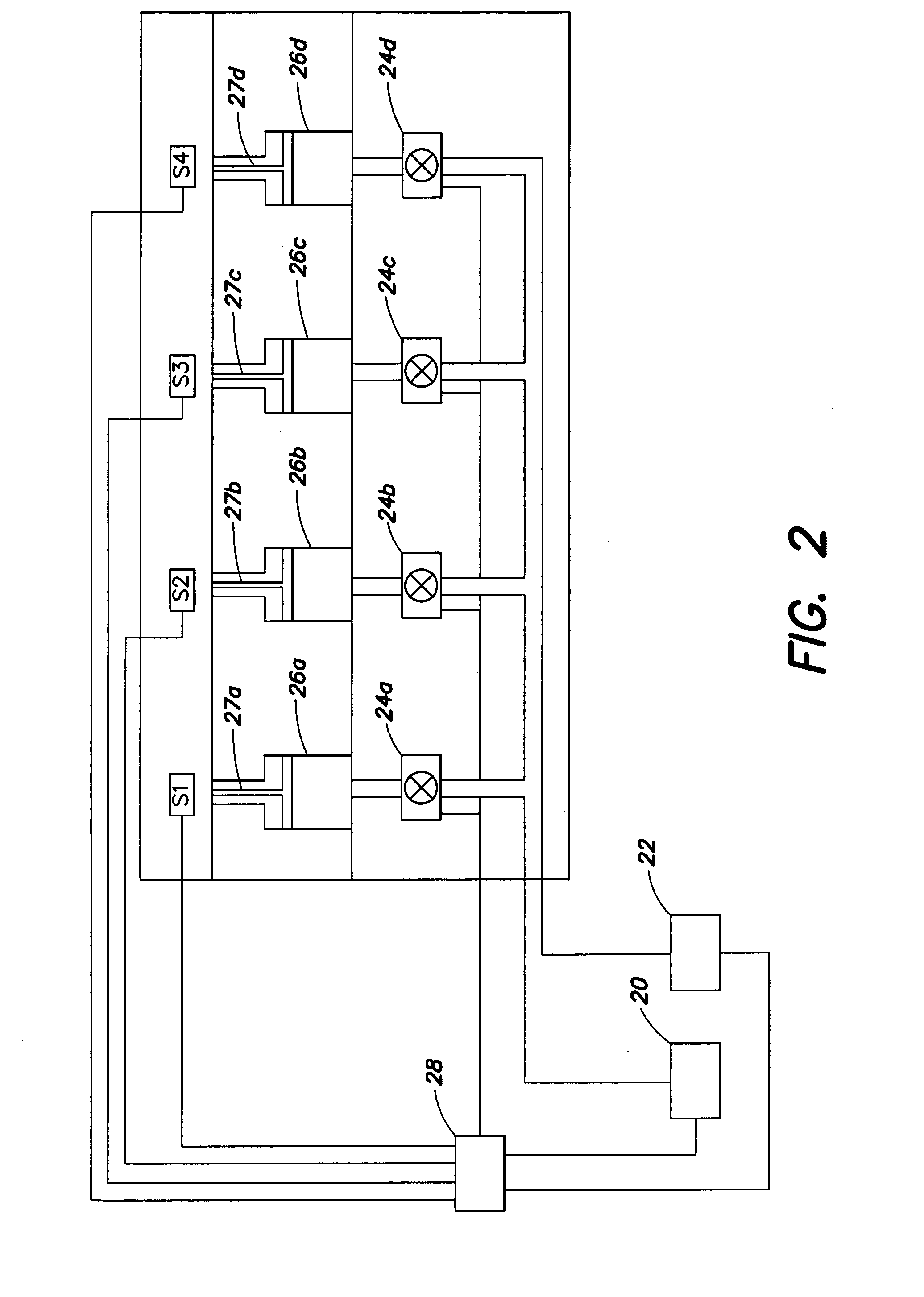

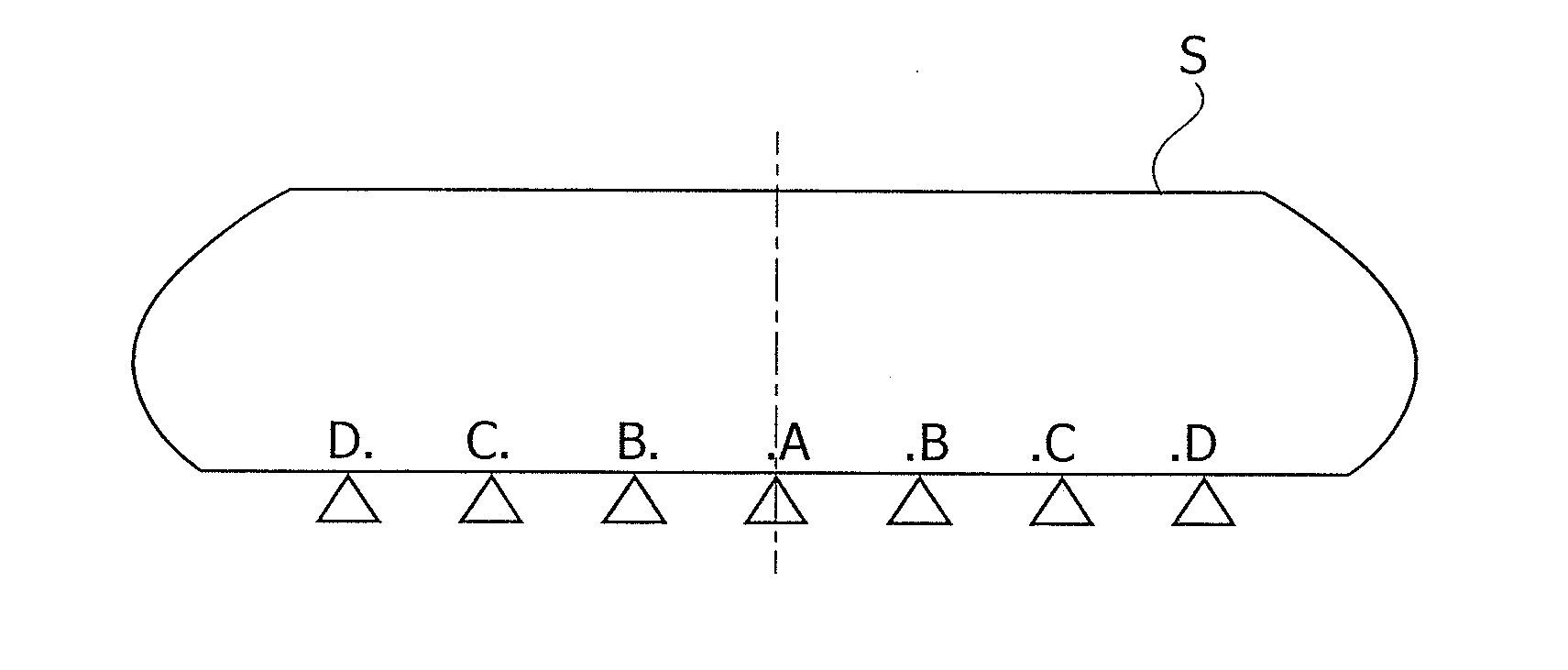

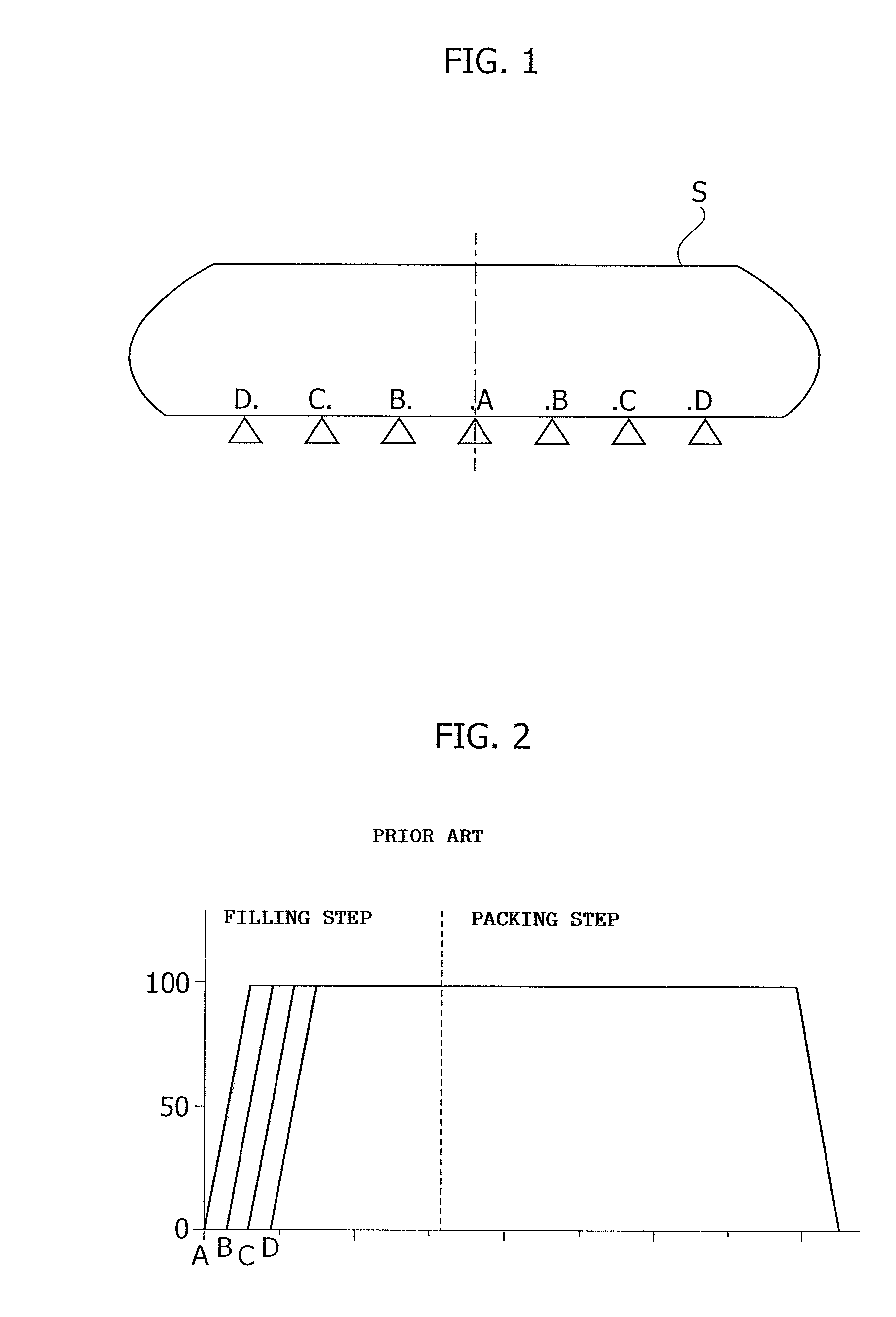

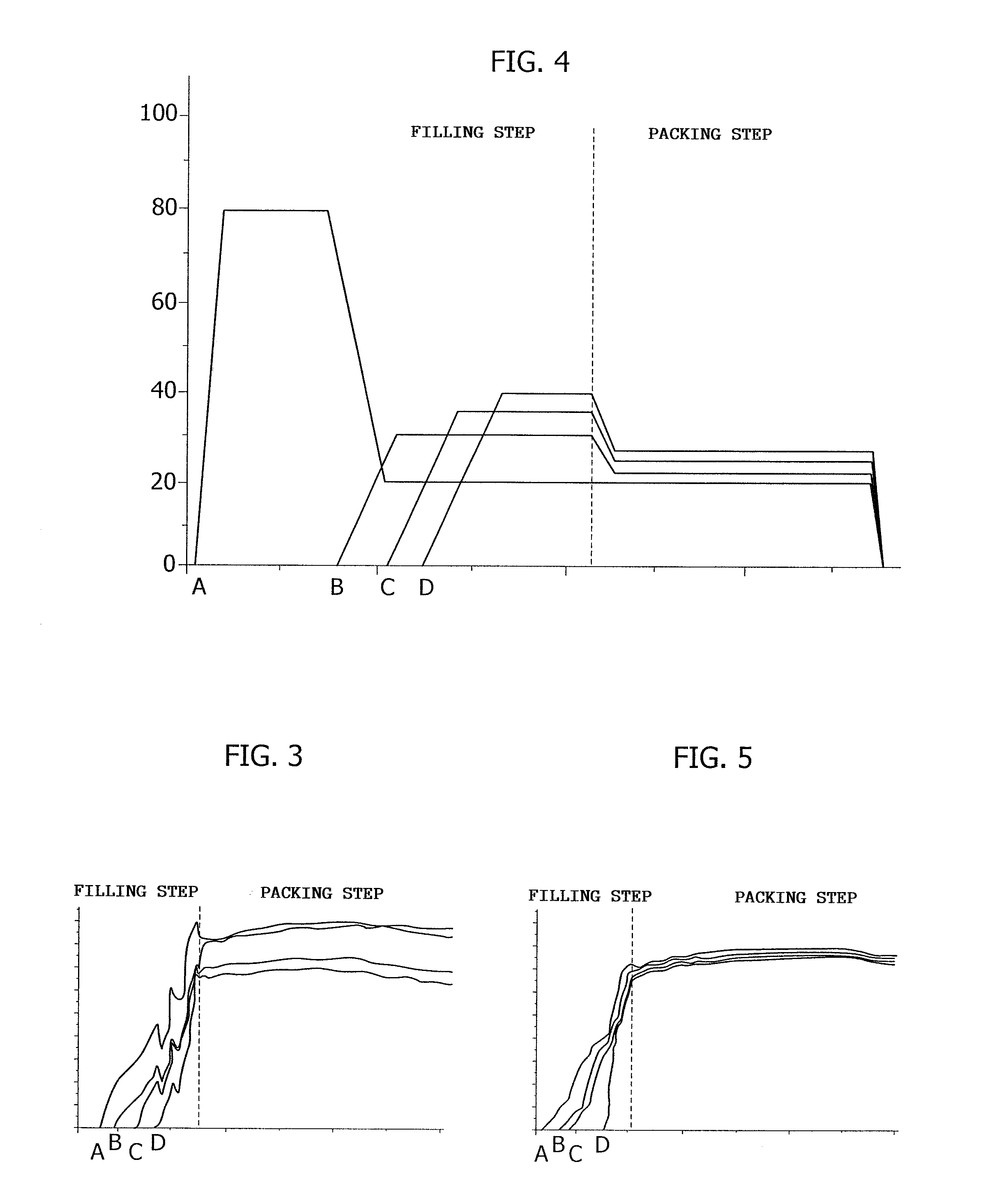

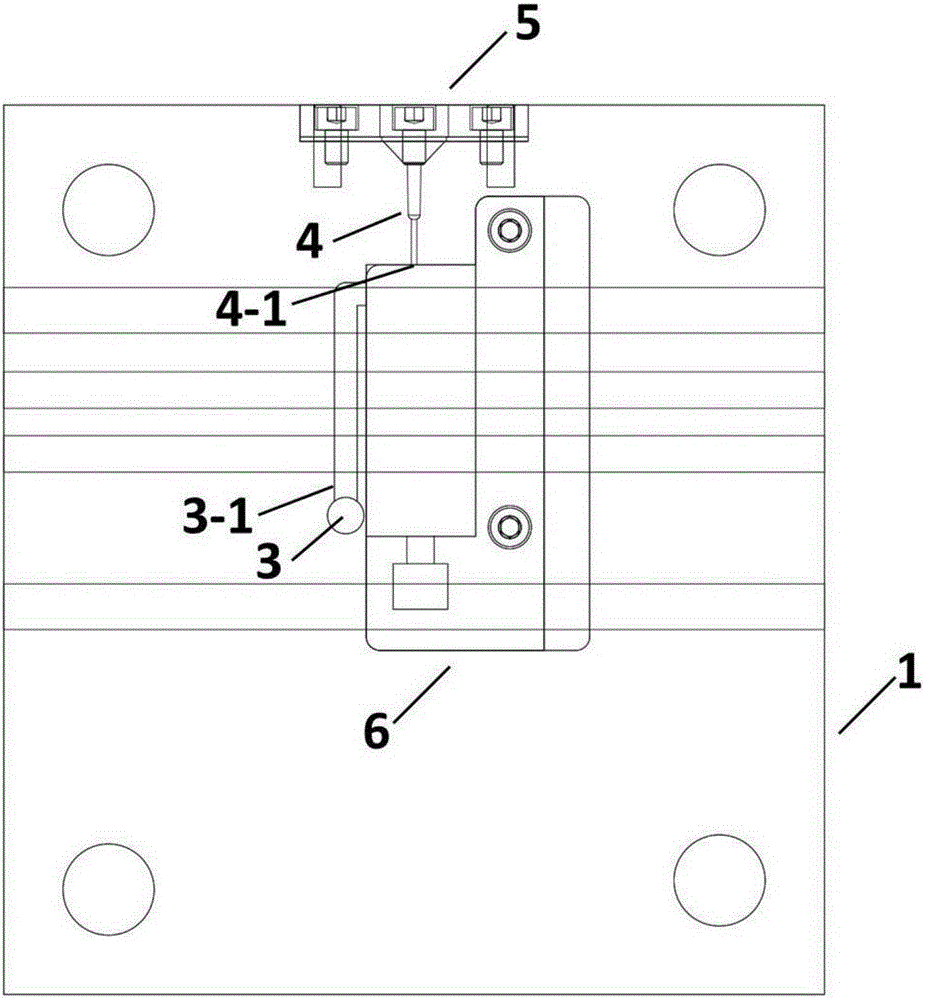

Controlling delivery of polymer material in a sequential injection molding process

ActiveUS7651644B2Reduce in quantitySimple equipmentAuxillary shaping apparatusFood shapingBiomedical engineeringPolymer

Method and apparatus for controlling the delivery of polymer material in a sequential injection molding process. In one embodiment, the method provides: delivering a first shot of a first material simultaneously to a plurality of mold cavities; independently sensing for each cavity a property that is indicative of a volume or flow of material that is delivered to the corresponding cavity during the step of delivering the first shot; independently stopping the step of delivering the first shot to one or more cavities according to a program that uses as a variable a signal indicative of the property sensed for the corresponding cavity during delivery of the first shot; and delivering a second shot of a second material simultaneously to the cavities subsequent to the step of stopping the step of delivering the first shot.

Owner:GRAHAM PACKAGING CO LP

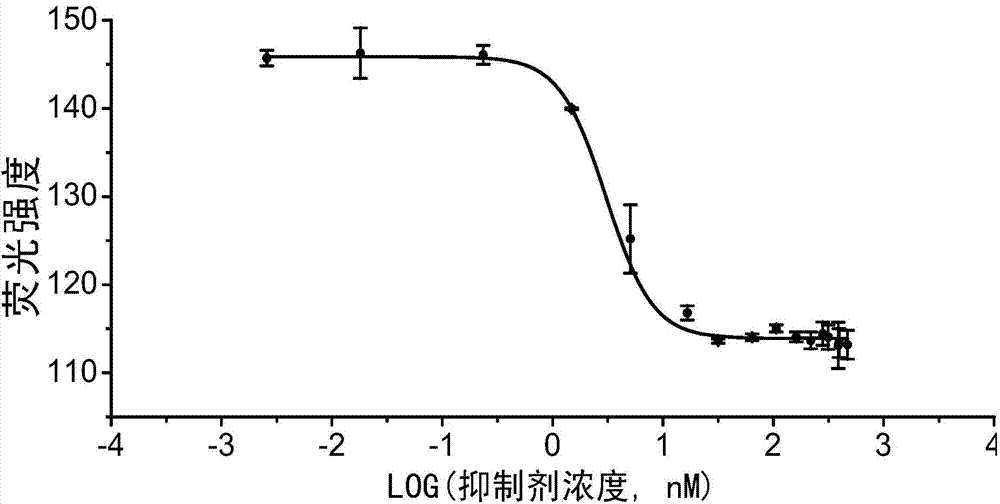

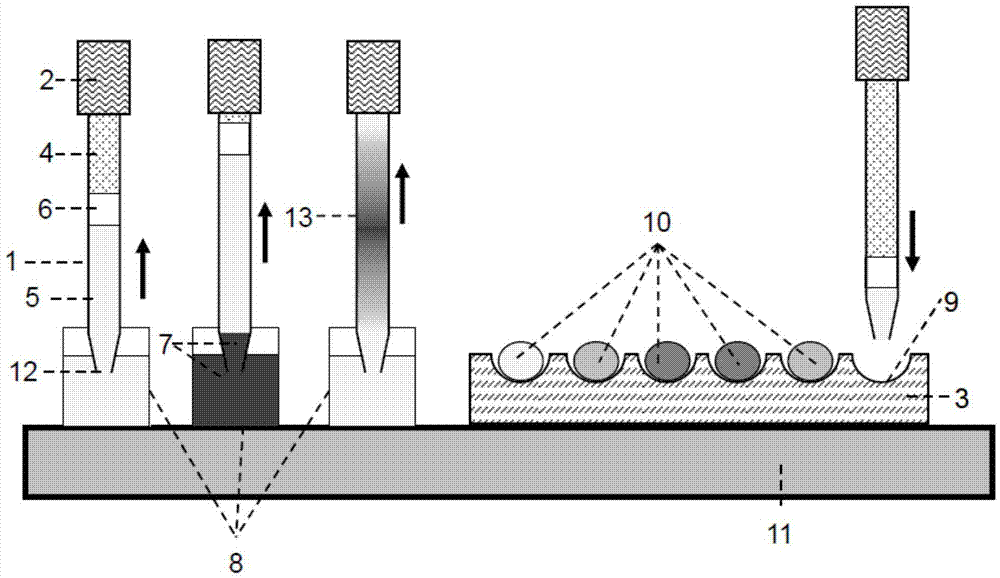

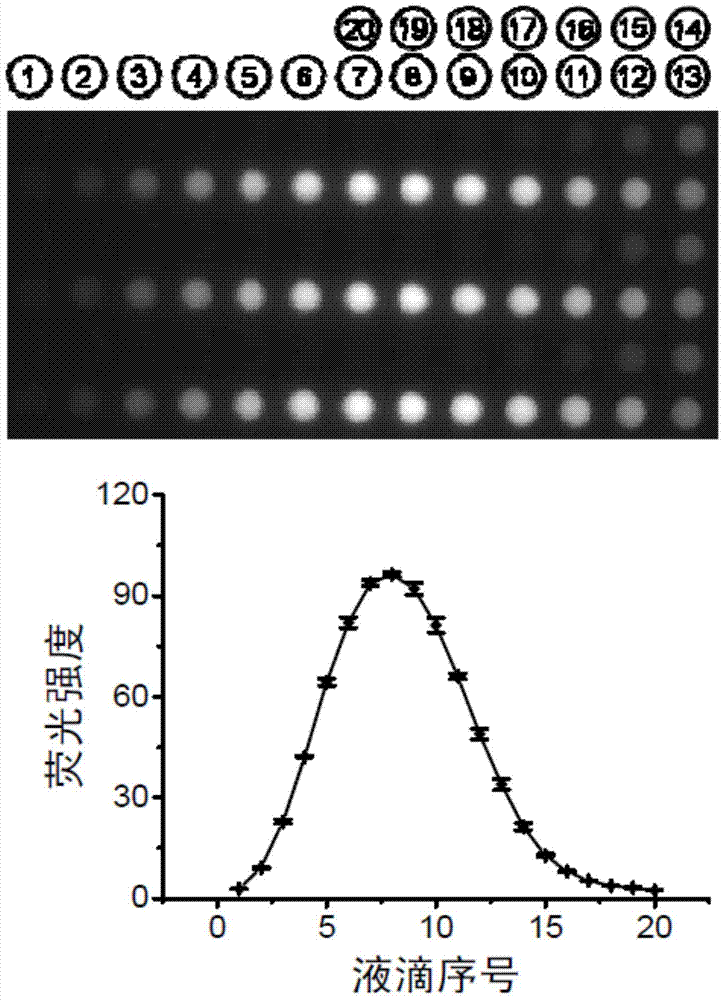

Gradient micro-droplet array forming method based on sequential injection and microfluidic technology

ActiveCN104849111AReduce consumptionHigh degree of automationPreparing sample for investigationLaboratory glasswaresHigh fluxDiluent

The invention discloses a gradient micro-droplet array forming method based on sequential injection and microfluidic technology. The gradient micro-droplet array forming method comprises following steps: step 1, one of a diluent and a sample I is taken using a capillary tube; step 2, the other one of the diluent and the sample I is taken using the capillary tube, and direct contact of the diluent with the sample I is ensured so as to form a sample zone belt with axial concentration gradient; and step 3, the sample zone belt is injected into certain areas of a microporous array chip via the capillary tube so as to obtain sample droplet array with different concentration on the microporous array chip. Advantages of the gradient micro-droplet array forming method are that: concentration gradient generation throughput is high, concentration information is abundant, automatic degree is high; sample consumption is low, and devices and principles are simple. The gradient micro-droplet array forming method can be used for biochemical analysis and screening such as high throughput drug screening, compound toxicity determination, protein crystallization condition screening, catalyst screening, and enzyme dynamic analysis.

Owner:ZHEJIANG UNIV

Controlling delivery of polymer material in a sequential injection molding process

ActiveUS20070278708A1Reduce in quantitySimple equipmentAuxillary shaping apparatusFood shapingBiomedical engineeringControlled delivery

Method and apparatus for controlling the delivery of polymer material in a sequential injection molding process. In one embodiment, the method provides: delivering a first shot of a first material simultaneously to a plurality of mold cavities; independently sensing for each cavity a property that is indicative of a volume or flow of material that is delivered to the corresponding cavity during the step of delivering the first shot; independently stopping the step of delivering the first shot to one or more cavities according to a program that uses as a variable a signal indicative of the property sensed for the corresponding cavity during delivery of the first shot; and delivering a second shot of a second material simultaneously to the cavities subsequent to the step of stopping the step of delivering the first shot.

Owner:GRAHAM PACKAGING CO LP

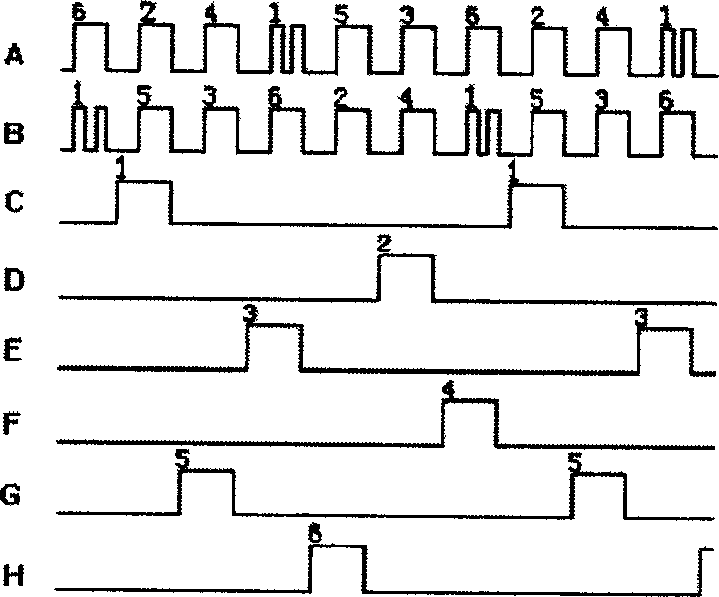

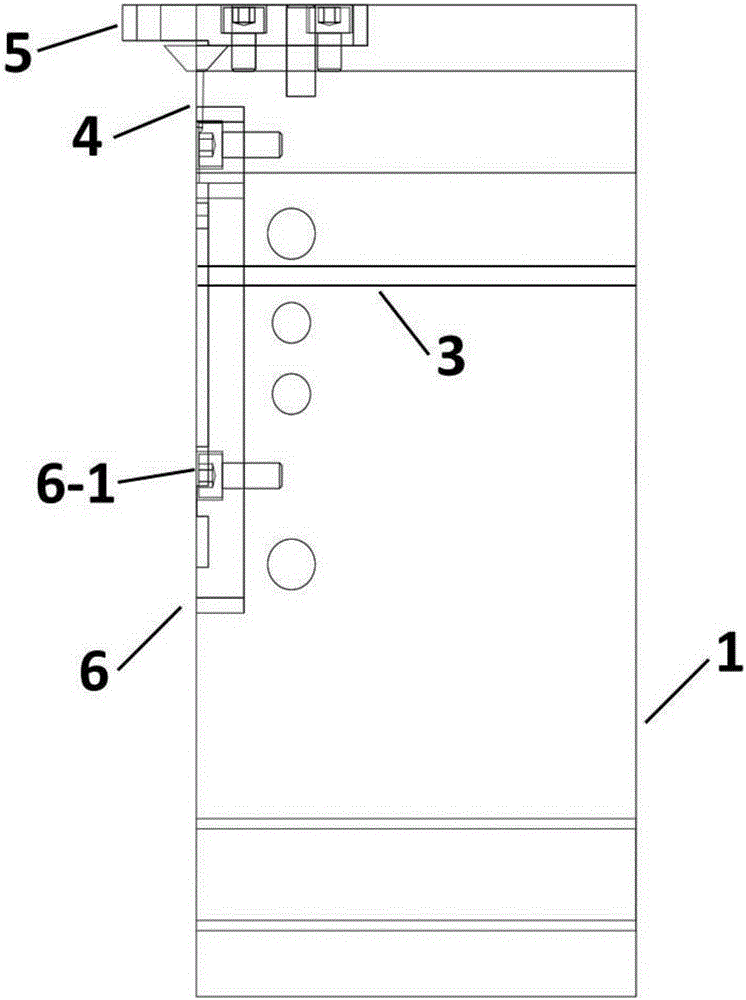

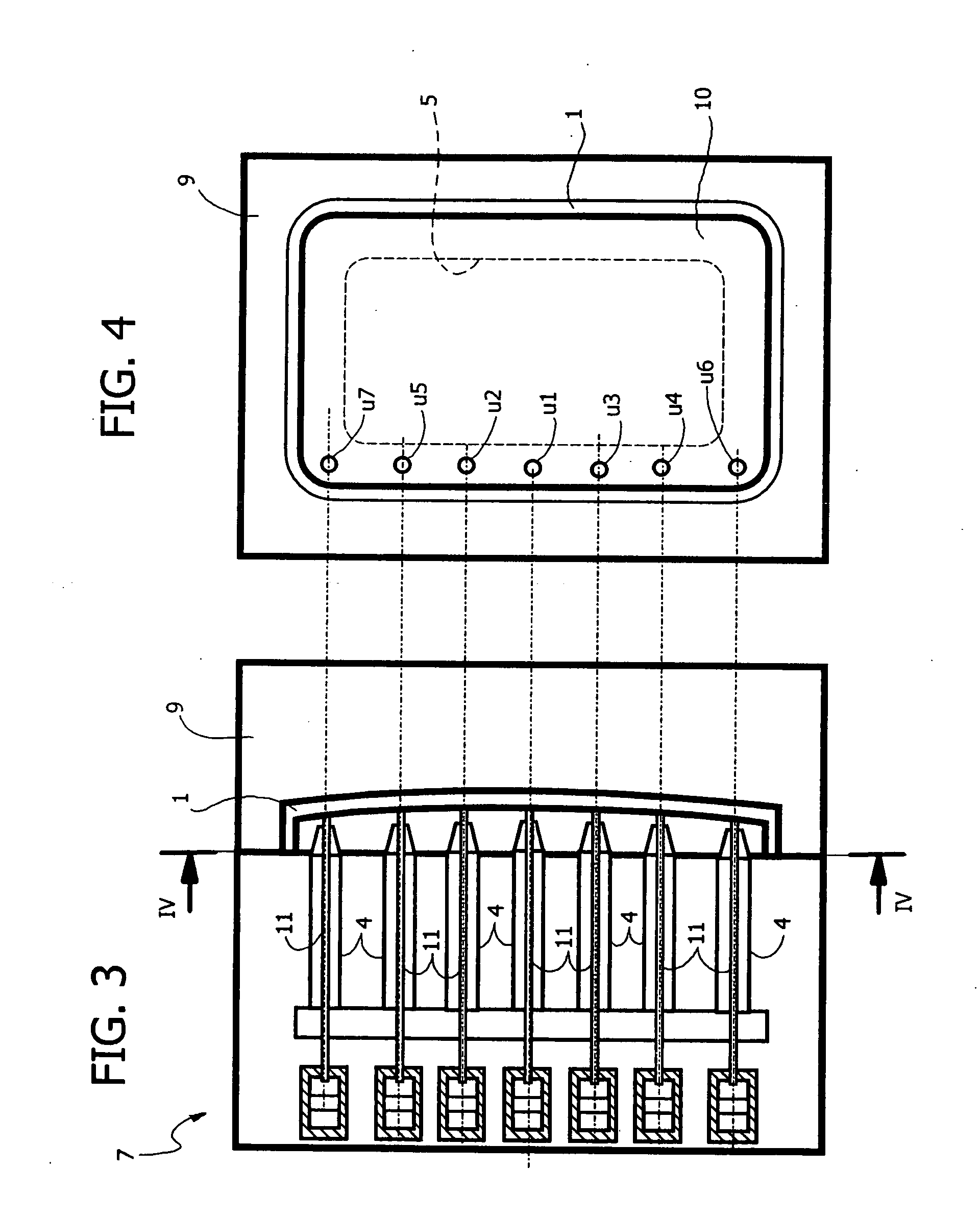

Molding apparatus and method for producing articles molded through sequential injection

ActiveUS20160167264A1Cavity-greater regularityCavity-greater homogeneityAuxillary shaping apparatusDomestic articlesElectronic systemsElectronic control system

A molding apparatus for the production of articles molded through sequential injection includes a mold having a cavity, a plurality of electrically actuated injectors arranged at central, intermediate and end positions, respectively, with respect to the mold cavity, and an electronic system for controlling the injectors for the actuation thereof according to a sequential cycle which provides for opening the central injector first, followed by the intermediate injectors and then the end injectors. The electronic control system is configured so that the opening sequential cycle occurs in such a way to obtain more linear and homogeneous pressure in the mold filling step, and lower packing pressure.

Owner:INGLASS SPA

Fuel heating in combined cycle turbomachinery

Owner:GENERAL ELECTRIC CO

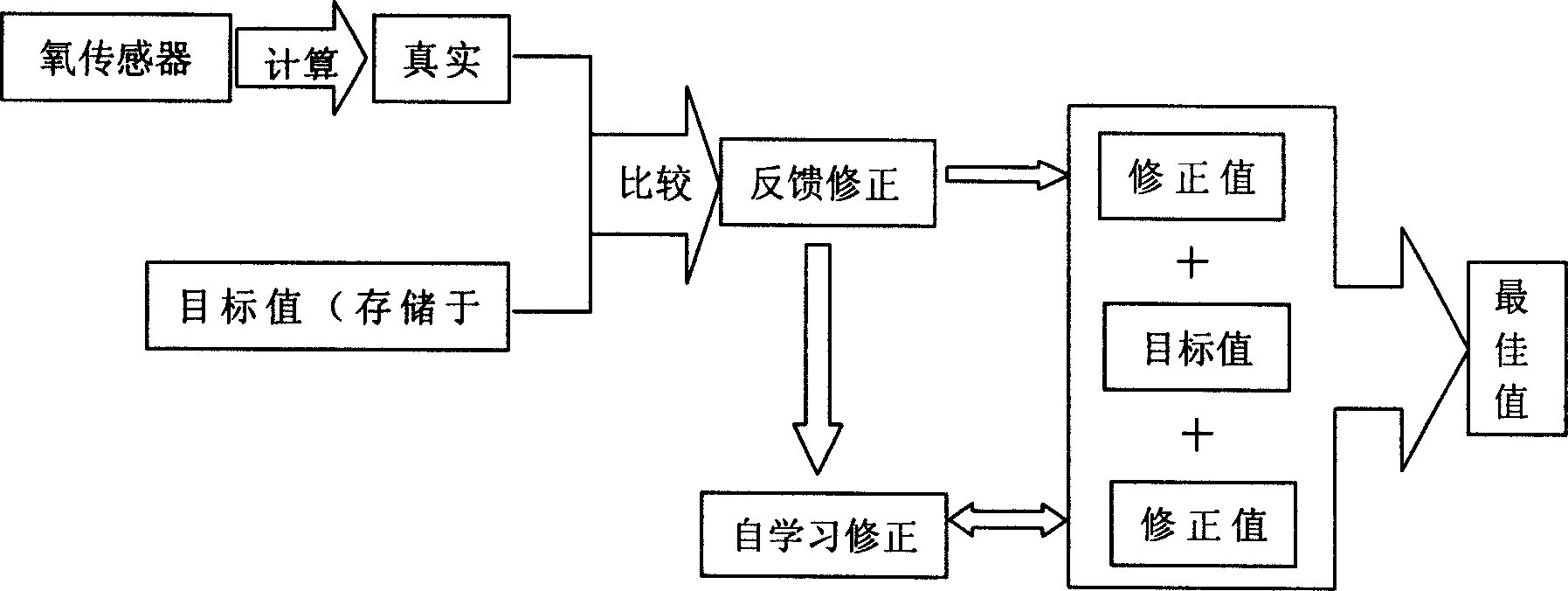

Electrically controlled multi-point sequential injection system and control method for natural gas engine

InactiveCN1763358AReduce volumeReduce heat dissipationElectrical controlMachines/enginesControl mannerProcess engineering

The invention relates to an electric control injection system of natural gas engine for controlling the natural gas injection quantity, which is characterized by the following: adding the natural gas supply system; adapting gas-valve injecting supply pattern; setting the valve in the root of inlet pipe. The invention improves the gas-valve activation circuit to guarantee each cylinder with quantitative gas supply, which controls the zero-burn ratio according to the rotary speed and load.

Owner:BEIJING JIAOTONG UNIV

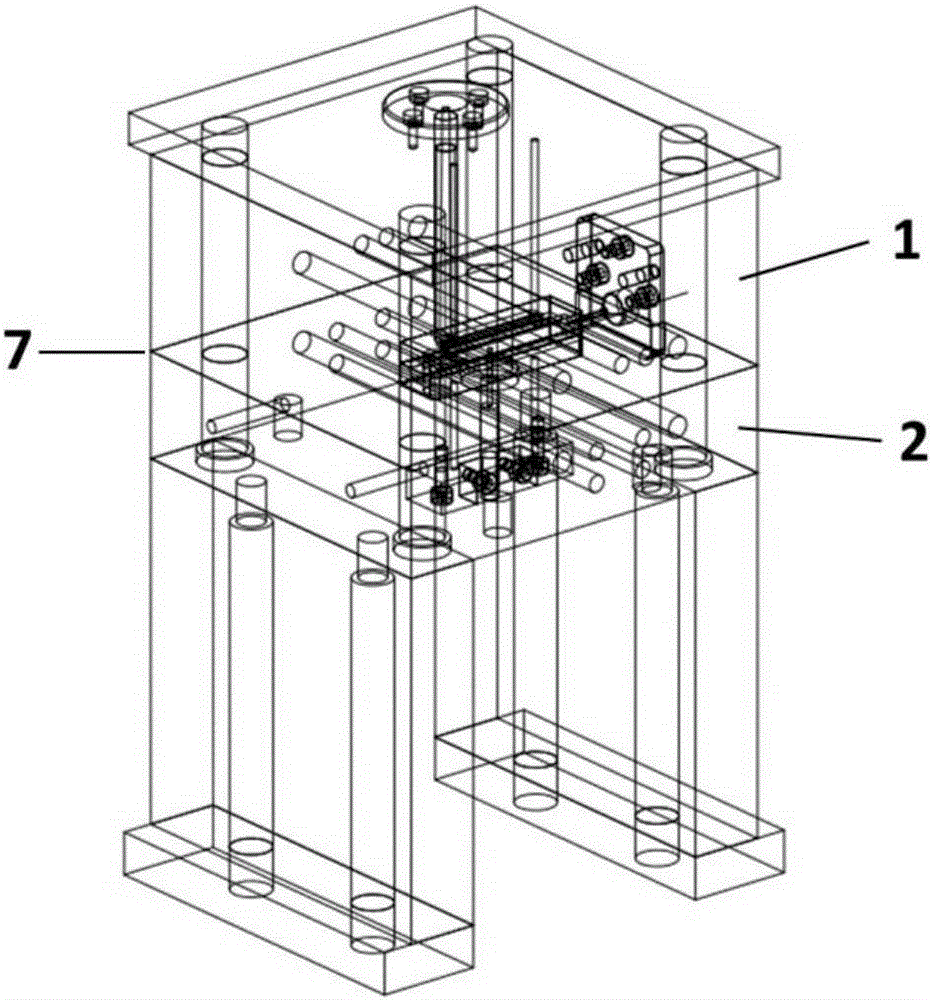

Multi-melt multi-injection molding mold

The invention discloses a multi-melt multi-injection molding mold which is suitable for effectively completing sequential injection of polymer melts without a double colored plastic injection machine. A primary injection runner, a secondary injection runner, a secondary injection system positioning plate and a mold cavity assembly which are located on the sides of a fixed mold and a movable mold are combined to form the multi-melt multi-injection molding mold. The multi-melt multi-injection molding mold accurately completes the sequential injection process of the polymer melts without the double colored plastic injection machine. Meanwhile, the mold structure is simplified, the equipment cost of the double colored plastic injection machine is omitted, and therefore the purposes of simplifying the process and reducing cost are achieved.

Owner:SICHUAN UNIV

Method and device for sequentially injecting lead in online detection of water quality

InactiveCN102998358AAccurate detectionEliminate distractionsPreparing sample for investigationMaterial electrochemical variablesWater sourceDose delivery

The invention relates to a method for sequentially injecting lead in online detection of water quality, wherein each step for detecting lead in stripping voltammetry and quantitative dose delivery of required solvent or solution are finished in sequence with sequential injection method; the method comprises the following steps: plating mercury on the surface of a working electrode by using mercury plating liquid HgSO4 solution or Hg(NO3)2 solution; absorbing lead ions in a raw water sample by using polystyrene-dithizone nanofiber; then eluting and condensing into sample water for detection; respectively injecting the sample water and carrier liquid in a electrolytic bath at fixed quantities, wherein the deposition potential is -1.0 to -1.2V, the deposition time is 140-160s, the cleaning potential is -0.3V, and the time is 15s; carrying out anode stripping voltammetry detection on the sample water so as to obtain a sample water stripping voltammetry curve, wherein the stripping peak area is combined with the stripping peak area of a guide sample; and calculating to obtain the lead concentration of sample water. The invention provides a special detection device, which is accurate in fixed quantity and high in sensitivity and can realize online and quick detection of lead content in various water sources.

Owner:DELIN ENVIRONMENTAL PROTECTION TECH

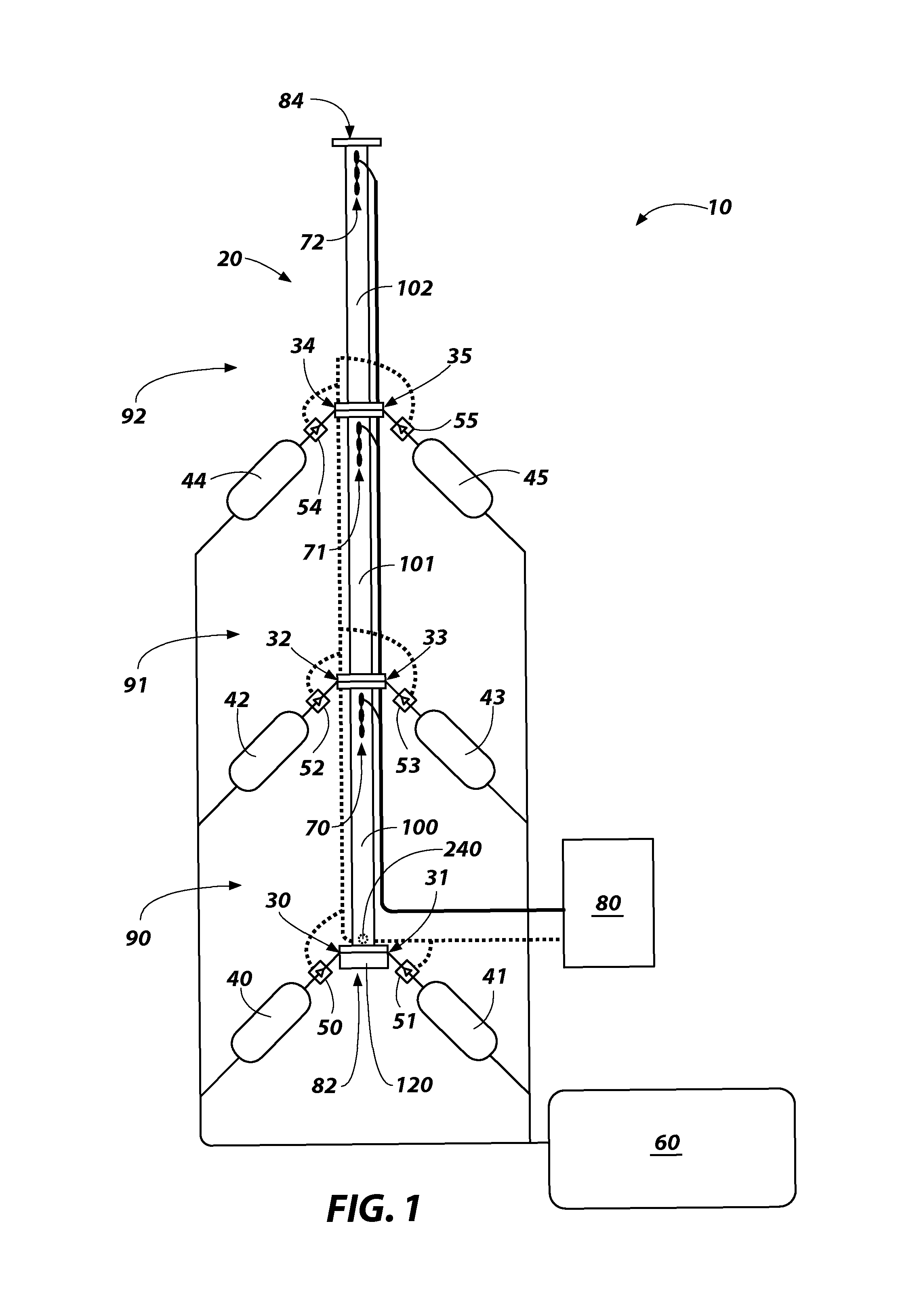

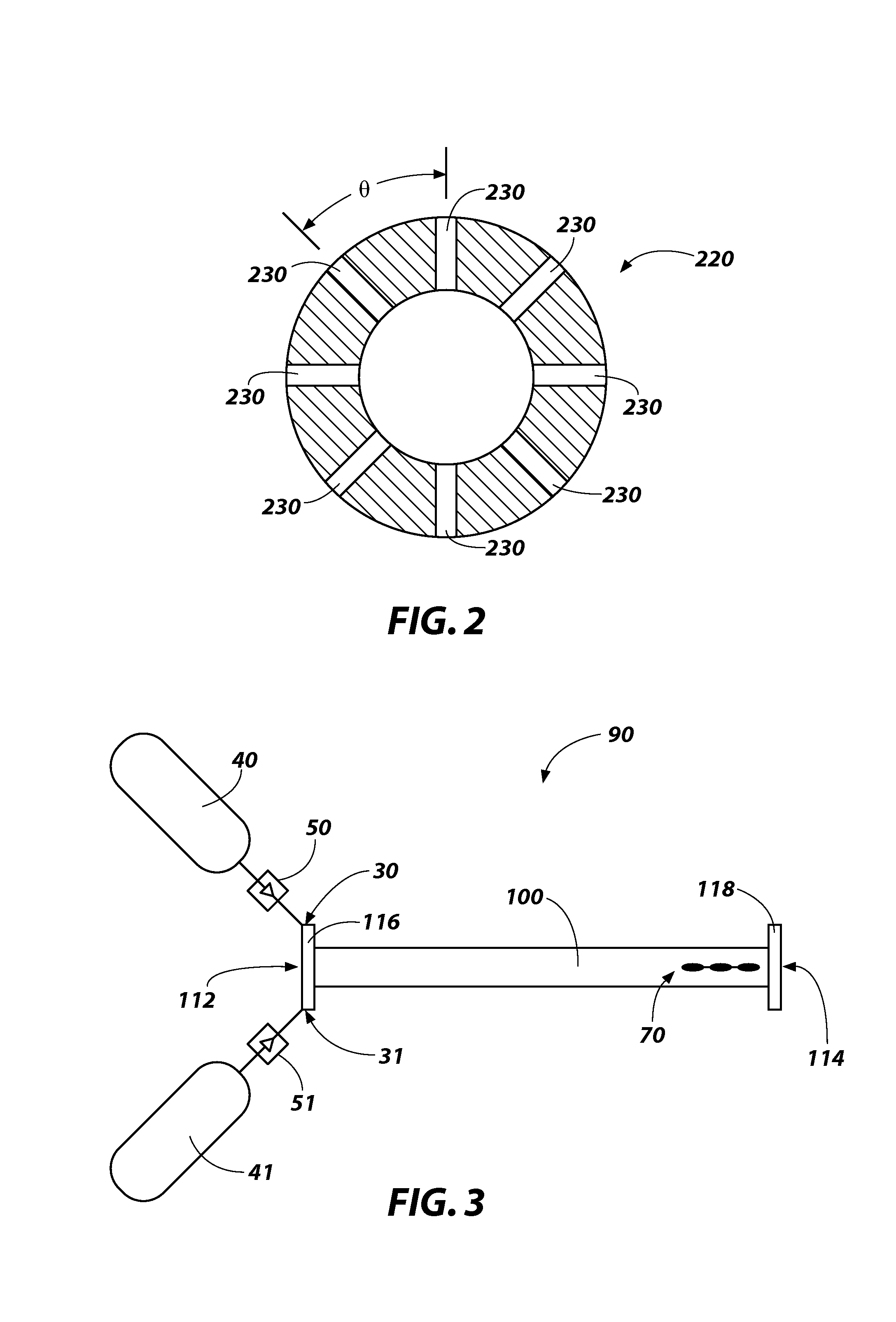

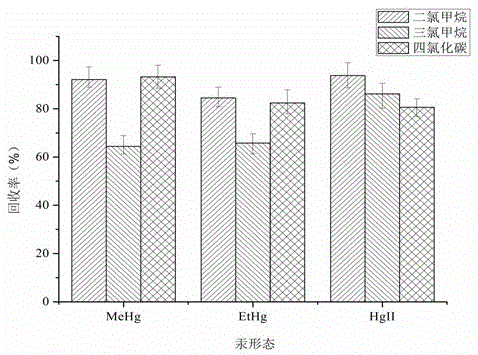

Sequential injection gas guns for accelerating projectiles

Gas guns and methods for accelerating projectiles through such gas guns are described. More particularly, gas guns having a first injection port located proximate a breech end of a barrel and a second injection port located longitudinally between the first injection port and a muzzle end of the barrel are described. Additionally, modular gas guns that include a plurality of modules are described, wherein each module may include a barrel segment having one or more longitudinally spaced injection ports. Also, methods of accelerating a projectile through a gas gun, such as injecting a first pressurized gas into a barrel through a first injection port to accelerate the projectile and propel the projectile down the barrel past a second injection port and injecting a second pressurized gas into the barrel through the second injection port after passage of the projectile and to further accelerate the projectile are described.

Owner:BATTELLE ENERGY ALLIANCE LLC

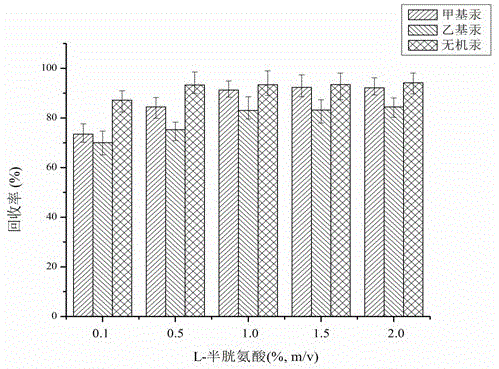

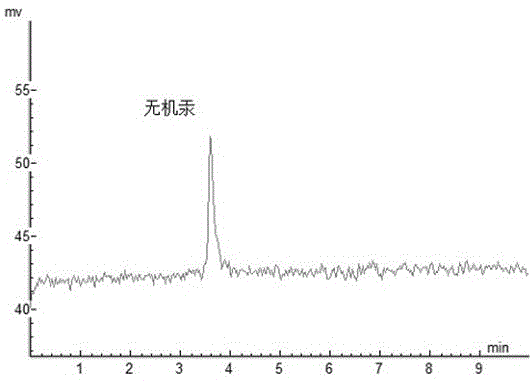

Method for detecting methyl mercury, ethyl mercury and inorganic mercury in water of aquaculture pond

ActiveCN105572245AOvercoming complexityOvercoming distractionsComponent separationAquacultureAtomic fluorescence

The invention discloses a method for detecting methyl mercury, ethyl mercury and inorganic mercury in water of an aquaculture pond. The method comprises the following steps: adding CH2Cl2 into a sample, carrying out vortex shake and centrifugation, taking out a sedimentary phase, adding L-cysteine into the sedimentary phase, extracting, centrifuging, and then removing supernatant liquid to obtain the sample to be detected; preparing the sample to be detected into 2-20 micrograms / L of liquid to be detected, and then detecting by a high performance liquid chromatography (HPLC)-cold vapor generation atomic fluorescence system. The method adopts a vortex-assisted liquid-liquid microextraction way to carry out pretreatment on the aquaculture pond water sample for the first time, thus solving the problems that the sample matrix is complicated, interference is serious, the method is lack of sensitivity, and the like; HPLC separation and sequential injection-cold vapor generation atomic fluorescence system (SI-CVAFS) sample introduction are utilized, so that the method fills into the blank of analyzing the methyl mercury, the ethyl mercury and the inorganic mercury in water of the aquaculture pond at the same time; the method has the characteristics of being simple and rapid in operation, low in cost, environment-friendly, efficient, high in enrichment efficiency, remarkable in interference resistance, high in precision and accuracy, low in detection limit, and the like.

Owner:四川威尔检测技术股份有限公司 +2

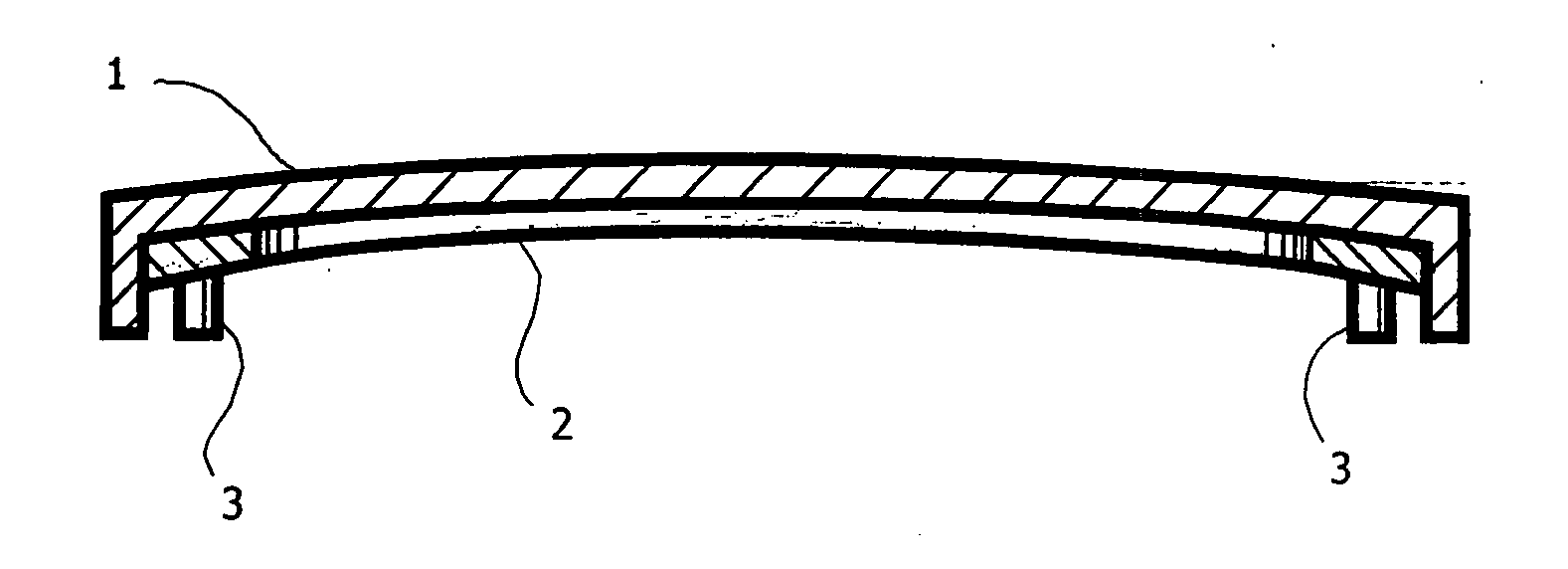

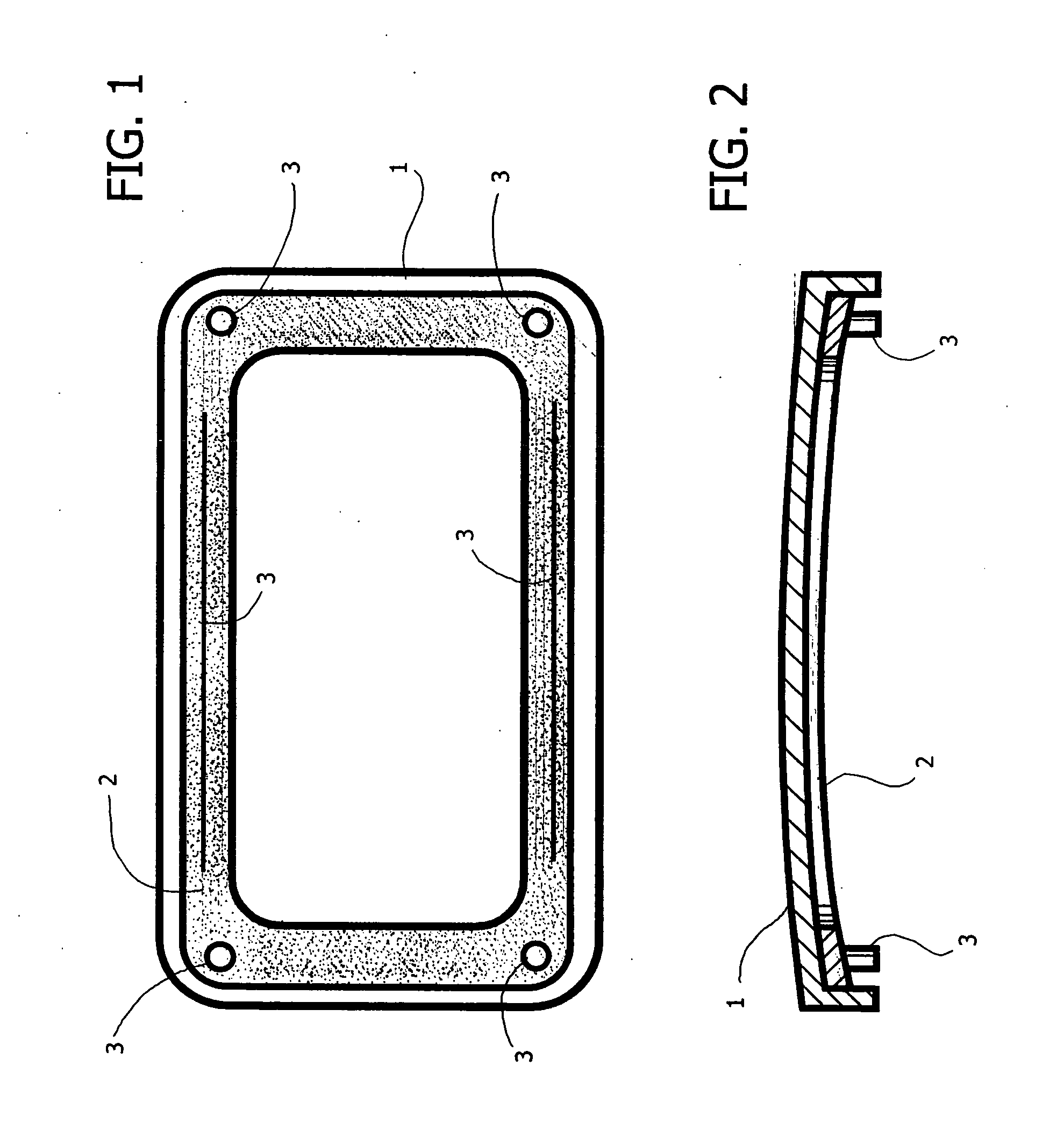

Process for the production of plates made of transparent plastic material with non-transparent areas

ActiveUS20060076711A1Low stress levelImprove mechanical propertiesMouldsWood working apparatusEngineeringSequential injection

Described herein is a process for the production of plates made of plastic material by means of sequential injection with the mould half-open and a subsequent step of compression obtained by closing the mould.

Owner:INGLASS SRL

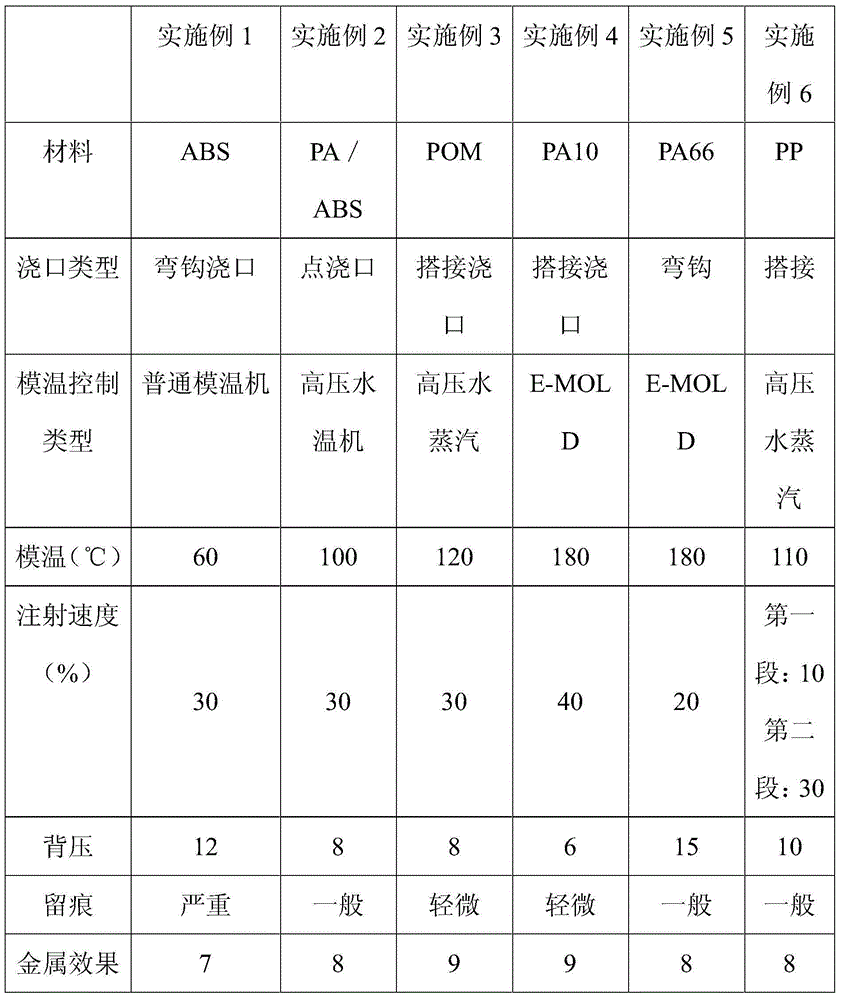

Free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts

The invention discloses a free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts. The free-spraying metallic-luster injection molding process comprises the following steps: adding metal powder into a raw material which is a plastic base material, and arranging a random water path close to a mould cavity of an injection mould with the high surface quality and the small thermal deformation to enable the surface temperature of the mould to be uniform; pouring the mould by adopting a hooked pouring gate, a pin-point gate and a side pouring gate; controlling the temperature of the surface of the mould in an injection-molding process; and pouring by adopting one or more pouring gates by adopting a high-pressure low-speed injection molding technique, a low-pressure high-speed injection molding technique or a normal-pressure normal-speed injection molding technique, and a sequential injection molding process, wherein the pouring gates adopt a needle valve type pouring gates. The parts produced by adopting the free-spraying metallic-luster injection molding process have no flow marks and solution marks on surfaces, have the good metallic luster and can be used for car interior trim parts and exterior parts.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

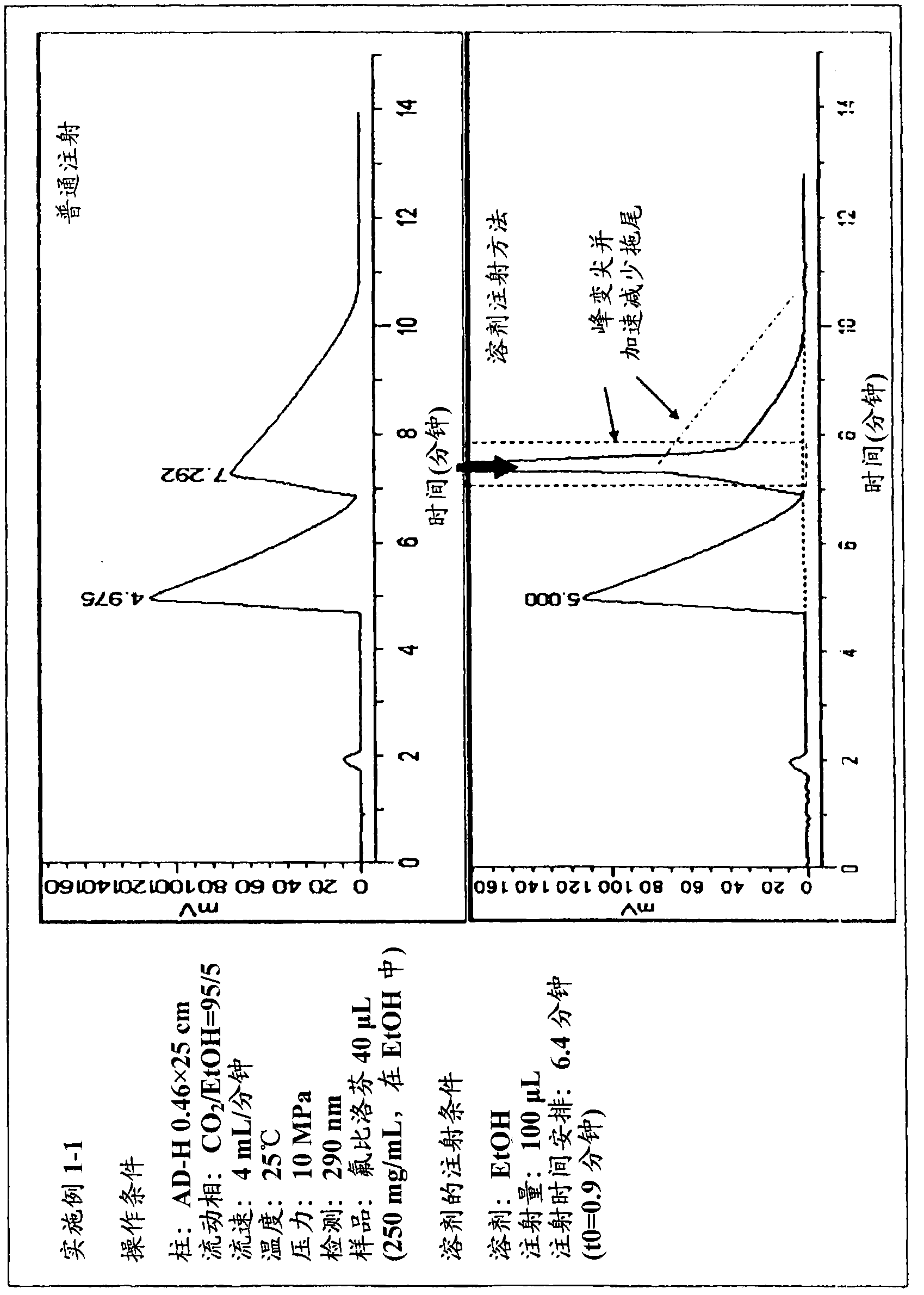

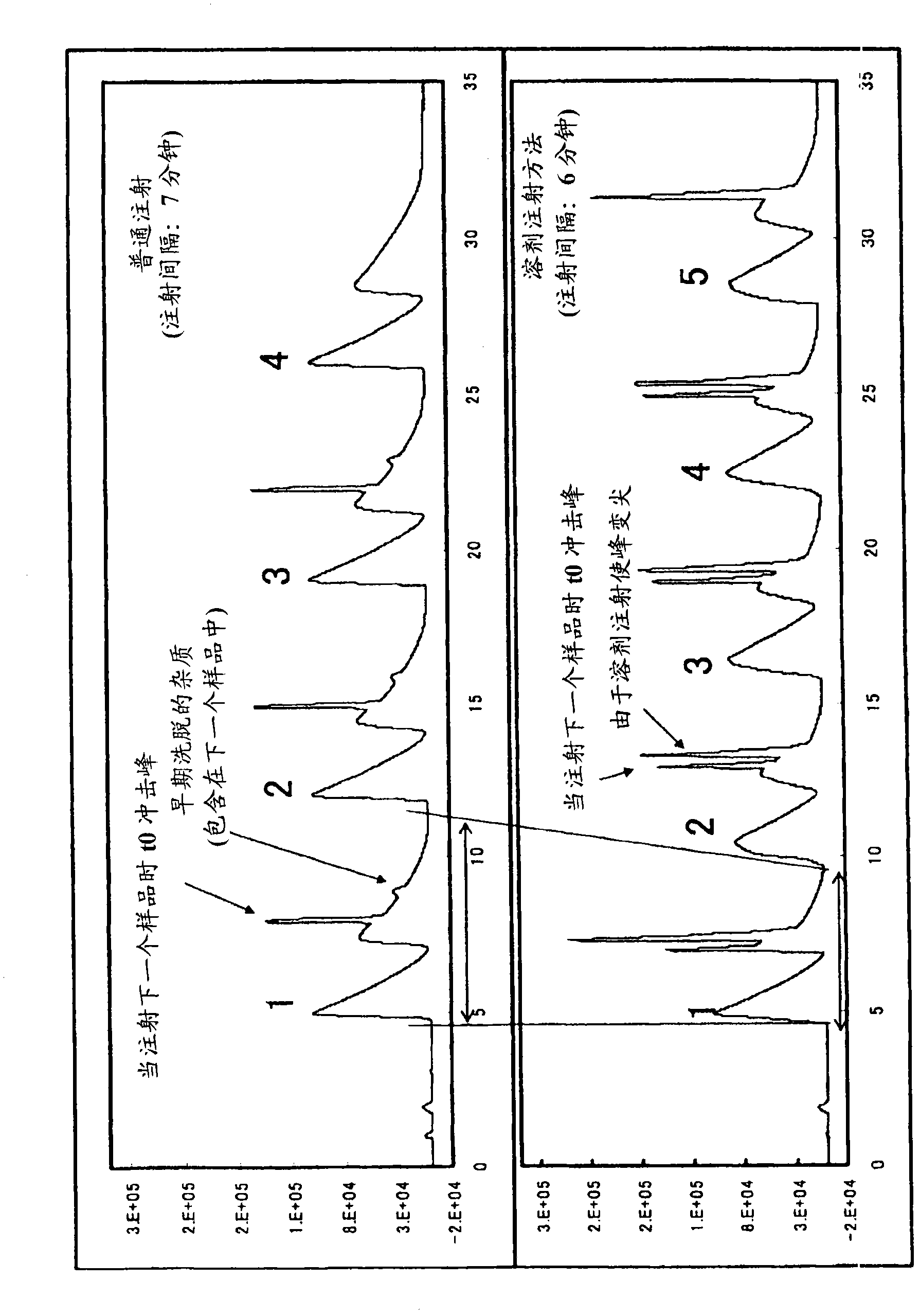

Method of manufacturing substances by supercritical fluid chromatography

ActiveCN102460146AIncrease throughputEasy to separateComponent separationSolid sorbent liquid separationTime segmentSequential injection

Provided is a method of manufacturing target substances with use of supercritical fluid chromatography, by which the following are achieved: solution of a problem at the time of sequential injections of samples containing the target substances; an increase of a treatment amount of separation per unit time; and improvement of efficiency in separation. The method includes the steps of: injecting the sample containing the target substances into a mobile phase; and returning composition of the mobile phase to a pre-change state after changing the composition of the mobile phase.; The step of returning the composition of the mobile phase to the pre-change state after changing the composition of the mobile phase is performed during a period of time from detection of a peak of one of the target substances which is eluted latest from a column among the target substances separated by the supercritical fluid chromatography apparatus to injection of the next sample, whereby the problem is solved.

Owner:DAICEL CHEM IND LTD

Small-size sequential injection nitride analysis system

ActiveCN102980858AAvoid detection impactThe overall structure is simple and reliableColor/spectral properties measurementsPeristaltic pumpEngineering

The invention relates to a small-size sequential injection nitride analysis system. A first electromagnetic valve is connected with a nitride standard solution; a second electromagnetic valve is connected with a development agent and deionized water; the first electromagnetic valve and the second electromagnetic valve are both connected to a third electromagnetic valve; the third electromagnetic valve is also connected to a fourth electromagnetic valve connected with a water sample; a fifth electromagnetic valve is connected with the deionized water and a waste liquid bottle with a liquid level detection device; a fourth electromagnetic valve and a fifth electromagnetic valve are respectively connected to a six-way valve through a first peristaltic pump and a second peristaltic pump; the six-way valve is connected with waste liquid, a quantifying ring and a colorimetric match pool respectively. On the basis of theories of an improved sequential injection analysis method and a spectrophotometric method, the system has the advantages of simple structure, simplicity in operation, quantification precision, high stability, high reproducibility, high precision, low detection limit and the like; and in actual application, the system is portable and can perform full-automatic real-time on-line monitoring.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

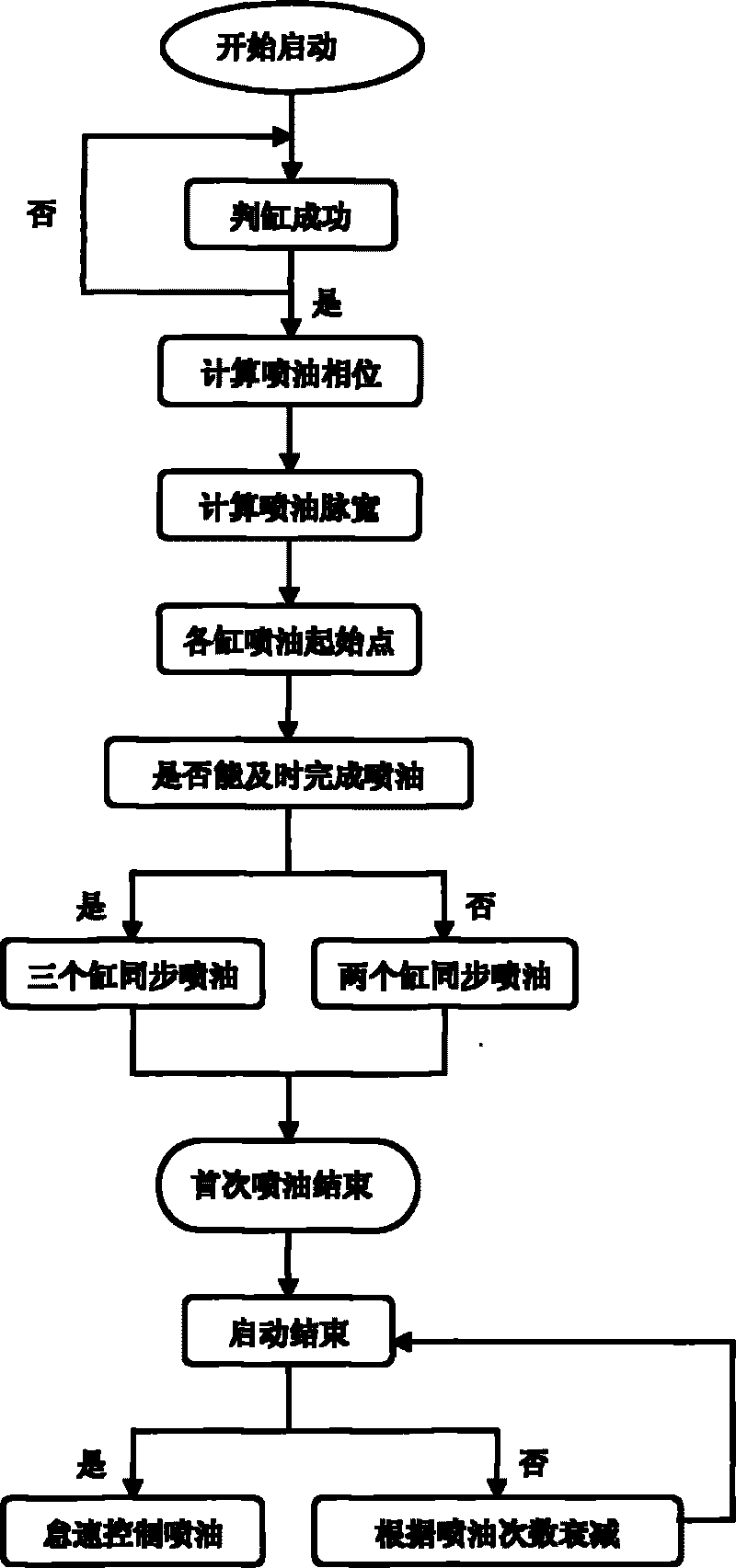

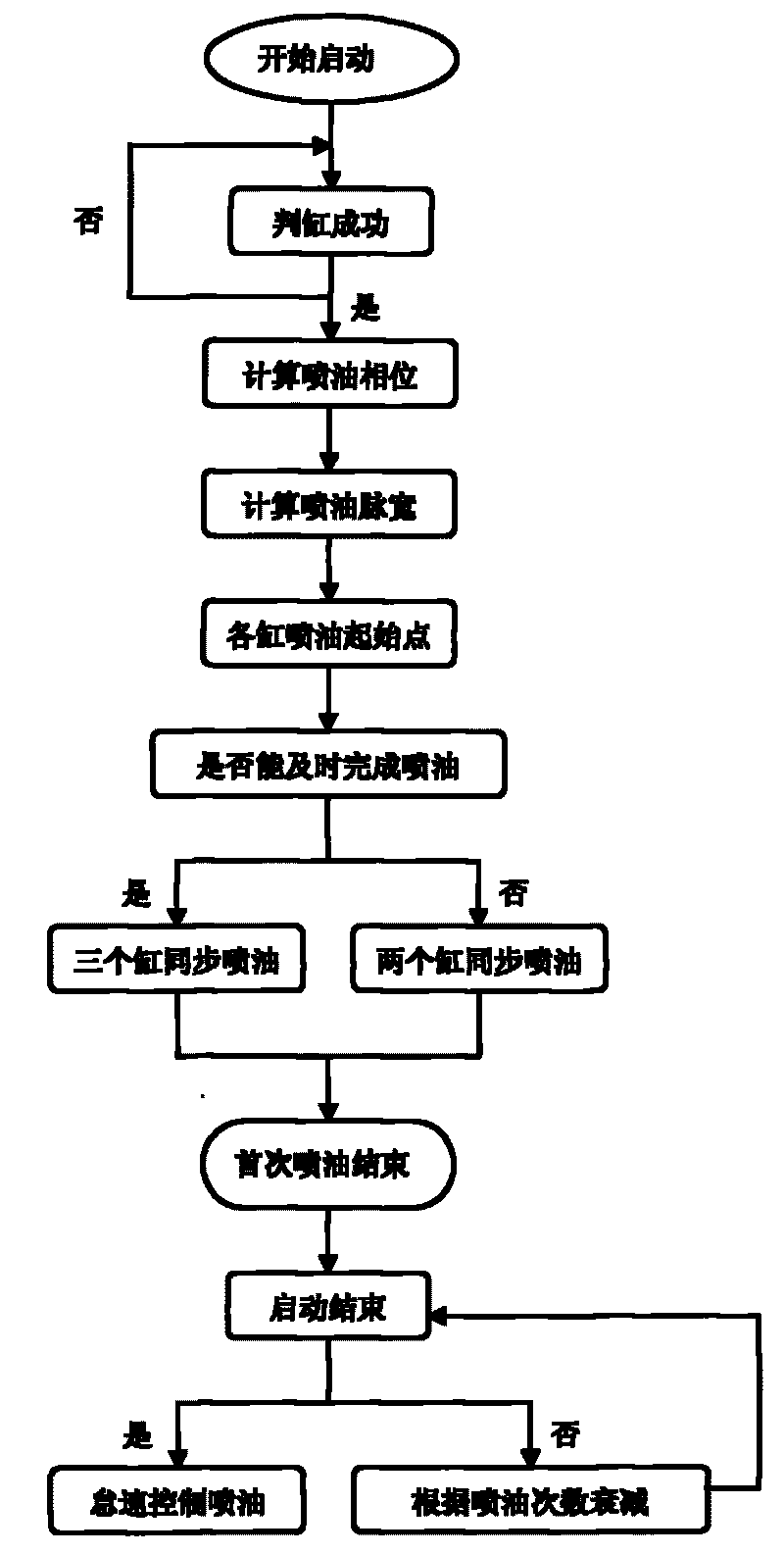

Method for controlling fuel injection when starting engine

The invention relates to a method for controlling fuel injection when starting an engine. The starting time of a fuel injector is determined according to the fuel injection time, and the duration time of the fuel injector after starting is determined according to the fuel injection pulse width, wherein the fuel injection time and the fuel injection cylinder number are determined according to the engine crankshaft signal and phase signal obtained by detection; and the fuel injection pulse width is determined according to the detected temperature of the engine, and the compensation is carried out according to the detected battery voltage. The method combines the advantages of the sequential injection and synchronous injection in the current fuel injection control of the engine, and carries out combined control to the synchronous fuel injection and sequential fuel injection on the fuel injection in the starting process.

Owner:CHERY AUTOMOBILE CO LTD

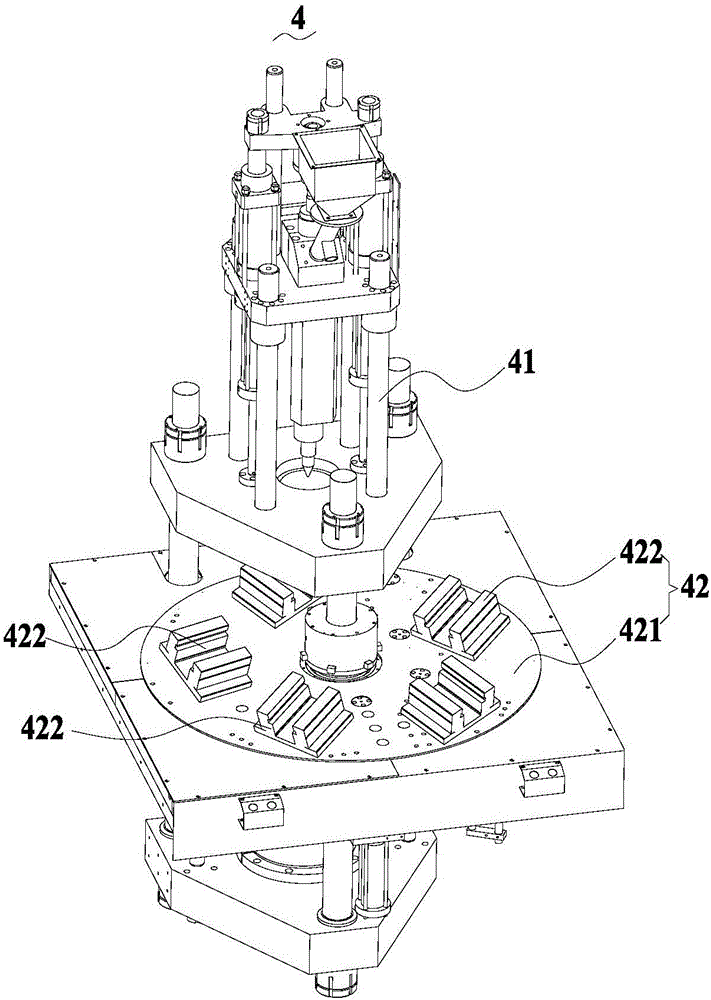

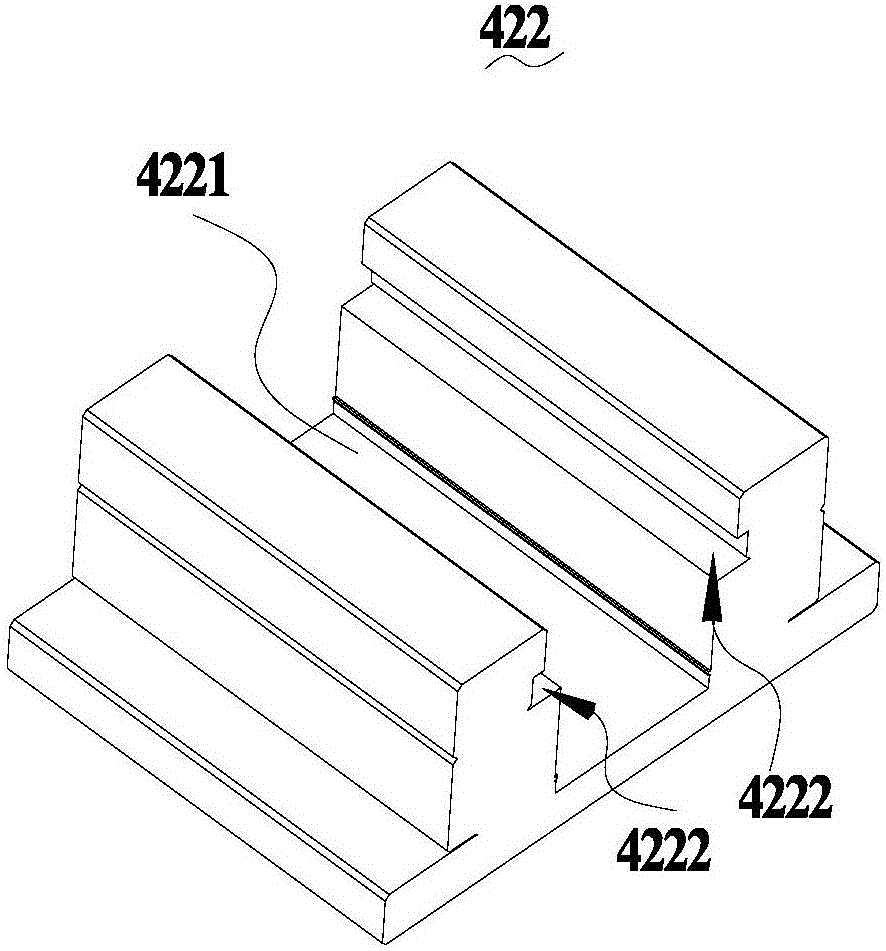

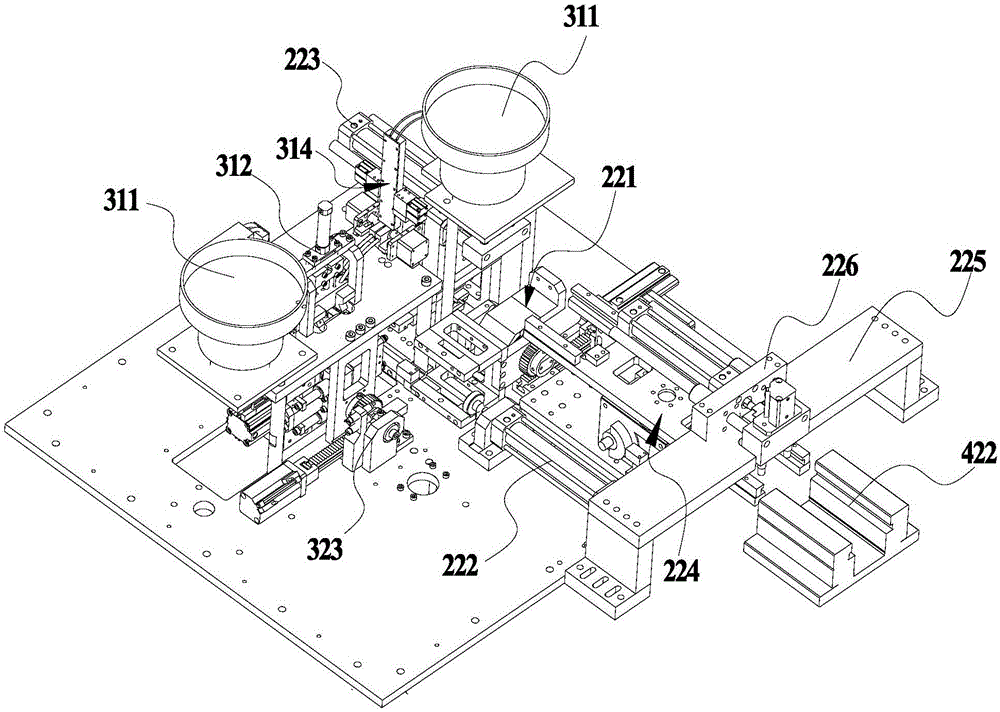

Automatic implantation injection molding device

The invention relates to the technical field of implantation injection molding, and provides an automatic implantation injection molding device. The automatic implantation injection molding device comprises a plurality of molds, a loading system used for loading the molds with objects to be subjected to injection molding, a multi-station injection molding device capable of sequentially performing injection molding on the loaded molds, and a transmission system used for moving the loaded molds to the multi-station injection molding device for injection molding and collecting the molds subjected to injection molding to be discharged, wherein the molds are periodically exchanged and transmitted between the multi-station injection molding device and the transmission system. According to the automatic implantation injection molding device provided by the invention, the molds are loaded with the objects to be subjected to injection molding, the loaded molds are transmitted to the multi-station injection molding device for sequential injection molding through the transmission system, the molds subjected to injection molding are collected and discharged through the transmission system, new empty molds are formed, and a work cycle is achieved; and besides, the molds can periodically move between the multi-station injection molding device and the transmission system, and the injection molding efficiency is greatly improved.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

Internal-combustion engine CNG device

InactiveCN101666275ALarge reservesSmooth switchingElectrical controlInternal combustion piston enginesHigh pressureInternal combustion engine

The invention discloses an internal-combustion engine CNG device, comprising a CNG gas bottle which is connected into an engine inlet port by a gas charging valve, a high-pressure electromagnetic valve, a decompressor and a sequential injection nozzle in sequence, the internal-combustion engine CNG device is provided with a vehicular ECU, and the vehicular ECU is used for controlling the opening aperture of the injection nozzle by a speed sensor for acquiring the rotation speed of a main shaft of an engine, a temperature sensor for acquiring the temperature of a water tank and a position sensor for acquiring the opening aperture of an accelerator. Based on the technical schemes, the internal-combustion engine CNG device can burn natural gas and diesel, and has good energy-saving and emission-reducing effects.

Owner:李英杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com