Method and device for sequentially injecting lead in online detection of water quality

A sequential injection and water quality technology, which is applied in the fields of chemical analysis and water environment monitoring and analysis, can solve the problems of low detection accuracy, many procedures, and troublesome operation, and achieve the effects of simple instrument system, improved sensitivity, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

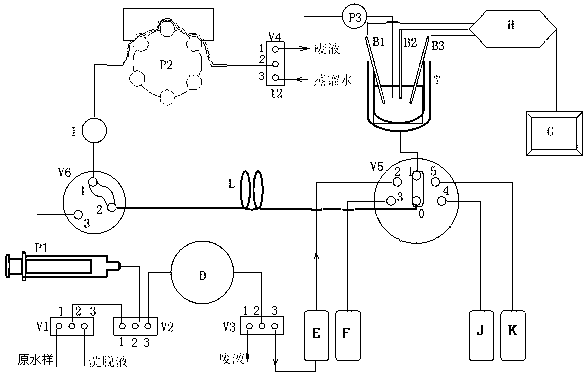

[0031] The method and process for detecting lead with this device will be described below in conjunction with the accompanying drawings.

[0032] one. Preparation of reagents:

[0033] (1) Preparation of water quality lead standard solution

[0034] Accurately weigh 1.0000 g of pure metallic lead (purity ≥ 99.9%) and dissolve it in 20 ml of nitric acid solution (made from 10 ml of concentrated nitric acid + 10 ml of water), then add water to 1000 ml, and dilute to a nitric acid solution with a concentration of 1000 mg / L , and use this as the mother liquor for later use.

[0035] Accurately pipette 12 ml of the mother liquor into a 500 ml volumetric flask, add distilled water to the mark, shake well, and make a spiked solution with a concentration of 24 mg / L for later use.

[0036] (2) Carrier liquid

[0037] Accurately weigh 11.69 g of sodium chloride in a 1000 ml volumetric flask, add distilled water to dissolve, then add 16.66 ml of concentrated hydrochloric acid, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com