Fuel heating in combined cycle turbomachinery

A turbomachinery, combined cycle technology, applied in the fuel heating of turbine/propulsion devices, turbine/propulsion fuel delivery systems, mechanical equipment, etc., can solve problems such as increasing the cost of fuel gas heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

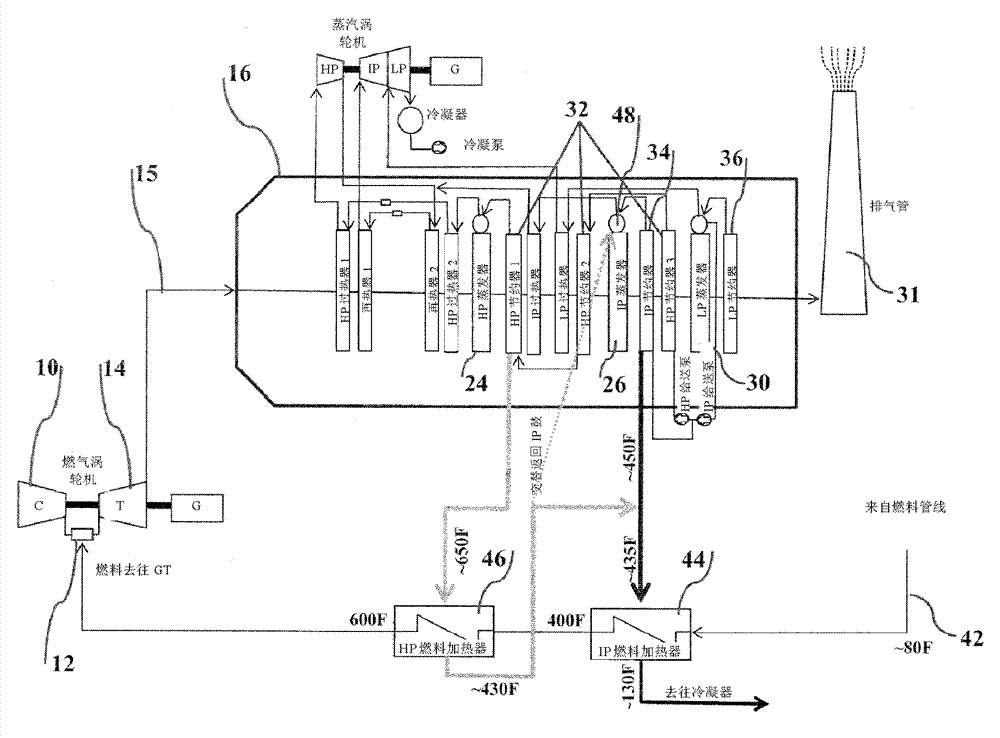

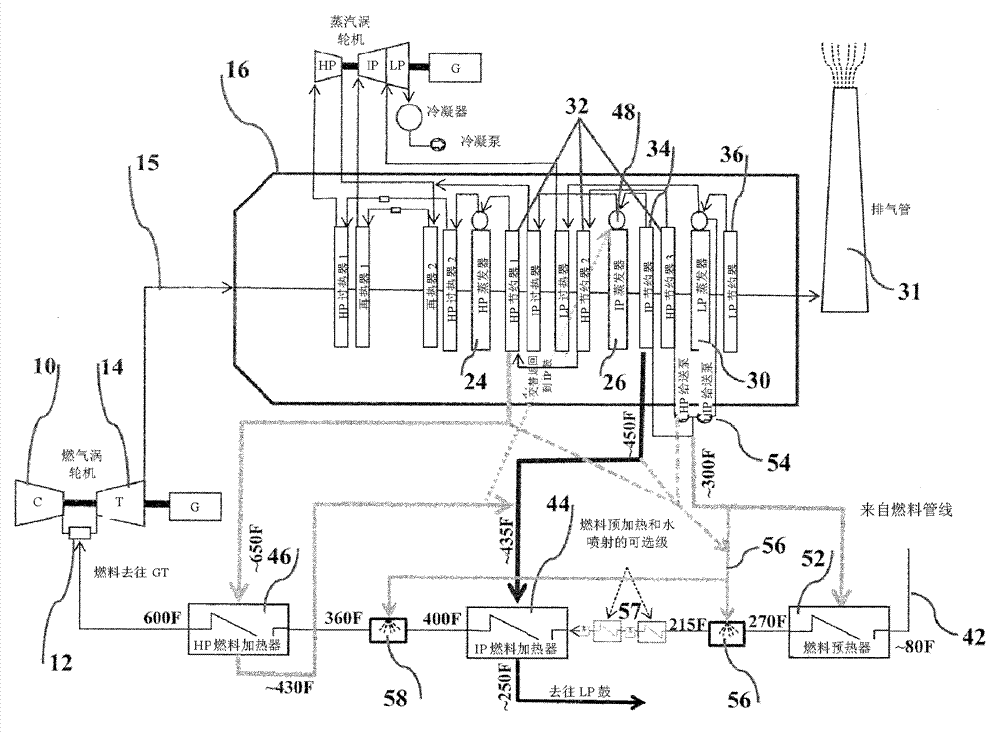

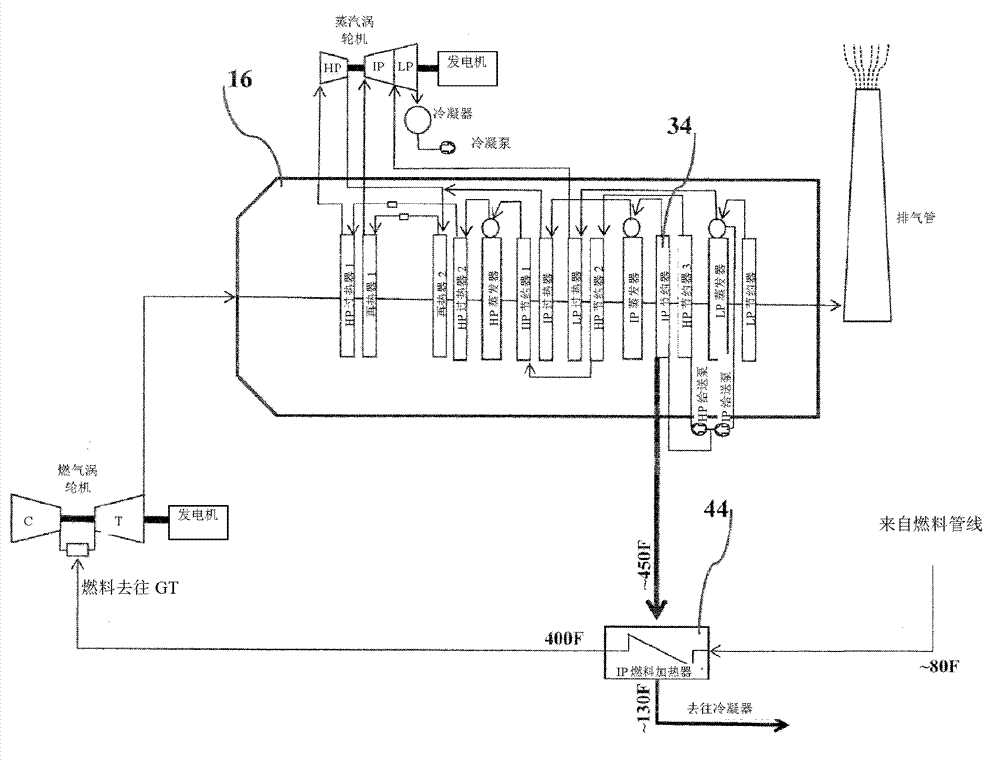

[0024] figure 2 A schematic flow diagram of a three-pressure combined cycle turbomachine is shown. The machine comprises a compressor 10 , a combustor 12 and a turbine 14 powered by expansion of the hot gases produced in the combustor 12 for driving a generator G . Exhaust gas from the gas turbine 14 is supplied via line 15 to a heat recovery steam generator (HRSG) 16 for recovering waste heat from the exhaust gas. The HRSG includes high pressure (HP), intermediate pressure (IP) and low pressure (LP) sections. Each of the HP, IP, LP sections includes a respective evaporator section 24, 26, 30, and a respective economizer section 32, 34, 36 within the respective evaporator section Used to preheat water before converting it to steam. Water is fed to HRSG 16 to generate steam. Heat recovered from the exhaust gas supplied to the HRSG 16 is transferred to water / steam in the HRSG 16 for generating steam which is supplied to a steam turbine ST for driving an electric generator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com