Automotive fuel cell hydrogen circulating system

A fuel cell and circulation system technology, applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve the problems of high equipment cost, equipment reliability, applicability and anti-interference ability are not as good as vehicle components, etc., and achieve simple installation , Improve the utilization rate of hydrogen, and improve the effect of hydrogen side humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

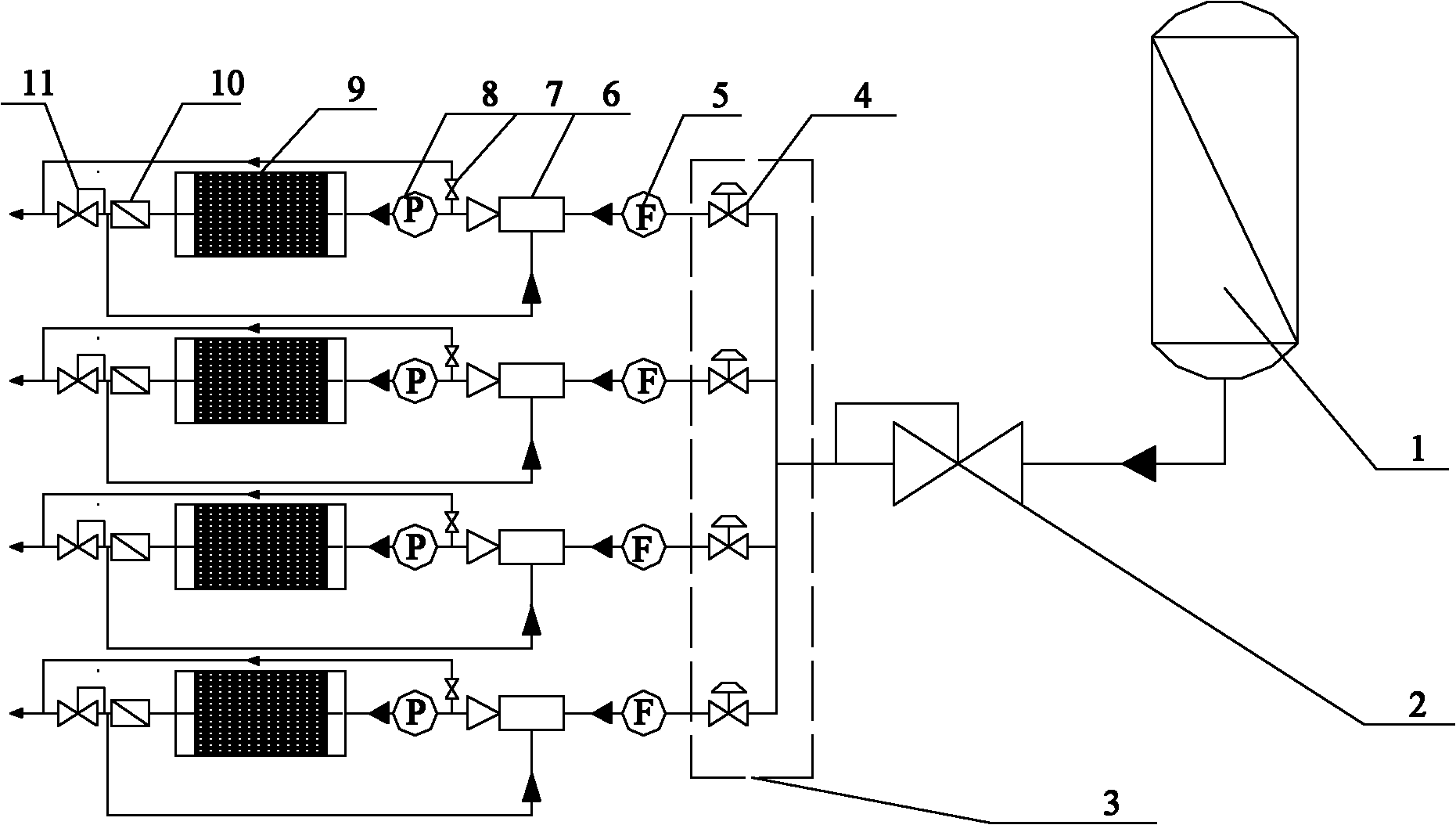

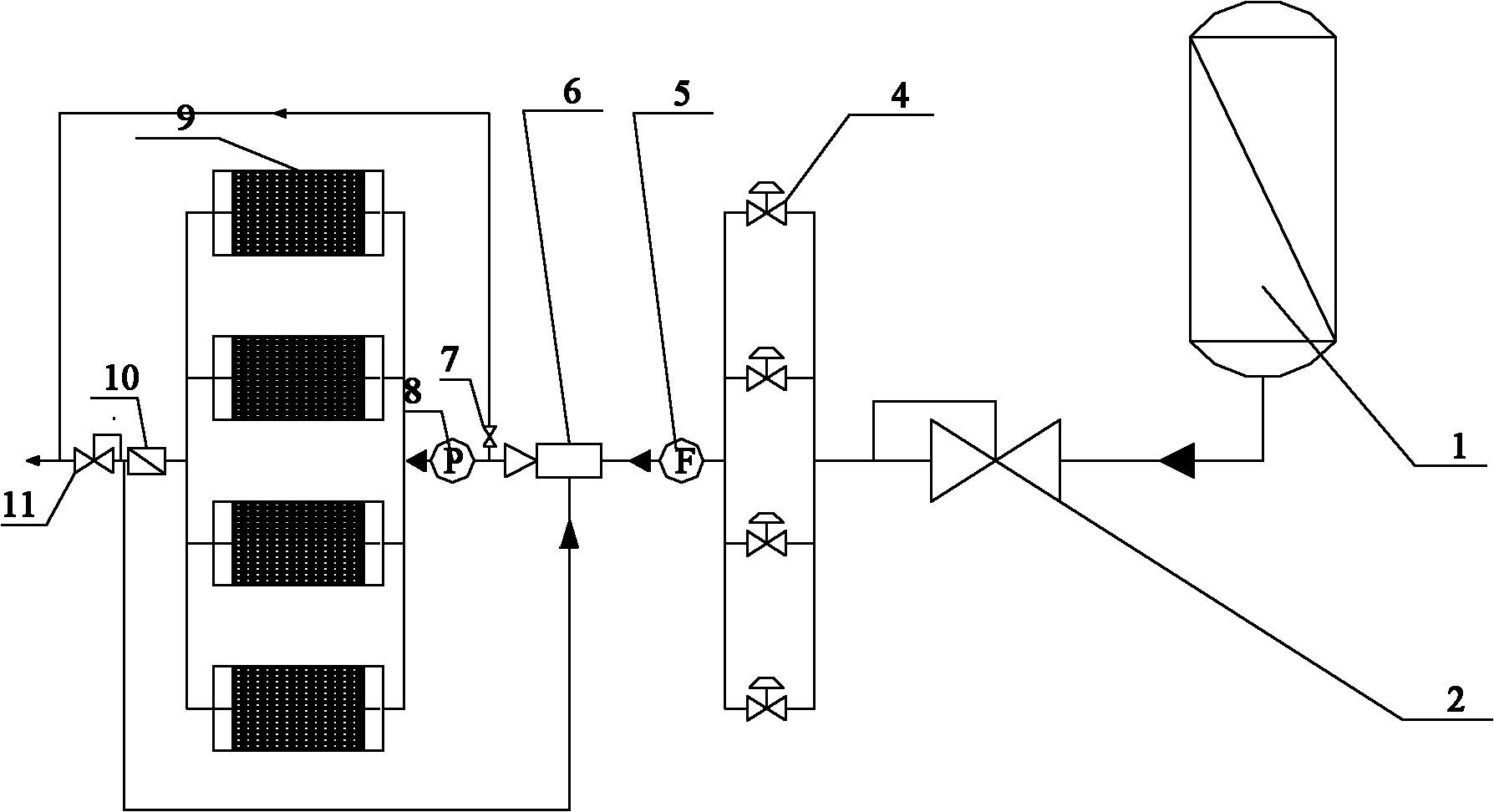

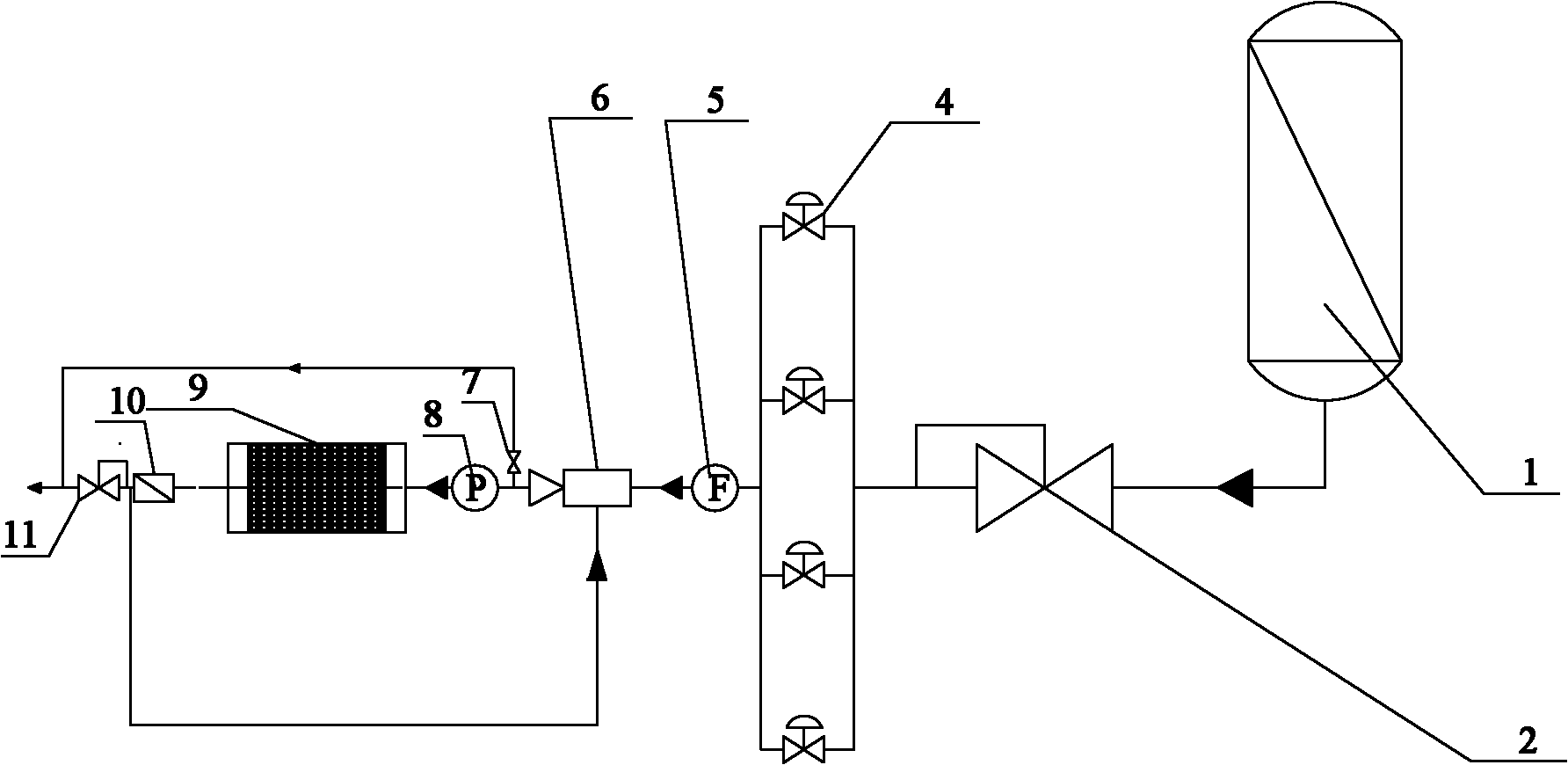

[0026] attached image 3 It is a flow chart of the vehicle fuel cell hydrogen circulation system of the embodiment, and it is a fuel cell hydrogen circulation system with an electric stack. In the system, the pressure of the hydrogen storage tank 1 is 35MPa, and the primary pressure reducing valve 2 decompresses the 35MPa hydrogen in the hydrogen storage tank 1 to 7bar. The multi-point sequential injection system adopts a CNG 4-cylinder multi-point sequential injection system. The meter is a differential pressure flowmeter, the Venturi tube is designed according to the actual situation of the vehicle, the safety pressure relief valve is set to a pressure of 80kPa, and the pressure sensor detects the working pressure of the anode inside the stack (for judging undervoltage and overpressure protection), 120 knots For the fuel cell stack, the set pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com