Method for controlling fuel injection when starting engine

A technology of engine start-up and control methods, which is applied in engine control, fuel injection control, machine/engine, etc., and can solve problems such as difficulty in start-up, deterioration of emissions, and deviation of sequential injection start-up response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

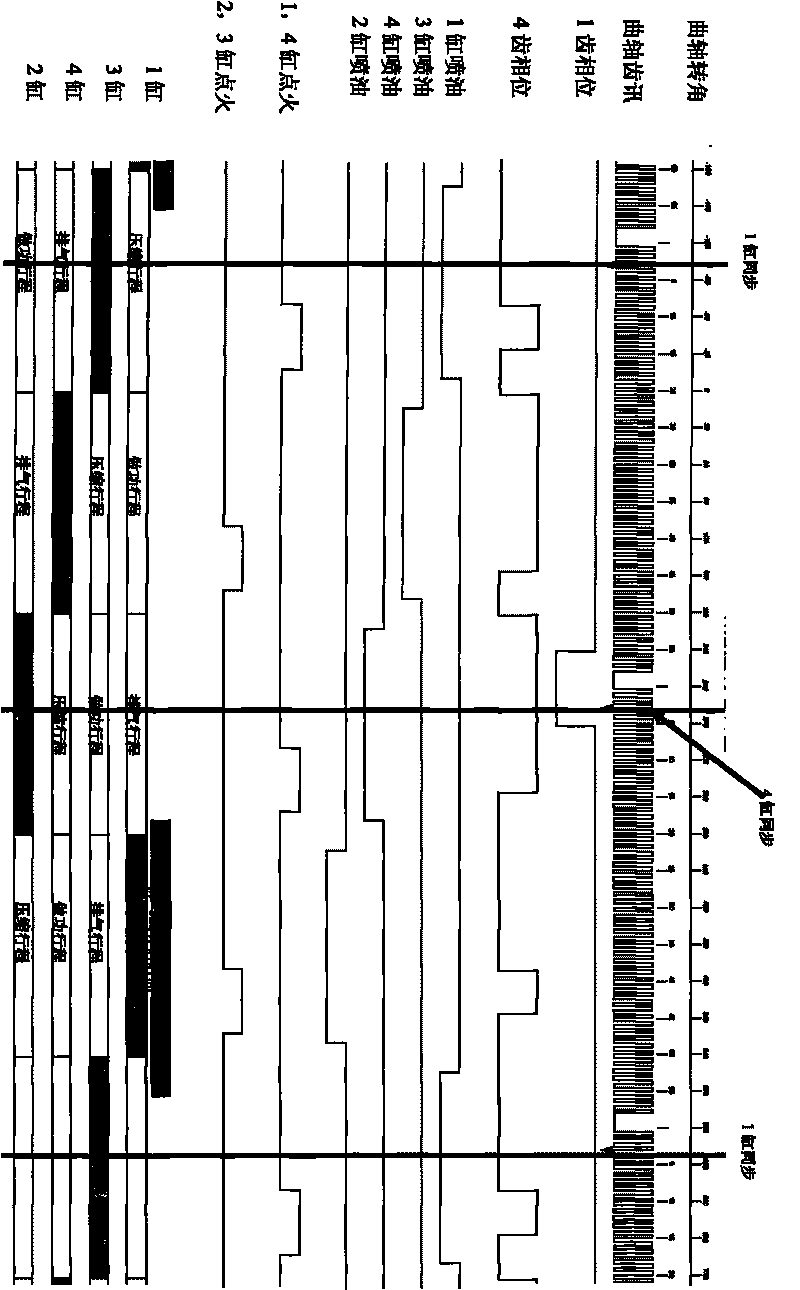

[0035] The first step is as figure 1 As shown, the system determines the synchronous cylinder number according to the engine crankshaft signal and phase signal (1-tooth or 4-tooth phase). Taking a 4-cylinder engine as an example, the synchronous cylinder is 1 cylinder or 4 cylinders. If cylinder 1 is synchronized (similar to cylinder 4), cylinder 1 is in the compression stroke, cylinder 3 is in the intake stroke, cylinder 4 is in the exhaust stroke, and cylinder 2 is in the power stroke.

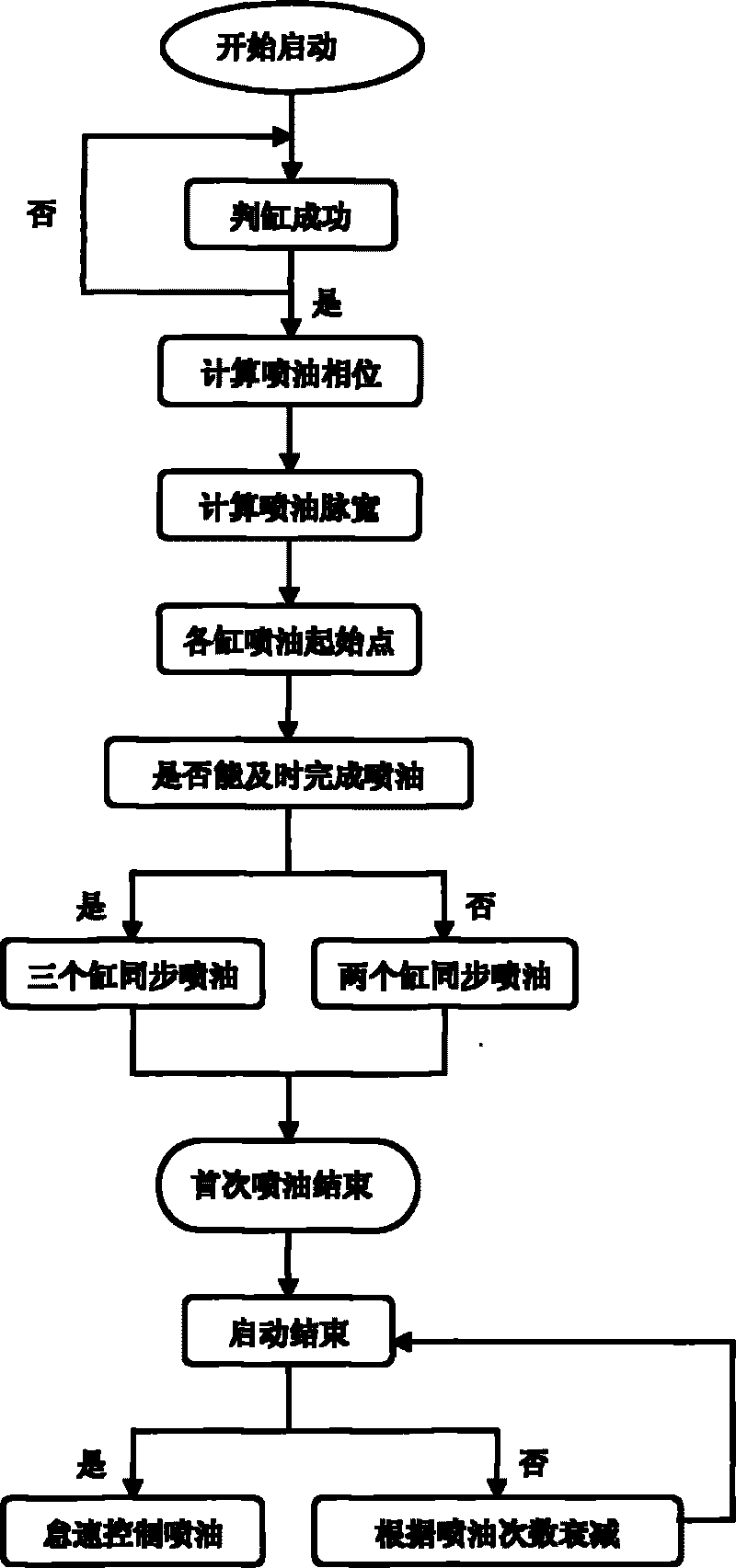

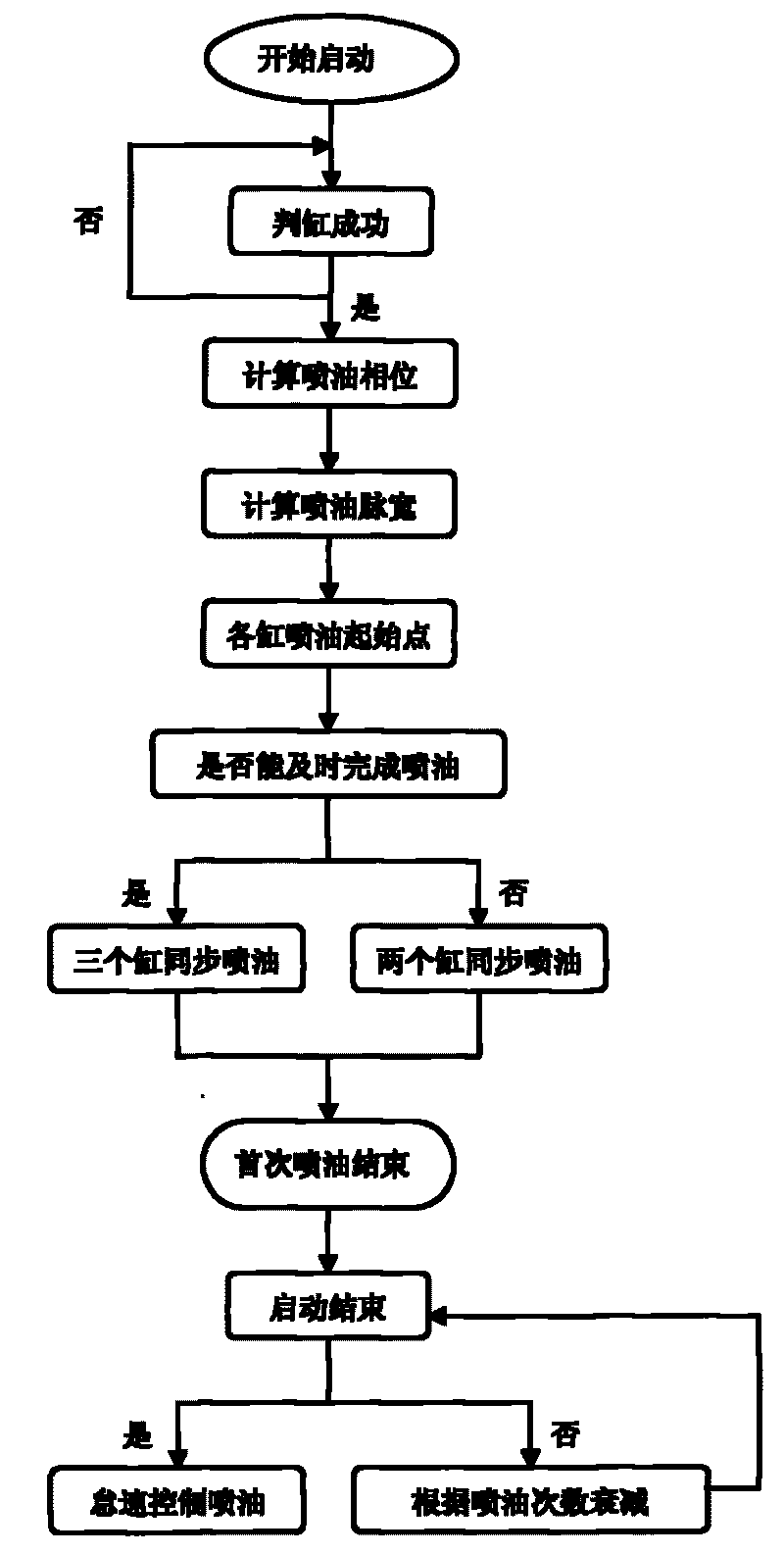

[0036] The second step is as figure 2 As shown, after judging the success of the cylinder, start to calculate the fuel injection phase. Calculate the fuel injection pulse width, that is, the fuel injection duration, based on the load, etc., and calculate the fuel injection start angle by combining t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com