Method of manufacturing substances by supercritical fluid chromatography

A technology of supercritical fluid and chromatography, which is applied in the field of manufacturing substances through supercritical fluid chromatography, can solve the problems of not being suitable for industrial mass production, etc., and achieve the effects of increasing processing capacity, reducing peak tailing, and improving separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

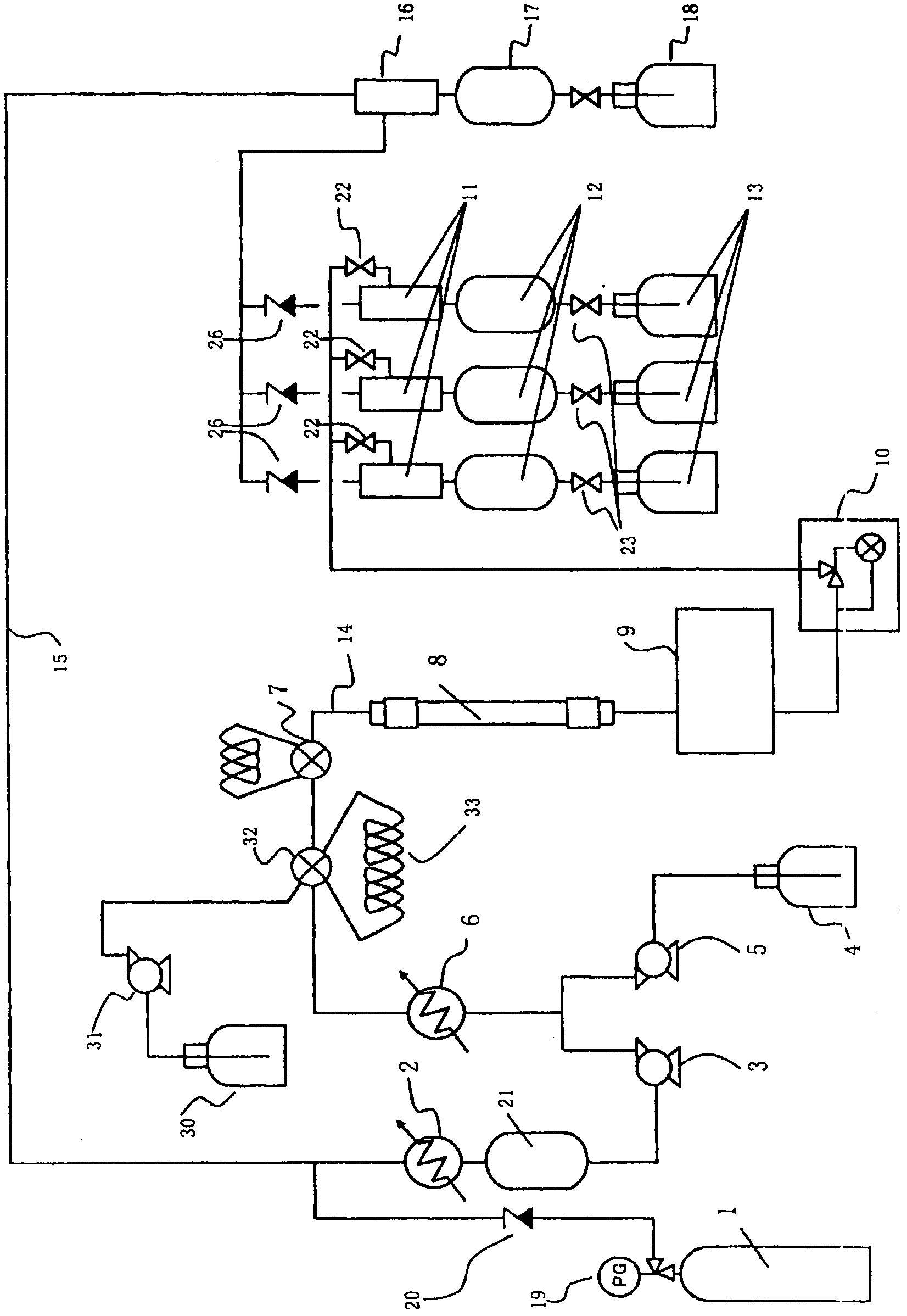

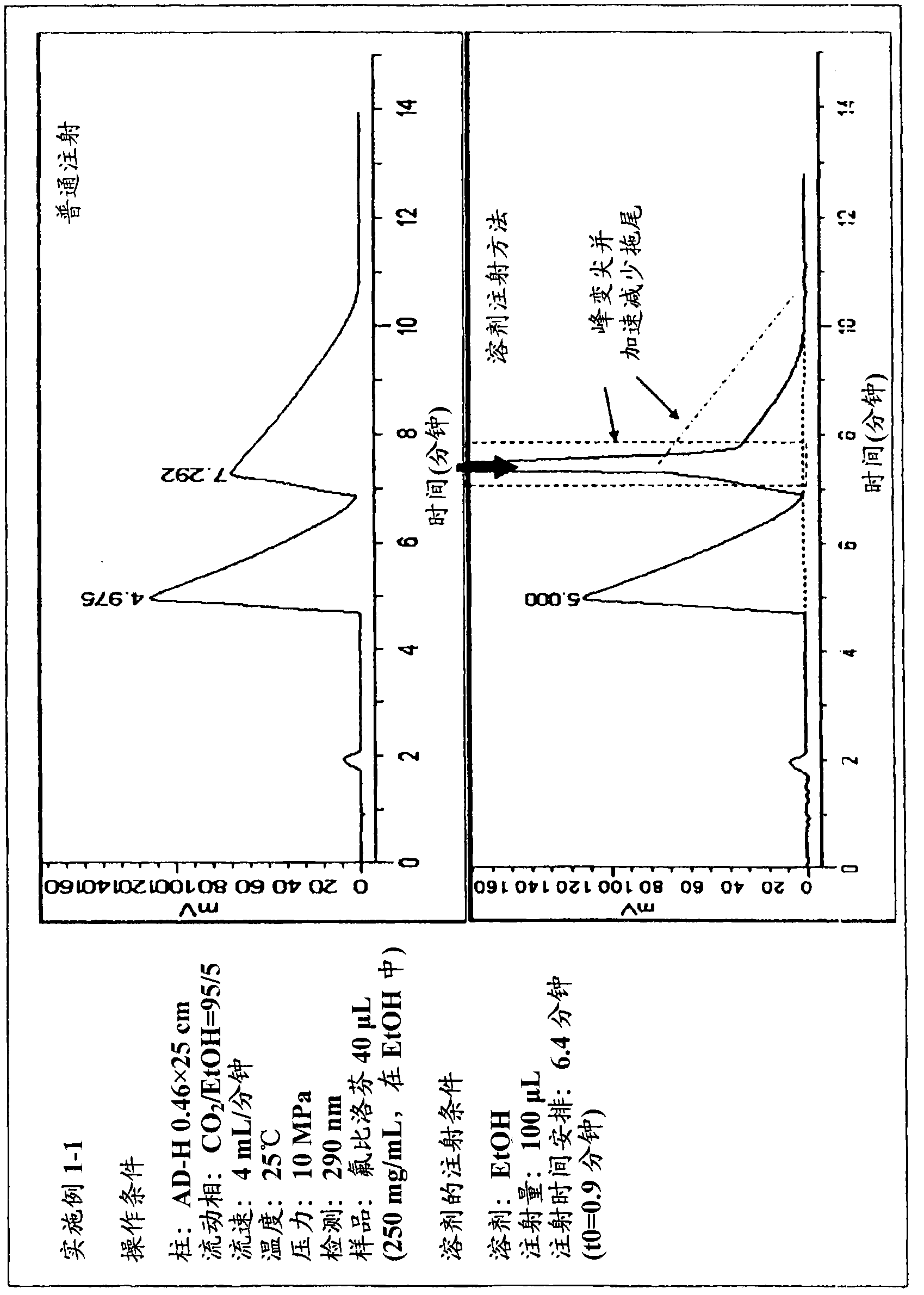

[0089] use for figure 1 In the supercritical fluid chromatography equipment exemplified in, flurbiprofen was separated from a sample containing flurbiprofen under the following conditions.

[0090] When 6.4 minutes had elapsed after the injection of the sample containing flurbiprofen, 100 μL of ethanol was immediately injected by switching the switching valve, returning the valve to its original state. In this case, the device had a dead volume, so ethanol eluted when 7.3 minutes had elapsed.

[0091] Due to the injection of ethanol, the peak components are extracted rapidly, thus, the peaks are sharpened, and the tailing is reduced and accelerated for 1 minute. The state of the peak is shown in figure 2 and image 3 .

[0092] Column: CHIRALPAK AD-H (0.46×25 cm), manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.

[0093] Mobile phase: CO 2 / EtOH=95 / 5

[0094] Flow rate of mobile phase: 4mL / min

[0095] Temperature: 25°C

[0096] Pressure: 10MPa

[0097] Detection: 2...

Embodiment 2

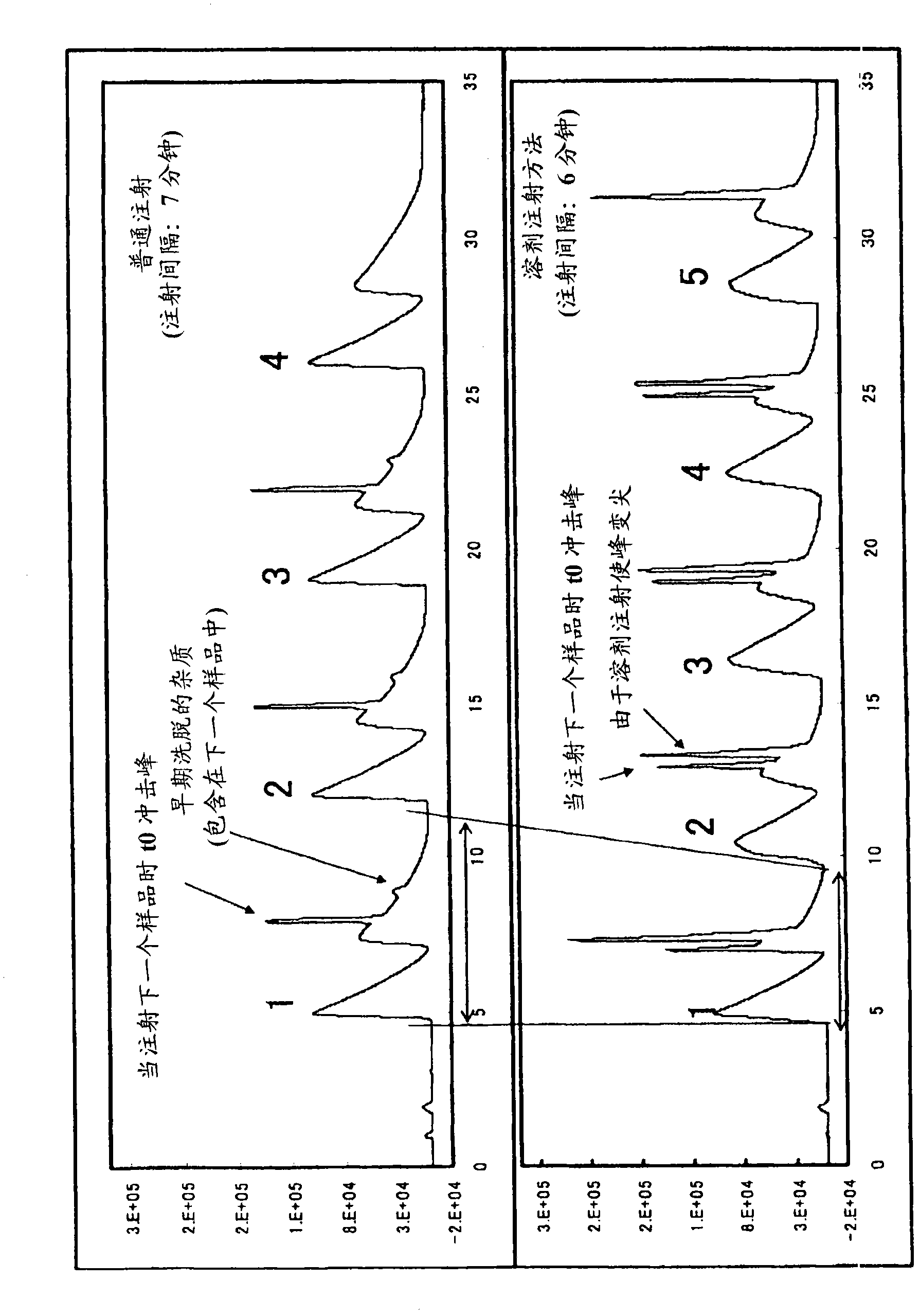

[0102] Similar to Example 1, use in figure 1 The supercritical fluid chromatography equipment exemplified in the following conditions separates benzoin diethyl ether from a sample containing benzoin diethyl ether.

[0103] When 3.2 minutes had elapsed after the injection of the sample containing benzoin ether, 300 μL of tetrahydrofuran (THF) was immediately injected by switching the switching valve, returning the valve to its original state. In this case, the device had a dead volume, so THF eluted when 4.1 minutes had elapsed.

[0104] Due to the injection of THF, the peak components are extracted rapidly, thus, the peaks are sharpened and the tailing is reduced and accelerated for 1 minute. The state of the peak is shown in Figure 4 and Figure 5 .

[0105] Column: CHIRALPAK IA (0.46×25 cm), manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.

[0106] Mobile phase: CO 2 / THF=90 / 10

[0107] Flow rate of mobile phase: 4mL / min

[0108] Temperature: 25°C

[0109] Pressur...

Embodiment 2

[0115] Similar to Example 2-(1), the difference is that methanol is used instead of THF as the solvent for injection, and benzoin ether is separated from the sample containing benzoin ether.

[0116] Due to the injection of methanol, the peak fractions are extracted rapidly, thus, the peaks are sharpened and the tailing is reduced and accelerated for 2 minutes. The state of the peak is shown in Figure 4 and Figure 5 .

[0117] (Reference Example 1)

[0118] The method for changing the composition of the mobile phase according to the present invention is applied to high performance liquid chromatography (HPLC), and under the following conditions, trans-stilbene oxide (t-SO) is removed from the sample containing t-SO separate.

[0119] When 5.8 minutes had elapsed after injection of the t-SO-containing sample, 30 μL of n-hexane / 2-propanol (IPA) was immediately injected by switching the switching valve, returning the valve to its initial state. In this case, the device had a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com