Multipoint sequential injection control system of gas fuel

A sequential injection, gas fuel technology, applied in the direction of fuel injection control, electrical control, charging system, etc., can solve the problems of low intake pressure, poor adaptability to different working conditions, inability to achieve rapid correction, etc., to reduce exhaust emissions, Improves consistency, eliminates gas flashback and fuel waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

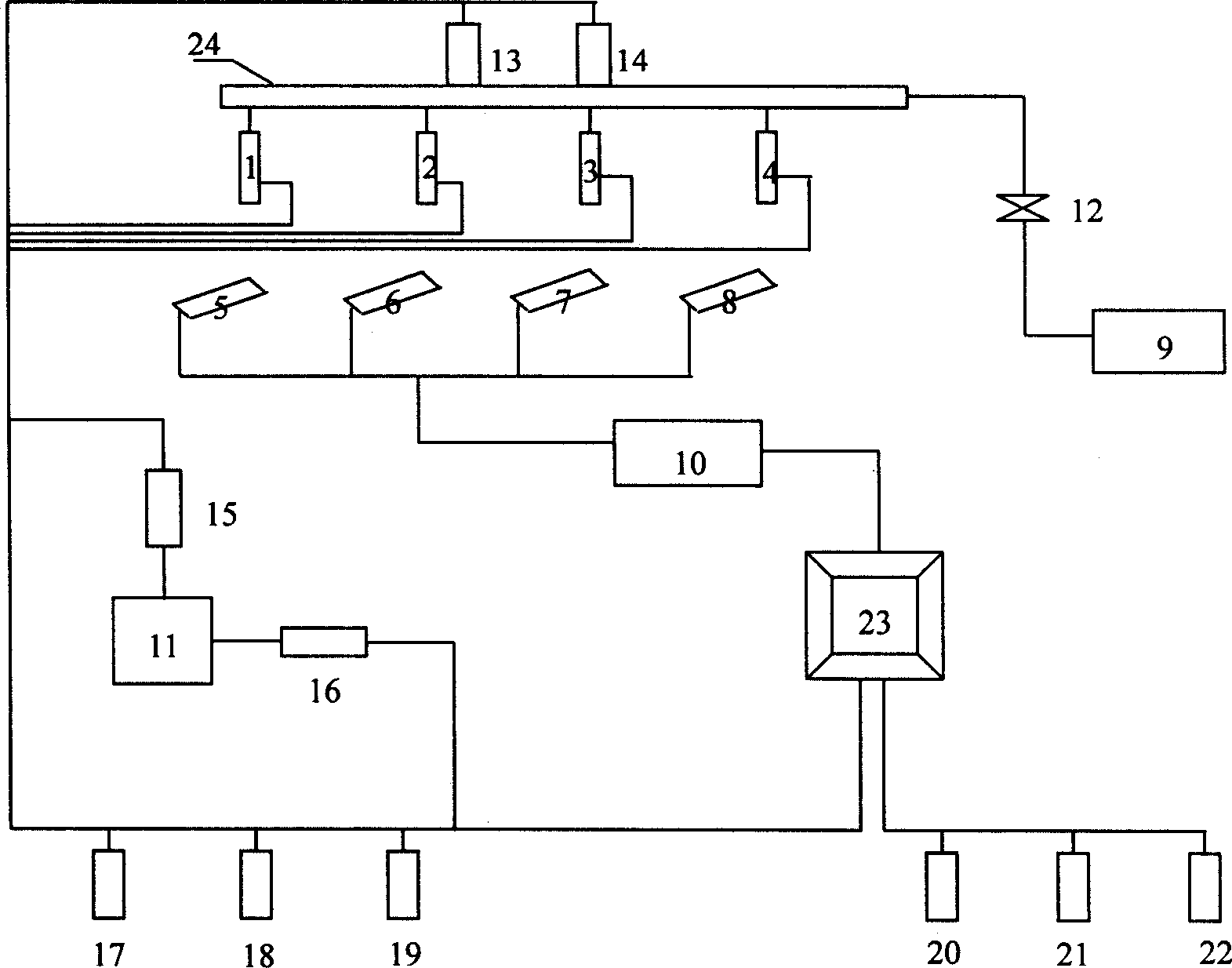

[0022] Such as figure 1 Shown: 1~4. Gas injection valve; 5~8. Cremation plug; 9. Gas fuel gas supply equipment; 10. Electronic igniter; 11. Throttle valve; 12. Gas pressure regulating valve; 13. Gas pressure sensor ;14. Gas temperature sensor; 15. Idle air control valve; 16. Throttle position sensor; 17. Crankshaft position sensor; 18. Oxygen sensor; 19. Speed sensor; 20. Intake pressure sensor; 21. Coolant temperature sensor ; 22. Intake air temperature sensor; 23. Electronic control unit ECU; 24. Gas rail.

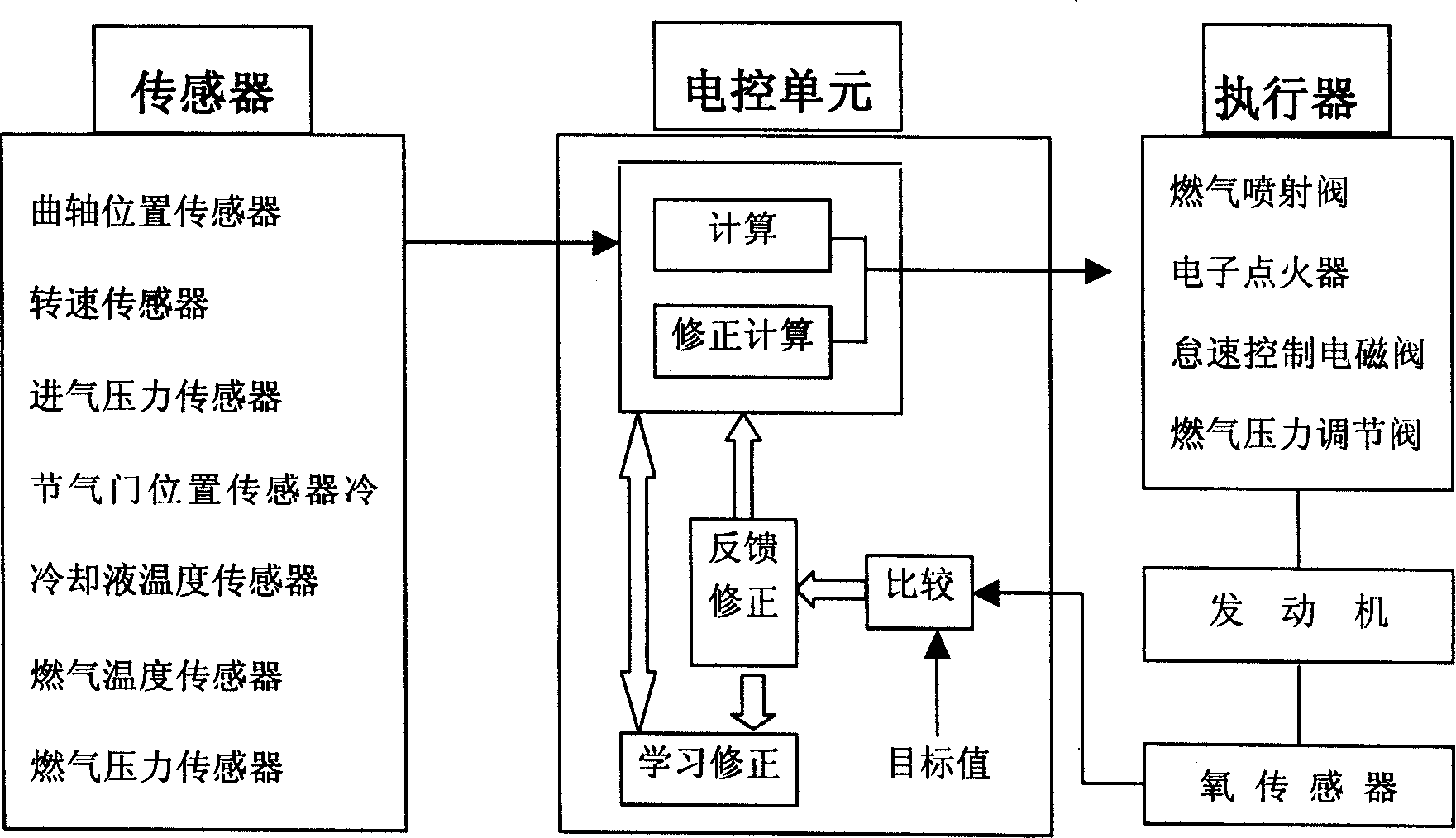

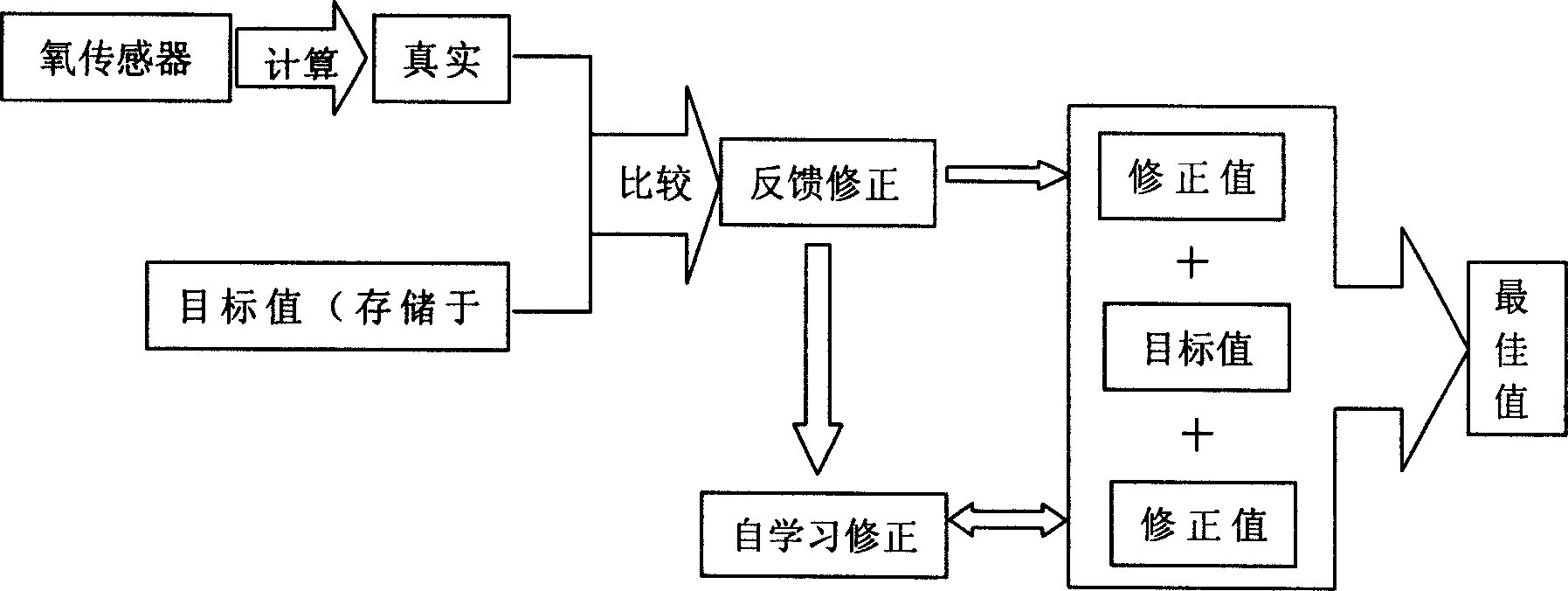

[0023] This set of gas fuel multi-point sequential injection control system is mainly composed of sensors, closed-loop control unit ECU and actuators. This set of control system can be widely used in various gas fuel engines, such as natural gas (NG), liquefied natural gas (LNG) , liquefied petroleum gas (LPG) and other gas engines; and can be applied to various engines with 4 to 12 cylinders and unlimited cylinder diameters. This patent takes an in-line four-cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com