Electrically controlled multi-point sequential injection system and control method for natural gas engine

A sequential injection, engine technology, applied in engine control, fuel injection control, electrical control and other directions, can solve the increase in heat generation of MOSFET tubes and solenoid valve coils, reduce the stability and reliability of components and systems, and increase the difficulty of heat dissipation and other problems, to achieve the effect of reducing heat dissipation, reducing volume and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

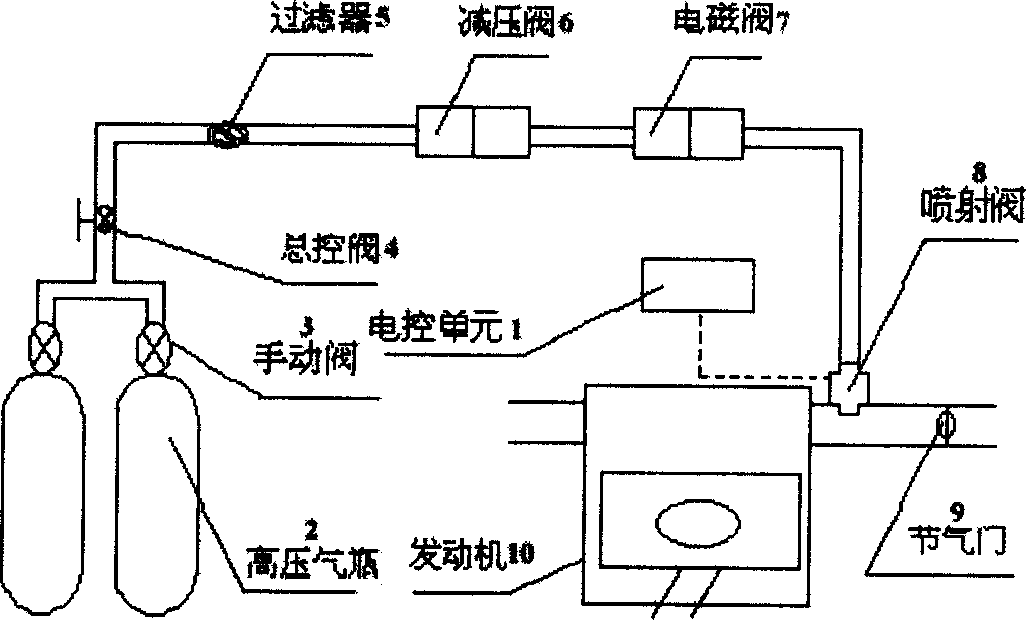

[0019] Below in conjunction with accompanying drawing, the implementation of the present invention is further described as follows: the present invention is achieved in this way. The system is mainly composed of electronic control unit 1 (see figure 1 ), high-pressure gas cylinder 2, manual valve 3, master control valve 4, filter 5, pressure reducing valve 6, solenoid valve 7, fuel injection valve 8, throttle valve 9, engine 10 and corresponding pipelines. CNG is stored in the high-pressure gas cylinder 2 with a pressure of 20MPa. When the engine 10 is working, the manual valve 3 of the gas cylinder is opened, and the CNG flows through the master control valve 4, and the impurity in the gas fuel is removed through the filter 5. CNG flows through the pressure reducing valve 6 to reduce to the required low pressure, enters the gas rail, and finally passes through the air injection solenoid valve 7 on the gas rail under the control of the electronic control unit (model: SP-21, Gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com