Free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts

An injection molding process and technology for automotive interiors, applied in the field of auto parts manufacturing, can solve problems such as affecting aesthetics, environmental pollution, and difficulty in meeting mandatory recycling regulations, and achieve a good metallic luster effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

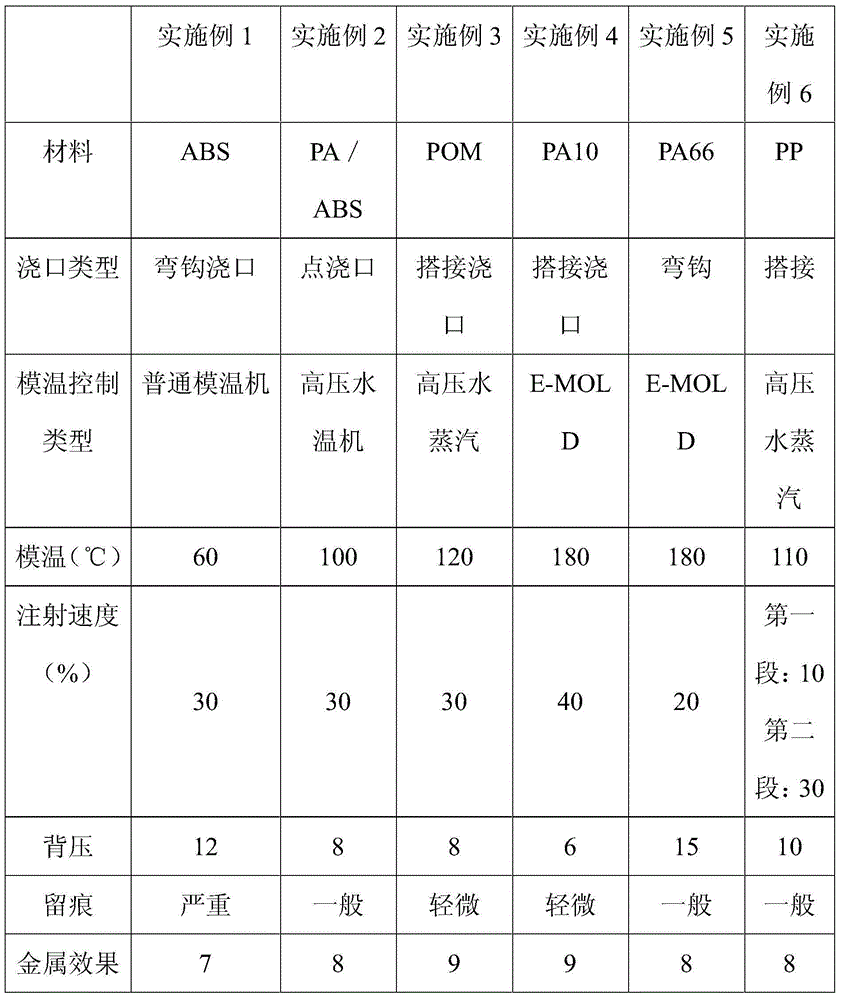

Embodiment 1

[0023] The raw material uses ABS base metal color material. The mold gate uses hook gates. The mold material uses stainless steel that is easy to polish and has small thermal deformation. The mold surface is arranged close to the mold cavity. The mold temperature is used during the injection molding process. The ordinary mold temperature machine controls the mold temperature to 60°C and the cooling water temperature to 25°C. During the injection molding process, the injection speed is 30% and the back pressure is 12 bar.

Embodiment 2

[0025] The raw material uses PC / ABS base metal color material, the mold gate uses point gates, the mold material uses stainless steel that is easy to polish and has small thermal deformation, and the mold surface is arranged close to the mold cavity. The mold temperature during the injection molding process Use a high-pressure water temperature machine to control the mold temperature to 100°C. During the injection molding process, the injection speed is 30% and the back pressure is 8 bar.

Embodiment 3

[0027] The raw material is made of POM base metal color material, the mold gate adopts lap gate, the mold material is stainless steel that is easy to polish and has small thermal deformation, and the mold surface is arranged close to the mold cavity. The mold temperature is used during the injection molding process. High-pressure water vapor controls the mold temperature to 120°C. During the injection molding process, the injection speed is 30% and the back pressure is 8 bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com