Aluminum alloy non-phosphorus nitrogen-free polishing solution and aluminum alloy surface treatment method

A technology of aluminum alloy surface and treatment method, applied in the field of metal surface treatment, can solve the problems of operating environment pollution, pollution of waste liquid environment, destruction of ecological balance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

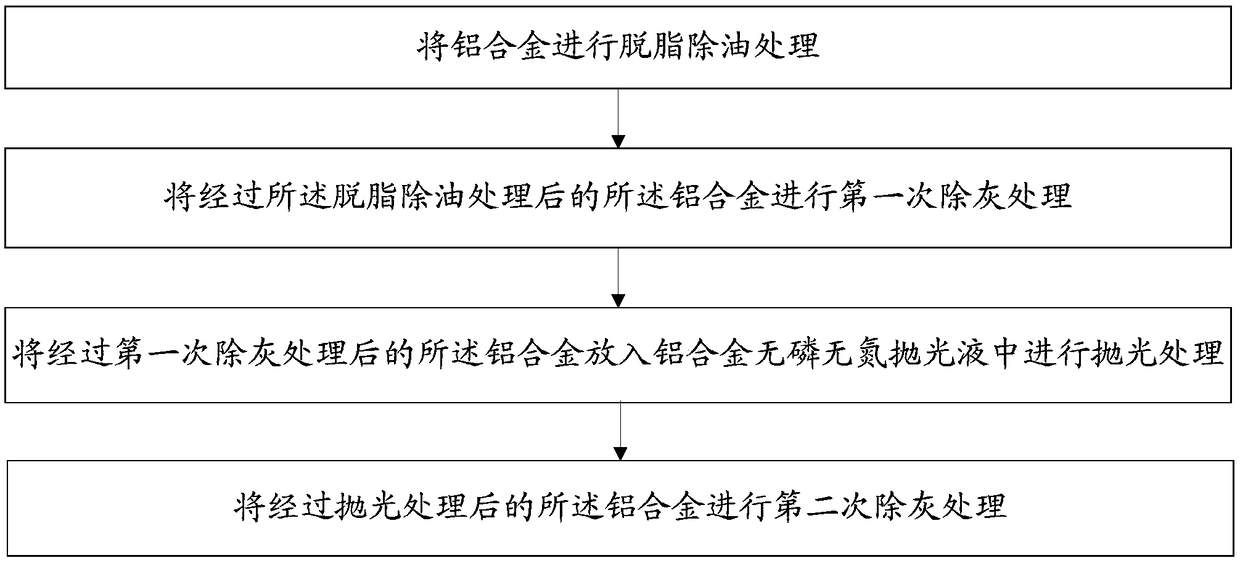

[0093] Aluminum alloy surface treatment method comprises the following steps:

[0094] 1. Put the aluminum alloy into a release agent for degreasing and degreasing treatment; wherein, the release agent includes the following components in parts by mass: 10 g / L of sodium hydroxide, 5 g / L of sodium metasilicate, sodium gluconate 2 g / L, OP-10 emulsifier 1.25 g / L, K12 anionic active agent 1 g / L.

[0095] 2. Use multi-stage countercurrent intermittent washing technology for cleaning; among them, three-stage countercurrent washing is carried out, the same below.

[0096] 3. Put the aluminum alloy into the deashing agent for the first time and carry out the deashing treatment for the first time; wherein, the first deashing agent includes each component of the following mass concentration: ammonium persulfate 175 grams per liter; ammonium bisulfate 7.2 g / L; ammonium nitrate 2.4 g / L; water balance. Temperature: room temperature. Time: 10-20 seconds.

[0097] 4. Use multi-stage coun...

Embodiment 2

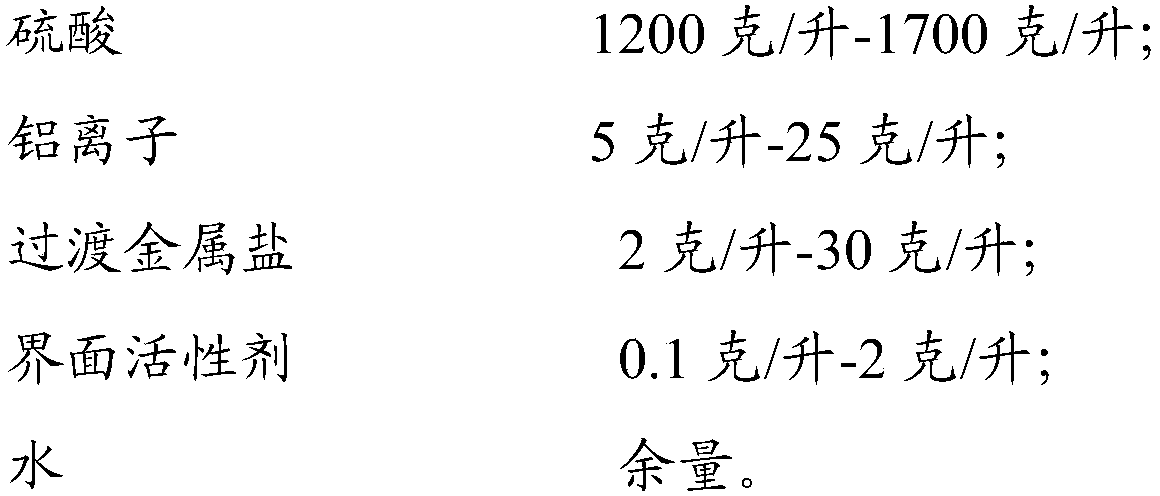

[0107] Different from Example 1, the aluminum alloy non-phosphorus and nitrogen-free polishing solution includes the following components in mass concentration:

[0108]

[0109] After testing, the brightness of sandblasting aluminum alloy after polishing can reach 63 degrees, and the brightness of aluminum profile can reach 405 degrees, and the surface of aluminum alloy has no stripes and patterns, and the corrosion uniformity is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com