Engineering vehicle door hinge and manufacturing process thereof

A door hinge and manufacturing process technology, applied in the field of hinges, can solve the problems of easy damage and opening of the hinge, insufficient structural strength, easy extravasation of lubricants, etc., to avoid extravasation, improve quality, improve lubricity and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

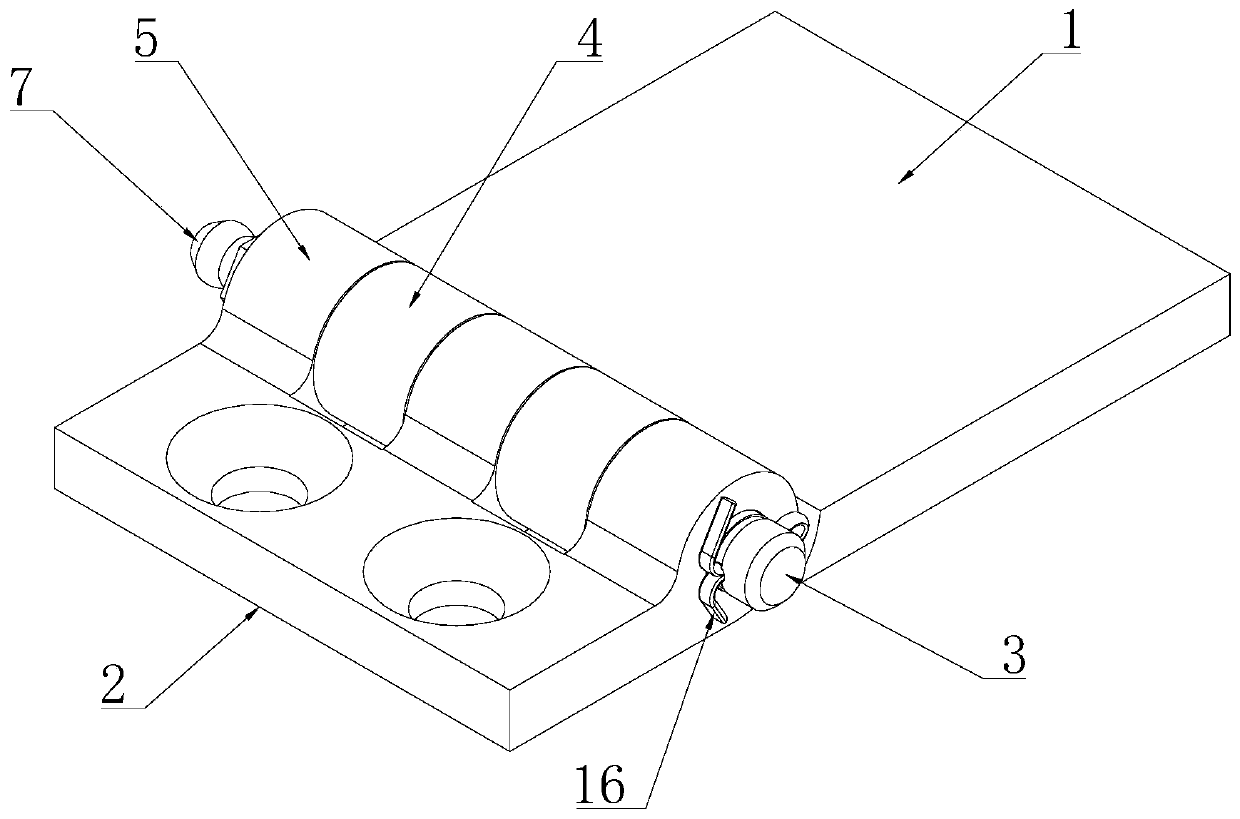

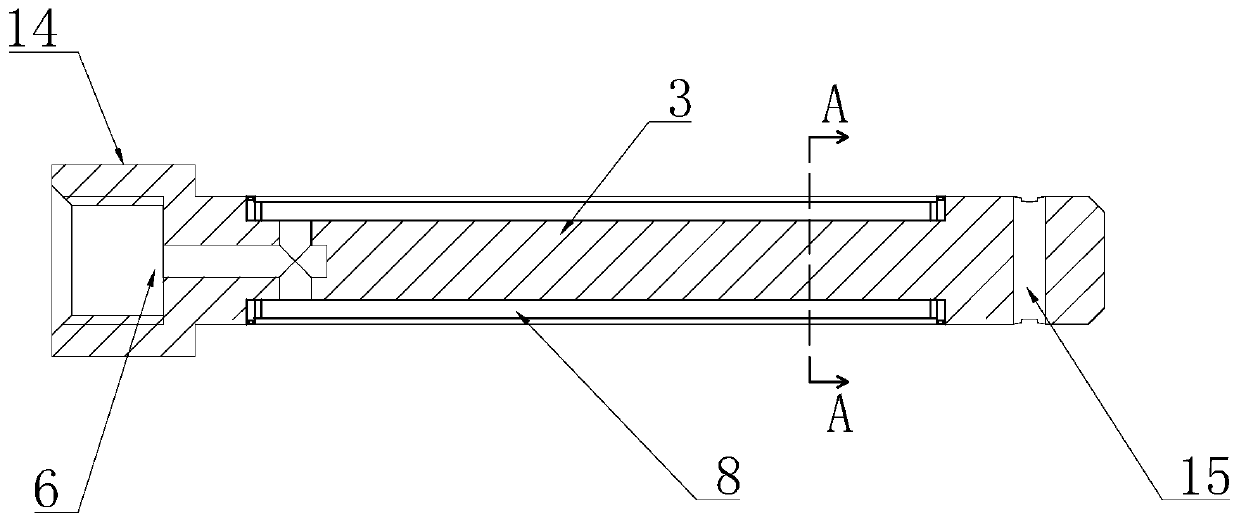

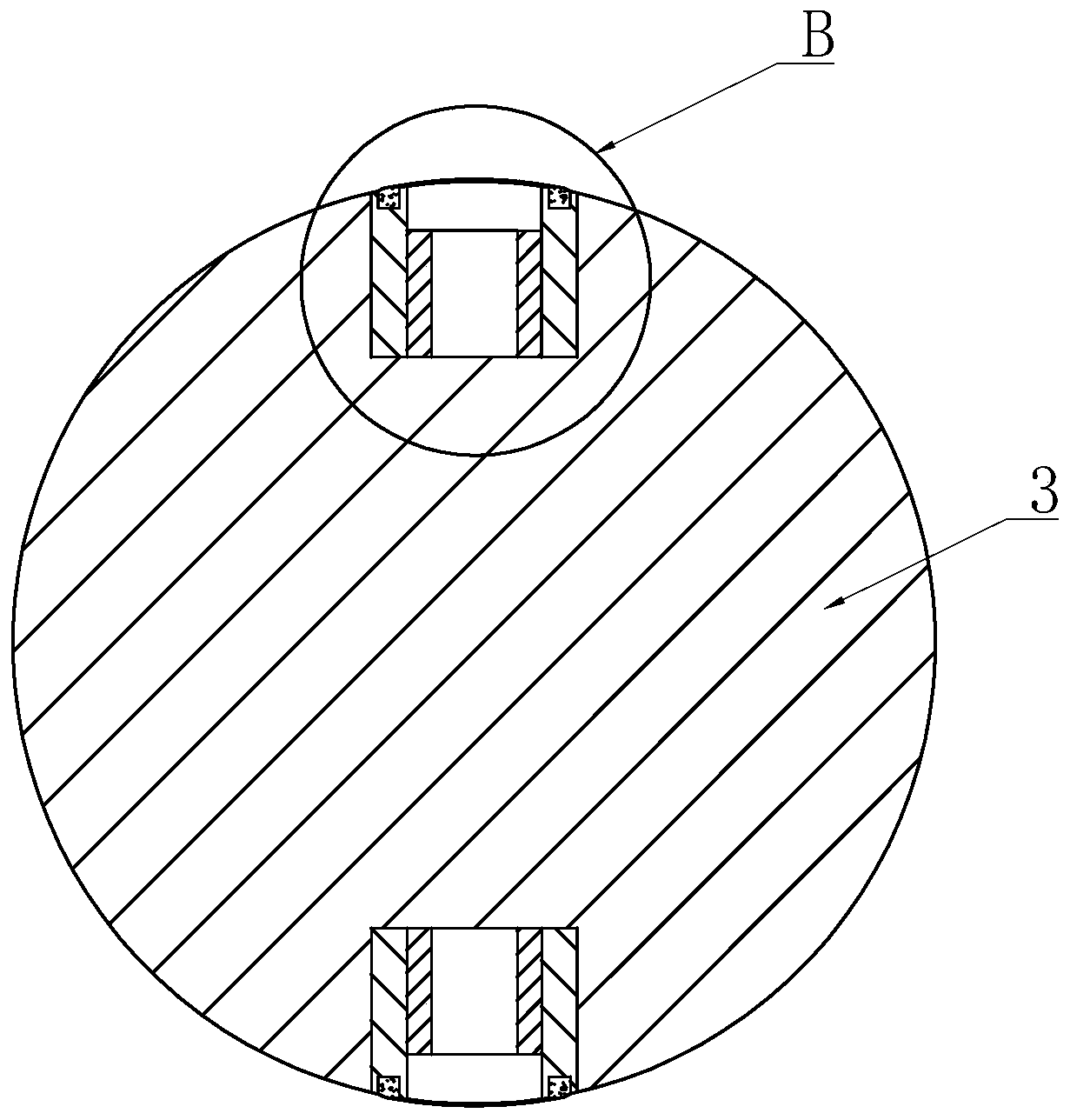

[0045] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-8 :

[0046] An engineering vehicle door hinge, comprising a first hinge piece 1, a second hinge piece 2 and a rotating shaft 3, a first movable sleeve 4 is arranged on one side of the first hinge piece 1, and a first movable sleeve 4 is arranged on one side of the second hinge piece 2 There is a second movable sleeve 5, the first movable sleeve 4 and the second movable sleeve 5 are all installed on the rotating shaft 3 and realize the rotational connection, one end of the rotating shaft 3 is provided with an oil hole 6, and the rotating shaft 3 is provided with There is an oil nipple 7 communicating with the oil hole 6. On the outer peripheral wall of the rotating shaft 3, there are several strip-shaped oil grooves 8 arranged in a circular equidistant manner. The hole 6 and the oil groove 8 are provided with a sealing sleeve 9 and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com