Molten steel deoxidizing and microalloying method

A technology of micro-alloying and molten steel, which is used in the improvement of process efficiency, electric furnaces, furnaces, etc., to achieve the effects of smooth blowing, uniform molten pool temperature, and improved micro-alloying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

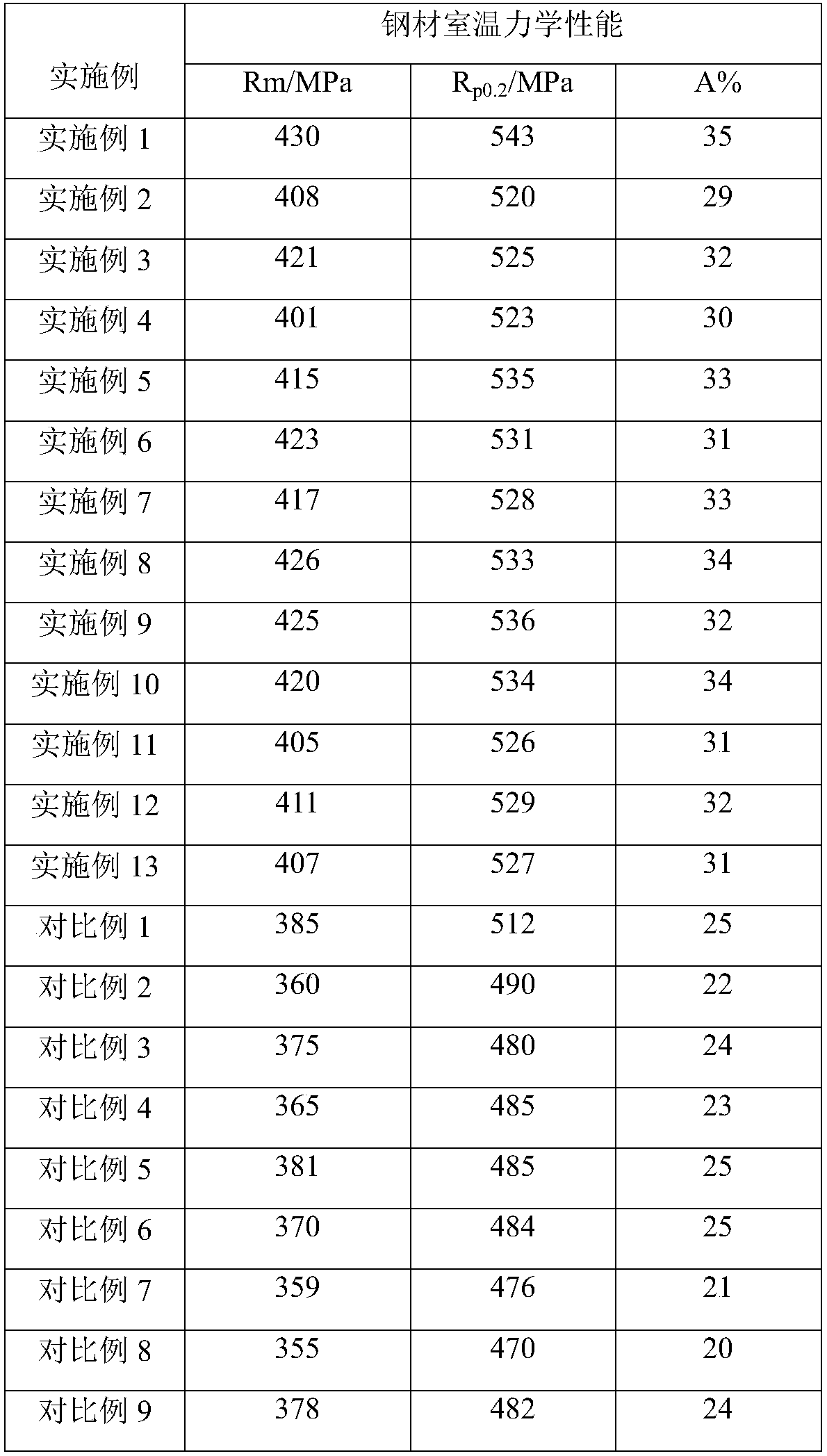

Examples

Embodiment 1

[0019] This example adopts the top-bottom combined blowing K-OBM-S converter, the volume of the furnace is 90t, and the maximum flow rate of top-blowing oxygen is 200m 3 / min; the maximum flow rate of bottom blowing gas is 60m 3 / min.

[0020] This embodiment provides a method for deoxidation and microalloying of molten steel, which includes the following steps: mixing molten iron with a temperature ≥ 1200°C into a top-bottom re-blowing converter, sampling and analyzing molten steel, C, Si, Mn, P and The mass percentages of S are: C4.0%; Si 0.60%; Mn0.70%; P 0.02%; When [O] in molten steel is ≤ 200ppm, nitrogen is used as the carrier gas at the bottom to spray vanadium alloy powder into molten steel for microalloying treatment, and the oxygen flow rate of top blowing is 2.0m 3 / (t·min), the bottom blowing nitrogen flow rate is 2.5m 3 / (t·min); wherein, the total amount of alloy powder added is 5kg / t molten steel.

Embodiment 2

[0022] This embodiment provides a method for deoxidation and microalloying of molten steel, which includes the following steps: mixing molten iron with a temperature ≥ 1200°C into a top-bottom re-blowing converter, sampling and analyzing molten steel, C, Si, Mn, P and The mass percentages of S are: C4.0%; Si 0.60%; Mn0.70%; P 0.02%; When [O] in molten steel is ≤ 200ppm, nitrogen is used as the carrier gas at the bottom to spray vanadium alloy powder into molten steel for microalloying treatment, and the oxygen flow rate of top blowing is 2.0m 3 / (t·min), the bottom blowing nitrogen flow rate is 2.5m 3 / (t·min); wherein, the total amount of alloy powder added is 0.03kg / t molten steel.

Embodiment 3

[0024] This embodiment provides a method for deoxidation and microalloying of molten steel, which includes the following steps: mixing molten iron with a temperature ≥ 1200°C into a top-bottom re-blowing converter, sampling and analyzing molten steel, C, Si, Mn, P and The mass percentages of S are: C4.0%; Si 0.60%; Mn0.70%; P 0.02%; When [O] in molten steel is ≤ 200ppm, nitrogen is used as the carrier gas at the bottom to spray vanadium alloy powder into molten steel for microalloying treatment, and the oxygen flow rate of top blowing is 2.0m 3 / (t·min), the bottom blowing nitrogen flow rate is 2.5m 3 / (t·min); wherein, the total amount of alloy powder added is 10kg / t molten steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com