Polyethylene resin composition for weathering resistance agriculture film, and preparation method thereof

A technology of resin composition and polyethylene resin, which is applied in the field of agricultural shed film resin composition, can solve the problems of limited weather resistance range of agricultural shed film, short service life of agricultural shed film, and unreasonable aging resistance system, so as to avoid migration And precipitation, improve efficiency, improve the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

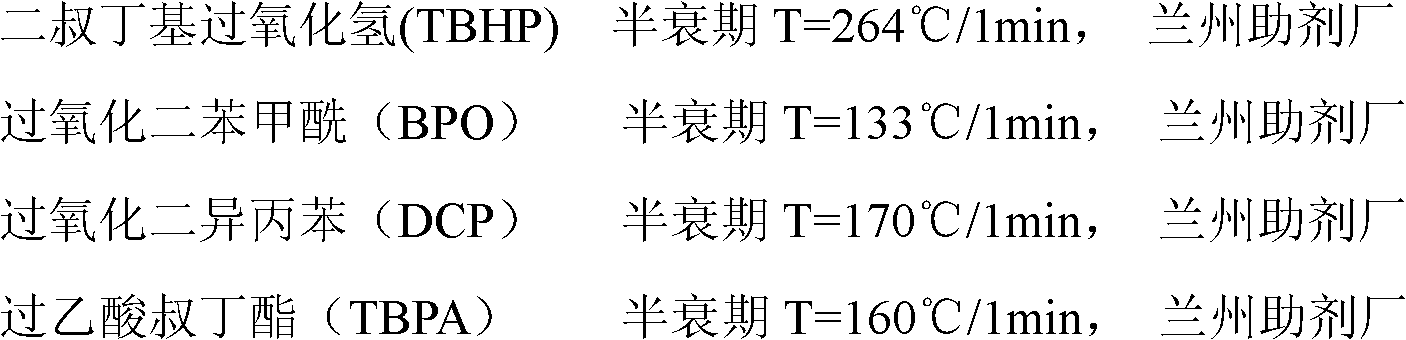

[0048] (1) Preparation of ULDPE-g-VA graft: According to the weight percentage of ULDPE, mix 6 parts of vinyl acetate (VA) with 100 parts of ULDPE at high speed for 6 minutes, and place the mixed material in a closed container for 10 hours ; Then get 0.02 part of DCP and 0.3 part of acetone and put it into a beaker and mix it, then put the mixed solution and the placed mixed material, 0.15 part of antioxidant 1010, and 0.15 part of calcium stearate together into a 10L high-speed mixer Medium and high speed mixing for 5 minutes; finally, add the mixed material into the Φ67 twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 160, 170, 180, 190, 200, 190, 180, 175, 170 Carry out melt grafting reaction, after reacting for 7 minutes, extrude, cool and granulate to obtain ULDPE-g-VA graft (grafting rate: 2.8%).

[0049] (2) Preparation of ULDPE weather-resistant masterbatch: according to the weight percentage of ULDPE, 100 parts of ULDPE and 5 parts o...

Embodiment 2

[0052] (1) The preparation of the ULDPE-g-VA graft is completely the same as in Example 1.

[0053] (2) The preparation of ULDPE weather-resistant masterbatch is completely identical with embodiment 1.

[0054] (3) Preparation of polyethylene resin composition: after mixing 0.005 part of BPO and 0.12 part of TBHP with 0.3 part of acetone solvent, then add 5 parts of LLDPE (101AA) powder resin, mix in a 10-liter high-speed mixer for 3 minutes, and prepare into a premix masterbatch; take out 13 parts of ULDPE weather-resistant masterbatch a and premix masterbatch, 95 parts of LLDPE (101AA) powder resin, 0.15 parts of antioxidant B561, and 0.2 parts of calcium stearate and add them to Φ67 through the feeding port In the twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 165, 180, 190, 195, 210, 220, 210, 200, 190; after 3 minutes of reaction, extrude, cool, granulate, and prepare Polyethylene resin composition. The composition was blown on a Φ12...

Embodiment 3

[0056] (1) The preparation of the ULDPE-g-VA graft is completely the same as in Example 1.

[0057] (2) The preparation of ULDPE weather-resistant masterbatch is completely identical with embodiment 1.

[0058] (3) Preparation of polyethylene resin composition: after mixing 0.008 part of BPO and 0.17 part of TBHP with 0.4 part of acetone solvent, then add 5 parts of LLDPE (101AA) powder resin, mix in a 10-liter high-speed mixer for 3 minutes, and prepare into a premixed masterbatch; take out 15 parts of ULDPE weather-resistant masterbatch a, premixed masterbatch, 95 parts of LLDPE (101AA) powder resin, 0.2 parts of antioxidant B561, and 0.2 parts of zinc stearate and add them to Φ67 through the feeding port In the twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 165, 180, 190, 195, 210, 220, 210, 200, 190; after 3 minutes of reaction, extrude, cool, granulate, and prepare Polyethylene resin composition. The composition was blown on a Φ120 t...

PUM

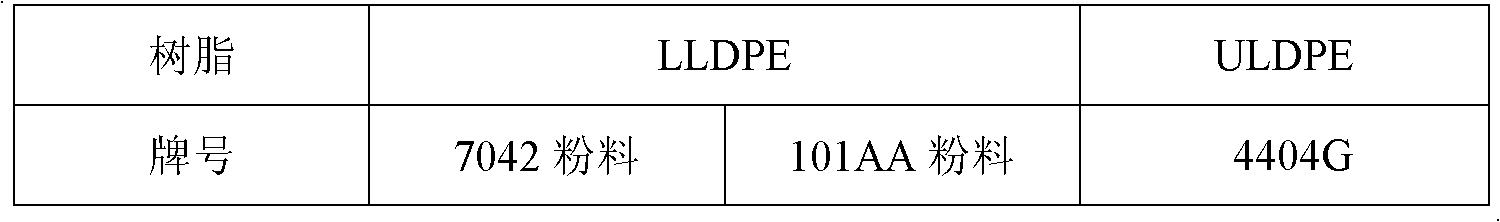

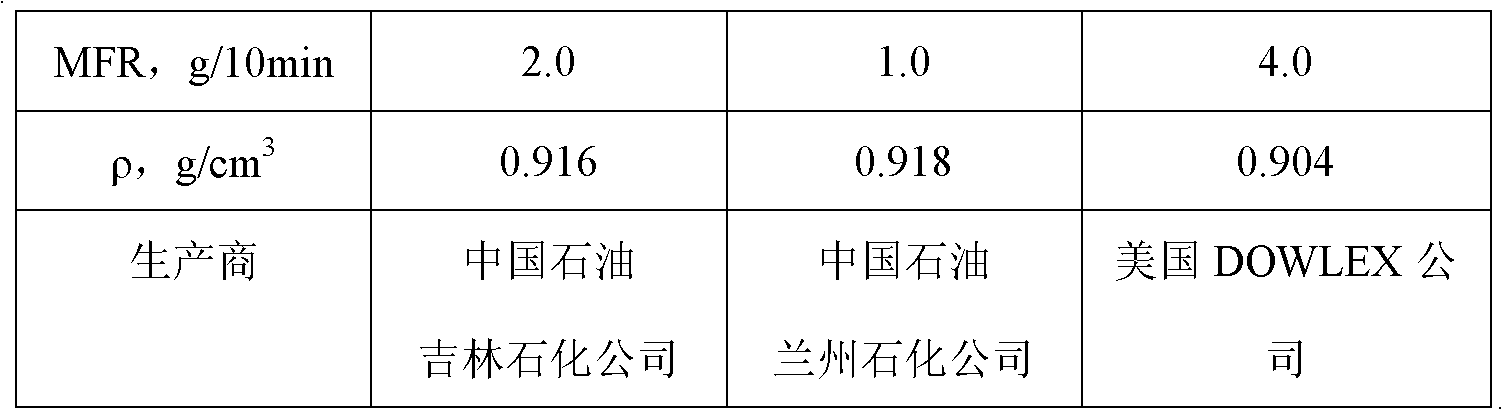

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com