Electronic paper display device with touch function

A display device, touch function technology, applied in electrical digital data processing, data processing input/output process, optics and other directions, can solve the problems of harsh environment, no backlight device, light attenuation, etc., to reduce reflection and refraction process, reduce the production process, display the effect of the effect change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

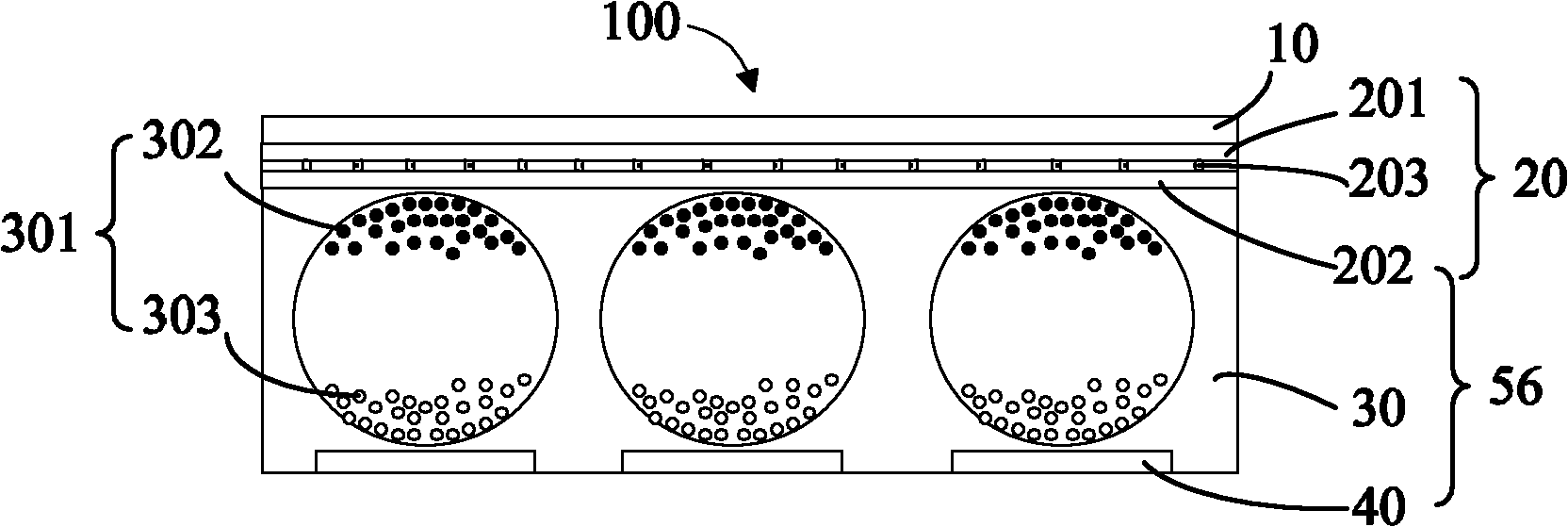

[0014] figure 1 is a schematic structural view of the electronic paper display device according to the first embodiment of the present invention. The electronic paper display device 100 sequentially includes a protective layer 10 , a composite transparent electrode layer 20 , an electrophoretic display medium layer 30 and a pixel electrode layer 40 .

[0015] The protective layer 10 is provided on the outer surface of the electronic paper display device 100 to protect the screen from being scratched or polluted. Usually, the protective layer 10 is a layer of insulating ink coated or a layer of plastic film with high transmittance.

[0016] The composite transparent electrode layer 20 includes a first transparent touch electrode layer 201 , a second transparent touch electrode layer 202 , and a transparent spacer 203 disposed between the first transparent touch electrode layer 201 and the second transparent touch electrode layer 202 . The first transparent touch electrode laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com