Premelting composite slugging agent for converter and preparation method thereof

A slagging agent and pre-melting technology, which is applied in the field of iron and steel smelting, can solve the problems of high-quality converter slagging agent, low content of basic oxides in the slagging agent, and large melting heat absorption, etc. Oxygen at the end of the converter, improving the effect of slag removal, and the effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned pre-melted composite slag-removing agent, the specific steps are as follows:

[0026] a. Mix lime, activated alumina powder and silica powder in proportion, and then pre-melt at 1350-1500°C to obtain pre-melt material. After the pre-melt material is cooled, it is crushed. After crushing, it passes through a 5mm sieve, and the residue ≤ 5 %, take the sieve for subsequent use;

[0027] b. Take the sieved material and active magnesium oxide powder, iron oxide powder, low-sulfur cement and activator to make ingredients in proportion, dry mix the ingredients, add water after mixing to get wet mix;

[0028] c. Press the wet mixture into balls to obtain wet balls with a particle size of 40-50mm. Heat the wet balls to 280-300°C, keep them warm for 4-6 hours, and dry them until the moisture content of the finished product is ≤0.5%. A pre-melted composite slag remover is obtained.

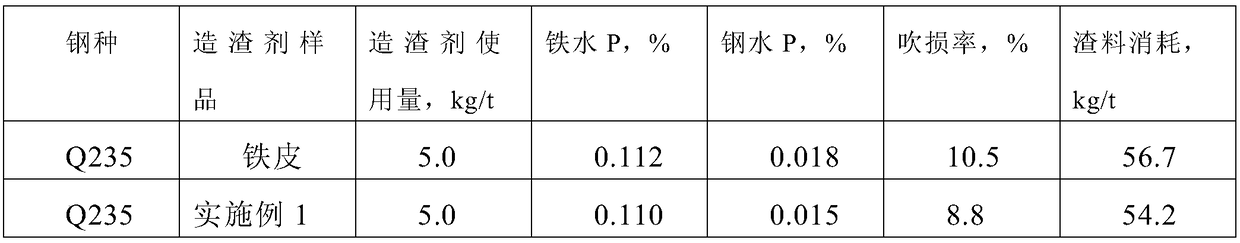

Embodiment 1

[0030] The invention discloses a composite slagging agent for converter steelmaking. The raw materials are lime, iron oxide powder, activated alumina powder, activated magnesium oxide powder, low-sulfur cement (low-sulfur Portland cement), silica powder and stearic acid. Raw material sampling analysis:

[0031] Lime: CaO85%, S 0.20%;

[0032] Activated alumina powder: Al 2 o 3 82%, Al 15%;

[0033] Activated magnesium oxide powder: MgO 85%;

[0034] Silica powder: SiO 2 90%, particle size ≤ 3mm;

[0035] Iron oxide powder: Fe 2 o 3 85%;

[0036] The specific production process is as follows:

[0037] 1) Mixing pre-melting

[0038]Lime, activated alumina powder, and silica powder are mixed according to the mass ratio of 70:10:30, mixed and heated to 1450°C for pre-melting, and the pre-melt is obtained after melting;

[0039] 2) Crushing and sieving of premelt

[0040] After the premelt is cooled, it is ground and crushed, passed through a 5mm sieve, and the unders...

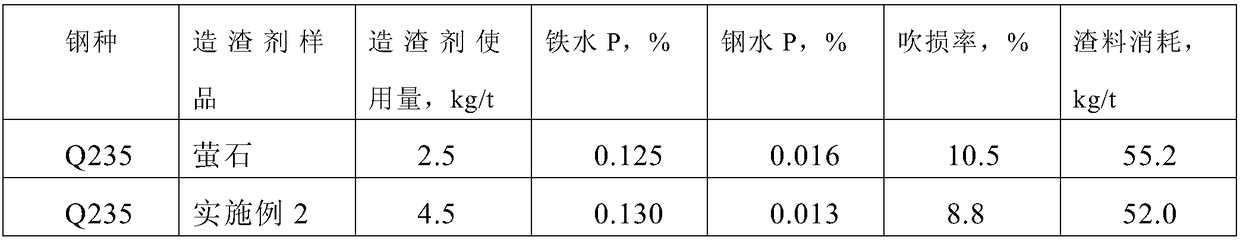

Embodiment 2

[0053] The invention discloses a composite slagging agent for converter steelmaking. The raw materials are lime, iron oxide powder, activated alumina powder, activated magnesium oxide powder, low-sulfur cement (low-sulfur Portland cement), silica powder and stearic acid. Raw material sampling analysis:

[0054] Lime: CaO 92%, S 0.22%;

[0055] Activated alumina powder: Al 2 o 3 70%, Al 26%;

[0056] Activated magnesium oxide powder: MgO 90%;

[0057] Silica powder: SiO 2 95%, particle size ≤ 3mm;

[0058] Iron oxide powder: Fe 2 o 3 90%;

[0059] The specific production process is as follows:

[0060] 1) Mixing pre-melting

[0061] Lime, activated alumina powder, and silica powder are mixed according to the mass ratio of 70:30:30, and then heated to 1350°C for pre-melting, and the pre-melt is obtained after melting;

[0062] 2) Crushing and sieving of premelt

[0063] After the premelt is cooled, it is ground and crushed, passed through a 5mm sieve, and the under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com