A kind of preparation method of spherical granular iron for steelmaking

A technology of spherical granules and granulated iron, which is applied in the field of iron and steel metallurgy, and can solve the problems of easy oxidation of granulated iron, affecting the recovery of small particle size granulated iron, and high loss of granulated iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

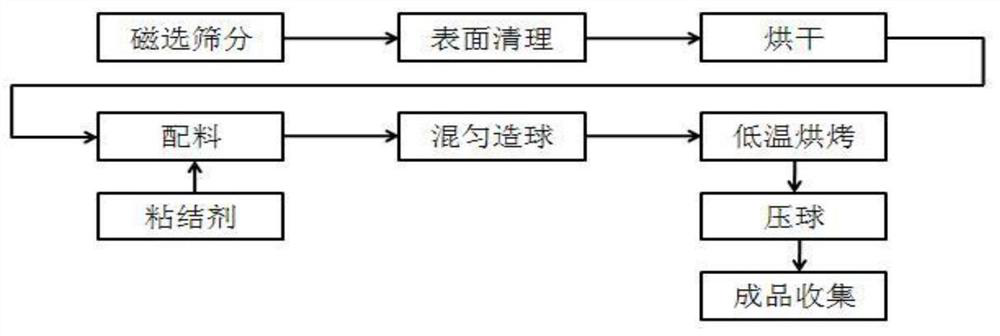

[0023] A method for preparing spherical granular iron for steelmaking, comprising the following steps:

[0024] 1) Magnetic separation and screening: the converter waste slag is crushed and magnetically separated, and then the granular iron obtained after magnetic separation is screened to select the granular iron with a particle size of less than 15mm; the granular iron with a particle size of less than 15mm is used as a raw material;

[0025] 2) Surface cleaning: Since the surface of the selected granular iron will have an embroidery layer or some residue will adhere to the surface after being placed for a period of time, it is necessary to treat the surface of the collected granular iron so as not to affect the bonding of the subsequent granular iron. Surface cleaning adopts simple physical treatment methods, and does not use pickling and other processes to avoid pollution to the environment. Put the screened granular iron into a container, fill the container with water, vi...

Embodiment 1

[0035] A method for preparing spherical granular iron for steelmaking, the production process of which is as follows: the converter waste slag is crushed and magnetically separated, and then the granular iron obtained after the magnetic separation is screened to select the granular iron with a particle size of less than 15 mm. Put a certain amount of granulated iron with a particle size of less than 15mm into a closed container, and the water surface in the closed container can cover the upper surface of the granulated iron. Through the vibration of the closed container, the granulated iron will collide and rub to remove surface rust and residue. Air-dry the small iron grains after surface treatment. Then it is prepared according to the proportion that the mass of the collected granular iron accounts for 80%, and the mass of the binder accounts for 20%, wherein the mass of metallurgical lime in the binder accounts for 45%, and the tar accounts for 55%. Put the small iron parti...

Embodiment 2

[0037] A method for preparing spherical granular iron for steelmaking, the production process of which is as follows: the converter waste slag is crushed and magnetically separated, and then the granular iron obtained after the magnetic separation is screened to select the granular iron with a particle size of less than 15mm. Put a certain amount of granulated iron with a particle size of less than 15mm into a closed container, and the water surface in the closed container can cover the upper surface of the granulated iron. Through the vibration of the closed container, the granulated iron will collide and rub to remove surface rust and residue. Air-dry the small iron grains after surface treatment. Then it is prepared according to the ratio that the mass of the collected granular iron accounts for 75%, and the mass of the binder accounts for 25%, wherein the mass of metallurgical lime in the binder accounts for 50%, and the tar accounts for 50%. Put the small iron particles i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com