A method for removing alkali metals by sintering

An alkali metal removal technology, applied in the field of metallurgy, can solve the problems of low overall utilization level, soaring iron ore prices, deterioration of material column permeability, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

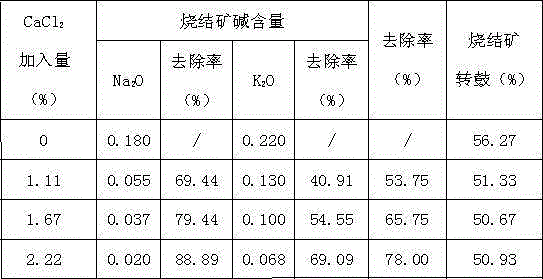

Embodiment 1

[0023] A. Raw materials are prepared according to the following mass percentages: iron powder ore: 30-60%, concentrate: 40-70%, CaCl 2 Powder: 1.11%, dolomite: 8-12%, limestone: 1.5-6.5%, quicklime: 3-5%, fuel: 5-6.5%;

[0024] B. Send the raw materials prepared in step A into the mixing mixer, add water to stir and granulate, and control the moisture content of the mixture particles to 6-8%;

[0025] C. Send the mixed material particles prepared in step B to the sintering machine trolley, control the material layer height of the mixed material particles to 600-700mm, and ignite and sinter at the ignition temperature of 1100-1300°C to obtain sintered ore ;

[0026] D. The sintered ore obtained in step C is conventionally crushed, sieved, cooled, and then sprayed with 0.5-0.7 kg of sintered ore per ton, and the concentration of 0.015% CaCl 2 The solution is sprayed on the sinter.

Embodiment 2

[0028] A. Raw materials are prepared according to the following mass percentages: iron powder ore: 30-60%, concentrate: 40-70%, CaCl 2 Powder: 1.67%, dolomite: 8-12%, limestone: 1.5-6.5%, quicklime: 3-5%, fuel: 5-6.5%;

[0029] B. Send the raw materials prepared in step A into the mixing mixer, add water to stir and granulate, and control the moisture content of the mixture particles to 6-8%;

[0030] C. Send the mixed material particles prepared in step B to the sintering machine trolley, control the material layer height of the mixed material particles to 600-700mm, and ignite and sinter at the ignition temperature of 1100-1300°C to obtain sintered ore ;

[0031] D. The sintered ore obtained in step C is conventionally crushed, sieved, cooled, and then sprayed with 0.5-0.7 kg of sintered ore per ton, and the concentration of 0.015% CaCl 2 The solution is sprayed on the sinter.

Embodiment 3

[0033] A. Raw materials are prepared according to the following mass percentages: iron powder ore: 30-60%, concentrate: 40-70%, CaCl 2 Powder: 2.22%, dolomite: 8-12%, limestone: 1.5-6.5%, quicklime: 3-5%, fuel: 5-6.5%;

[0034] B. Send the raw materials prepared in step A into the mixing mixer, add water to stir and granulate, and control the moisture content of the mixture particles to 6-8%;

[0035] C. Send the mixed material particles prepared in step B to the sintering machine trolley, control the material layer height of the mixed material particles to 600-700mm, and ignite and sinter at the ignition temperature of 1100-1300°C to obtain sintered ore ;

[0036] D. The sintered ore obtained in step C is conventionally crushed, sieved, cooled, and then sprayed with 0.5-0.7 kg of sintered ore per ton, and the concentration of 0.015% CaCl 2 The solution is sprayed on the sinter.

[0037] In all the above-mentioned embodiments, the conventional sintering process is used in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com