Automatic controlling method for converter oxygen lance used for converting low-carbon steel

A converter blowing and steel oxygen lance technology, which is applied in the manufacture of converters and other directions, can solve problems such as difficulty in monitoring, inability to reduce the probability of slag drying and splashing, and model errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below by embodiment the present invention will be further described.

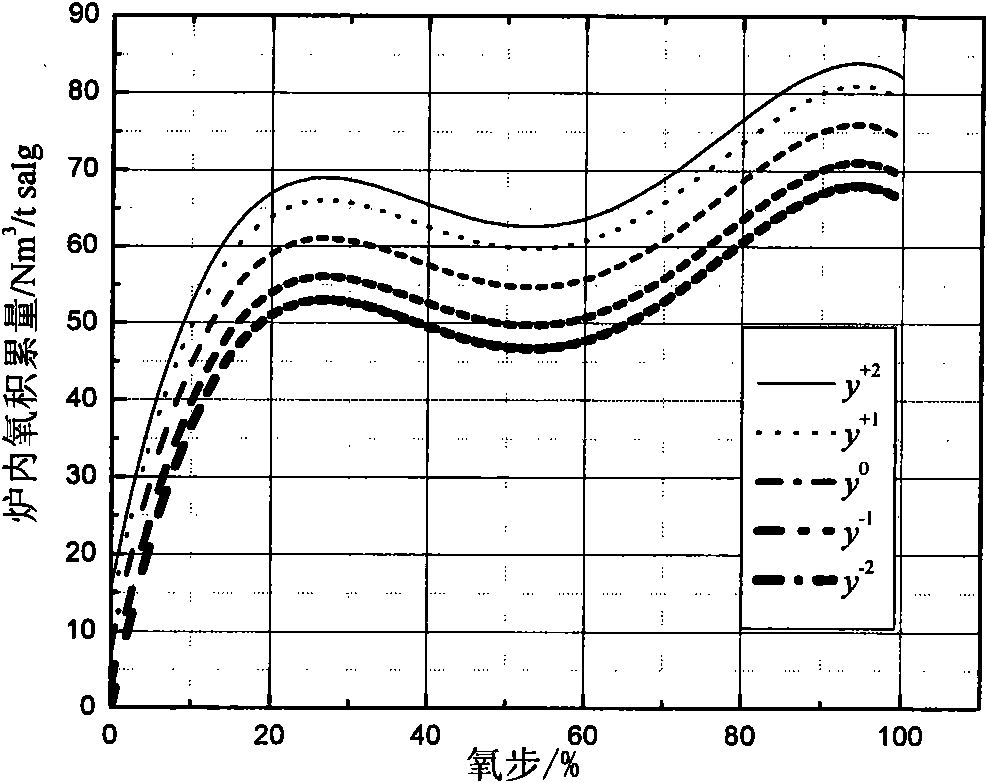

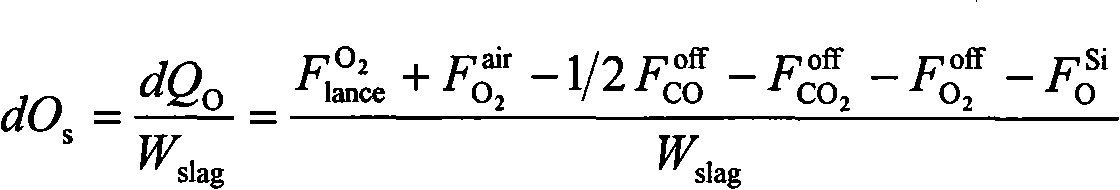

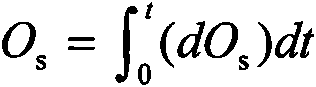

[0055] In the embodiment, the furnace raw material conditions are 8-19% of steel scrap ratio (light steel scrap accounts for 30%-70% of the total amount of steel scrap), lime consumption 34-54kg / t, light burnt dolomite consumption 18-37kg / t, molten iron The carbon content is 3.63%-4.60%, the silicon content of the molten iron is 0.06%-0.58%, the manganese content of the molten iron is 0.17%-0.33%, the phosphorus content of the molten iron is 3 / t min; the furnace gas component analysis system analyzes the obtained furnace gas sample gas, times / 3s; the oxygen lance is controlled in the blowing process according to the automatic oxygen lance position determination scheme, k in the embodiment 0 =2.55,k 1 =4.37,k 2 =-0.11,k 3 =1.21×10 -3 , k 4 =-4.64×10 -6 , a 1 = 8, a 2 = 12, a 3 = 8, a 4 = 12, during the blowing process, the furnace conditions were controlled and there was no back-drying and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com