A method for eliminating partial splashing phenomenon in the process of slag splashing and furnace protection

A technology of slag splashing to protect the furnace and phenomenon, which is applied to the improvement of process efficiency, manufacturing converters, etc. Increase the effect of mixing and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

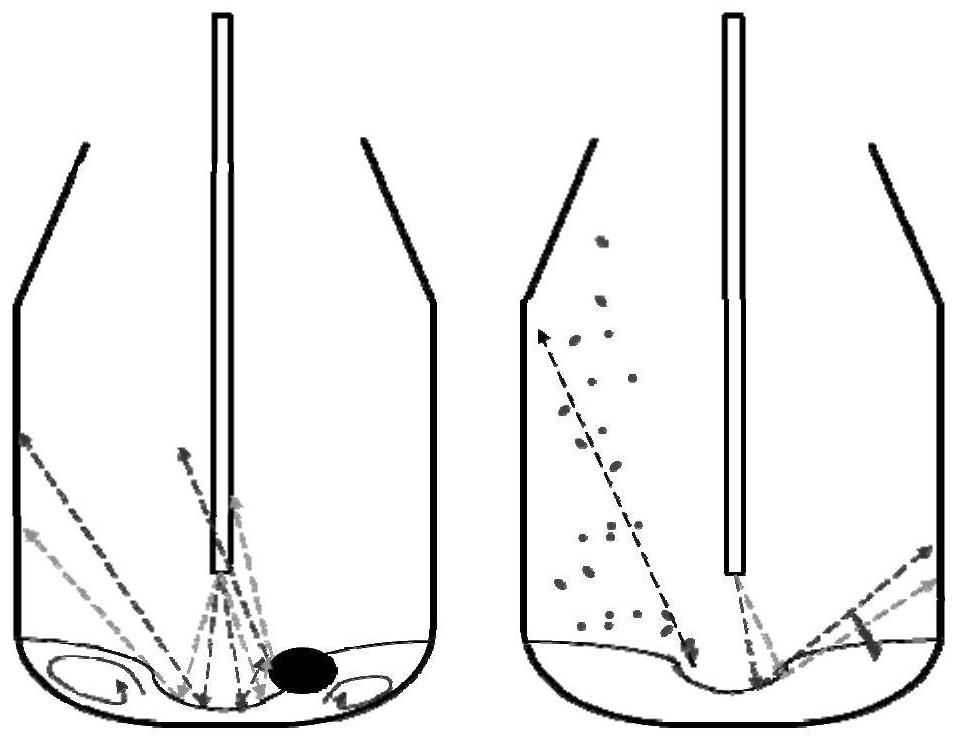

Method used

Image

Examples

Embodiment 1

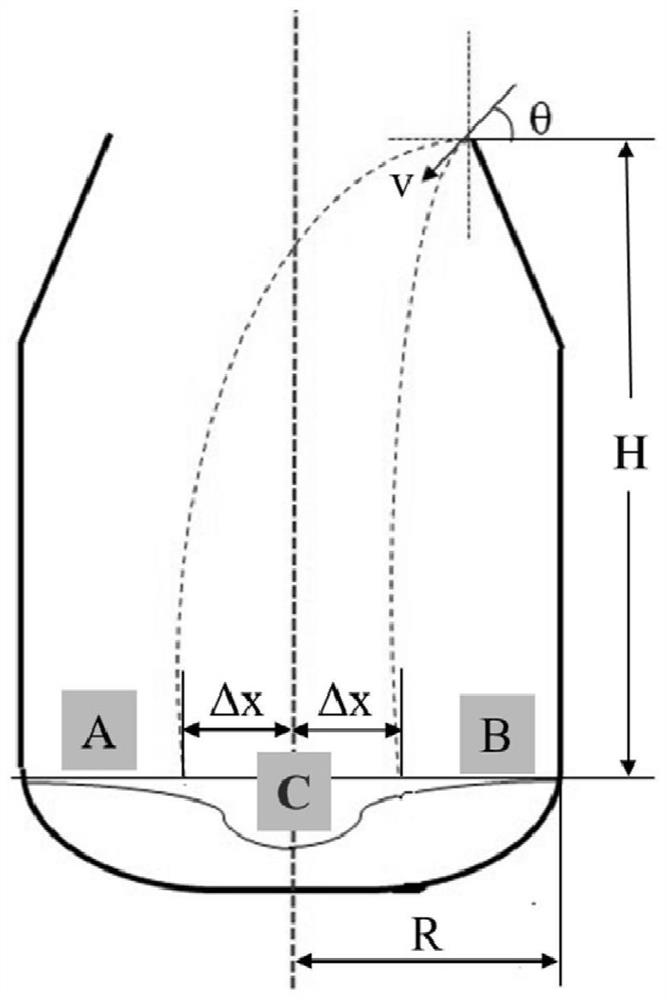

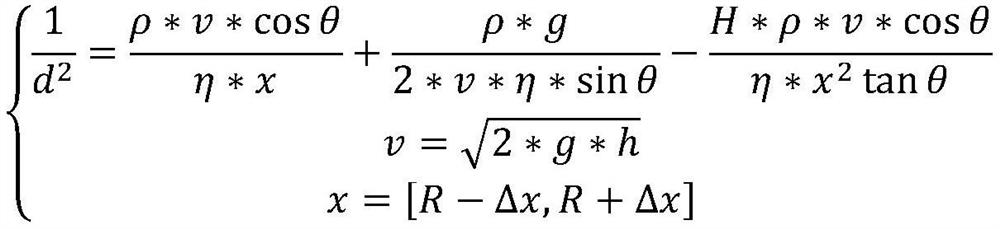

[0039] A method of eliminating slag splashing in the process of protecting the furnace in this embodiment has been successfully tested in a 120-ton top-bottom combined blowing converter in a domestic steel factory. figure 2 As shown, in this embodiment, the specific content of eliminating the phenomenon of slag splashing in the process of protecting the furnace by controlling the drop area, addition amount, and addition timing of raw dolomite in the converter is as follows:

[0040] 105t of molten iron at a temperature of 1390°C was blended into the converter, and 25t of scrap steel was added at the same time. The composition of the molten iron was C: 4.84%, Si: 0.36%, Mn: 0.25%, and P: 106%.

[0041] When the smelting end point is reached, the gun is lifted to measure the temperature and take samples, and the measured data: the tapping temperature T is 1655°C, the end point C=0.08%, and the slag melting point t is 1619°C.

[0042] At this time, T-t=36°C>15°C, reaching the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com