Engine oil-gas separation mechanism

A separation mechanism and engine technology, applied in the direction of engine components, machines/engines, engine lubrication, etc., can solve the problems of energy saving and environmental protection, inability to separate oil and gas, and high working temperature, and achieve simple structure, eliminate splashing, The effect of improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

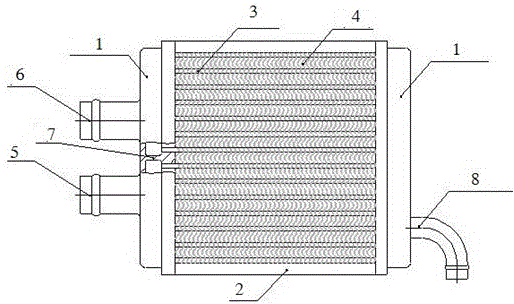

[0014] An engine oil-gas separation mechanism, including a condenser, the two sides of the condenser are provided with clamping seats 1, and the other two sides are provided with splints 2 to fix the condenser together, one side of the condenser is provided with an outlet 5 and an inlet 6, and the condenser is composed of Condenser pipe 3 and heat sink 4 are composed, condenser pipe 3 is parallel to each other, arranged side by side between clamping seats 1, heat sink 4 is set on condenser pipe 3, outlet 5 and inlet 6 are separated by partition 7, condenser There is also a degreasing pipe 8 below, and a condensing pipe 3 is a 2*26 flat pipe made of 2A12 aluminum, which has high thermal conductivity and good heat dissipation effect. In addition, the oil removal pipe joint is arranged at the bottom, and the condensed oil can be drained in time to ensure that the breath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com