Additive for improving fluidity of pulverized coal for blast furnace injection and using method thereof

An additive and fluidity technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of increasing sources of iron-containing minerals in blast furnace ironmaking and poor fluidity, and achieve the effects of increasing sources, reducing costs, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Under non-public circumstances, the blast furnace of an ironworks carried out the following implementation verification:

[0019] (1) Selection of dust removal ash and pulverized coal.

[0020] The sintered dedusting ash was selected as the dedusting ash in this embodiment, and the chemical composition of the sintering dedusting ash is shown in Table 1.

[0021] The chemical composition (mass percentage, wt%) of table 1 embodiment 1 dedusting ash

[0022] ingredient name

TF

C

SiO 2

CaO

MgO

al 2 o 3

Cl

K+Na

Included ratio

57.29

4.47

5.31

3.92

0.71

2.95

0.01

0.17

1.0

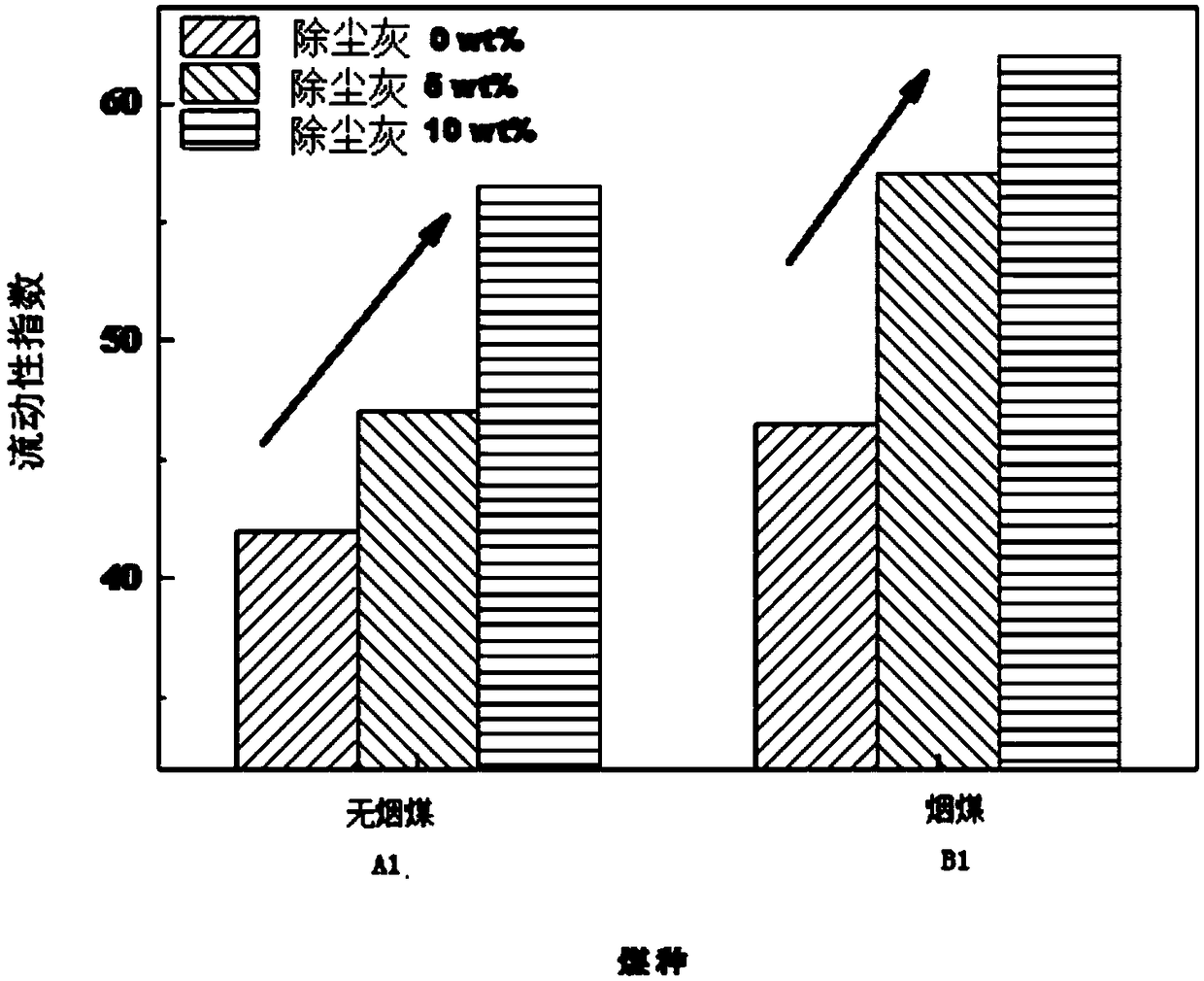

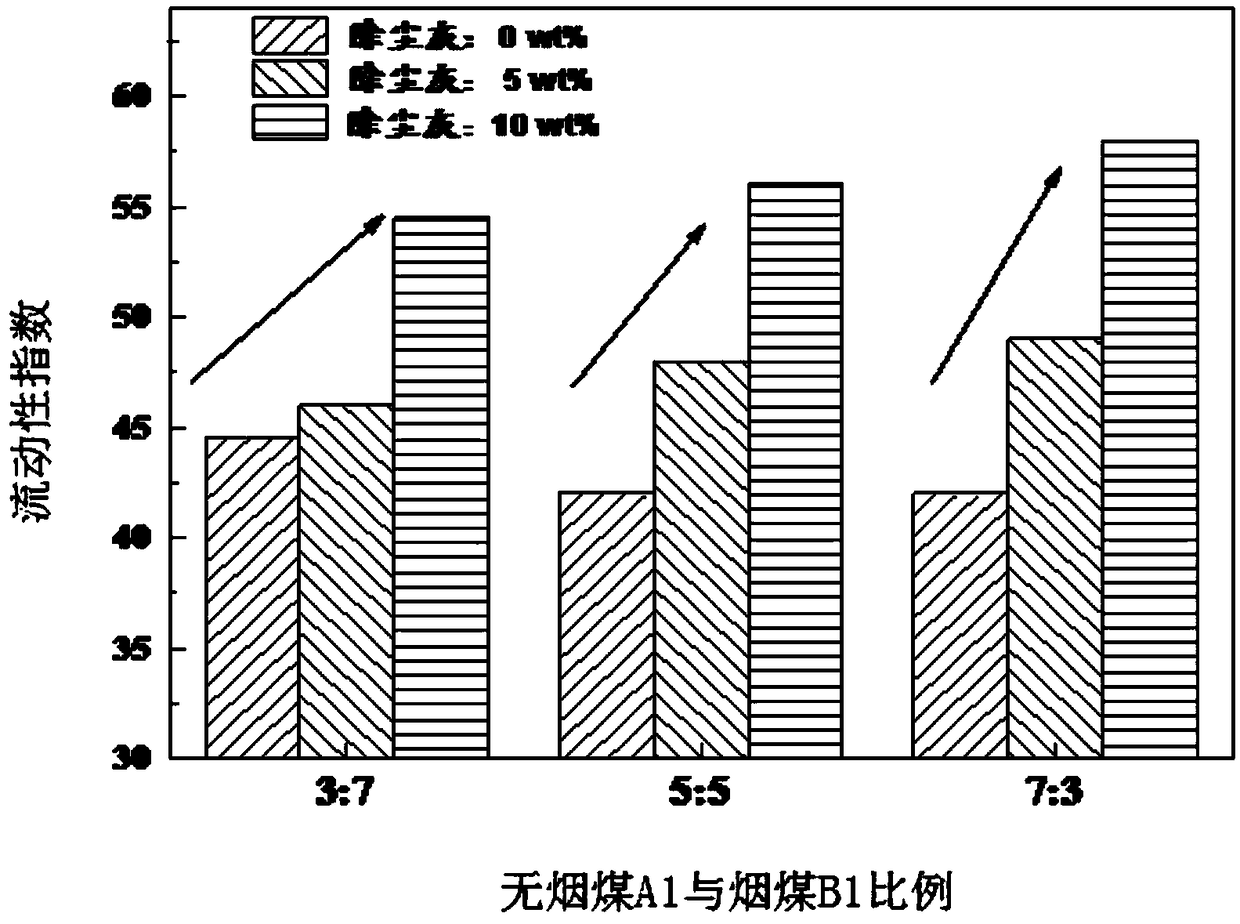

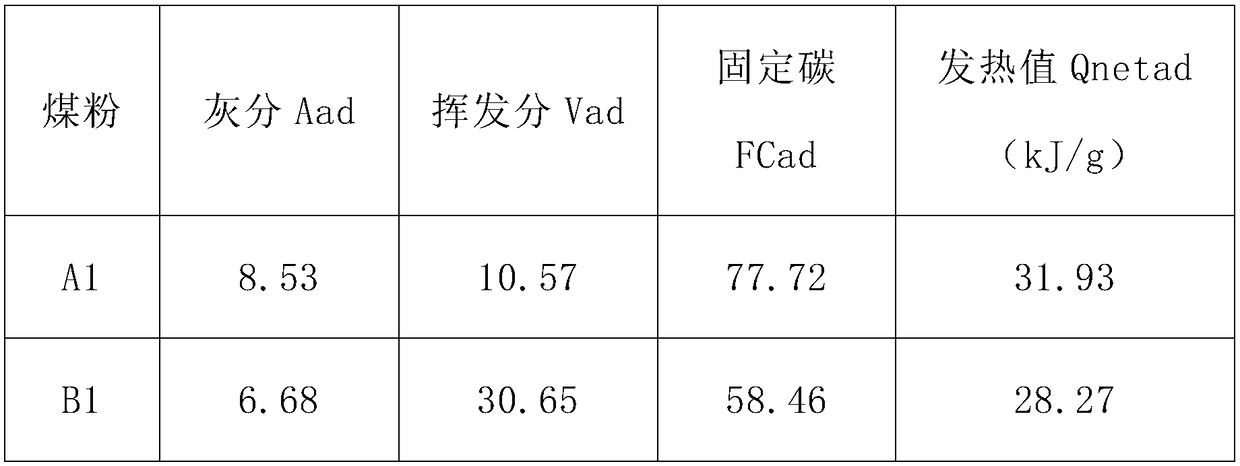

[0023] Embodiment 1 Coal powder is selected from the pulverized coal (anthracite A1, bituminous coal B1) used for on-site injection, and its industrial analysis is as shown in Table 2. From the composition, it can be seen that the volatile matter Vad of A1 is 10.57wt%, which is a typical anthracite coal powder;...

Embodiment 2

[0036] A certain pellet dust removal ash was selected as the dust removal dust of Example 2, and the chemical composition of the pellet dust removal dust is shown in Table 4.

[0037] The chemical composition (mass percentage, wt%) of table 4 embodiment 2 pelletizing dust removal ash

[0038] ingredient name

[0039] Example 2 The pulverized coal is selected from pulverized coal (anthracite A2) for on-site injection blast furnace.

[0040] Table 5 Example 2 Industrial analysis of pulverized coal injection (mass percentage, wt%)

[0041] anthracite

[0042] Table 6 Embodiment 2 Pellet dedusting ash and self physical properties of anthracite

[0043]

[0044] Dry the coal powder at 80°C for 2 hours, dry the pellet ash at 120°C for 3 hours and mix it with a mixer. Similarly, mix the coal powder A2 and the pellet ash with a mixer, According to the Carr liquidity index (F (index) ) to determine the fluidity of the powder. The ratio of pellet dust removal ...

Embodiment 3

[0049] In this embodiment, a blast furnace bag dust is selected as the dust of Example 3, and the chemical composition of the dust is shown in Table 8.

[0050] The chemical composition (mass percentage, wt%) of table 8 embodiment 3 blast furnace dedusting ash

[0051] ingredient name

TF

C

SiO 2

CaO

MgO

al 2 o 3

Cl

K+Na

Included ratio

40.0

30.0

11.33

10.55

4.0

2.72

0.1

0.05

[0052]The coal powder of embodiment 3 is the same as that of embodiment 2 (anthracite A2). The physical properties of blast furnace bag dust removal ash are shown in Table 9.

[0053] The self physical property of table 9 embodiment 3 blast furnace dedusting ash

[0054]

[0055] Dry the coal powder at 60°C for 4 hours, dry the dust at 80°C for 5 hours and mix it with a mixer. Similarly, mix the coal powder A2 and the dust with a mixer. Index (F (index) ) to determine the fluidity of the powder. The ratio of blast fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com