Method for determining saturated moisture of coke

A technology of coke and moisture, applied in the field of determination of saturated moisture in coke, to achieve the effect of reducing fuel consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

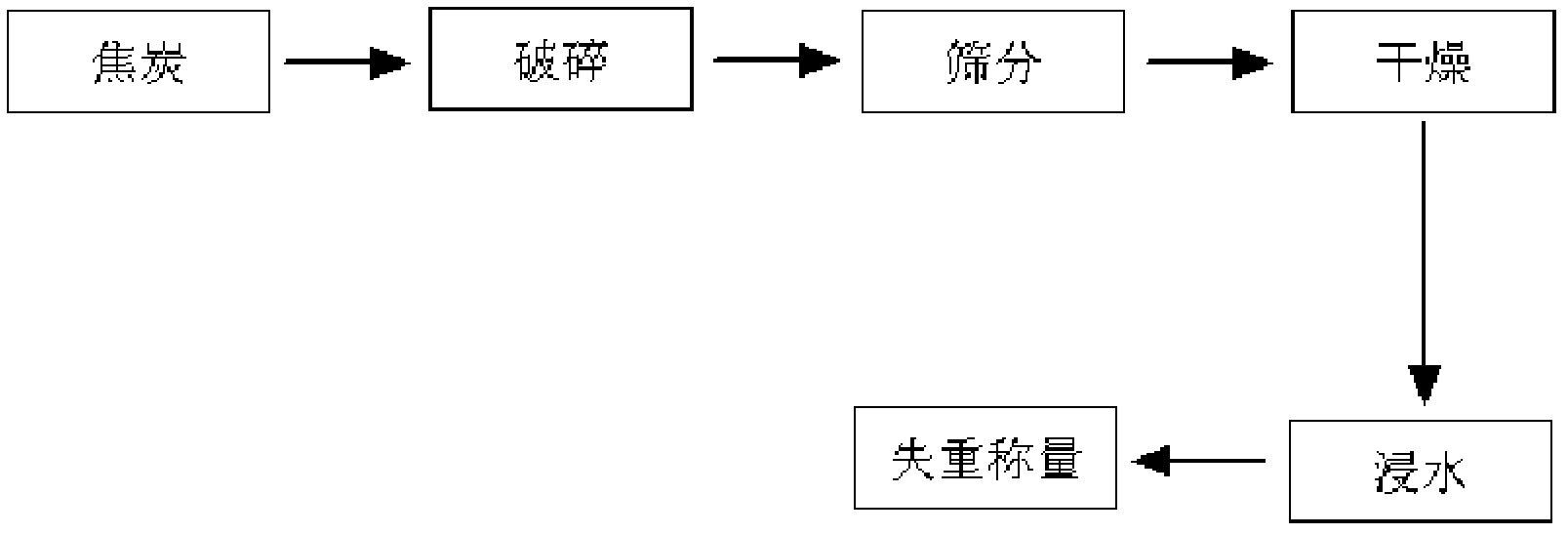

Method used

Image

Examples

Embodiment 1

[0022] Take 20kg of Shanxi coke with a moisture content of 0.66%, ash content of 14.26%, and a volatile content of 1.62%, and put it into a crusher for crushing. The sieves were sieved to record and calculate the coke content of each particle size. The calculated data after sieving are shown in Table 1. Put the sieved samples in a drying oven at 105°C for 4 hours, then take them out, and mix them according to the weight ratio of the particle size ranges in Table 1. The amount of ingredients is 3kg, and 2 parts are used as parallel samples. That is, the coke of 30-25mm is at a weight ratio of 47.1%, the coke of 25-20mm is at a weight ratio of 24.08%, the coke of 20-16mm is at a weight ratio of 13.31%, the coke of 16-8mm is at a weight ratio of 13.97%, 8 -5mm coke is batched according to the weight ratio of 1.54%. Put the prepared coke in the hanging basket and immerse it in water together. After soaking in water for 24 hours, take it out and hang it under the balance. Read the ...

Embodiment 2

[0026] Take 20kg of small Baosteel coke with a moisture content of 0.59%, ash content of Ad of 11.55%, and a volatile content of Vd of 0.89%, and put it into a crusher for crushing. Sieve the sieve with sieve holes to record and calculate the coke content of each particle size. The calculated data after sieving are shown in Table 2. Put the sieved sample in a drying oven at 105°C for 4 hours and take it out. Sieve as before. Data batching, one batch is 3kg, and two batches are used as parallel samples. Put the prepared coke in the hanging basket and immerse in water together. After soaking in water for 24 hours, take it out and hang it under the balance. Read the balance data once every 5 minutes. When the balance data remains unchanged within 5 minutes, it is considered to be saturated. At this time, the moisture content in the coke is the coke saturated moisture. Record the balance reading at this time, and the saturated moisture of Baosteel small coke is 9.18% through calcul...

Embodiment 3

[0030] Take 20kg of Shanxi coke with a water content of 0.8%, ash content of 14.40%, and a volatile content of 1.62%, and put it into a crusher for crushing. The crushed coke is screened with sieves of 30mm, 20mm, 12mm, and 5mm. Record and calculate the coke content of each particle size, and the calculated data after sieving are shown in Table 3. Put the sieved sample in a drying oven at 110°C for 5 hours, then take it out, and mix according to the weight ratio of the particle size ranges in Table 3. The amount of ingredients is 3kg, and 2 parts are used as parallel samples. Others are the same as in Example 1, and the saturated moisture of Shanxi coke is 13.01%.

[0031] Table 3 Coke particle size range

[0032] Particle size range

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com