Grouting method of blast furnace taphole duct

A technology of tunnel grouting and tap hole, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc. It can solve problems such as unclean slag and iron discharge, divergent iron flow, and tap hole splashing, so as to ensure smoothness and improve stability Sexuality, the effect of reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

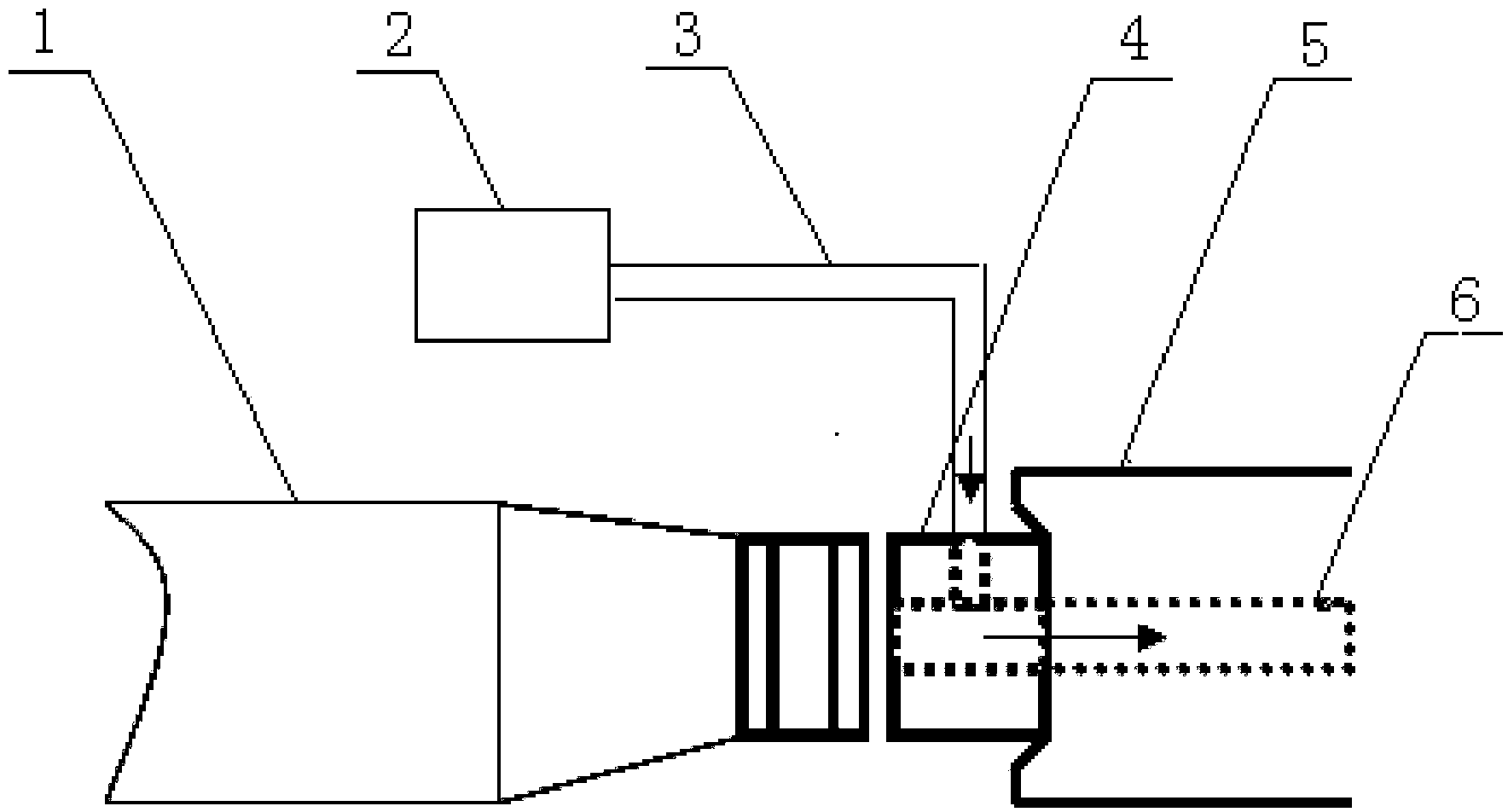

[0017] Depend on figure 1 Visible, blast furnace tap hole grouting method of the present invention mainly is under normal production situation, utilizes the original mud cannon 1, grouting machine 2, sealing gun head 4 and tap hole mud cover 5 equipment and the grouting material before the blast furnace stove, Fill and block the inner wall of the tap hole, and control the splashing of molten iron from the tap hole by preventing the cross-wind of the tap hole. Its specific method and steps are:

[0018] 1. Firstly, drill out a 3.0 m deep hole in the iron hole with a tapping machine.

[0019] 2. Close the rear end of the sealing nozzle 4, and open a grouting interface on the side of the sealing nozzle 4, and then use the mud gun 1 to seal the sealing nozzle 4 on the iron nozzle mud sleeve 5.

[0020] 3. Connect the grouting pipe 3 of the grouting machine 2 to the grouting interface of the sealing nozzle 4 .

[0021] 4. Use the grouting machine 2 to press the unshaped refracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com