Iron ore concentrate for increasing low-temperature reduction pulverization rate of iron ore sinter and preparation method

A technology for iron ore concentrate and sintered ore, which is applied in the field of iron ore concentrate for improving the low-temperature reduction and pulverization rate of iron ore sintering ore, can solve the problems of high cost, high operation difficulty, increased operation difficulty, etc., and achieves improvement of blast furnace charging capacity. The effect of quality, low temperature reduction and pulverization improvement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

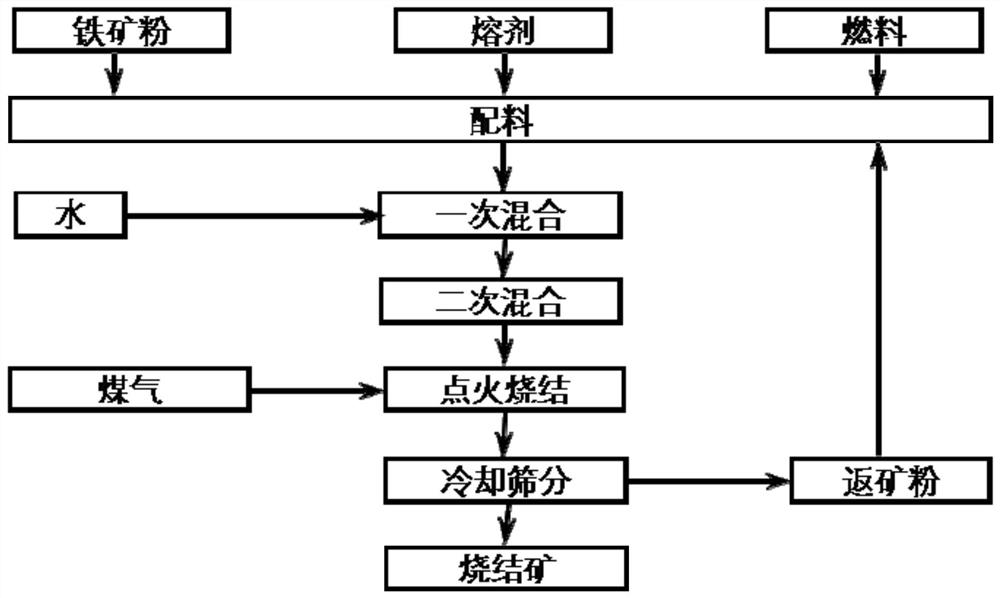

[0027] A method for preparing iron ore concentrates for improving the low-temperature reduction pulverization rate of iron ore sinters, comprising the following steps:

[0028] S1: the sintering raw material iron ore powder, flux and fuel are mixed once in the batching room of the sintering process;

[0029] S2: add water to the mixed raw materials in step S1, mix and granulate;

[0030] S3: cloth is carried out ignition sintering on the sintering machine;

[0031] S4: the finished ore obtained in step S3 is cooled by air blast and sieved by size to obtain ordinary sintered ore;

[0032] S5: The material that does not form mineral after sintering in step S3, returns to ore and enters step S1 to continue the cycle of steps S1-S4.

[0033] The flux is mixed with one or more of limestone, quicklime and dolomite in a certain proportion.

[0034] The fuel is mixed with one or more of coke powder and anthracite clean coal in a certain proportion.

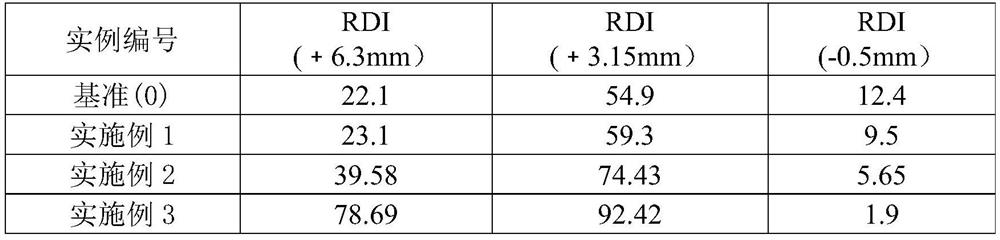

[0035] The sinter sample was t...

Embodiment 1

[0047] The iron ore concentrate provided by the present invention is mainly composed of the following components in terms of mass fraction: Fe 2 o 3 : 57.83%, FeO: 16.29%, CaO: 1.47%, SiO 2 : 8.23%, Al 2 o 3 : 1.28%; MgO: 3.14%; BaO: 0.85%, MnO: 1.28%, and the burning loss is 8.48%.

[0048] In terms of mass fraction, 5% iron concentrate and 75% iron ore powder are mixed to form a mixture, and the sintering raw material is composed of mixture: 80%, flux: 15% and fuel: 5%.

[0049] The particle size of iron concentrate is not more than 0.09mm, and the content of particles with a particle size of less than 0.074mm is 90%.

[0050] A method for preparing iron ore concentrates for improving the low-temperature reduction pulverization rate of iron ore sinters, comprising the following steps:

[0051] S1: the sintering raw materials are mixed once in the batching chamber of the sintering process;

[0052] S2: add water to the mixed raw materials in step S1, mix and granulate; ...

Embodiment 2

[0060] Compared with Example 1, the present invention differs in that the ratio of iron concentrate to sintering raw materials is changed to 20%, the ratio of iron ore powder to sintering raw materials is changed to 60%, and the contents of other components remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com