Suspended free-oscillating type separating stock stop for charging billets

A swing-type, steel billet technology, applied in the field of roller table feeding equipment for steel rolling heating furnaces, can solve the problems of efficiently meeting the technical requirements for entering the furnace, high quality requirements for the steel entering the furnace, and prone to industrial accidents, etc., and achieves simple structure, Increased speed, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

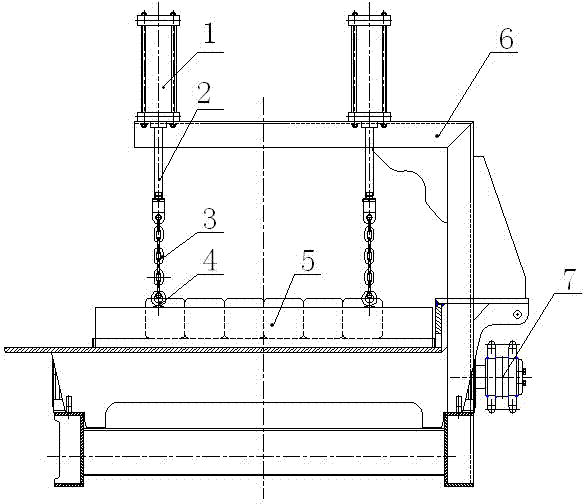

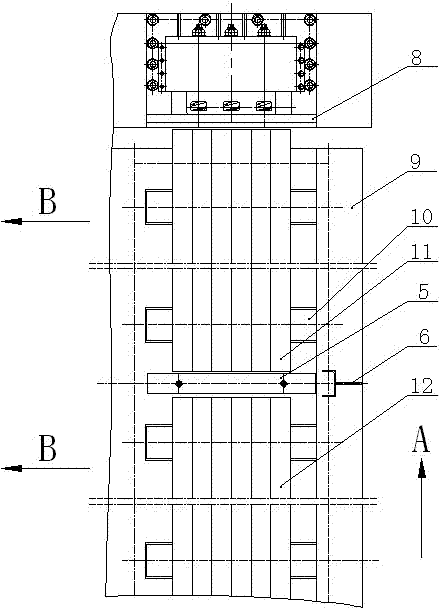

[0009] From figure 1 It can be seen that the suspended freely swinging billet-into-furnace partition stopper of the present invention is composed of a cylinder 1, a suspension frame 6, a balance stop beam 5, a chain 3 and an electromagnetic reversing valve. The cylinder 1 is fixed on the suspension frame 6 by bolts, the cylinder 1 is connected to the electromagnetic reversing valve by the air hose, and the single-leg support of the steel structure suspension frame 6 is connected and fixed by electric welding with the roller table 11 to form a 90° suspension frame; the chain 3 and The cylinder piston rod 2 is threaded, and the balance beam 5 is threaded with the chain 3 suspension ring 4 to form a suspension free swing mechanism, and the screw thread can adjust the level of the balance retaining beam 5.

[0010] Such as figure 2 As shown, the up and down movement of the cylinder 1 is connected to the electromagnetic reversing valve by the air hose, and is controlled by the "s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com